Small-size oscillation grain dehuller

A technology of oscillating mechanism and grain, applied in the direction of solid separation, sieve, grille, etc., can solve the problems of high labor intensity, complete removal, mixing, etc., achieve the effect of large blowing coverage, avoid rigid contact, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

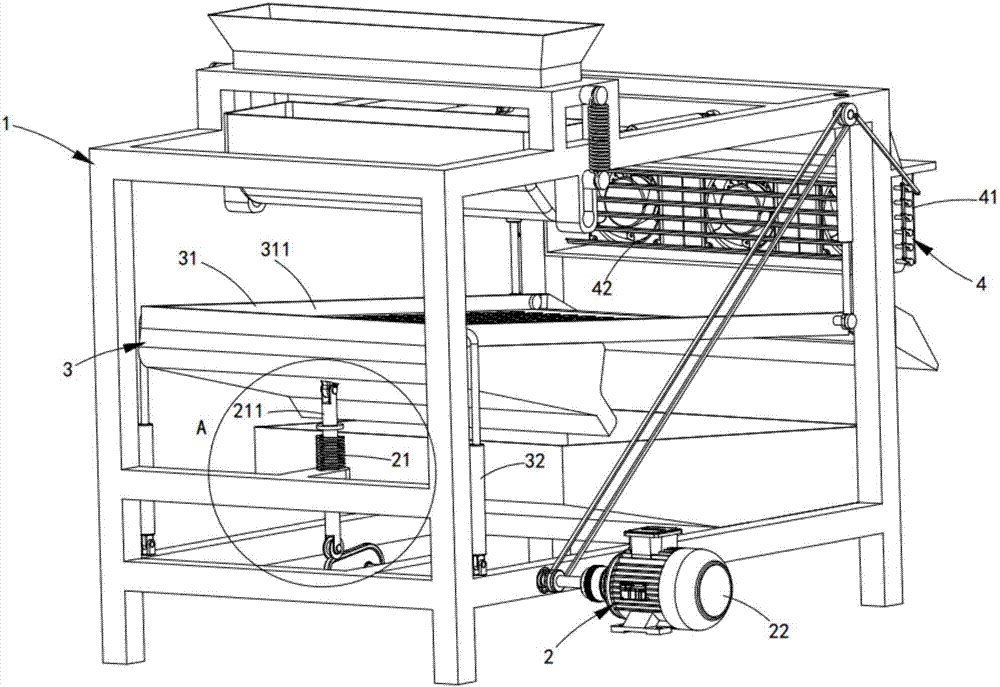

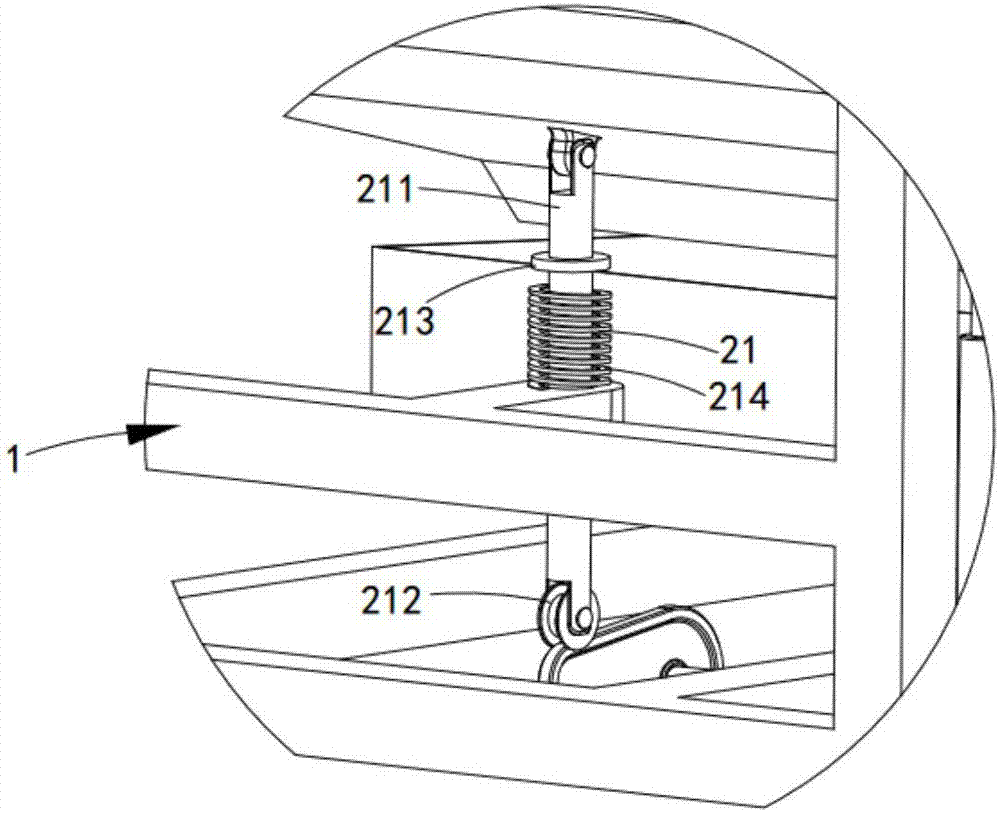

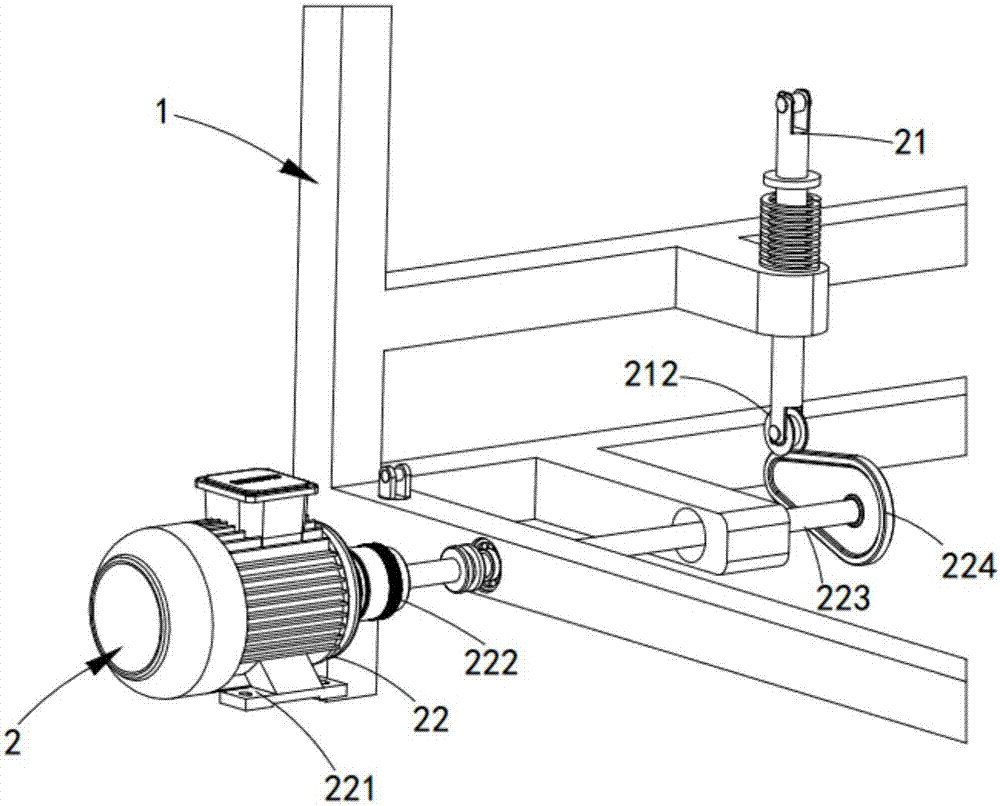

[0042] Such as figure 1 As shown, a small vibrating grain sheller includes a frame 1, an oscillating mechanism 2, a screening mechanism 3 and an air outlet mechanism 4. Assembly 21 and drive assembly 22, the oscillation assembly 21 is slidably arranged on the frame 1, and the drive assembly 22 is provided on one side thereof, the drive assembly 22 drives the oscillation arm 211 in the oscillation assembly 21 along the frame 1 up and down movement;

[0043] The screening mechanism 3 is arranged above the oscillating mechanism 2, and it includes a screening assembly 31 and an elastic connection assembly 32. 211 hinged, the vibrating arm 211 drives the screening net 311 in the screening assembly 31 to vibrate up and down, the elastic connecting assembly 32 is arranged at both ends of the screening assembly 31, one end is connected with the screening net 311, and the other end is connected with the screening net 311. The rack 1 is connected;

[0044] The air outlet mechanism 4 ...

Embodiment 2

[0066] Figure 10 It is a schematic structural view of Embodiment 2 of a small vibrating grain huller of the present invention; as Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0067] Such as Figure 10 As shown, a small vibrating grain huller also includes an intermittent feeding mechanism 5 fixedly arranged on the top of the frame 1, and the intermittent feeding mechanism 5 is located above the screening mechanism 3, and it is used for screening Mechanism 3 performs intermittent feeding, and the intermittent feeding mechanism 5 includes a feed hopper 51, an overturning material box 52, a tension spring 53 and a third elastic connector 54, and the feed hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com