Method for oligomerization production of alpha olefin from ethylene

A technology of ethylene oligomerization and olefin, applied in the direction of addition of unsaturated hydrocarbons to hydrocarbon production, organic chemistry, etc., to achieve the effects of increasing the contact area, increasing the concentration, and speeding up the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

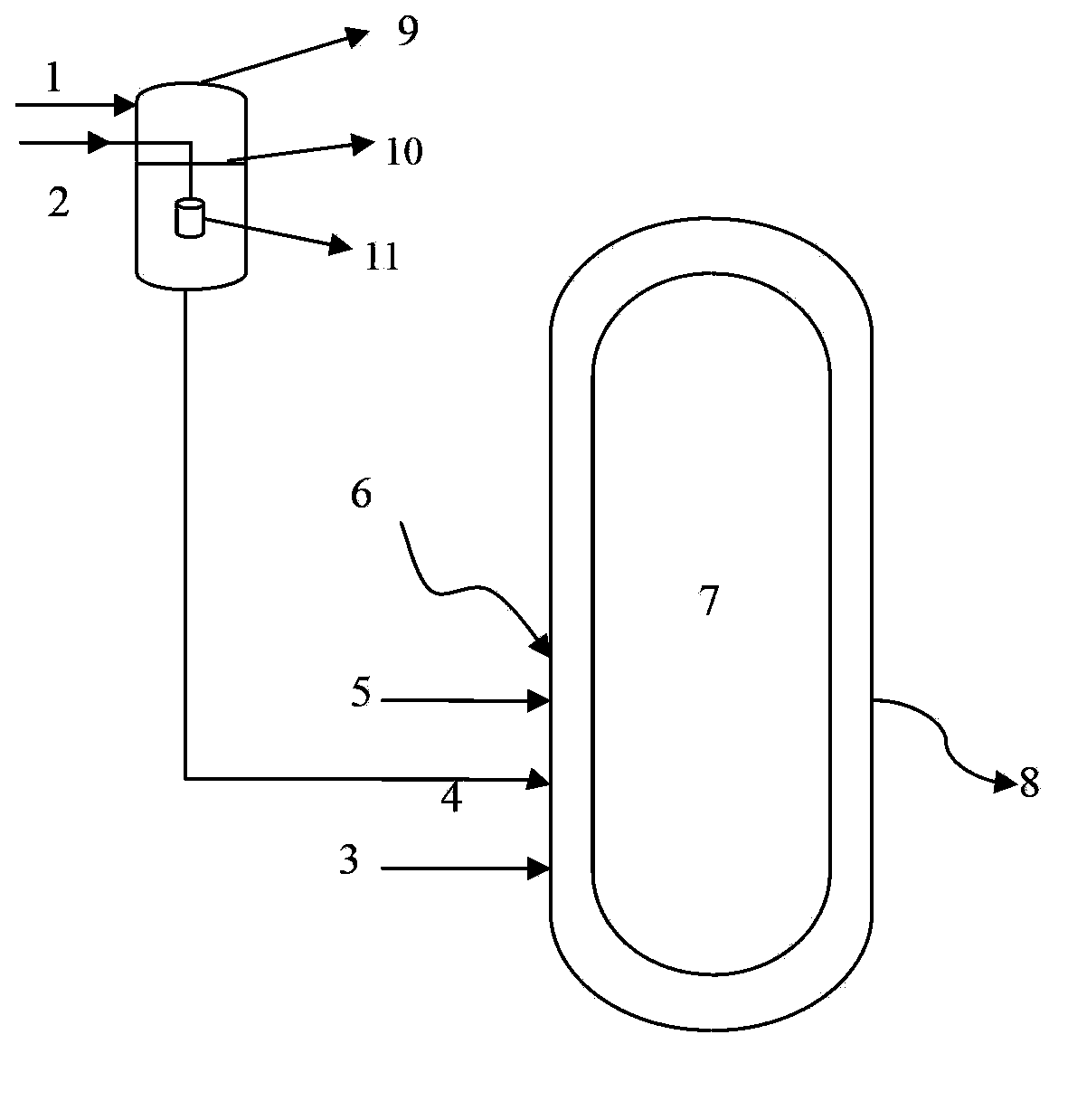

[0031] Such as figure 1 As shown, the technical process according to the present invention is as follows, taking ethylene trimerization to produce 1-hexene as an example, the material ethylene flow rate in the reaction (200kg / h, polymer grade, commercially available), the reaction solvent is heptane (flow rate is 380kg / h, commercially available) and chromium-based catalysts (calculated as chromium, with a concentration of 1mol / L Cr, commercially available). After purging the closed reaction system with inert gas, replace it with ethylene for 2-3 times and dry it at 120°C for 3 hours, then feed ethylene to keep the pressure of the external container at 5.5 MPa, and the flow rate of ethylene into the external container is 80kg / h (accounting for 40% of the total ethylene feed), and the flow rate of the reaction solvent entering the external container is 320kg / h (accounting for 84% of the total solvent consumption). Here, the external container is a cylindrical container, and the ...

Embodiment 2

[0036] Embodiment 2 is the same as Example 1, except that the ethylene flow entering the external container is 20Kg / h (accounting for 10% of the total amount of ethylene feed, and the solvent flow is 190kg / h (accounting for 50% of the total solvent consumption). ), the shape of the gas distributor in the external container is disc-shaped, and its opening rate is 85%.

[0037] According to this example, the activity of the catalyst was 365kg oligomerization product / (g·Cr·h), and the loop reactor operated continuously for 93 days without any abnormal fluctuations, maintaining stable production.

Embodiment 3

[0039] Embodiment 3 is the same as Example 1, except that the ethylene flow entering the external container is 100Kg / h (accounting for 50% of the total amount of ethylene feed), and the solvent flow is 342kg / h (accounting for 90% of the total solvent consumption). %), the external container is ellipsoidal, the shape of the gas distributor in the external container is cylindrical, and its opening ratio is 35%. The reaction temperature in the reactor was maintained at 110° C., and the reaction pressure was 5.1 MPa.

[0040] According to this example, the activity of the catalyst is 360kg oligomerization product / (g·Cr·h), the reaction system has been running stably for 92 days, and there is no polymer blockage or abnormal pressure fluctuation in the loop reactor, and it remains stable Production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com