Vibration damping fastener for groove type rail of streetcar

A technology for vibration reduction fasteners and trams, applied in the field of rail transit, can solve the problems of weak vibration reduction effect and poor noise reduction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

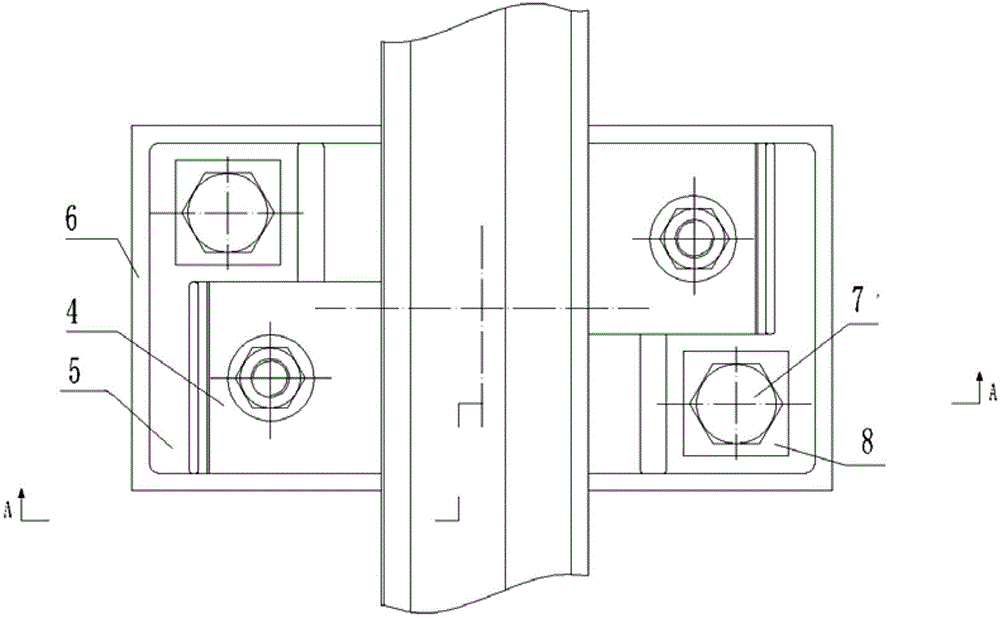

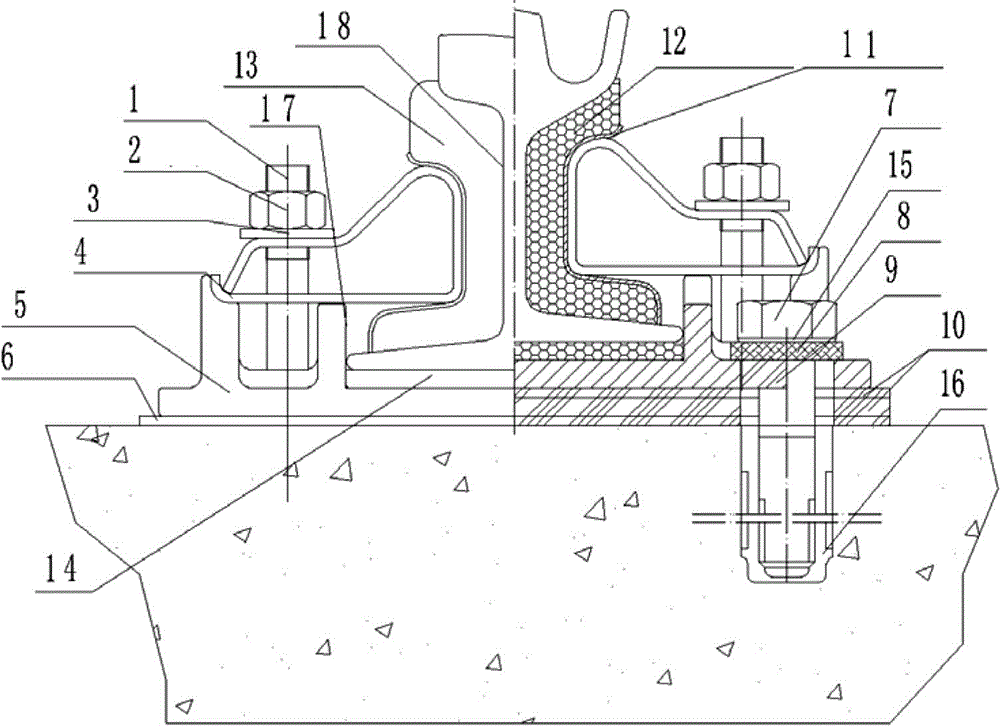

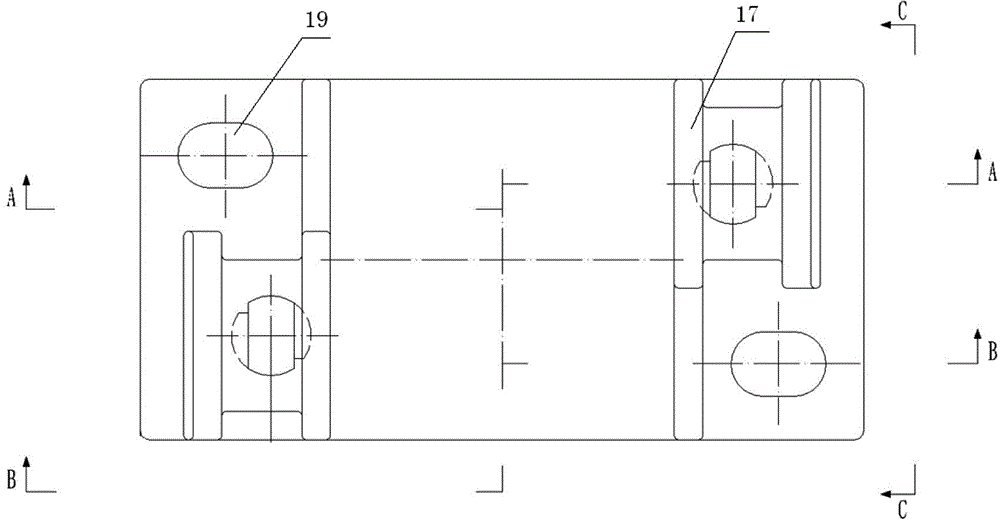

[0018] Such as figure 1 As shown, a vibration-damping fastener for a grooved rail of a tram, including a vibration-damping strip (vibration-damping strip I13 and vibration-damping strip II12) arranged at the waist of the grooved rail and a positioning shrapnel for squeezing and fixing the vibration-damping strip 4. The positioning elastic piece 4 supports the damping strip and fits closely on the waist 18 of the grooved rail. The whole vibration-damping fastener is fixed by oblique bolt sets and anchor bolt sets. The bolt sets include bolts 1, nuts 2 and flat washers 3. The anchor bolt sets include anchor bolts 7 and flat spacers 8. The anchor bolts of the vibration-damping fasteners Fix the positioning shrapnel on the iron backing plate 5. And the iron backing plate 5 is fixed on the sleeper by the bolt set and the anchor bolt set.

[0019] The positioning shrapnel 4 is arranged horizontally and fixed by anchor bolts, and the fixed center line is located away from the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com