Residual iron hole plugging device

A technology of plugging and residual iron, applied in blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of personnel prone to collision, tripping, long time, and difficult operation, so as to reduce labor intensity and operation safety risks. , time saving, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] For the convenience of description, in this paper, the length direction of the mud beating barrel is defined as the front and rear direction, and the outlet direction of the plugging mud in the mud beating barrel is the front.

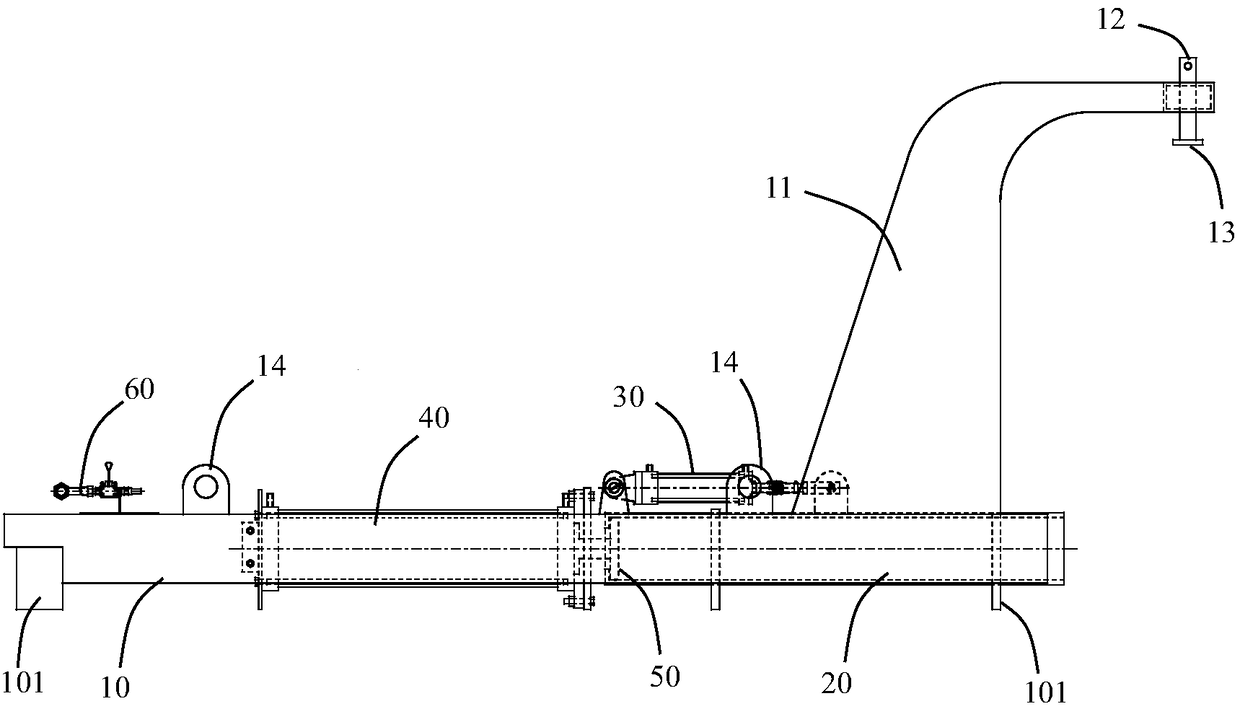

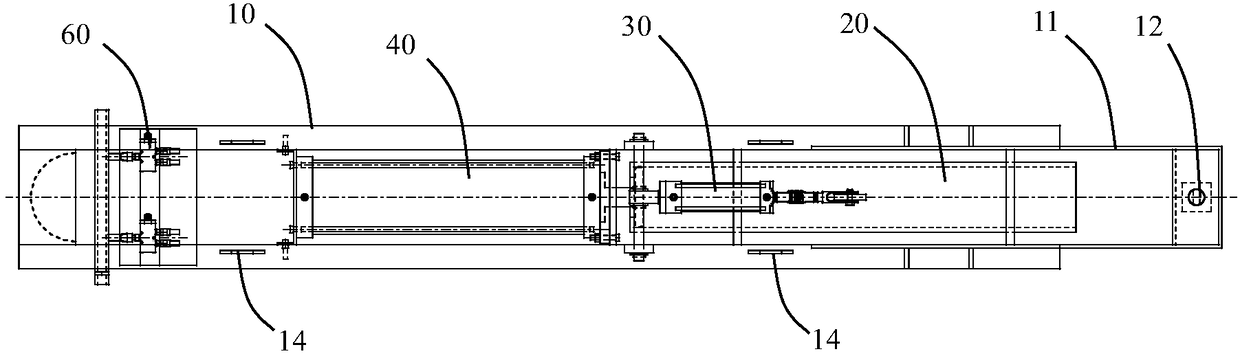

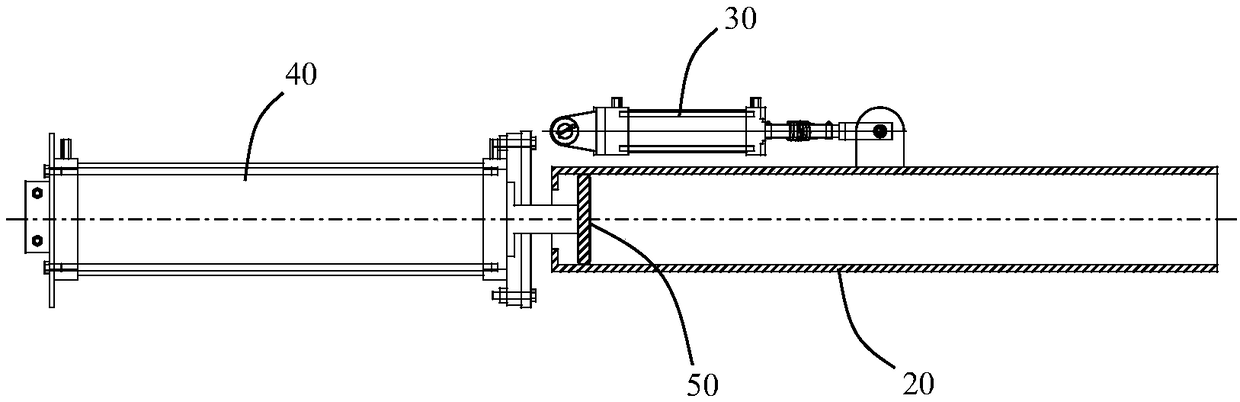

[0018] Such as Figure 1~3 As shown, the residual iron hole plugging device of the present invention includes a body frame 10, a mud beating barrel 20, a pressure maintaining cylinder 30 and a mud beating cylinder 40, and the mud beating barrel 20 is placed in the body frame 10 and Can move back and forth relative to the body frame 10; the mud beating cylinder 20 is provided with a mud beating disc 50, and the mud beating disc 50 is fixed on the end of the piston rod of the mud beating cylinder 40, and the mud beating disc 50 is fixed on the end of the piston rod of the mud beating cylinder 40. The cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com