Final transmission structure, bulldozer and turning control method

A technology of transmission structure and bulldozer, which is applied in the fields of final drive structure, bulldozer and turning control. It can solve the problems of large wheel-side deceleration structure, small transmission ratio, and difficulty in providing torque, etc., and achieve good application, stable transmission torque, and versatility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

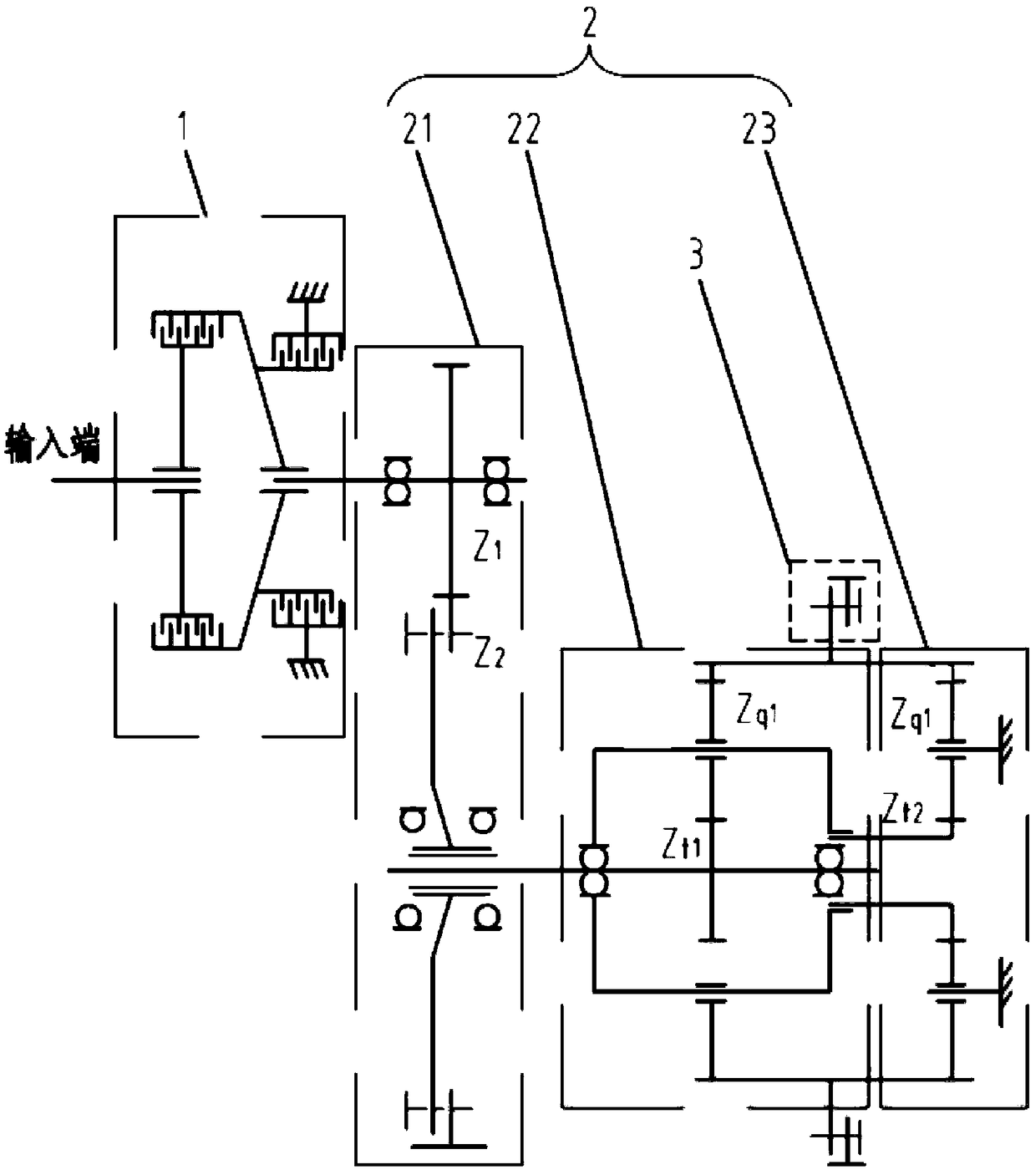

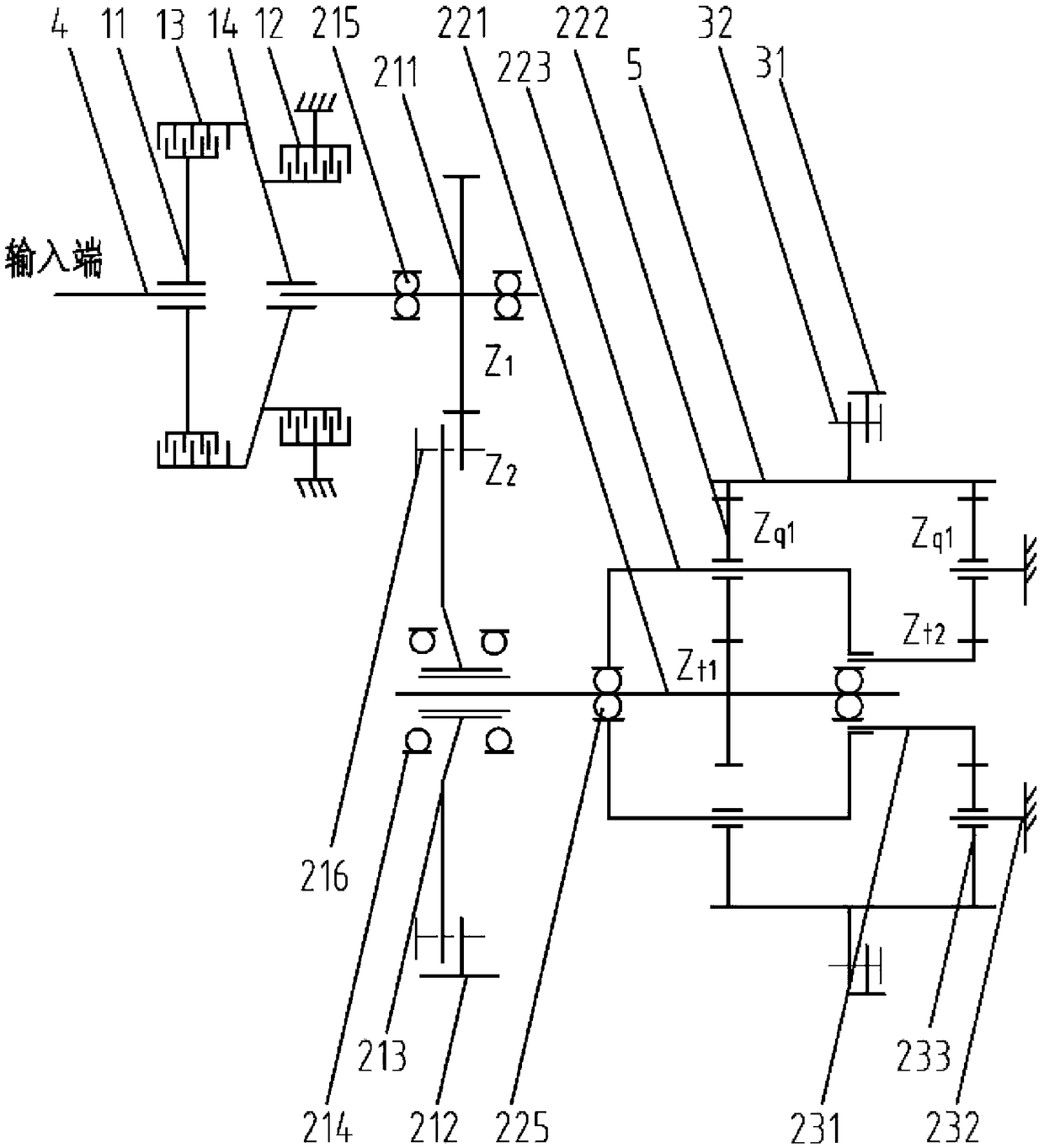

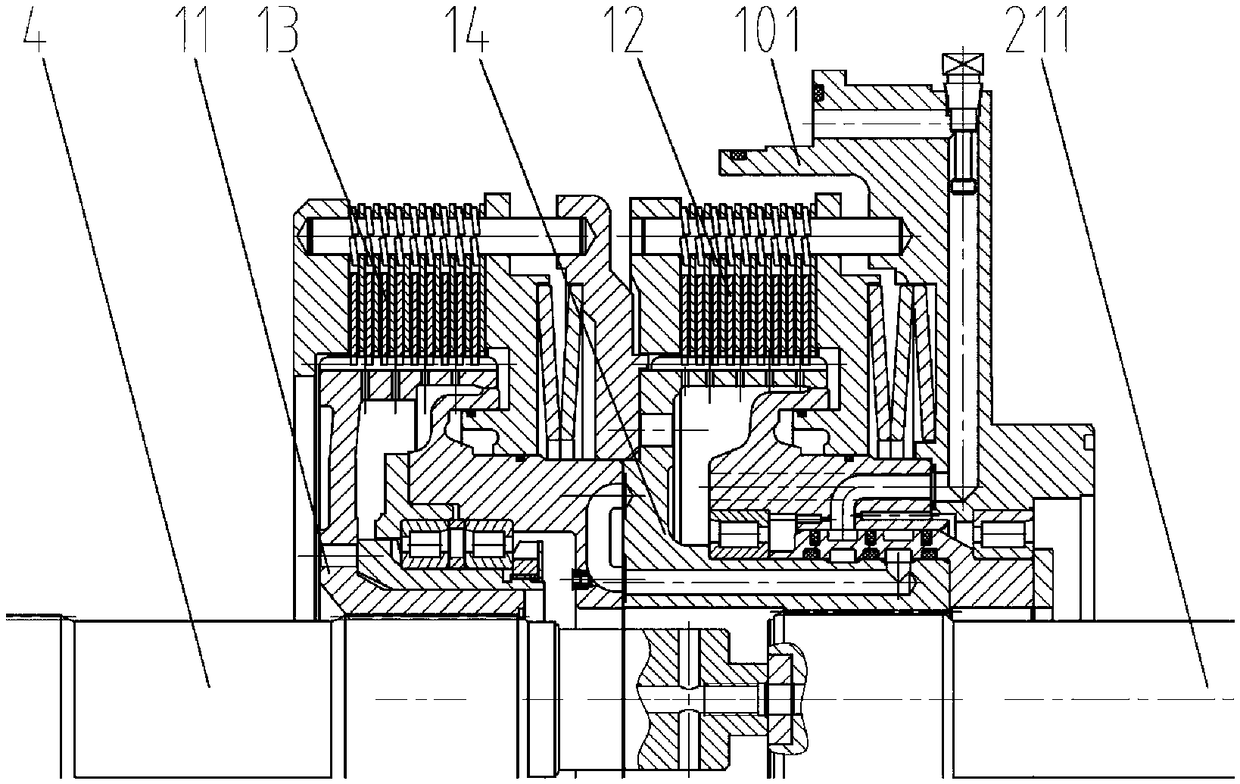

[0056] Embodiment 1 of the present invention provides a final drive structure, figure 1 It is a structural schematic diagram of multiple functional units in the final drive structure provided by Embodiment 1 of the present invention, from figure 1 It can be seen from the figure that it mainly includes the input shaft 4, the steering brake unit 1, the transmission unit 2 and the drive unit 3 connected in sequence, wherein the input shaft 4 is the power source, powered by the engine; the steering brake unit 1 is used to control the input power Transmission; the transmission unit 2 is used to achieve a larger transmission ratio; the drive unit 3 is used to connect with an external actuator to transmit power to the actuator, such as the wheel / walking track of an engineering vehicle. Among them, the steering brake unit 1 can be selectively unlocked or locked, so that the power of the input shaft 4 can be selectively transmitted to the transmission unit 2. The transmission unit 2 is...

Embodiment 2

[0078] The invention also provides a bulldozer, Image 6 It is a schematic diagram of the transmission structure of the bulldozer provided in Embodiment 2 of the present invention, Figure 7 It is a schematic diagram of the opening and closing process of the bulldozer's walking control. Image 6 and Figure 7 As shown, the bulldozer mainly includes an engine 61 providing power output, a hydraulic torque converter 62, a gearbox 63, a central transmission structure 64, a left final drive 71 and a right final drive 72, wherein the left final drive 71 and the right final drive 72 are the final drive structures in the first embodiment. like Image 6 As shown in , taking a bulldozer including two final drive structures as an example, the two final drive structures are respectively a left final drive 71 and a right final drive 72, and the left final drive 71 and the right final drive 72 are symmetrically arranged relative to the center of the car body, and the left The respective...

Embodiment 3

[0081] The invention also proposes a bulldozer turning control method, Figure 7 It is a schematic diagram of the walking operation, opening and closing process of the bulldozer provided in Embodiment 3 of the present invention, as shown in Figure 7 As shown in , the bulldozer walking states include forward, backward, left-turning, right-turning and other states, wherein turning left or turning right includes the first turning radius and the second turning radius, and the first turning radius is greater than the second turning radius Radius, that is, the first radius of rotation represents the bulldozer turning a large turn, and the second radius of rotation represents the bulldozer turning a sharp turn.

[0082] Specifically include:

[0083] (1) When the travel handle is in neutral (locking the car) or the engine is turned off, the left and right brakes and left and right clutches are locked;

[0084] (2) When the travel handle is in neutral (the lock lever is open), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com