Scroll compressor with pressure regulating device and assembling method thereof

A technology for scroll compressors and pressure regulation, which is applied to the components of pumping devices for elastic fluids, rotary piston machines, mechanical equipment, etc., and can solve the problem of inability to control the gas pressure at the compressor inlet Unstable environment, large air pressure fluctuation amplitude and other problems, to achieve the effect of convenient connection and assembly, easy implementation, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

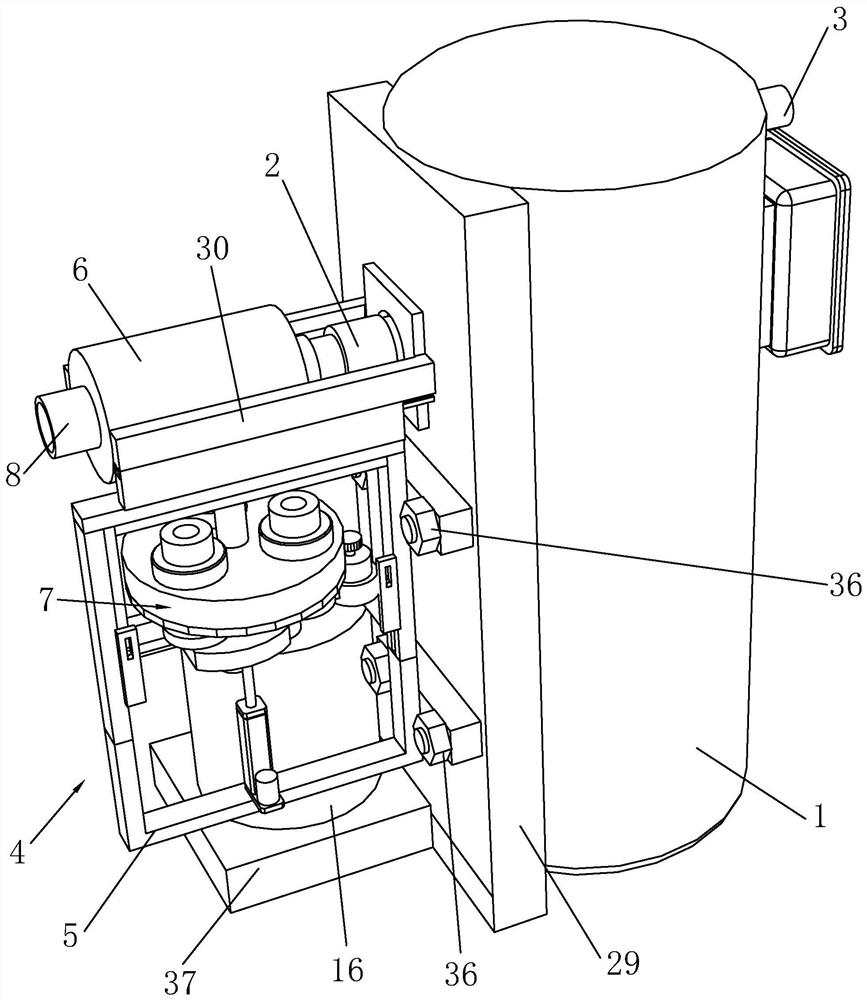

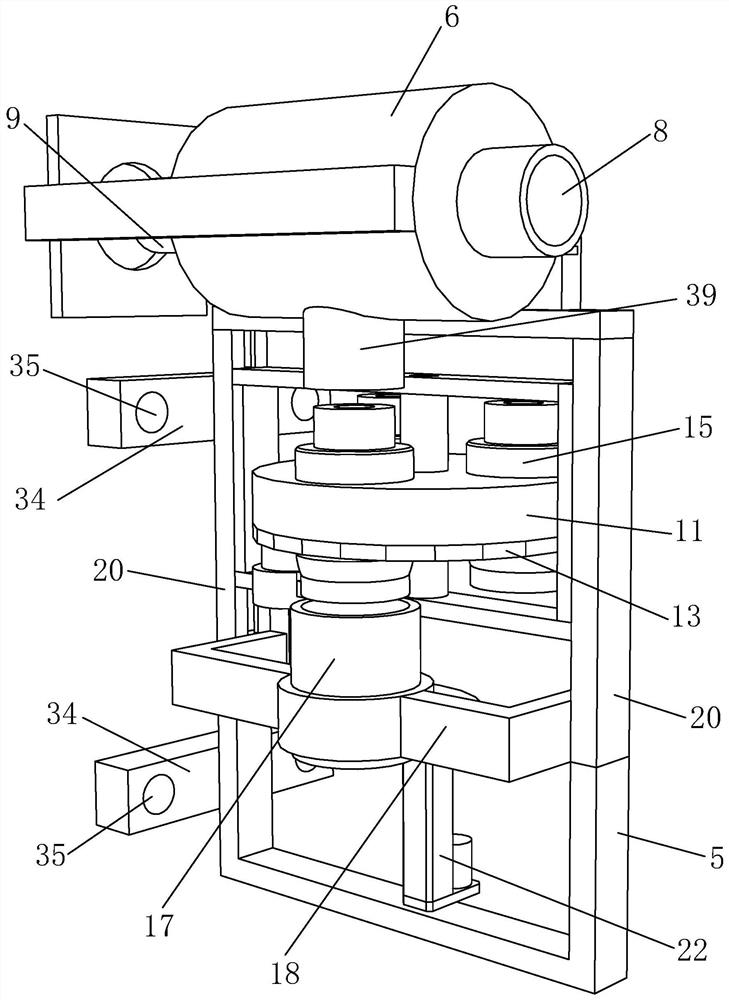

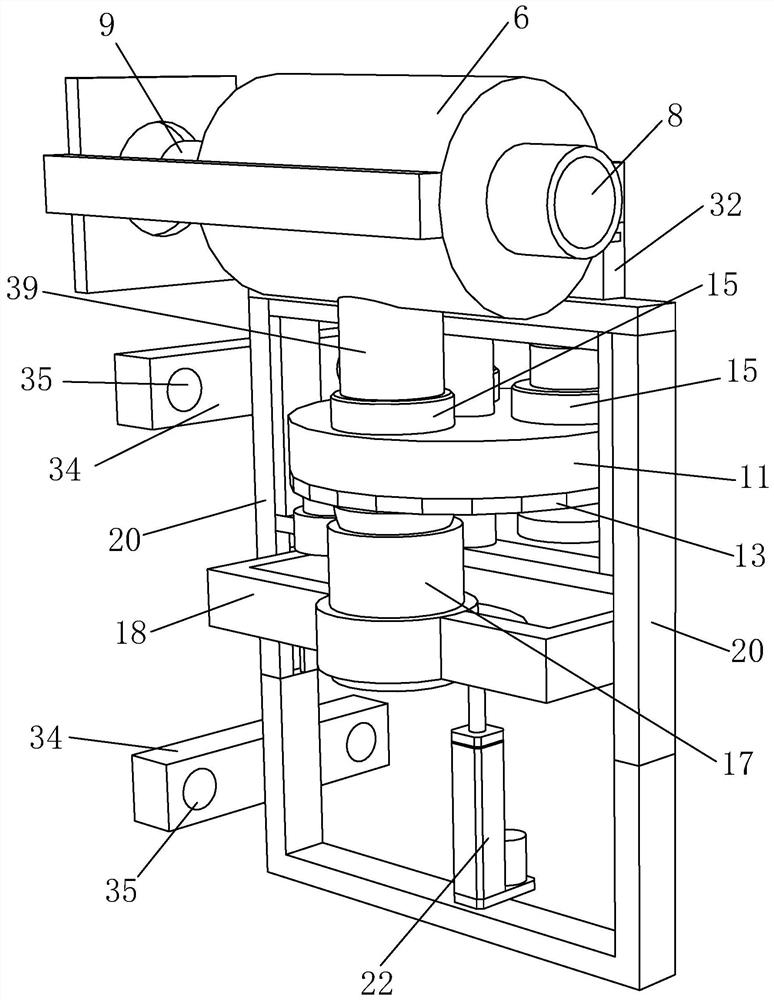

[0039] Such as Figure 1 to Figure 10 As shown, it is a scroll compressor with a pressure regulating device according to the present invention, which includes a compressor body 1, the compressor body 1 is provided with an air inlet 2 and an air outlet 3, and the air inlet 2 is provided with a pressure regulating mechanism 4, The pressure regulating mechanism 4 includes a support frame 5, a decompression cylinder 6 and a pressure limiting assembly 7, the decompression cylinder 6 and the pressure limiting assembly 7 are both arranged on the support frame 5, the support frame 5 is arranged on the compressor body 1, and the decompression cylinder 6 is provided with inlet pipe 8 and outlet pipe 9, outlet pipe 9 is connected with air inlet 2, decompression cylinder 6 is provided with decompression pipe 39, decompression pipe 39 is connected with decompression cylinder 6, and pressure limiting assembly 7 is connected with The decompression pipe 39 is connected. The air pressure ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com