Furnace combustion flue gas online monitoring system and monitoring method

A combustion flue gas and monitoring system technology, applied to chemical instruments and methods, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problems of low accuracy and stability, and achieve improved response time and improved smoke Effect of gas flow rate and improvement of analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

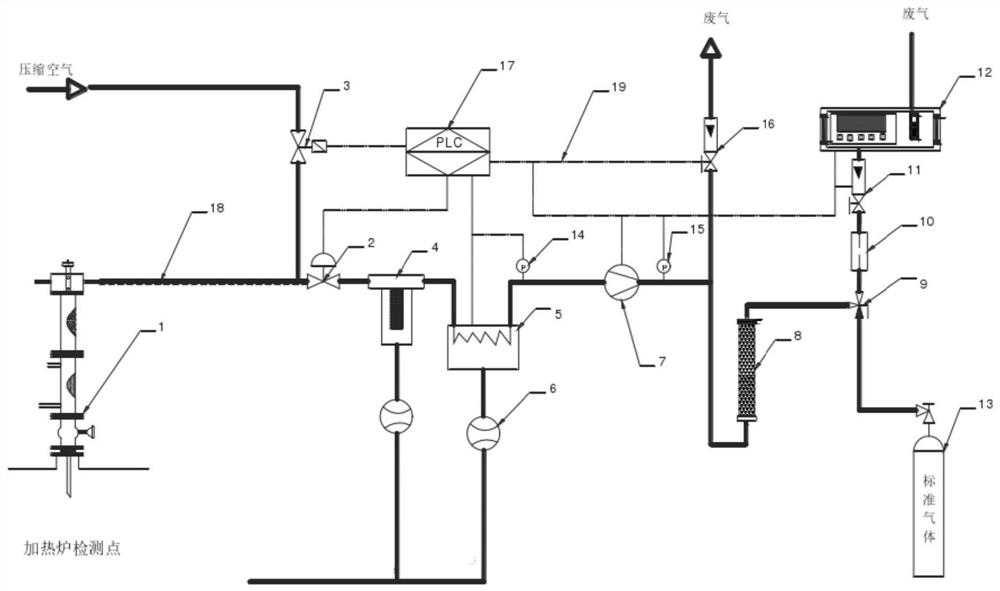

[0044] An online monitoring system for kiln combustion flue gas is used to collect and analyze the combustion flue gas of the kiln, and judge the air-fuel ratio of the kiln combustion according to the analyzed flue gas composition, so as to adjust the industrial production. Such as figure 1 As shown, the system mainly includes a sampling unit, a processing unit, a vacuum pump 7, an analysis unit 12, an electronic control device 17, a backflushing unit, a calibration unit, and some monitoring and control devices for flue gas flow and pressure in pipelines, which are detailed below The structure and working principle are described in detail. The analysis unit 12 is a common device on the market for detecting NOx, CO and other gases. This embodiment is a gas analyzer, and the electronic control device 17 is a PLC controller.

[0045] The sampling unit is used to take flue gas as a sample gas from a kiln such as a heating furnace, and includes a sampling probe 1 and an electric s...

Embodiment 2

[0056] A method for on-line monitoring of furnace combustion flue gas, using the on-line monitoring system of embodiment 1, comprising the following steps:

[0057] 1. Analysis unit calibration

[0058] Before the system runs, the three-way switching valve 9 is controlled to be switched to connect with the standard gas source 13, and the analysis unit 12 is calibrated, and then the three-way switching valve 9 is controlled to be switched back to be connected to the vacuum pump 7.

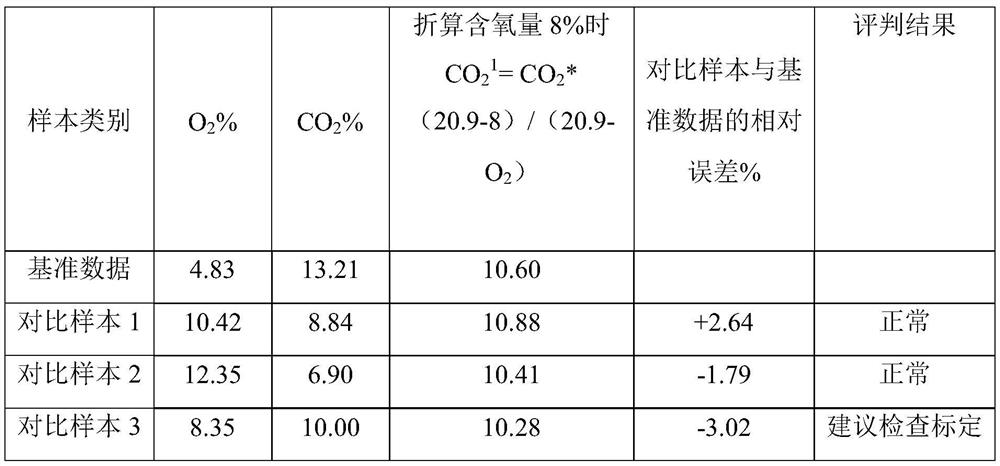

[0059] Then, based on the actual measurement data of the analysis unit 12 that has just been calibrated, the CO after conversion is tracked and monitored when the oxygen content is 8%. 2 The change of the value can be used to judge the accuracy of the analyzer. When the relative error with the benchmark data is more than 3%, it is reminded that there may be abnormality in the analysis result, and it is recommended that the staff check the calibration of the analysis unit 12 again.

[0060] The fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com