Simulation test loading device for automobile wheel hub bearing unit

A loading device and automobile wheel hub technology, applied in vehicle testing, mechanical bearing testing, measuring devices, etc., can solve the problems of affecting test results, distortion of test load values, mutual interference of loading forces, etc., to improve reliability and control pressure. Stable and easy to install and adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

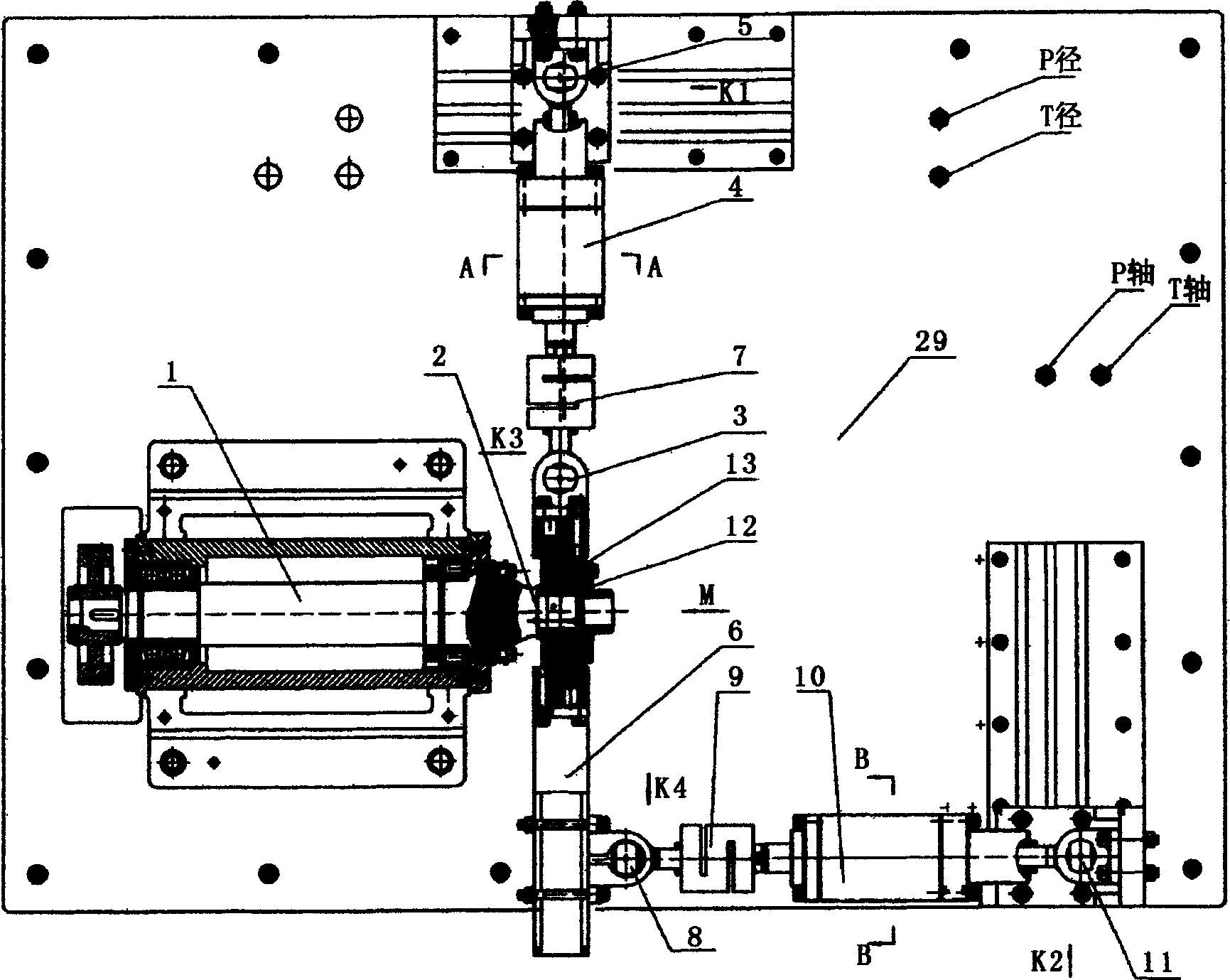

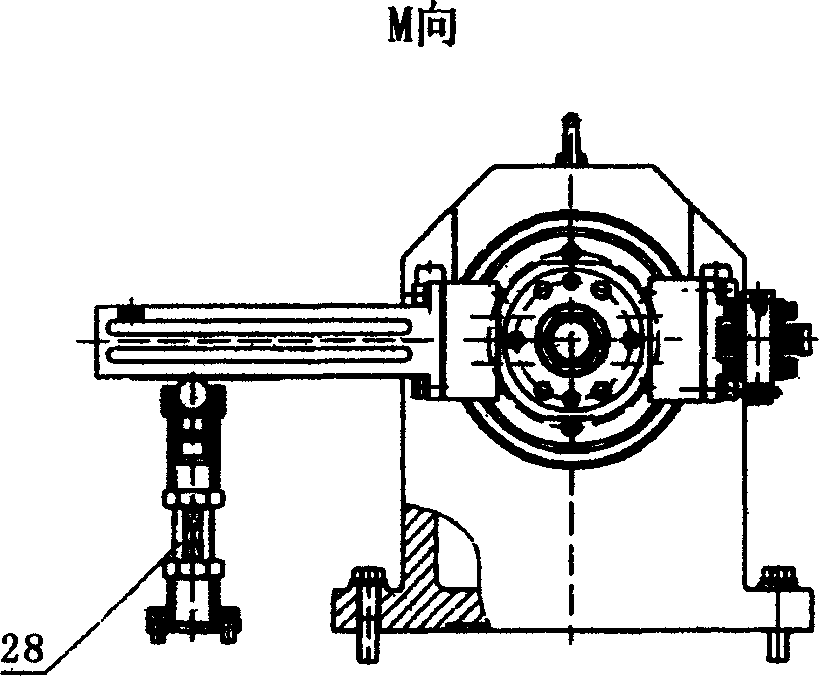

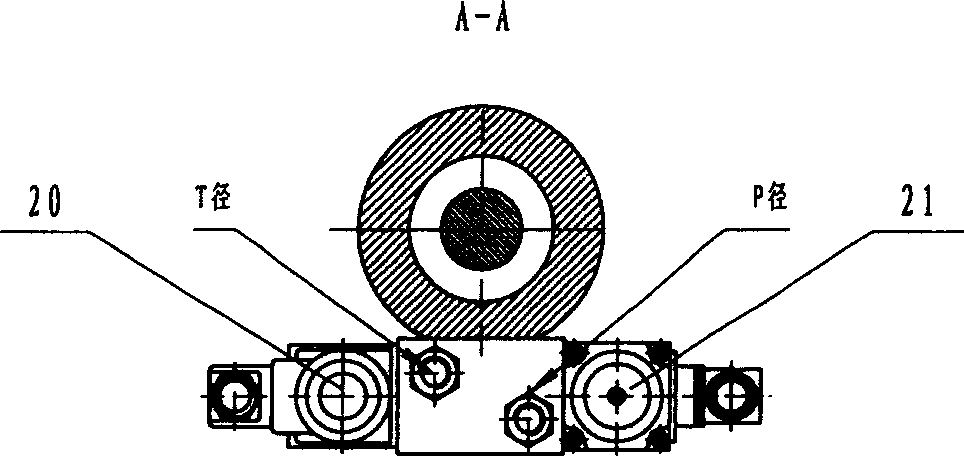

[0029] The front end of the main shaft (1) is fixedly connected to the test main shaft (2), and the test bearing (12) is installed on the test main shaft (2), and the test bearing (12) and the carrier (13) are fixed together. One side is connected to the tension pressure sensor (7) through the joint bearing (3), the tension pressure sensor (7) is connected to one end of the radial loading cylinder (4), and the other end of the radial loading cylinder (4) is connected through the joint bearing (5) It is connected with the mechanism frame (29), and the proportional pressure reducing valve (21) and the electromagnetic reversing valve (20) which have been connected to each other as one are directly installed under the radial loading cylinder (4). ) is connected to the axial loading arm (6), the axial loading arm (6) is connected to the tension pressure sensor (9) through the joint bearing (8), and the other end of the tension pressure sensor (9) is connected to the axial loading cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com