Pressurizing oil-saving type piston of diesel engine

A diesel engine and piston technology, applied in the field of Aeolus 4H supercharged fuel-saving diesel engine pistons, can solve the problems of noise, aggravate hazards, and impair the durability of pistons, so as to reduce wear, prolong piston life, and reduce oil consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

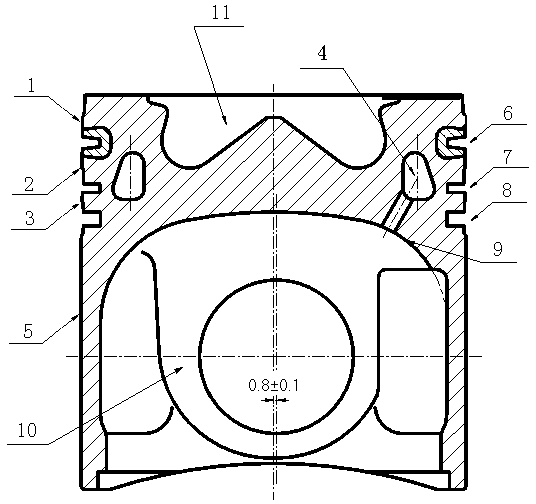

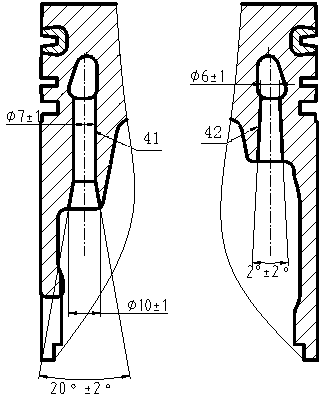

[0045] Supercharged and fuel-efficient diesel engine pistons, such as figure 1 As shown, including head, skirt 5 and piston pin seat 10. The head is composed of a piston top and a ring groove, that is, the head includes figure 1 From the top down to the third ring groove 8. The skirt refers to the downward part of the third ring groove 8 . The piston pin seat 10 is used to install the connecting rod. A hollow cavity 9 is provided inside the piston.

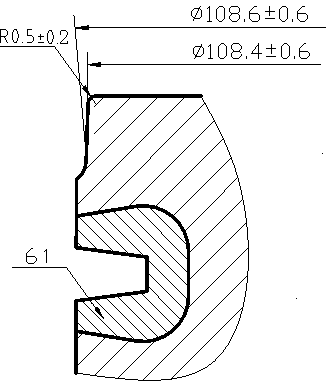

[0046] The total height of the piston is 113 mm, and the ratio of the total height of the piston to the inner diameter of the cylinder is 1.028. Such as figure 2 As shown, the minimum diameter of the top of the piston head is 107.8mm, and the maximum gap between the head and the inner diameter of the cylinder after installation is 2.2mm.

[0047] Such as image 3 As shown, the top surface of the head of the piston is provided with a pit-shaped top combustion chamber 11, and the cross-section of the pit is in a shape simila...

Embodiment 2

[0054] The structure of this embodiment is the same as that of Embodiment 1 except that the dimensions are slightly changed.

[0055] The total height of the piston is 112.6mm, the height of the fire bank is 13.9mm, the height of the second ring bank is 9.9mm, and the height of the third ring bank is 5.4mm.

[0056] The rounded chamfer at the junction of the side wall of the top combustion chamber 11 and the top surface of the piston is R0.95mm, and the inner arc of R1.2mm is at a position above 2.05mm vertically downward from the top surface of the piston. The position below 2.05mm is a convex arc of R2.2mm. The inner arc with a radius of R1.2mm is connected to the outer convex arc with a radius of R2.2mm by a downwardly inclined tangent line forming an angle of 15°30' with the horizontal line.

[0057] The diameter of the skirt changes from 109.85mm at the 0mm position at the lower end of the skirt to 109.017mm at 48mm upward from the 0mm position at the lower end of the sk...

Embodiment 3

[0061] The structure of this embodiment is the same as that of Embodiment 1 except that the dimensions are slightly changed.

[0062] The total height of the piston is 112.8mm, the height of the fire power bank is 14.0mm, the height of the second ring bank is 10.1mm, and the height of the third ring bank is 5.6mm.

[0063] The rounded chamfer at the intersection of the side wall of the top combustion chamber 11 and the top surface of the piston is R0.55mm, and the position above 1.95mm vertically downward from the top surface of the piston is an inner arc of R0.8mm, vertically downward from the top surface of the piston The position below 1.95mm is a convex arc of R1.8mm. The inner arc with a radius of R0.8mm is connected to the outer convex arc with a radius of R1.8mm by a downwardly inclined tangent line forming an angle of 14°30' with the horizontal line.

[0064]The diameter of the skirt changes from 109.83 mm at the 0mm position to 109.015mm at the 48mm upward position f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com