Gripper with guided cleaning function

A gripper and functional technology, applied in the field of grippers with guided cleaning function, can solve the problems affecting the processing quality of workpieces, the wear of the clamping block clamping structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

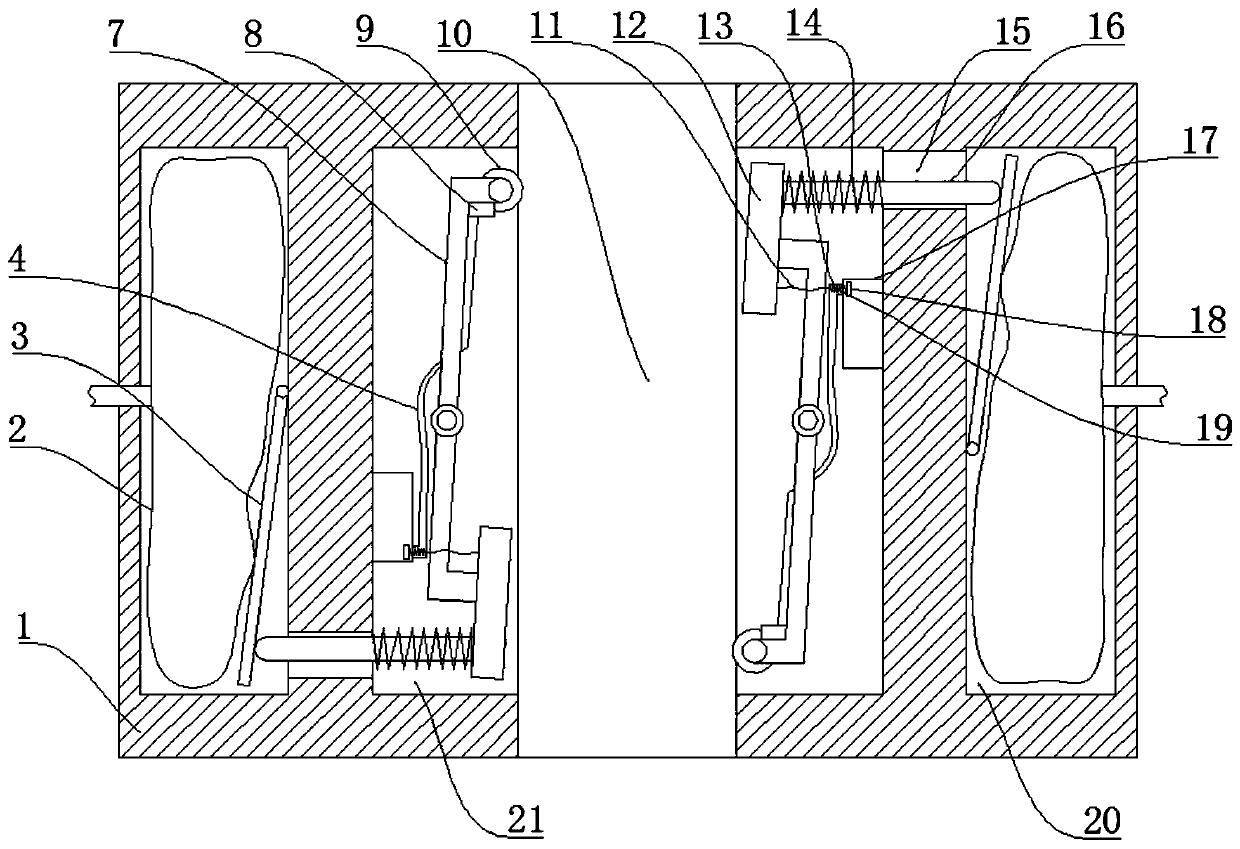

[0021] Embodiment 1, basically as attached figure 1 Shown: a holder with guided cleaning function, including a base 1, the base 1 is provided with an opening groove 10, and the base 1 on both sides of the opening groove 10 is provided with a clamping cavity 21, the clamping cavity 21 One side of the open groove 10 is open, and a lever 7 is arranged in the clamping cavity 21. One end of the lever 7 is welded with a clamping block 12, and the other end is equipped with a freely rotating guide wheel 9 through a pin shaft. The guide wheel 9 is hard. Rollers made of solid material. A tension spring 14 is bonded or welded between the clamping block 12 and the wall of the clamping chamber 21, and a drive chamber 20 is provided in the base 1 on the side of the clamping chamber 21 away from the opening groove 10, and a hydraulic drive chamber 20 is provided in the drive chamber 20. Mechanism, the hydraulic drive mechanism includes a hydraulic bladder 2, which communicates with the ext...

Embodiment 2

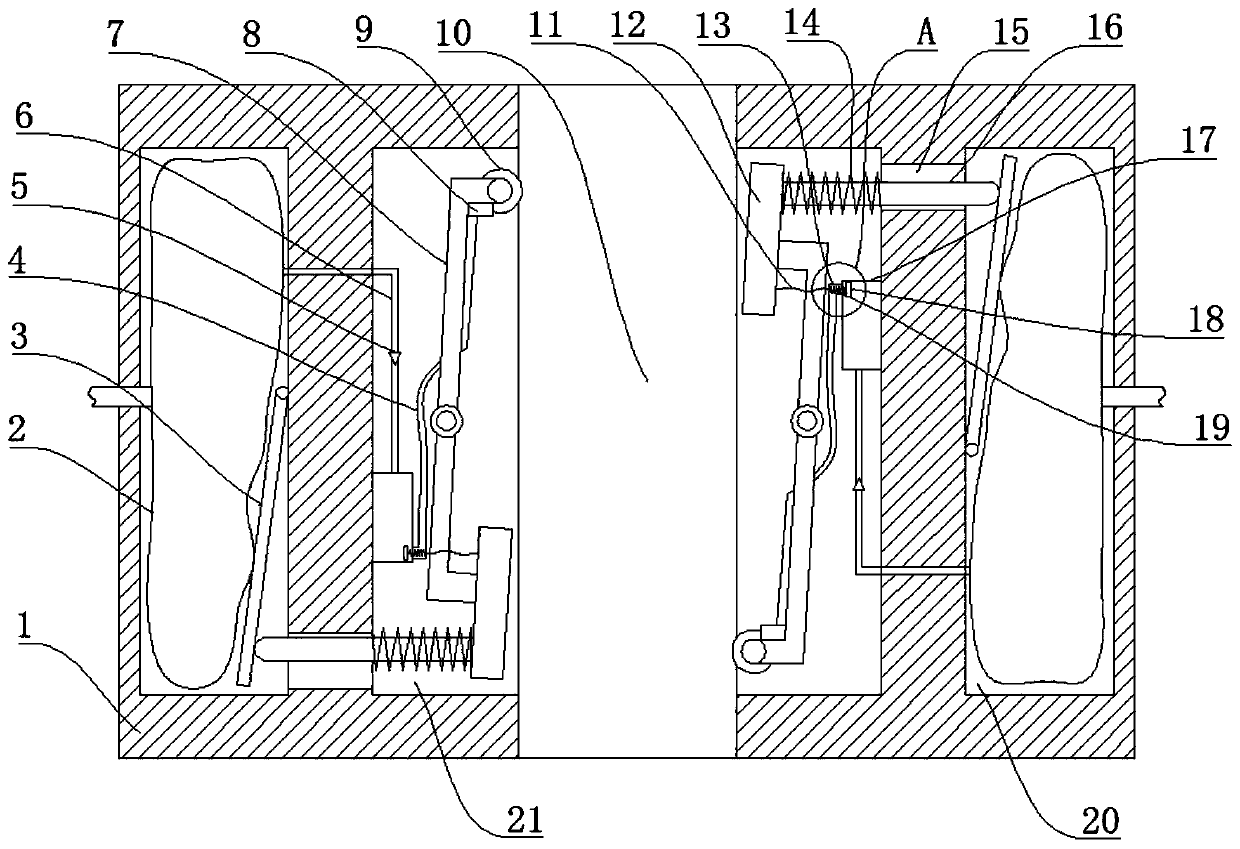

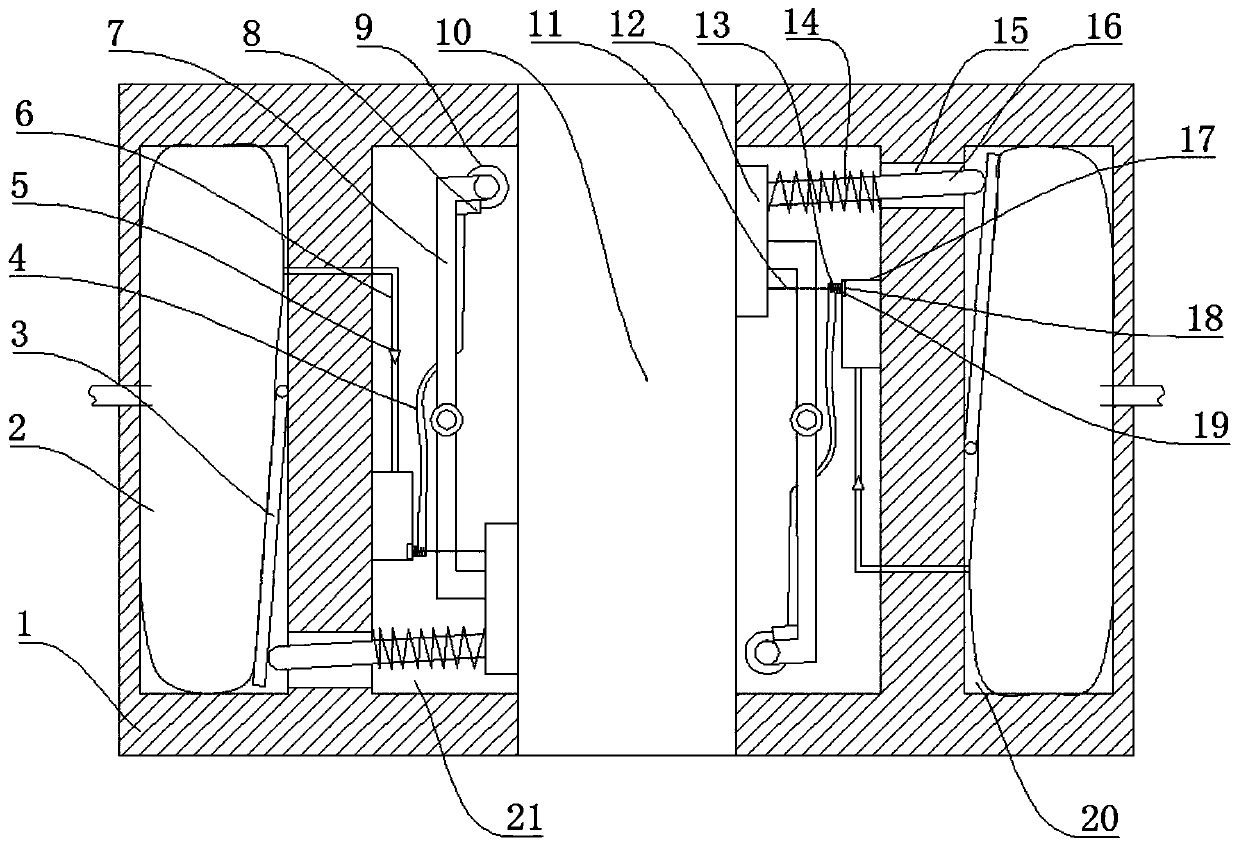

[0023] Example 2, combined with figure 2 , image 3 , Figure 4 As shown, this embodiment further improves the oil storage box 17 on the basis of Embodiment 1. Specifically, the oil storage box 17 is connected with an oil inlet pipe 6, and the oil inlet pipe 6 communicates with the hydraulic bag 2, and the oil inlet pipe 6 is The high-pressure pipe, the oil inlet pipe 6 is connected with a one-way valve 5 leading to the oil storage box 17 .

[0024]The specific implementation process is as follows: during use, the clamper of the present application is installed on the components of the CNC machine tool, and the clamper straddles the guide rail of the machine tool, that is, the guide rail passes through the open slot 10 of the clamper. During the movement of the component on the guide rail, the state of each component in the holder is as follows. The external hydraulic oil source does not provide hydraulic oil to the hydraulic bladder 2, and the oil pressure in the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com