High-strength aluminum alloy hub structure

An aluminum alloy wheel hub, high-strength technology, applied to highly elastic wheels, wheels, spoked wheels, etc., can solve the problems of the hub being unable to resist the force, the permanent damage of the wheel hub, the large moment of inertia of the tire, etc., to reduce the moment of inertia, The effect of reducing unsprung mass and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

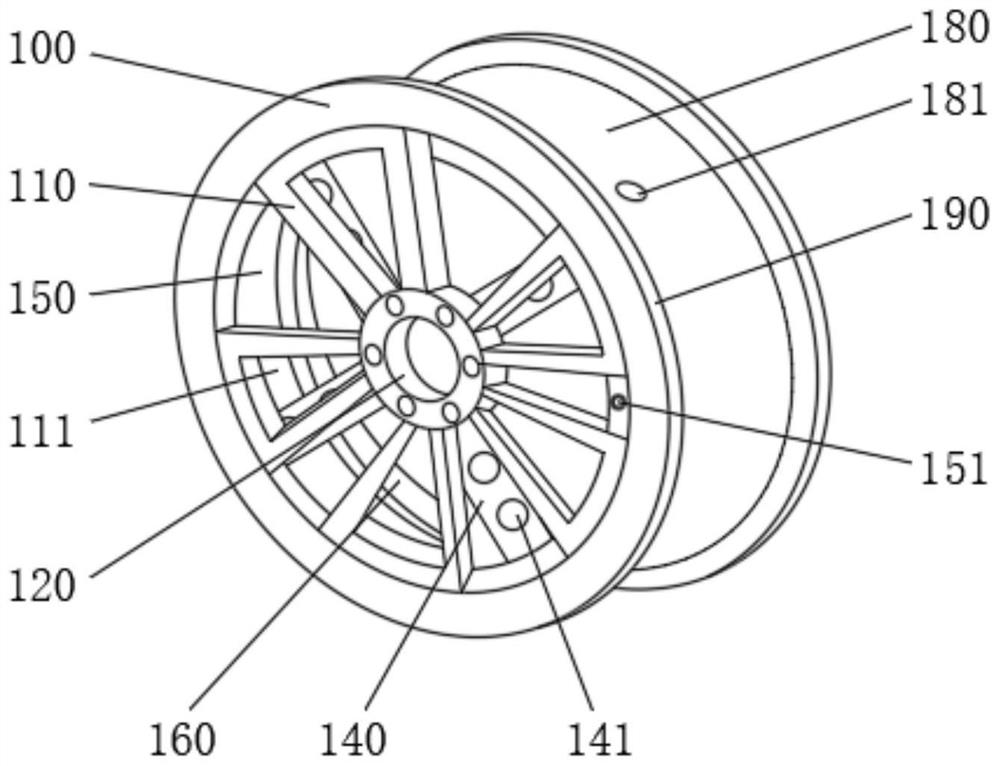

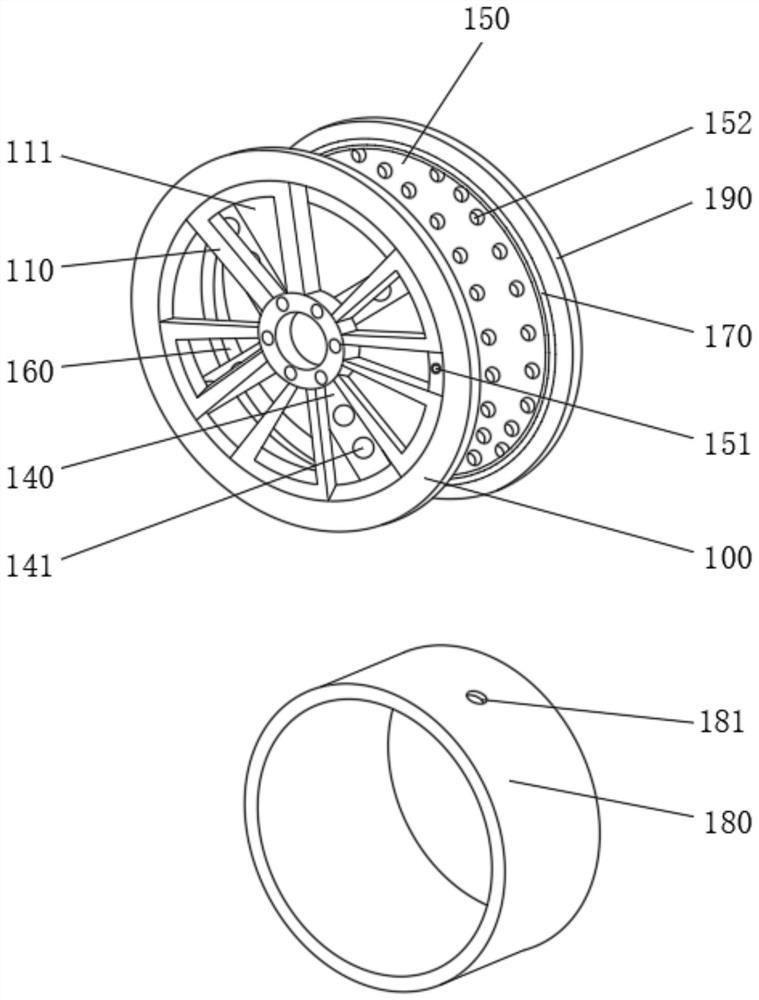

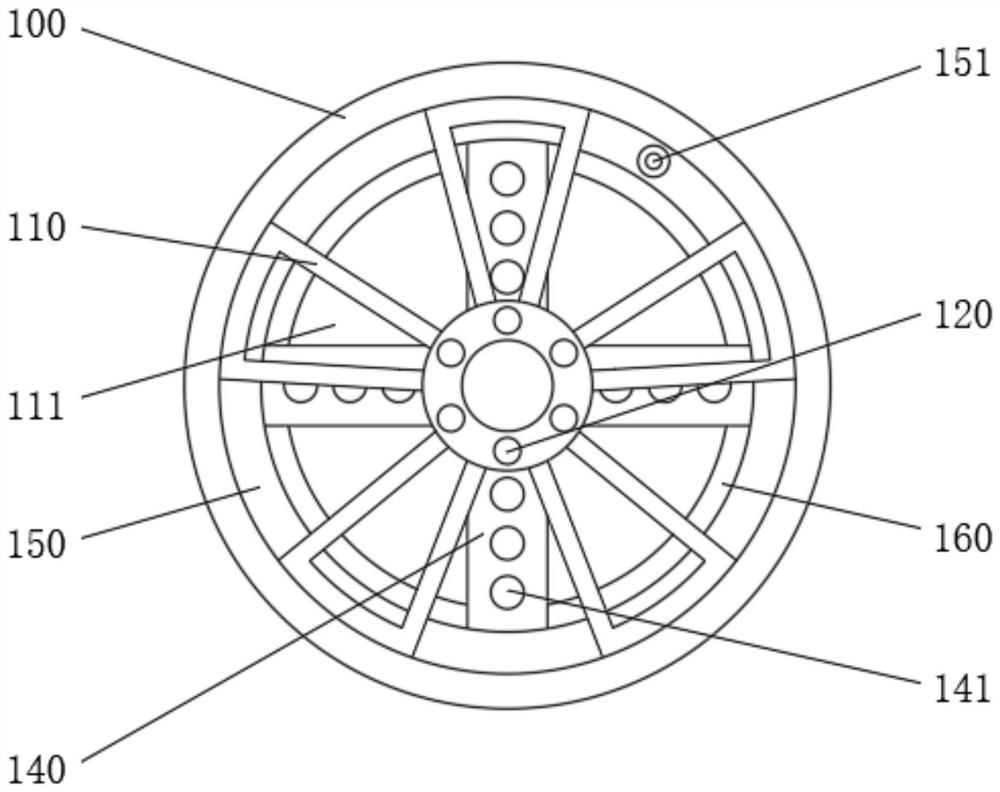

[0030] see Figure 1-5 and Figure 7 , the present invention provides a technical solution: a high-strength aluminum alloy wheel hub structure, including a hub body 100, the center of the front side wall of the hub body 100 is provided with a mounting seat 120, the outer wall of the mounting seat 120 is connected to the inner side of the wheel hub body 100 A number of spokes 110 are arranged between the walls, and the outer side wall of the installation seat 120 is located behind the spokes 110 and is socketed with a mating seat 130. The outer side wall of the mating seat 130 is integrally formed with four supporting columns 140, and the four supporting columns 140 are all Located in the inner cavity of the hub body 100, the center of the inner side wall of the hub body 100 is provided with an inner groove bottom 150, and the ends of the four support columns 140 are welded to the inner side wall of the inner groove bottom 150, and the front side wall of the inner groove bottom...

Embodiment 2

[0033] see Figure 1-3 and Figure 7 , the present invention provides a technical solution: a high-strength aluminum alloy wheel hub structure, including a hub body 100, the center of the front side wall of the hub body 100 is provided with a mounting seat 120, the outer wall of the mounting seat 120 is connected to the inner side of the wheel hub body 100 A number of spokes 110 are arranged between the walls, and the outer side wall of the installation seat 120 is located behind the spokes 110 and is socketed with a mating seat 130. The outer side wall of the mating seat 130 is integrally formed with four supporting columns 140, and the four supporting columns 140 are all Located in the inner cavity of the hub body 100, the center of the inner side wall of the hub body 100 is provided with an inner groove bottom 150, and the ends of the four support columns 140 are welded to the inner side wall of the inner groove bottom 150, and the front side wall of the inner groove bottom...

Embodiment 3

[0036] see Figure 1-2 and Figure 5-6 , the present invention provides a technical solution: a high-strength aluminum alloy wheel hub structure, including a hub body 100, the center of the front side wall of the hub body 100 is provided with a mounting seat 120, the outer wall of the mounting seat 120 is connected to the inner side of the wheel hub body 100 A number of spokes 110 are arranged between the walls, and the outer side wall of the installation seat 120 is located behind the spokes 110 and is socketed with a mating seat 130. The outer side wall of the mating seat 130 is integrally formed with four supporting columns 140, and the four supporting columns 140 are all Located in the inner cavity of the hub body 100, the center of the inner side wall of the hub body 100 is provided with an inner groove bottom 150, and the ends of the four support columns 140 are welded to the inner side wall of the inner groove bottom 150, and the front side wall of the inner groove bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com