Rope fixture type shearing resisting, dip angle changing and mutual inlaying barricade block and rope fixing method

A blocking wall block and variable inclination technology, which is applied in the fields of civil engineering, transportation and water transportation engineering, and municipal engineering, can solve the problems that are not conducive to the growth of vegetation on the block retaining wall layer, the masonry structure has a great influence, and the safety of the retaining wall. and other problems, to achieve excellent alkali resistance, prevent water penetration, and excellent waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

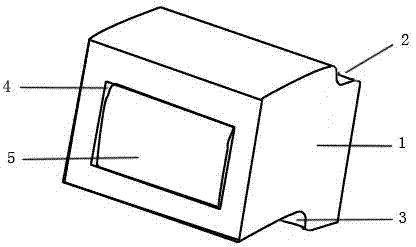

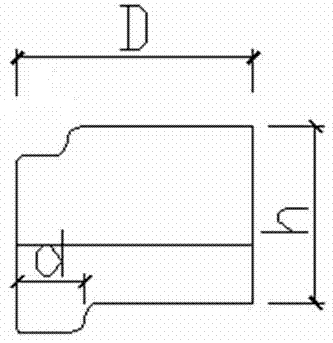

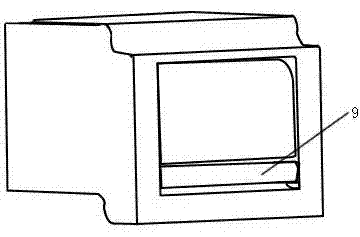

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] As shown in the figure: the new rope clamp type shear-resistant green variable-inclination inter-embedded retaining wall block is characterized in that the block has three structural forms: standard layer block, top layer block and bottom block, and standard layer block The left and right end faces are concave-convex arcs that can be embedded, and the block is made of concrete material, which is poured at one time with a mold, and a rectangular through-long hole is opened in the middle. The rear upper part of the block is provided with an arc-shaped concave body rear edge, and the rear lower part of the block is provided with an arc-shaped convex body rear edge which can be embedded with the concave body rear edge. Apply an anti-alkali primer (a high quality acidic acrylic copolymer emulsion) that will reduce the alkalinity of the concrete inside and behind the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com