A Safe Nail Roller

A nail-rolling and machine-rolling technology, applied in the direction of nails, mechanical equipment, connecting components, etc., can solve the problems of nail-rolling shaft wear, unstable transmission torque, large idle stroke, etc., to improve quality, reduce sliding resistance torque, reduce The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

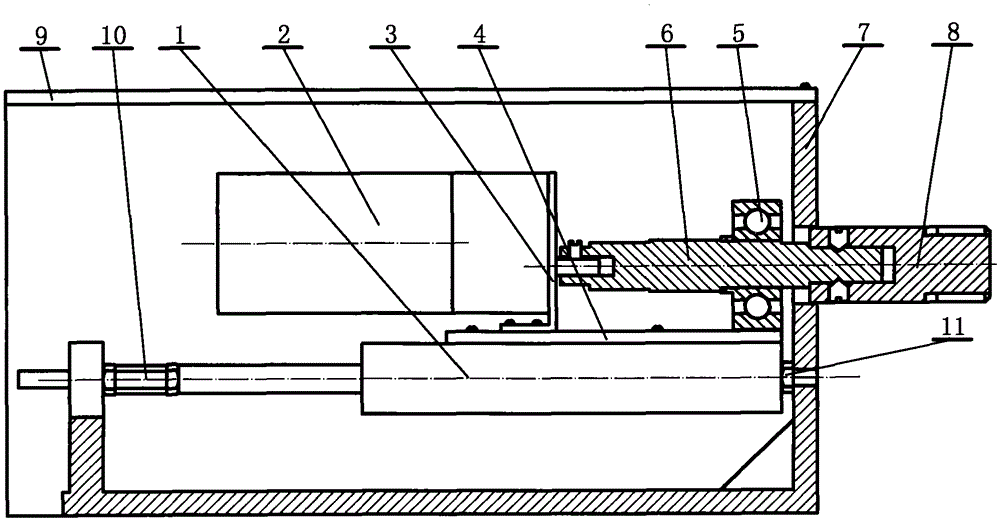

[0032] Embodiment one: if figure 1 , figure 2 As shown, the DC gear motor is 24V, 30W DC gear motor, the constant current drive circuit is 24V electric bicycle constant current charging power supply, the double slide cylinder is a STM25*100 series double slide cylinder, and the bearing is a small bearing with a seat. Two-position five-way reversing valve is selected as the solenoid valve controlling the double slide cylinder; a double slide cylinder support, a bearing support, a geared motor support, a protective cover, a coupling and a nail coil shaft are made .

[0033] The double sliding cylinder is fixedly installed on the support of the double sliding cylinder; the bearing support is fixed on the sliding platform of the double sliding cylinder; the motor support and the bearing are fixed on the bearing support; the DC gear motor is fixed on the motor On the support; the output shaft of the DC deceleration motor is connected to the nail shaft through the coupling shaft,...

Embodiment 2

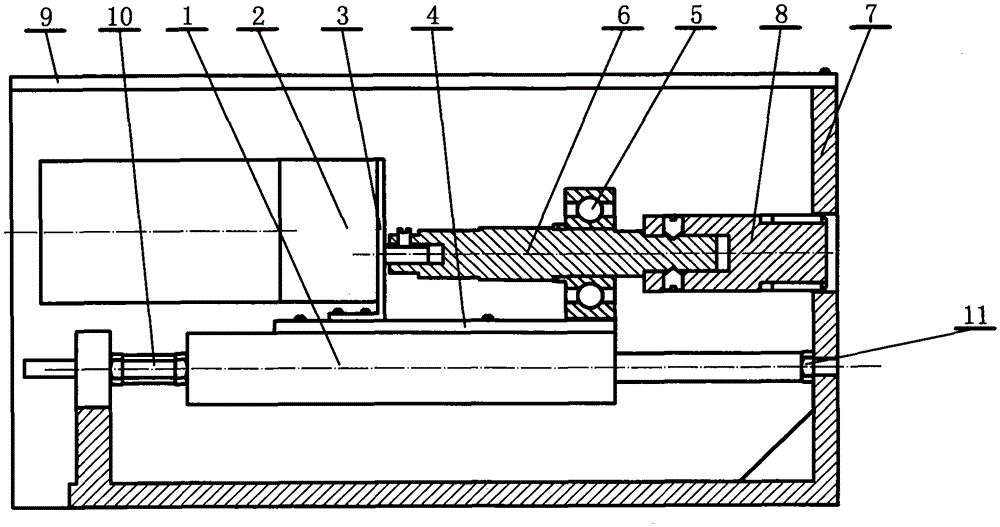

[0036] Embodiment two: if image 3 , Figure 4 As shown, by adjusting the installation position of the bearing seat, the length of the fixed baffle plate stretched out from the double sliding cylinder support 7 to facilitate the adjustment of the nail volume shaft is adjusted, so as to adapt to the needs of processing volume nails of different lengths. Two of the bearings are selected to reduce the bending moment of the output shaft of the DC geared motor.

Embodiment 3

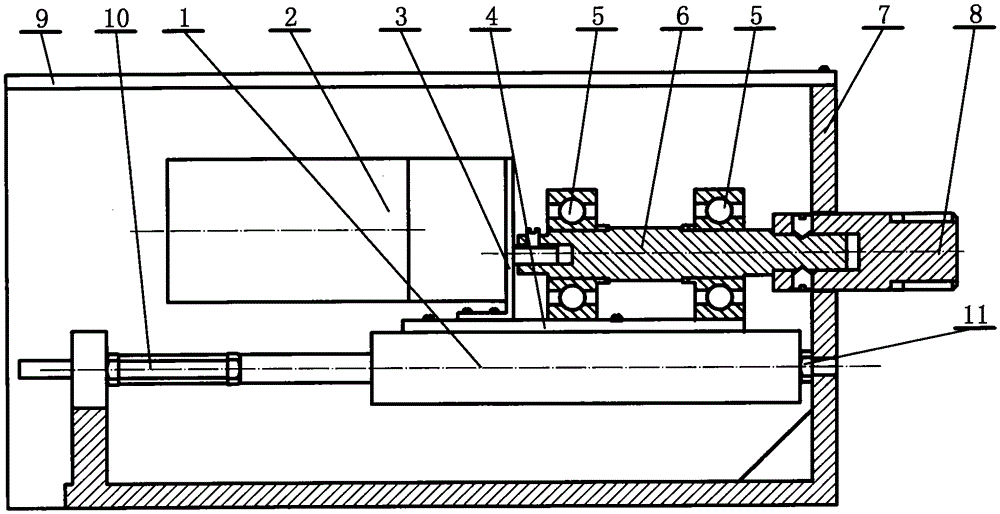

[0037] Embodiment three: as Figure 5 , Figure 6 As shown, by changing the length of the right-hand gear bar, the length of the fixed baffle plate stretched out from the double-linked sliding cylinder support 7 to facilitate the adjustment of the volume nail shaft is to adapt to the needs of processing the volume nails of different lengths. Simultaneously, the coupling mode of coiling nail shaft and coupling shaft is screw connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com