Low-noise mild type damping assembly

A gentle and integrated technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as reducing comfort and safety, damage to spring piston rods, and affecting the use of motorcycles, etc., to achieve Reduce the friction contact area, avoid collision and friction, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

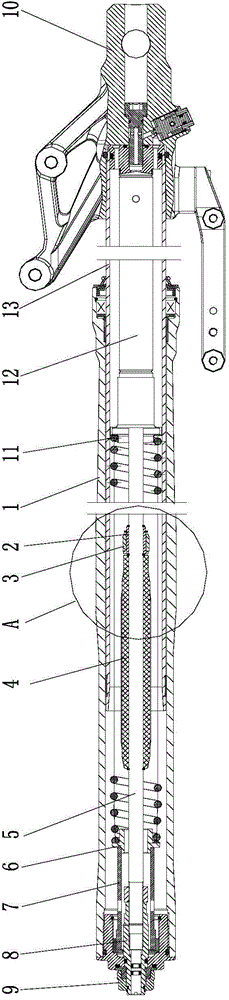

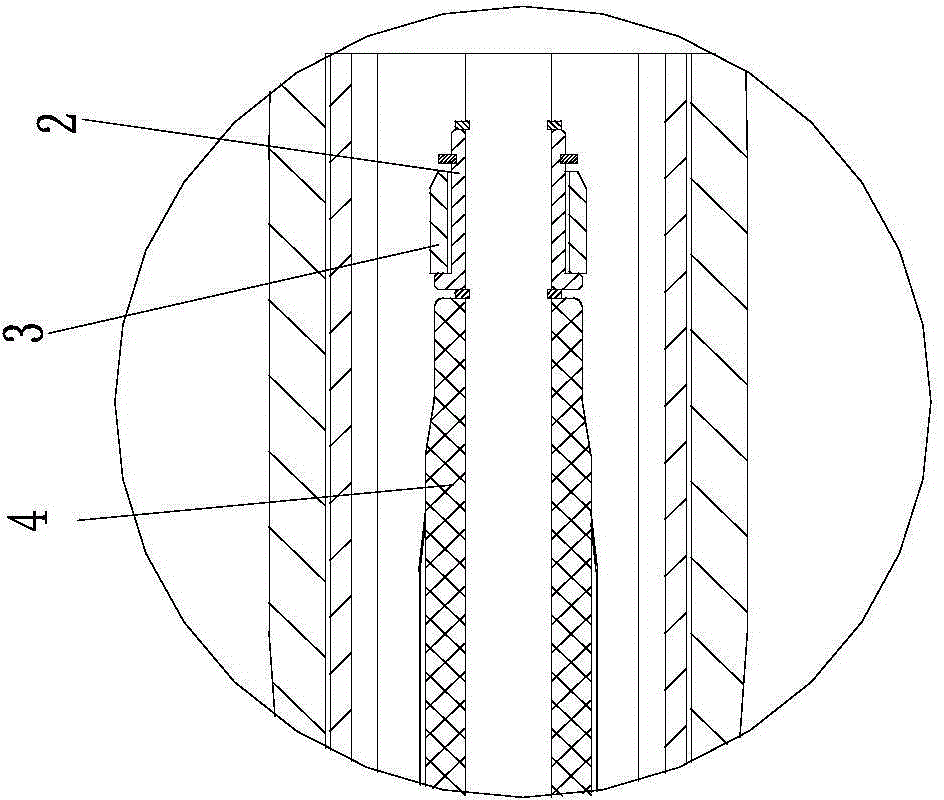

[0018] figure 1 Is a schematic diagram of the structure of the present invention, figure 2 for figure 1 The enlarged view at A, as shown in the figure: the low-noise and gentle damping assembly of this embodiment includes a damping spring 11 and a damper assembly, the damper assembly includes a damping cylinder 12 and a piston assembly, the piston assembly Including the piston and the piston rod 5, the damping spring 11 can be sleeved on the piston rod 5, or can be sleeved on the piston rod 5 and the damping cylinder 12, which will not be repeated here; there is a guide sleeve 4 in the middle of the piston rod, which is sleeved on the piston The exposed part of the rod 5; the guide sleeve 4 is axially limited on the piston rod 5; the axial limit method can be a mechanical limit structure such as the method of setting baffles at both ends as shown in the figure; the guide sleeve generally adopts Materials that are softer than the spring, such as plastic or nylon, can prevent ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com