Electronic control friction method and electronic control friction device for micro-nano textured surface

An electronically controlled friction, micro-nano technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to control the tribological properties and the inability to change the friction coefficient, and achieve high load loading resolution, convenient testing, and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The friction method includes preliminary preparation, constant pressure loading, electronic control signal input and friction detection, and the specific steps are as follows:

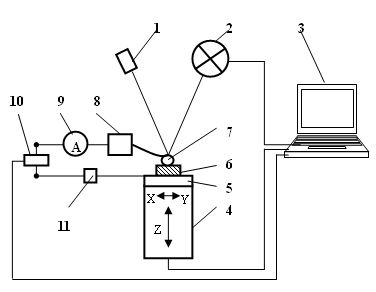

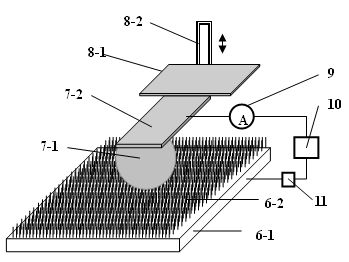

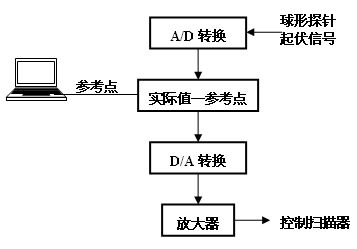

[0022] Preliminary preparations: first prepare the samples for electrical control tribological performance testing, the samples have micron texture, submicron texture or nano texture, put the samples on the sample stage; then place the samples with spherical The needle-point probe is installed on the probe bracket; finally, the micro-nano texture electronic control friction test device is established, and the micro-nano texture electronic control friction test device includes a friction detection module and an electronic control signal input module. The detection module and the electric control signal input module are sequentially connected;

[0023] Constant pressure loading: firstly adjust the height of the probe holder until the spherical probe is in contact with the sample surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com