Clamping device for camshaft machining

A clamping device and camshaft technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low clamping efficiency, achieve good clamping effect, improve efficiency, and shorten the use of clamping the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

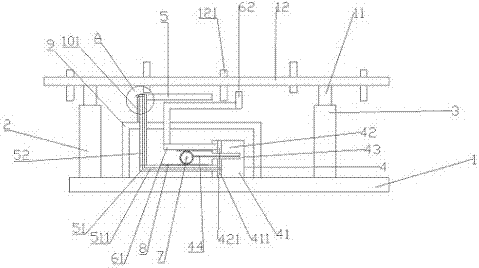

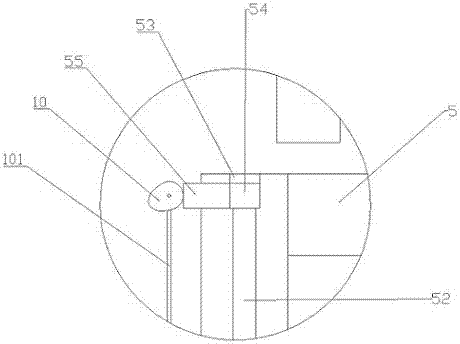

[0024] The reference signs in the accompanying drawings of the description include: base 1, first support column 2, second support column 3, U-shaped connector 4, first horizontal tube 41, first piston 411, second horizontal tube 42, second Piston 421, vertical pipe 43, limit rod 44, positioning column 5, first horizontal push rod 51, air hole 511, through hole 52, installation groove 53, bump 54, positioning block 55, locking column 6, second horizontal Push rod 61, clamping block 62, gear 7, rack 8, support frame 9, cam 10, bracket 101, height adjustment block 11, camshaft 12, protruding ring 121.

[0025] Such as figure 1 As shown, the clamping device for cam 10 shaft processing includes a base 1, on which a first support column 2, a U-shaped connector 4 with an opening facing left, a second support column 3, and a first support column 3 are arranged on the base 1 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com