Pressure stabilization adjusting method for gas collecting pipe of coke oven

A technology for voltage regulation and gas collector pressure, applied in the field of coke ovens, can solve problems such as visible pollution, achieve the effects of reducing pressure fluctuations, improving emergency response capabilities, improving configuration capabilities and pressure regulation levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

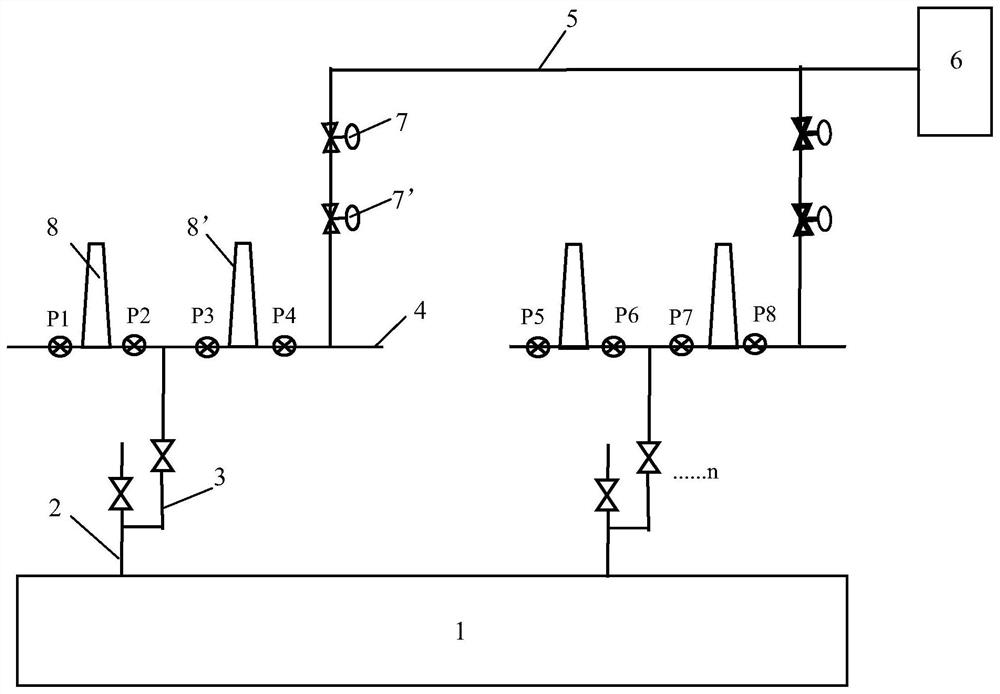

[0033] see figure 1 , the coke oven gas collecting pipe voltage stabilizing and regulating method of the present invention, it comprises:

[0034] 1) Suction pipe double flap adjustment

[0035] The raw coal gas produced during the coking coal carbonization process in the carbonization chamber of the coke oven 1 is collected to the gas collecting pipe 4 through the ascending pipe 2 and the bridge pipe 3, and then connected to the gas exhaust fan 6 through the suction pipe 5 and then purified and treated. The suction pipe 5 is connected in series Two pressure regulating flaps 7, 7' are provided, and the adjustment ranges of the openings of the two pressure regulating flaps 7, 7' are both 10% to 80%;

[0036] 2) Ignition and release system control

[0037]Control the pressure change rate V of the air collecting pipe 4, V=ΔP / T, V unit Pa / ms, ΔP is the pressure change of the air collecting pipe 4, the unit is Pa, T time, the unit is ms; The pressure rises rapidly. When the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com