A new type of wheel-side reduction structure and reducer

A wheel-side deceleration and deceleration unit technology, used in mechanical equipment, gear transmissions, belts/chains/gears, etc., can solve the problems of large wheel-side deceleration structure, poor compactness, long working time, etc., to meet the requirements of transmission deceleration. ratio of demand, high compactness and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

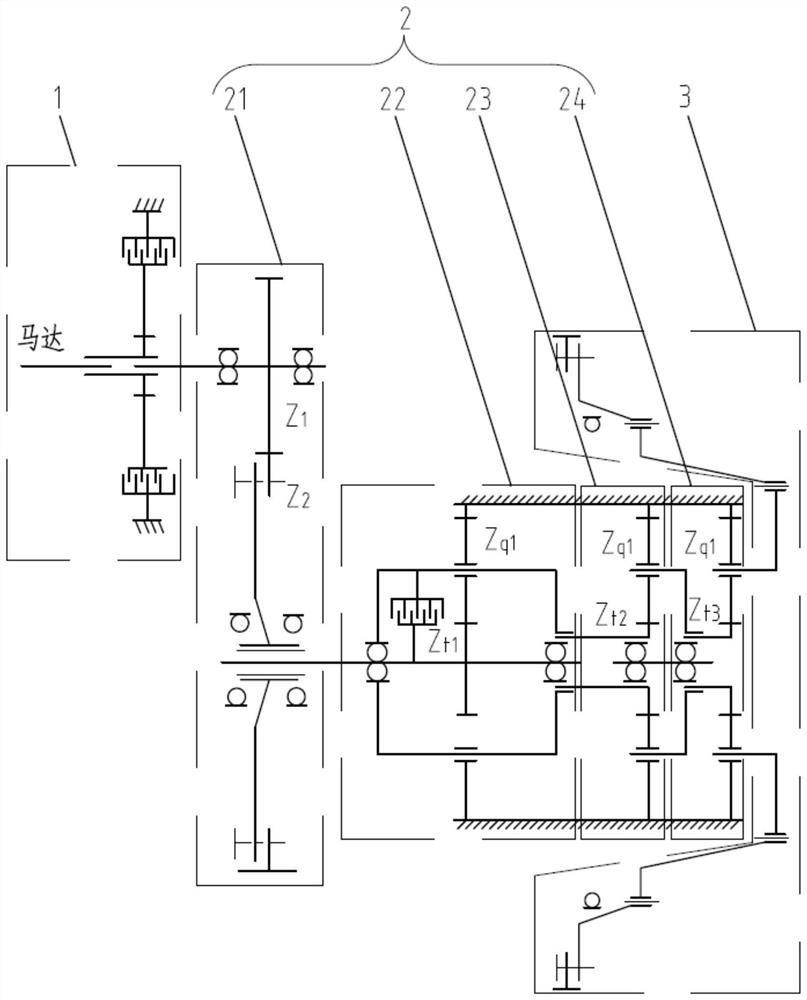

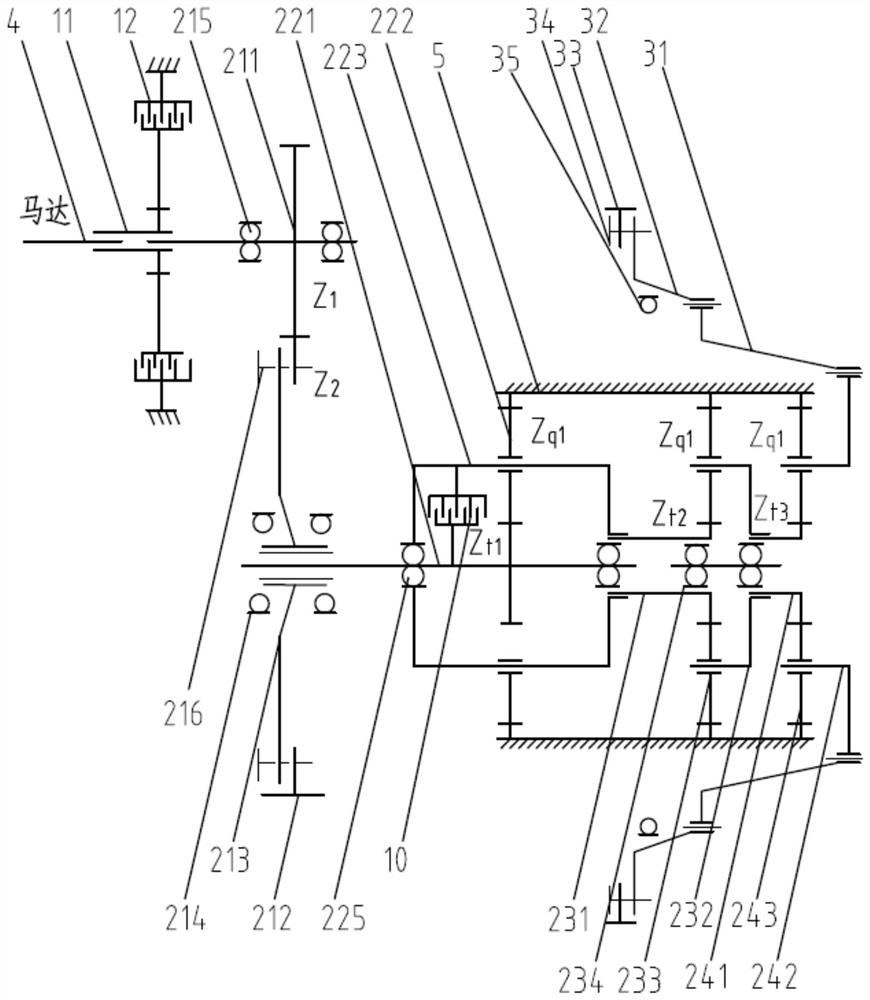

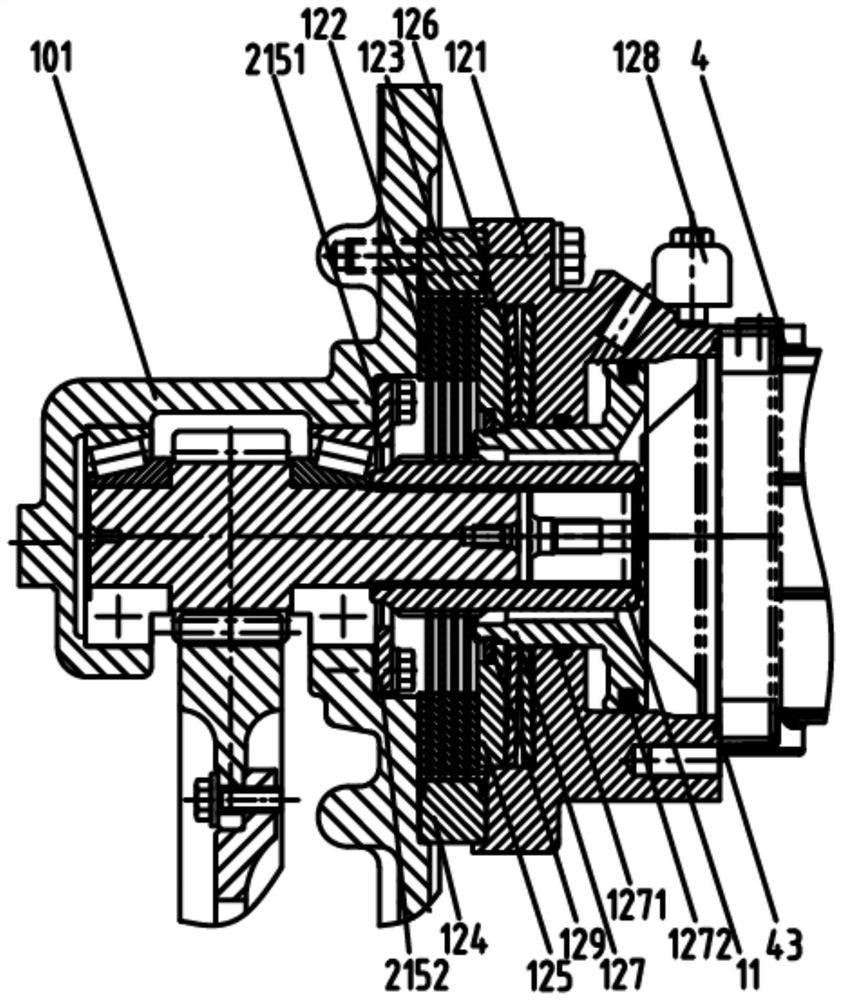

[0031] The invention provides a wheel-side deceleration structure, such as Figure 1-3 As shown, it mainly includes a brake unit 1, a transmission system 2, a drive unit 3 and a planetary ring gear 5, wherein the transmission system 2 includes a first-stage reduction unit 21, a second-stage reduction unit 22, a third-stage reduction unit 23 and a fourth-stage reduction unit 24 , wherein the first-stage reduction unit 21 includes a two-stage spur gear reduction structure, the second-stage reduction unit 22 includes a first planetary row structure and the clutch 10, the third-stage reduction unit 23 includes a second planetary row structure, and the fourth-stage reduction unit 24 includes a second planetary row structure. Two star row structure. A plurality of corresponding planetary gears in the secondary reduction unit 22 , the tertiary reduction unit 23 and the fourth reduction unit 24 are all internally meshed with the planetary ring gear 5 . The brake unit 1 is connected t...

Embodiment 2

[0057] The present invention also provides a speed reducer, such as Figure 5 As shown in the schematic diagram of the travel operation of the reducer, it includes: an engine 61 providing power output, a coupling 62 and a pump 7 connected to the motor 4, the coupling 62 is respectively connected to the engine 61 and the pump 7, and the motor 4 is connected to the corresponding wheel. Edge deceleration structure. The pump 7 and the motor 4 constitute a closed walking hydraulic system. That is, the oil circulates between the pump 7 and the motor 4, the pump 7 converts the torque provided by the engine 61 into high-pressure oil, and the high-pressure oil transfers energy to the motor 4, and then the motor 4 converts the oil flow into torque again Drive sprocket wheel hub 33, promote crawler belt walking.

[0058] Preferably, the speed reducer includes a left wheel-side reduction structure 81 and a right wheel-side reduction structure 82, the pump 7 includes a rear pump 71 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com