Crankshaft bush and connecting rod bush of internal combustion engine

A technology of crankshaft bushes and connecting rod bushes is applied in the field of internal combustion engine components, which can solve the problems of large friction surface, affecting the power and fuel consumption of the internal combustion engine, and large friction coefficient, and achieve good lubrication, reduce friction contact area, and reduce friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in conjunction with the accompanying drawings.

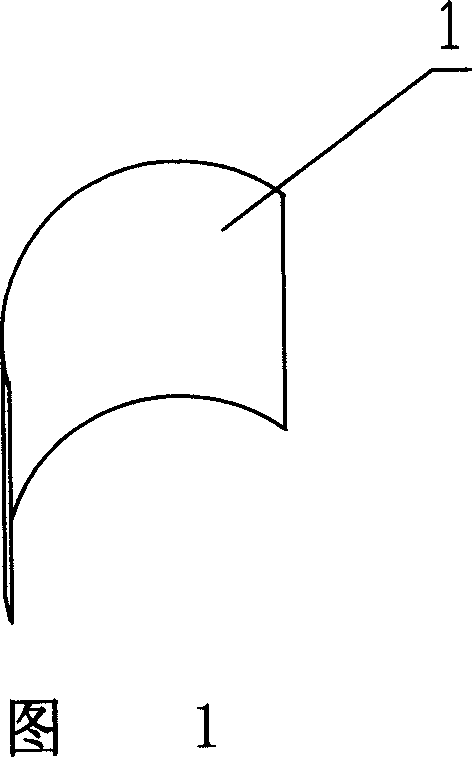

[0010] As shown in Fig. 1, Fig. 1 is a schematic structural diagram of a crank bush and a connecting rod bush without lubricating oil passages on the inner surface, and the inner surface 1 is a smooth arc without lubricating oil passages.

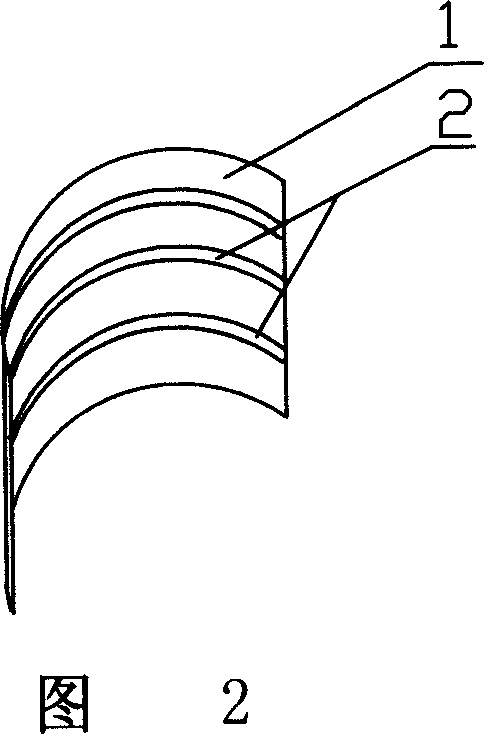

[0011] As shown in Figure 2, the crankshaft and connecting rod bushes of the present invention are provided with several lubricating oil channel grooves 2 on the inner surface 1 in contact with the crankshaft, which reduces the frictional contact surface, increases the oil contact surface, and reduces At the same time, with the operation of the internal combustion engine, the oil pump pumps the lubricating oil to the lubricating surfaces, and the oil passage grooves on the inner surfaces of the crankshaft and connecting rod bushes are also filled with lubricating oil. The lubrication between the connecting rod bush and the crankshaft is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com