Valve device with adjustable compression damping

A valve device and damping technology, which is applied in the direction of vibration suppression adjustment, shock absorber, shock absorber, etc., can solve the problems of compression valve dependence, low system reliability, and high product cost, so as to reduce high-speed damping force and reduce vehicle Effect of weight and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

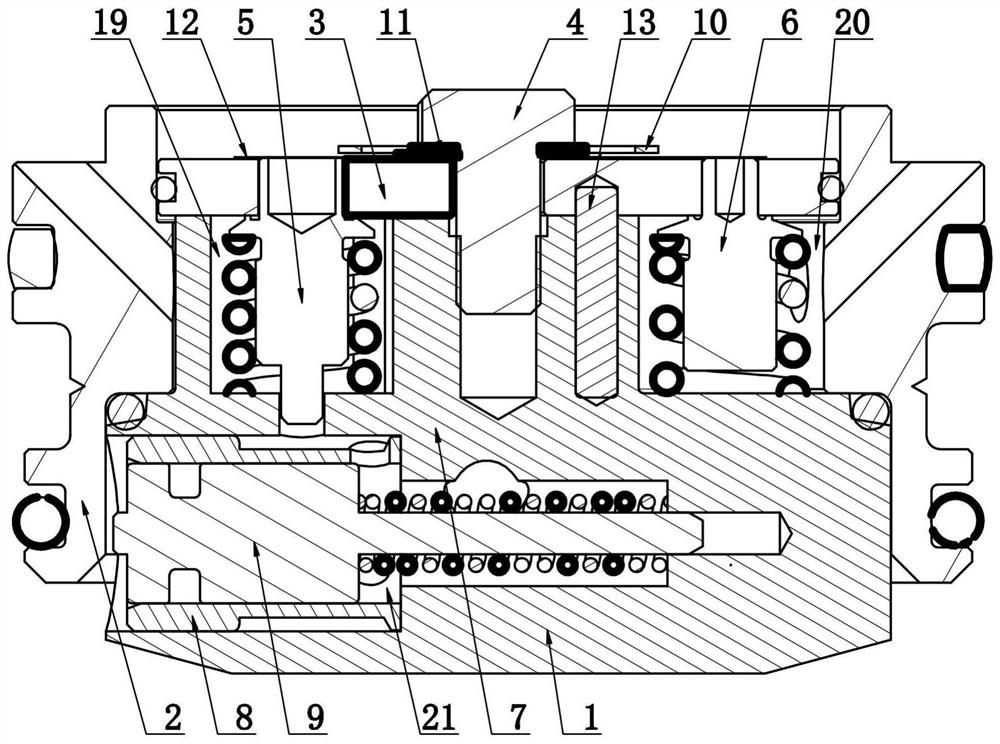

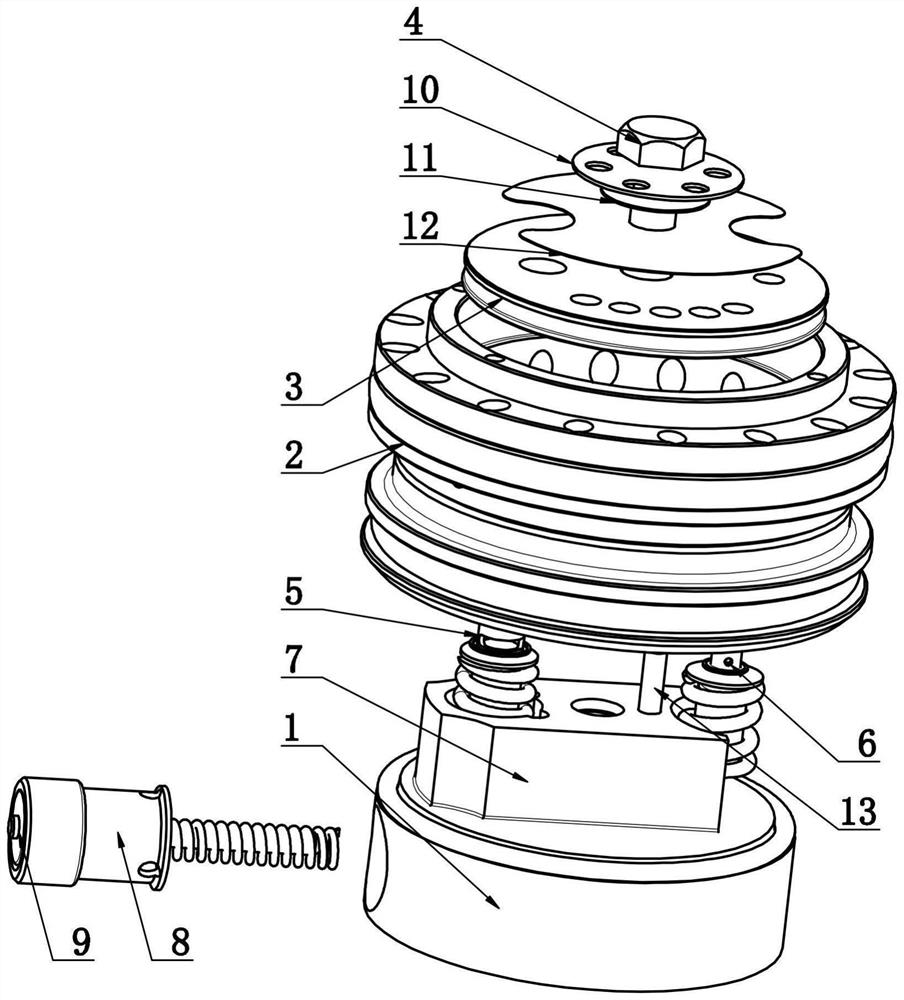

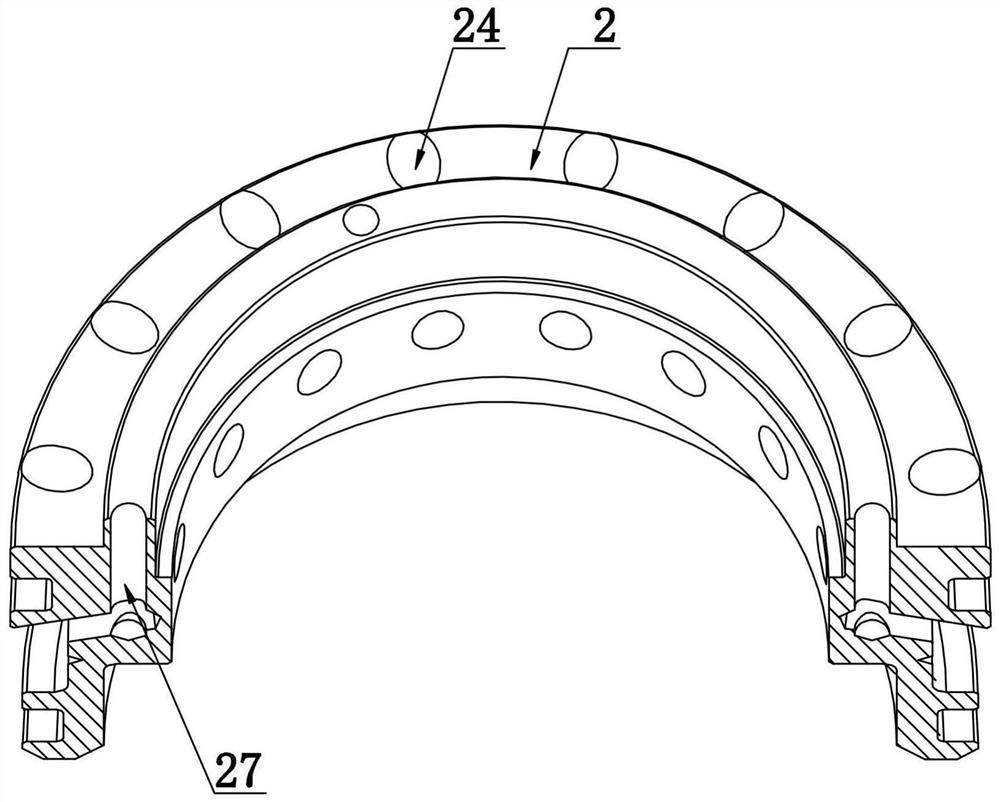

[0039] Such as Figure 1-11 As shown, a valve device with adjustable compression damping includes a valve seat 1, a valve sleeve 2, a valve body 3, a valve stem 4, a low-pressure valve pin 5, a high-pressure valve pin 6 and a slide valve assembly. The valve sleeve 2 is in the shape of a circular tube , the valve body 3 and the valve seat 1 are respectively located at the upper and lower ends of the valve sleeve 2, and the valve stem 4 for fastening the valve seat 1, the valve sleeve 2 and the valve body 3 passes through the valve body 3 from top to bottom and The thread fits on the valve seat 1;

[0040] The valve body 3 is provided with a low-pressure valve hole 17 and a high-pressure valve hole 18, and the outer wall of the valve body 3 is in sealing connection with the inner wall of the valve sleeve 2;

[0041] The upper part of the valve seat 1 is provided with a boss 7, which fits inside the valve sleeve 2 and has a first counterbore longitudinally. A second counterbore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com