Hydraulic extrusion type magnetorheological fluid clutch

A magnetorheological fluid, extrusion technology, applied in the field of intelligent clutch, can solve the problems of small transmission torque, complex structure, low driving power density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

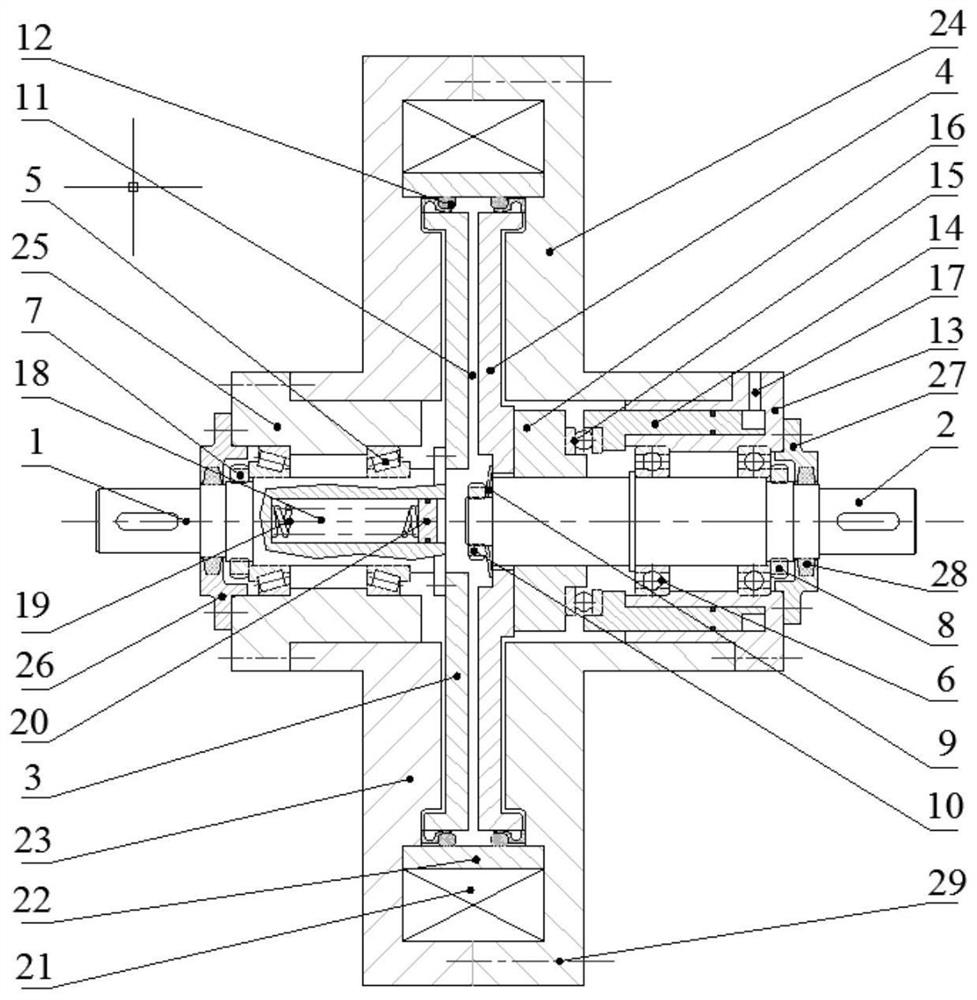

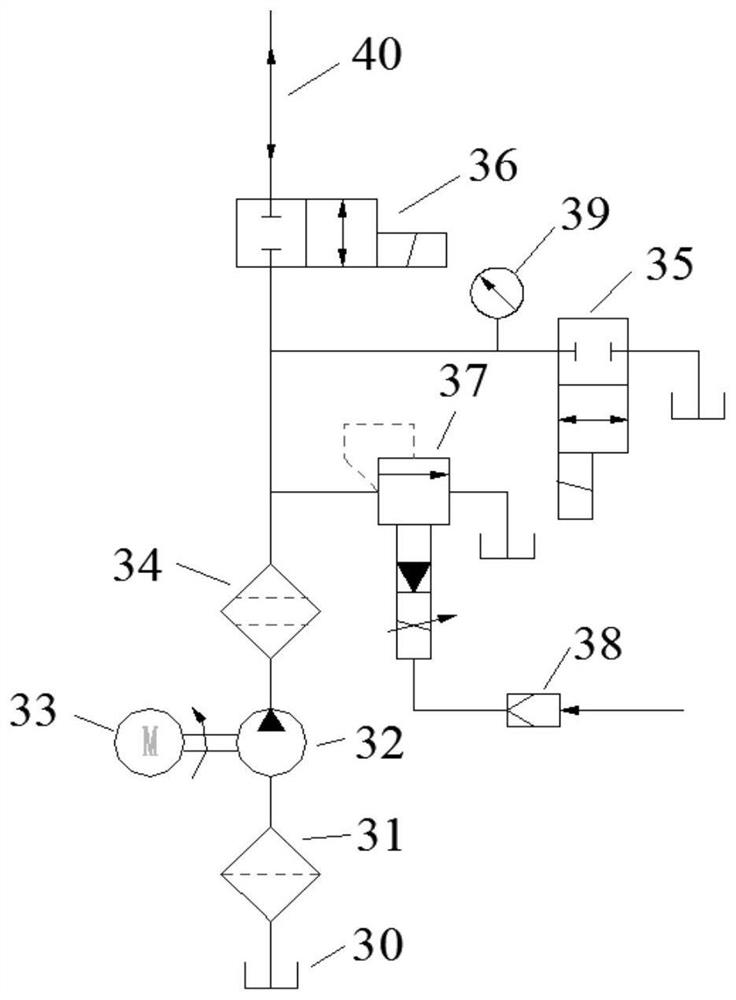

[0016] A hydraulic extrusion magneto-rheological fluid clutch is composed of a mechanical structure part and a hydraulic control part. The mechanical part includes a casing, a driving component, a driven component, a magnetorheological fluid, a magnetorheological fluid extruding device, a volume fine-tuning device and a magnetic field generating device. The hydraulic control system includes a motor, an oil pump, a two-position two-way solenoid valve, and an electro-hydraulic proportional overflow valve, which are used to control the oil pressure of the oil cylinder in the magneto-rheological fluid extrusion device to control the magneto-rheological fluid under the action of the magnetic field in the working gap. The axial extrusion force of the liquid.

[0017] The active components of the mechanical structure part mainly include a drive shaft 1 , a drive disc 3 , a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com