Two-shaft three-stage deceleration middle torque transmission system

A three-stage deceleration and transmission system technology, which is applied in wheel transmissions, vehicle gearboxes, rider drives, etc., can solve the problems of low deceleration and large space size, and achieve strong climbing ability, improved system efficiency, Good follow-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

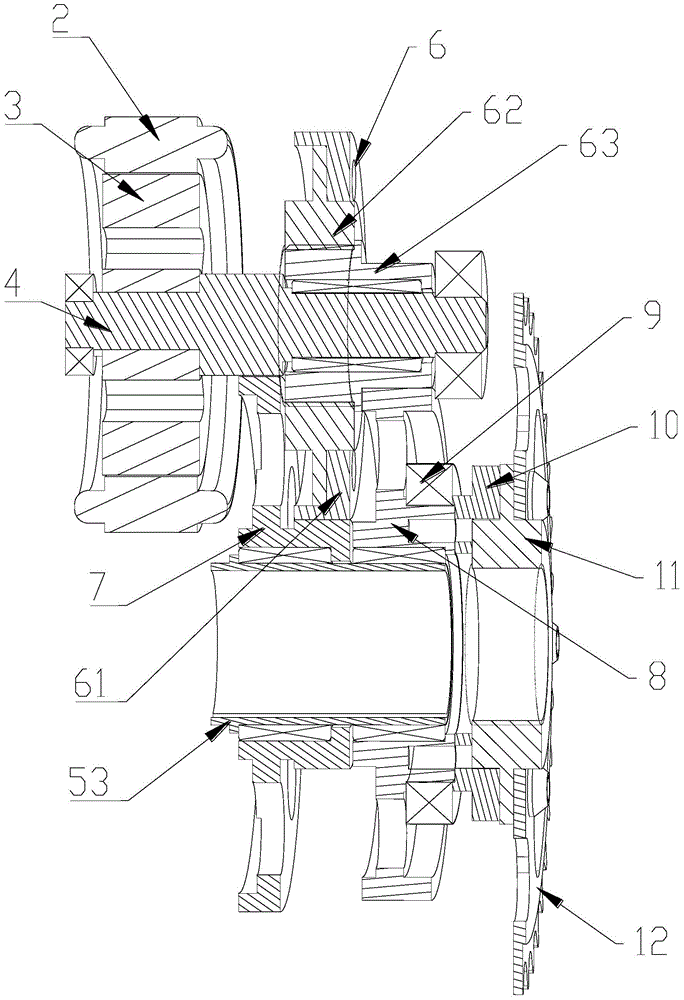

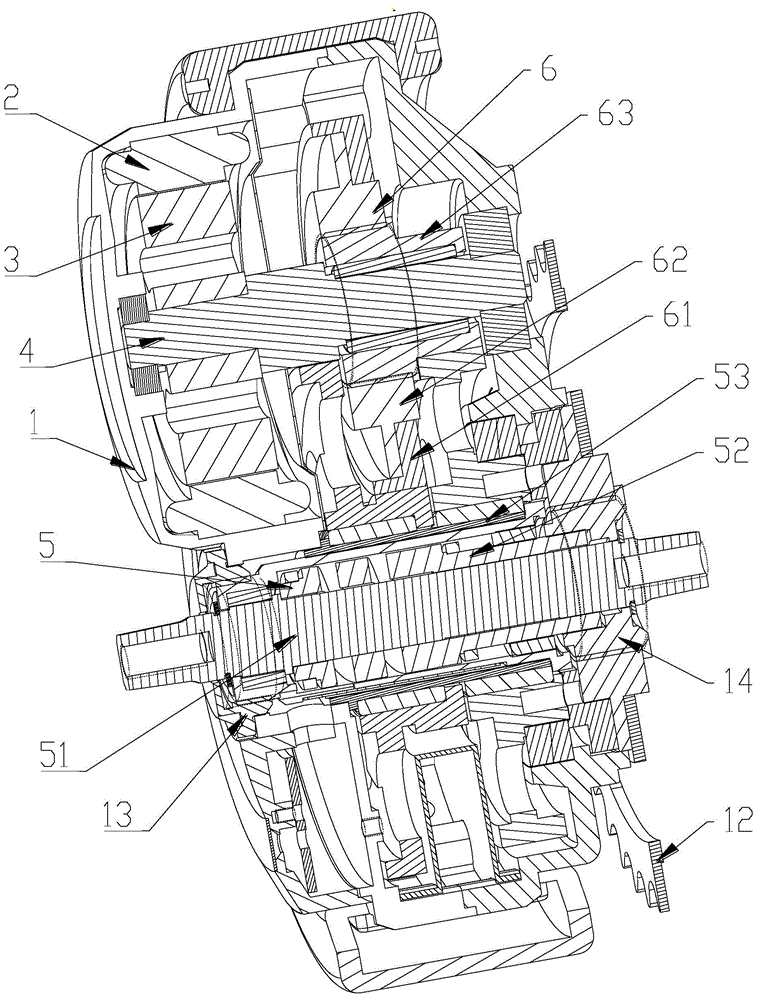

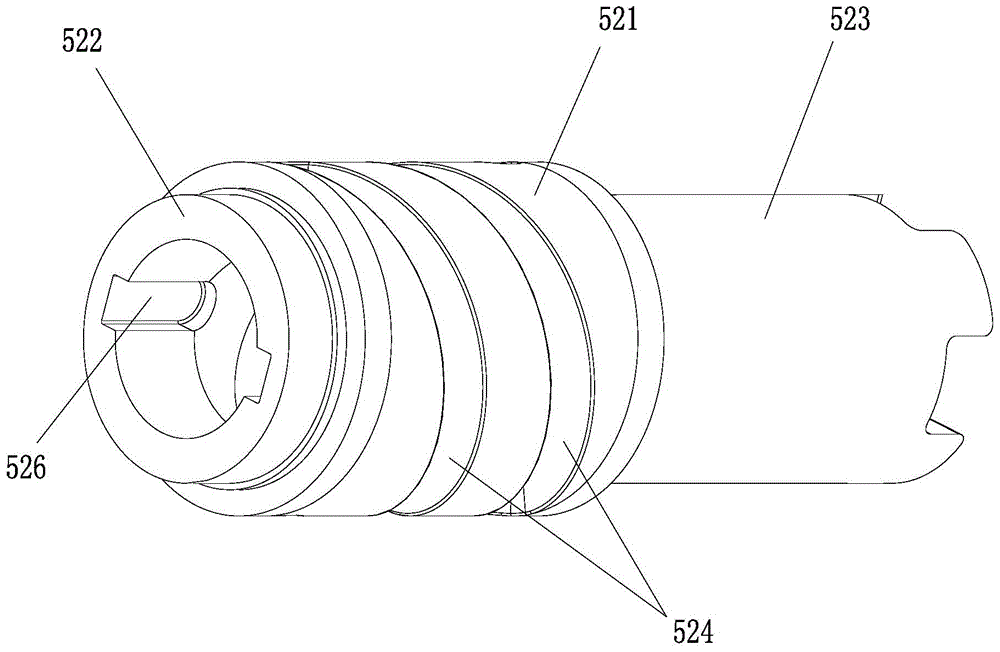

[0039] Example: such as Figure 1 to Figure 6 As shown, a two-axis three-stage deceleration central torque transmission system includes a stator 2 and a rotor 3 arranged in a motor housing 1, a motor shaft 4 for driving the rotor 3 to rotate, and a central shaft torque sensor device 5, gear plate 12, and controller 14, the central shaft type torque sensing device 5 includes a central shaft 51, an elastic connector 52 sleeved on the central shaft 51, sleeved on the elastic connector 52 and can be The shaft sleeve 53 and the sensor that rotate relatively with the central shaft 51 and the elastic connector 52, the motor shaft 4 has a first-stage transmission gear, and the motor shaft 4 is supported by a transmission assembly 6 through a bearing. The transmission assembly 6 includes The concentrically fixed second-stage transmission gear 61, the first toothless flywheel 62 and the third-stage input gear 63, the bushing 53 respectively supports the double gear 7 and the third-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com