Patents

Literature

83results about How to "Sync removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

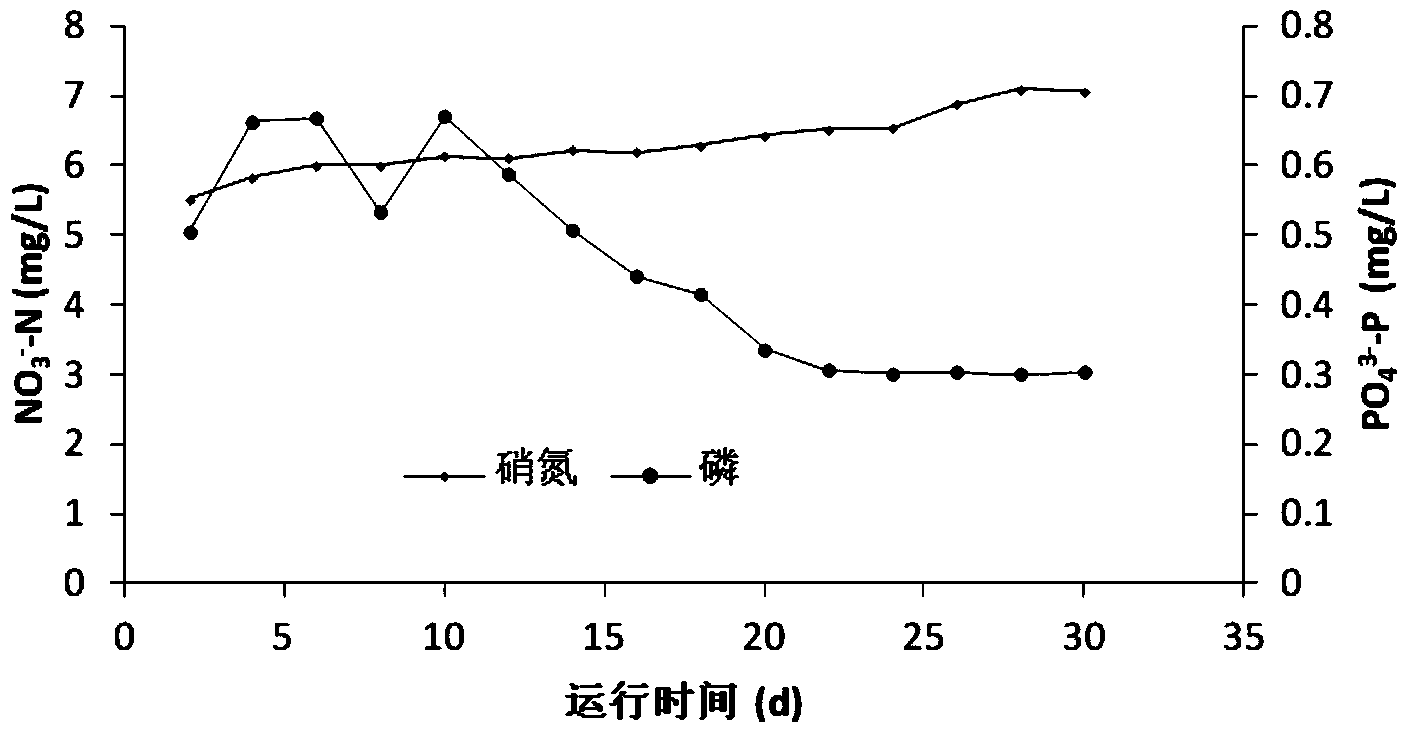

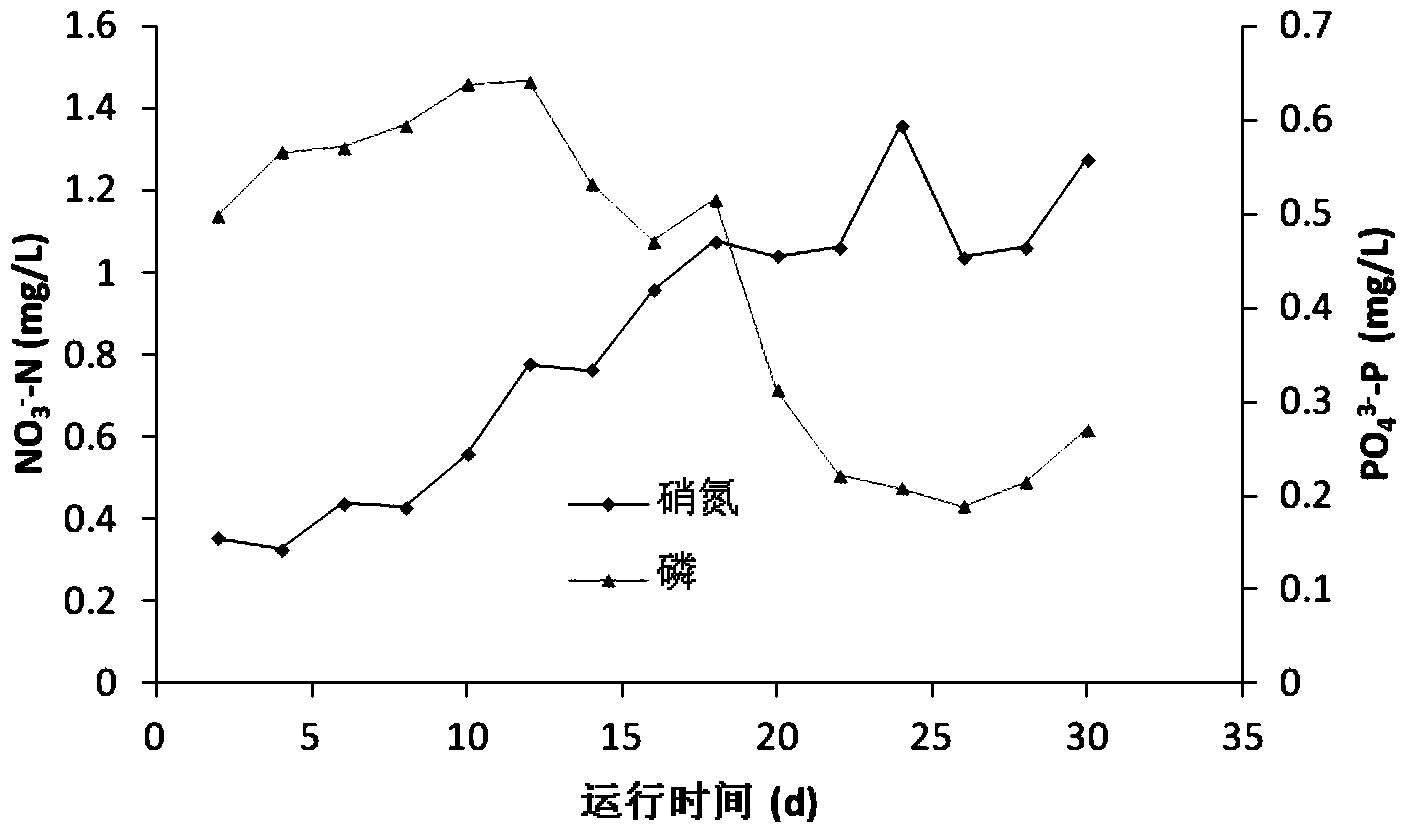

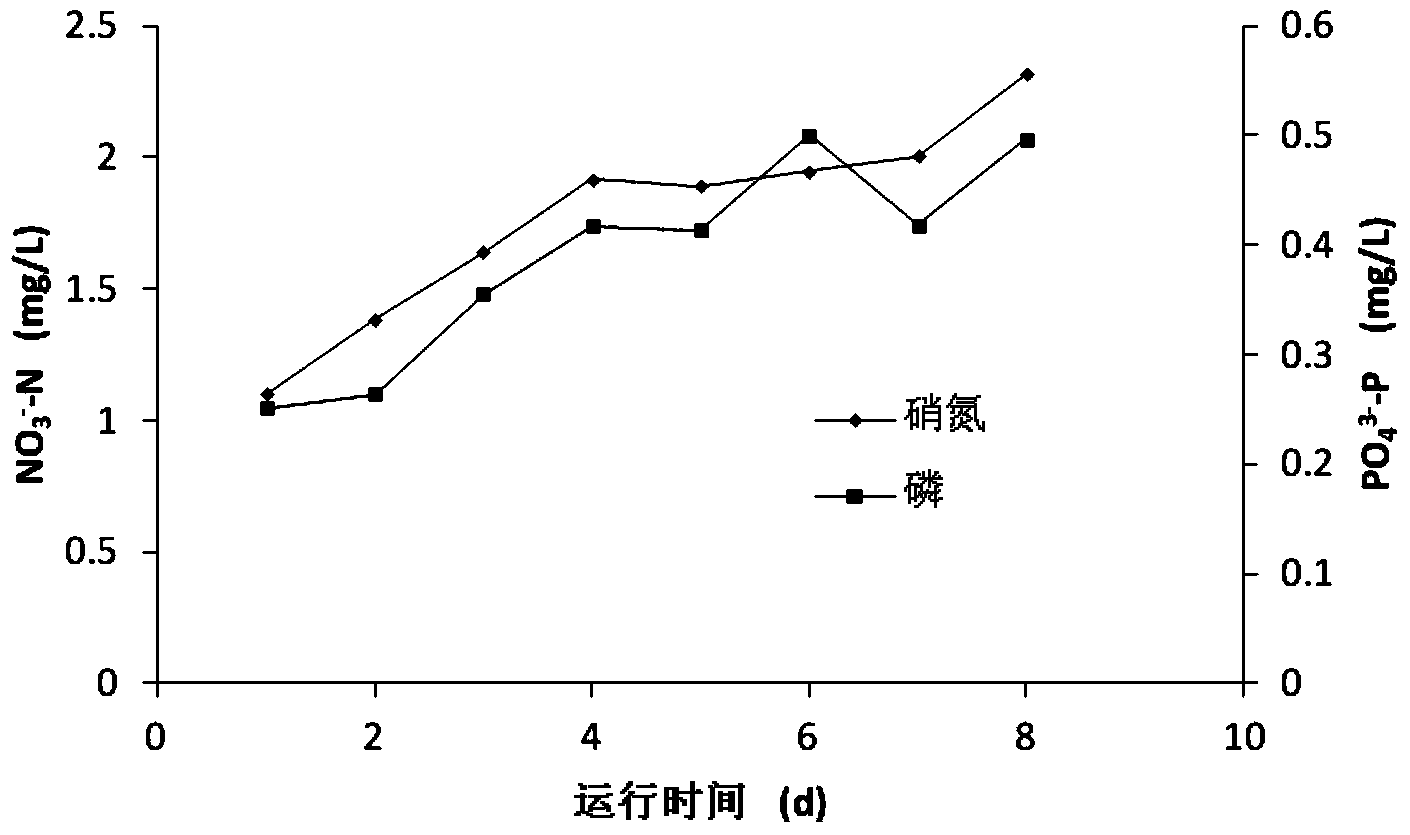

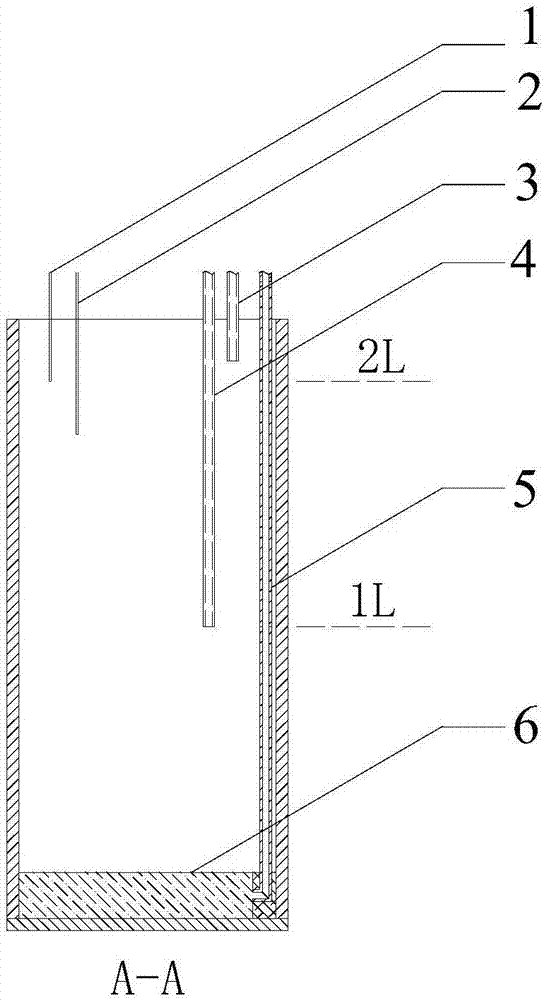

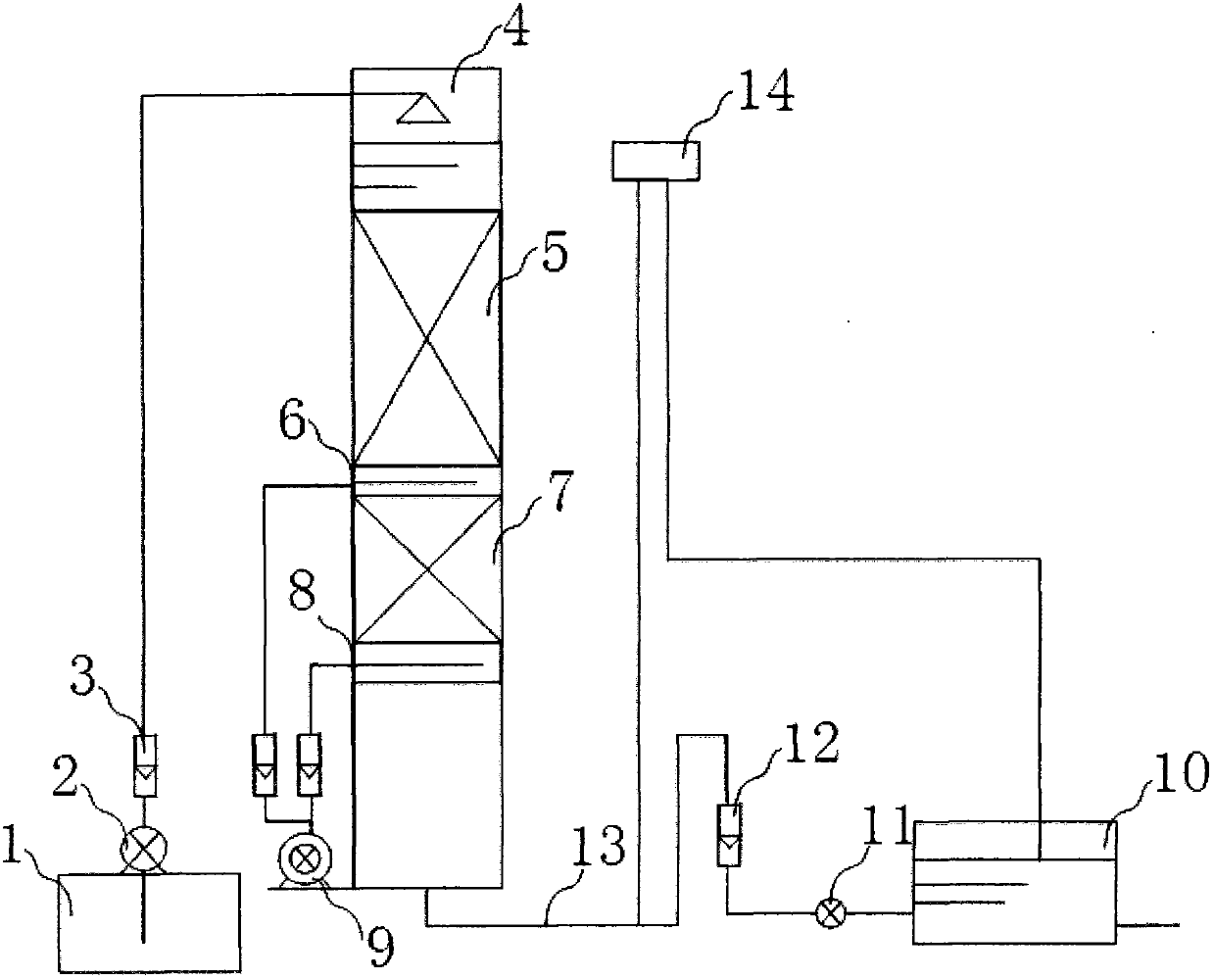

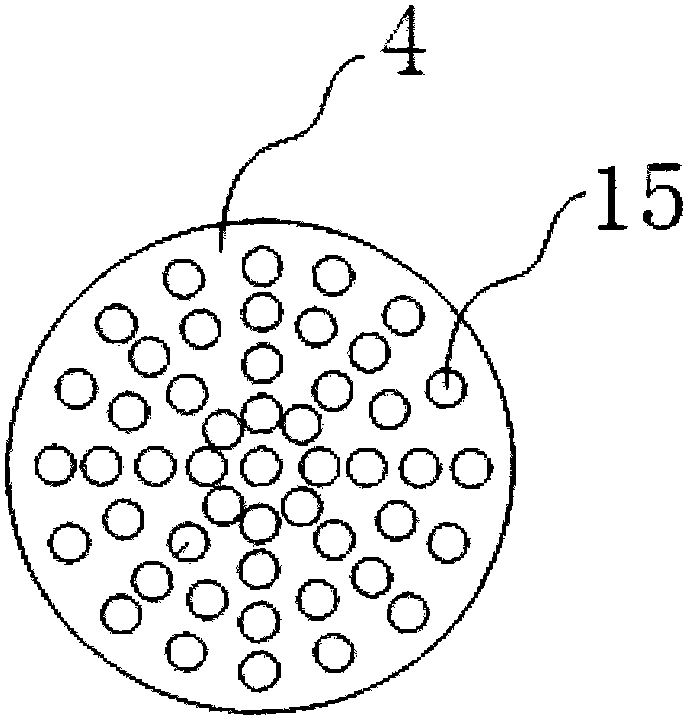

Natural pyrrhotite biological filter and method for synchronously removing nitrate nitrogen and phosphorus out of water by using natural pyrrhotite biological filter

ActiveCN103626293ASync removalEasy to handleWater treatment parameter controlWater treatment compoundsElectron donorBiological filter

The invention discloses a natural pyrrhotite biological filter and a method for synchronously removing nitrate nitrogen and phosphorus out of water by using the natural pyrrhotite biological filter, which belongs to the field of advanced wastewater treatment. The method comprises the following steps: (1) preparing and constructing biological filter fillers; (2) starting the biological filter; and (3) operating the biological filter. Pyrrhotite is used as an electron donor of sulfur autotrophic denitrification bacteria to reduce nitrate in the water to nitrogen so as to remove nitrate nitrogen out of the water; and the pyrrhotite and an oxidative product of the pyrrhotite remove phosphorus in such manners as adsorption and chemical precipitation so as to synchronously remove nitrate nitrogen and phosphorus out of the water. The biological filter disclosed by the invention is simple to construct, convenient to start, stable to operate, high in nitrogen and phosphorus removal efficiency and free of auxiliary materials, and the biological filter is applied to advanced wastewater treatment.

Owner:NANJING UNIV

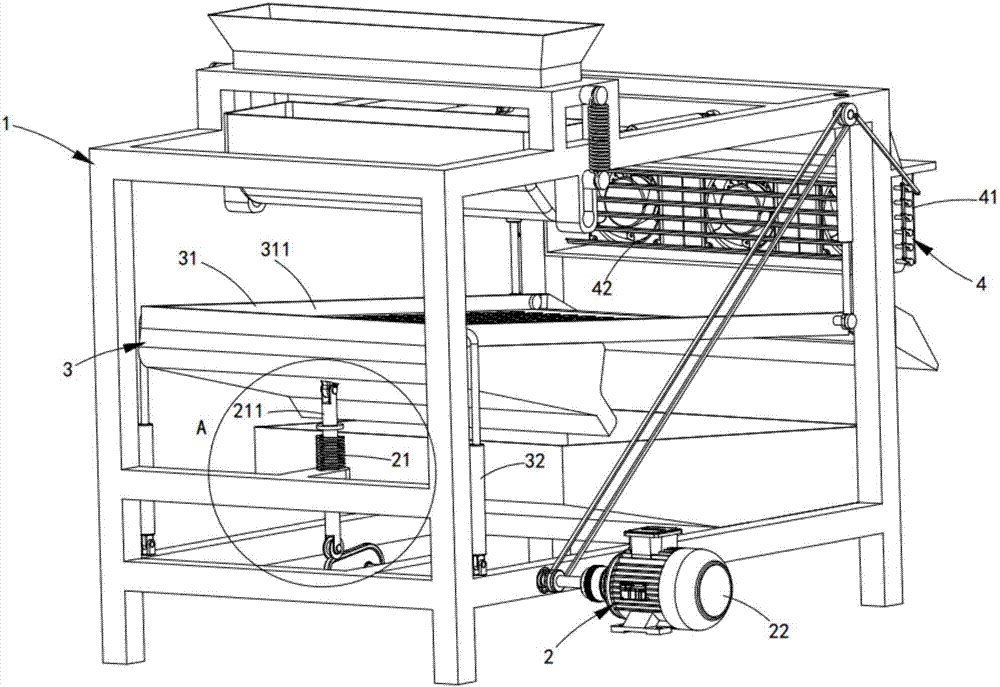

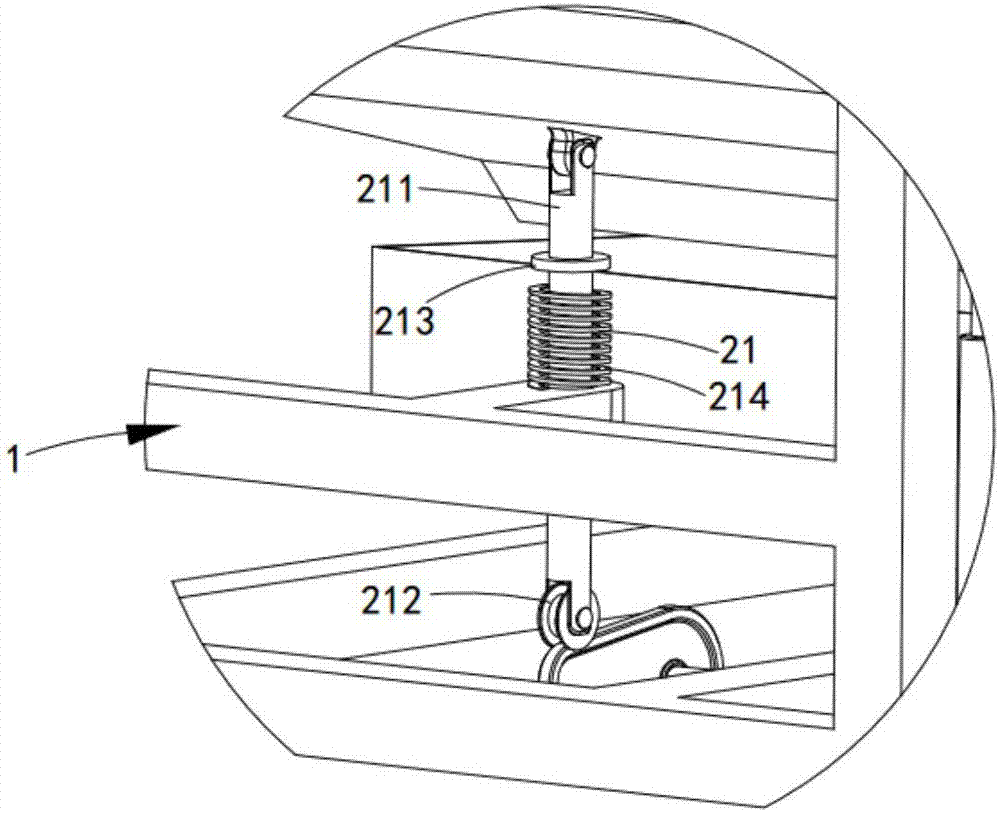

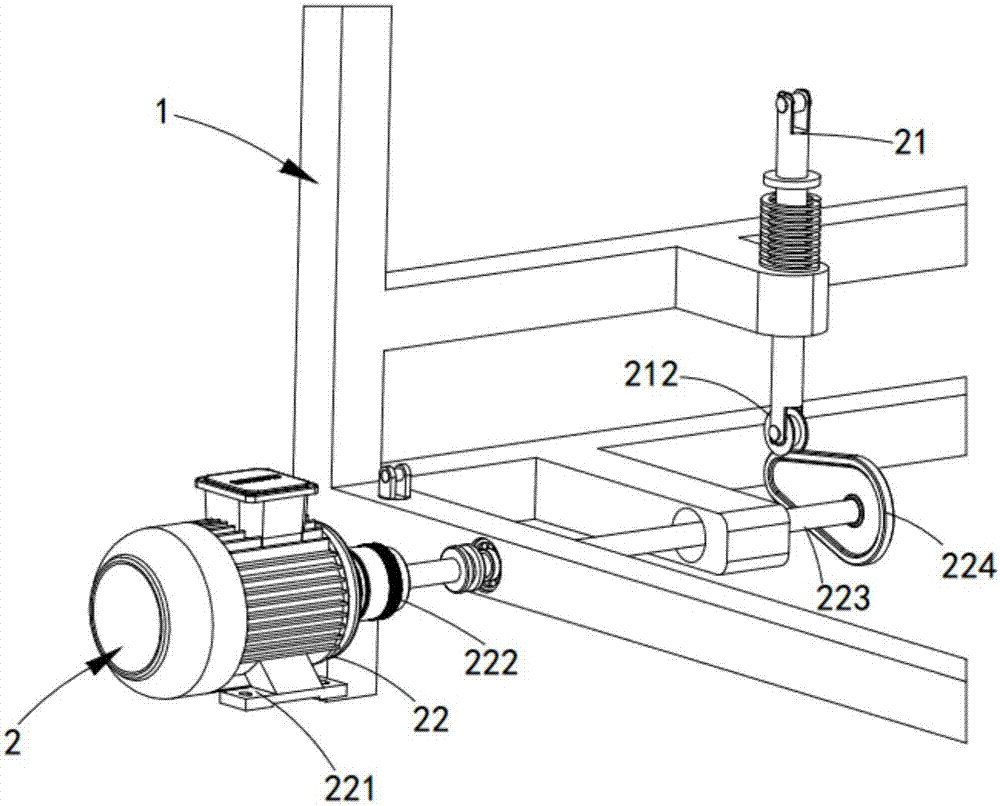

Small-size oscillation grain dehuller

InactiveCN106862081AImprove efficiencyAvoid rigid contactSievingGas current separationEngineeringImpurity

The invention discloses a small oscillating grain hulling machine, which comprises a frame, an oscillating mechanism, a screening mechanism and an air outlet mechanism. The air outlet component and the damper component drive the vibration component to run through the driving component. After the vibration component pushes the screening net in the screening component to a high place, the screening net drops rapidly by gravity, throws the grain on the screening net into the air, and is removed by the wind component. Light impurities such as chaff in the grain, and then the grain is returned to the screening net, and the granular impurities in the grain are screened and removed by the screening net. Repeat this process to completely remove the chaff impurities and granular impurities in the grain, and improve the screening efficiency.

Owner:奥林精密机械科技(长兴)有限公司

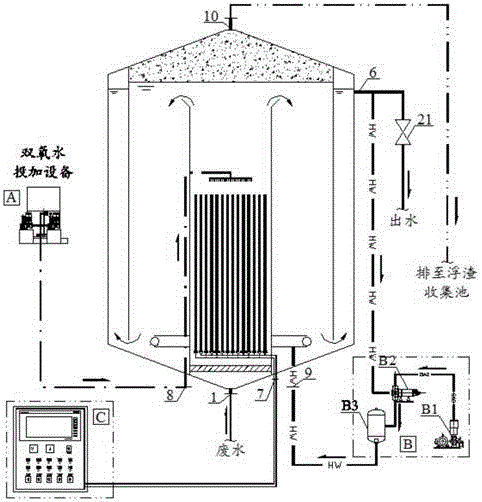

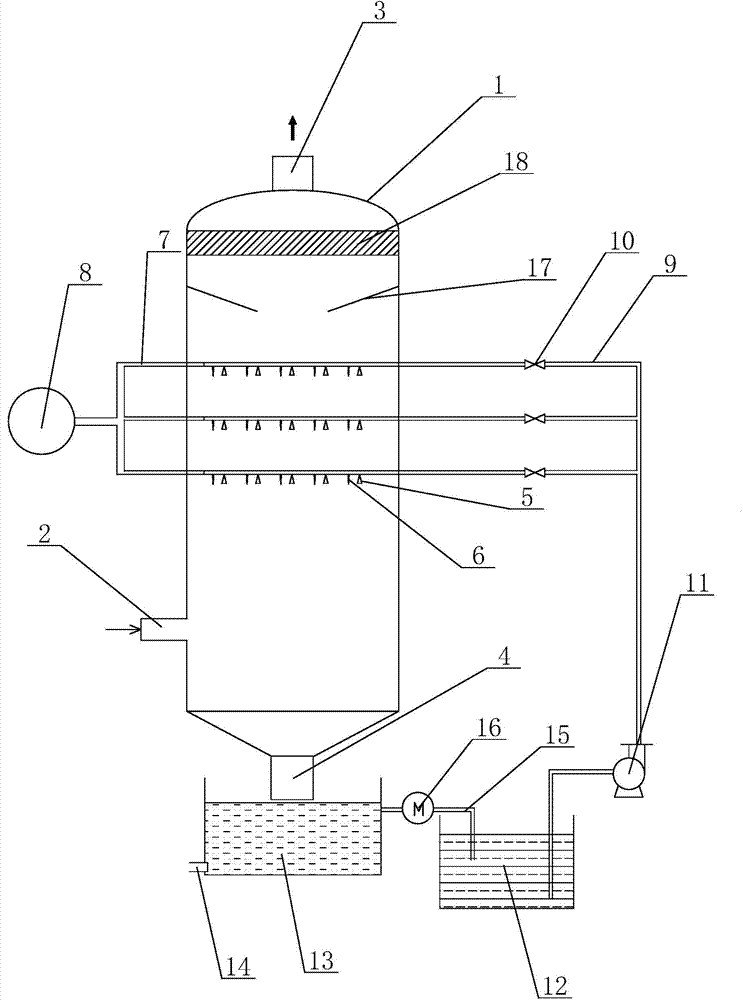

Electrolysis induction and ozone floatation integrated device

ActiveCN106495370AEfficient removalSync removalWater treatment compoundsMultistage water/sewage treatmentElectrolysisCatalytic oxidation

The invention discloses an electrolysis induction and ozone floatation integrated device. The device comprises an electric flocculation core barrel, an ozone floatation / catalytic oxidation zone, a water outlet barrel and a scum zone, wherein waste water accomplishes destabilization agglomeration in the electric flocculation core barrel; hydrogen peroxide is added to the upper part of the electric flocculation core barrel, so as to form a Fenton oxidation system with iron ion in the water; the ozone floatation / catalytic oxidation zone is connected with the top of the electric flocculation core barrel; waste water forms an ozone / hydrogen peroxide / iron ion ozone catalytic oxidation system in the ozone floatation / catalytic oxidation zone; refractory organics are further removed through oxidation; flotation process is further accomplished in ozone gas dissolved water under the action of microbubbles; the water outlet barrel is communicated with the bottom of the ozone floatation / catalytic oxidation zone, and ensures that the ozone floatation / catalytic oxidation zone has certain liquid level; the scum zone is positioned at the tops of the electric flocculation core barrel and the ozone floatation / catalytic oxidation zone, and stores and eliminates ozone floatation scums. The device can synchronously and efficiently remove various pollutants, such as SS, emulsified oil, chroma and the soluble refractory organics, only through a stable power supply and necessary hydrogen peroxide supply, and is simple to operate, and low in operation and maintenance costs.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

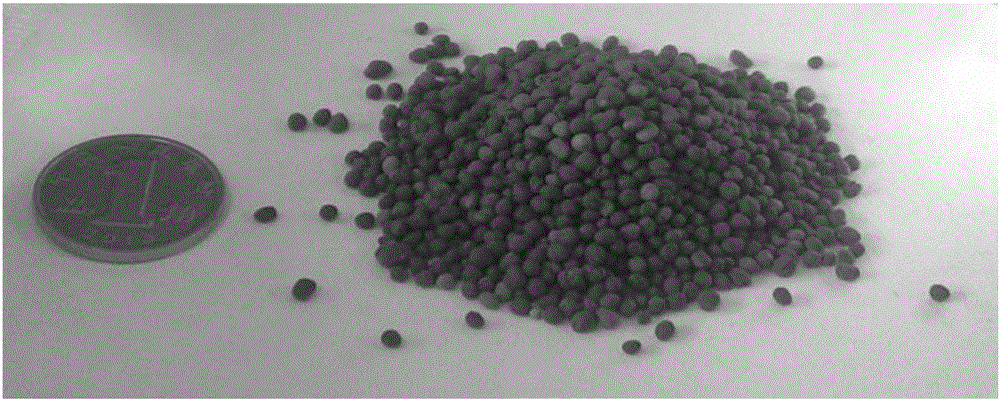

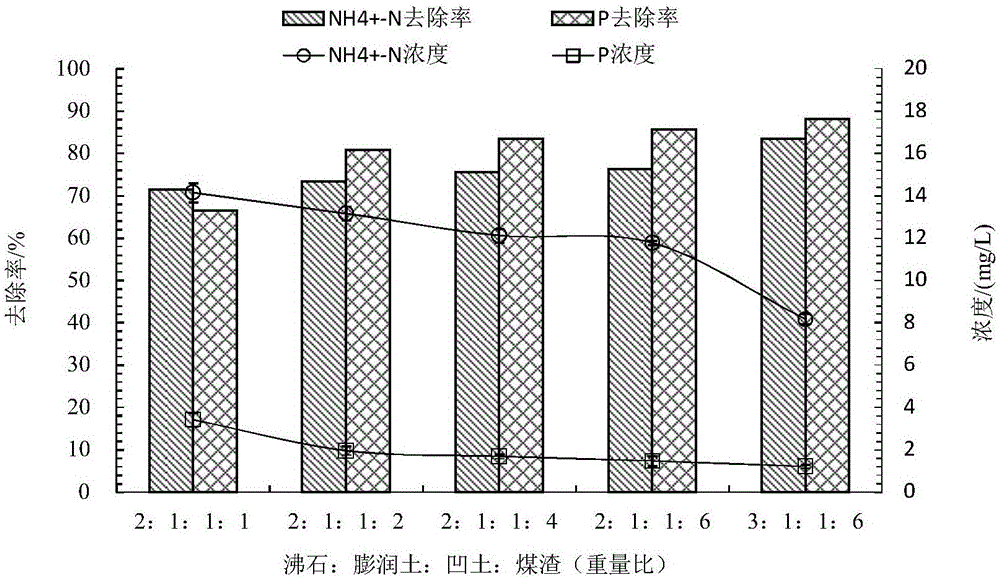

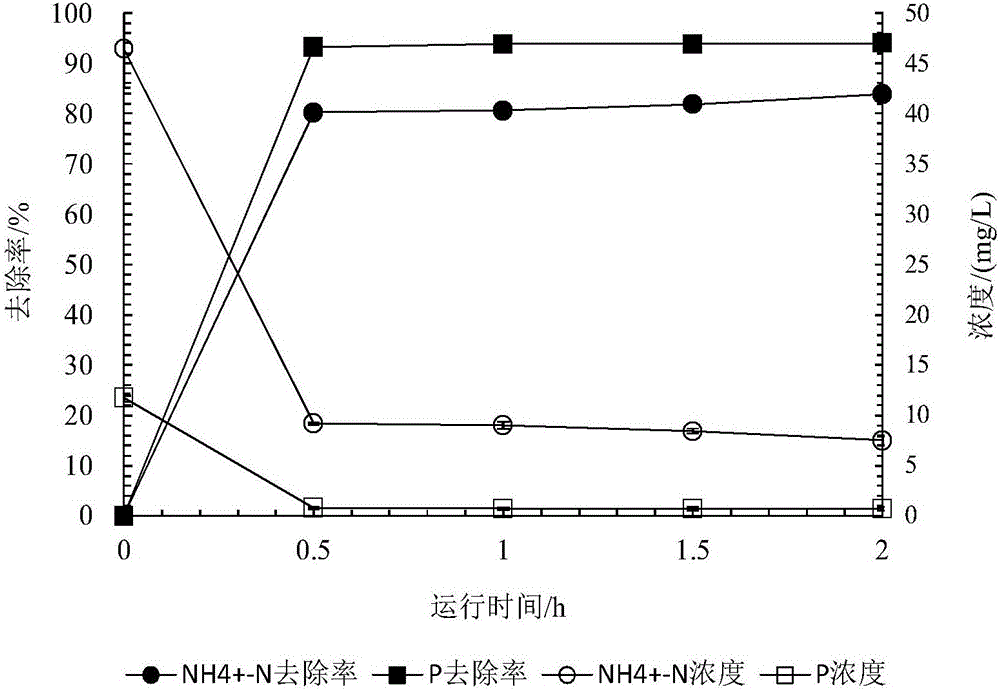

Composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and method for preparing composite reaction medium

ActiveCN106396134ASync removalEfficient removalWater contaminantsWater/sewage treatmentSodium BentoniteInstability

The invention discloses a composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and a method for preparing the composite reaction medium. The composite reaction medium comprises, by weight, 1.0-3.0 parts of zeolite, 0.7-1.3 parts of bentonite, 0.5-1.5 parts of attapulgite and 1.0-6.0 parts of coal cinder. The zeolite, the bentonite, the attapulgite and the coal cinder are sintered to obtain the composite reaction medium. The composite reaction medium and the method have the advantages that the nitrogen and the phosphorus can be synchronously, efficiently and quickly removed by the composite reaction medium, the composite reaction medium can be used as a biological carrier, accordingly, shortcomings of instability of biological phosphorus removal, large quantity of mud due to chemical phosphorus removal and the like can be overcome, and detour flow of water at the fronts of the barriers and the like can be prevented.

Owner:FOODSTUFF INST BEIJING

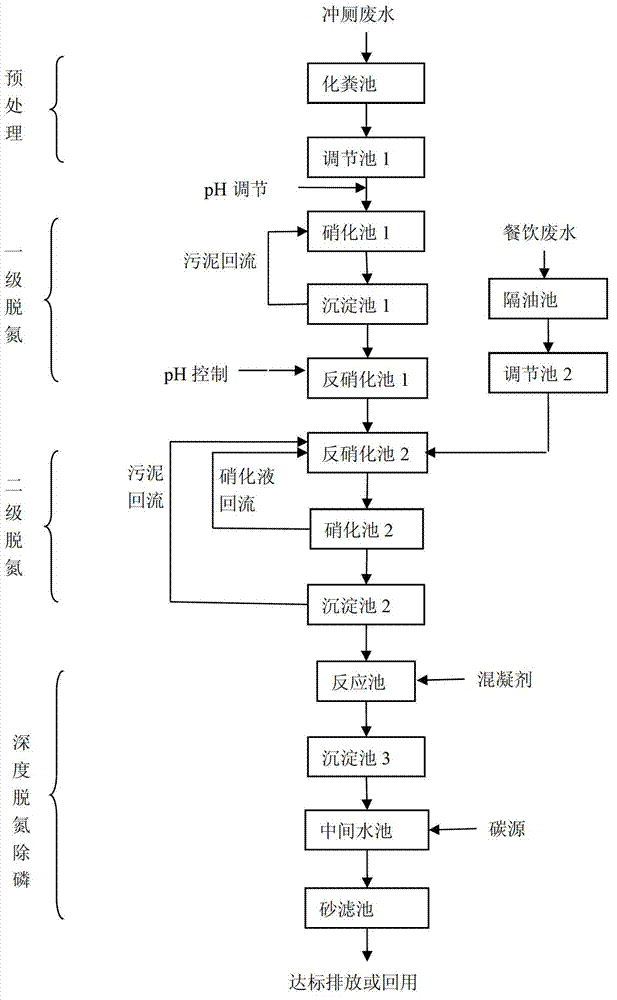

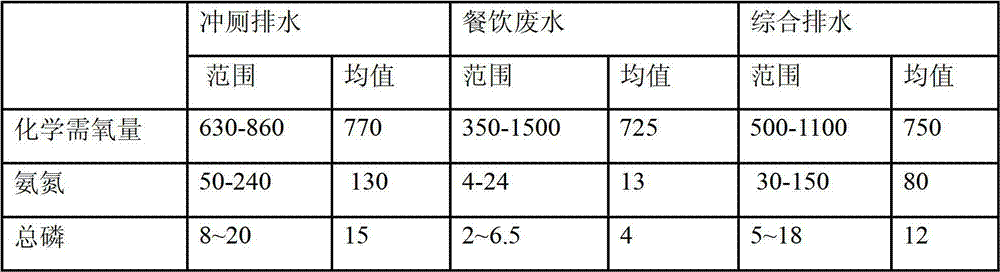

Efficient nitrogen and phosphorus removal method for sewage properties-classified treatment in highway service area

InactiveCN102757160AOptimize allocationImprove nitrogen removal efficiencyMultistage water/sewage treatmentOil separationSewage

The invention discloses an efficient nitrogen and phosphorus removal method for sewage properties-classified treatment in a highway service area. The efficient nitrogen and phosphorus removal method includes that toilet flushing sewage in the highway service area flows into a septic tank to be treated, the sewage in the septic tank sequentially flows through an adjusting tank (1), a nitration tank (1), a settling tank (1), a denitrification tank (1), a denitrification tank (2), a nitration tank (2) and a settling tank (2), and when effluent in the settling tank (2) reaches the standard, the effluent is discharged; simultaneously, catering sewage flows into an oil separation tank to be treated, and the sewage in the oil separation tank flows into an adjusting tank (2); the catering sewage and the toilet flushing sewage share the denitrification tank (1) and the denitrification tank (2), and the treatment method of the catering sewage flowing into the denitrification tank (1) or the denitrification tank (2) is identical to that of the toilet flushing sewage flowing into the denitrification tank (1) or the denitrification tank (2); simultaneously, other sewage flows into the adjusting tank (1) or the adjusting tank (2); if the other sewage flows into the adjusting tank (1), the treatment method of the other sewage flowing into the adjusting tank (1) is identical to that of the toilet flushing sewage flowing into the adjusting tank (1); and if the other sewage flows into the adjusting tank (2), the treatment method of the other sewage flowing into the adjusting tank (2) is identical to that of the catering sewage flowing into the adjusting tank (2).

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

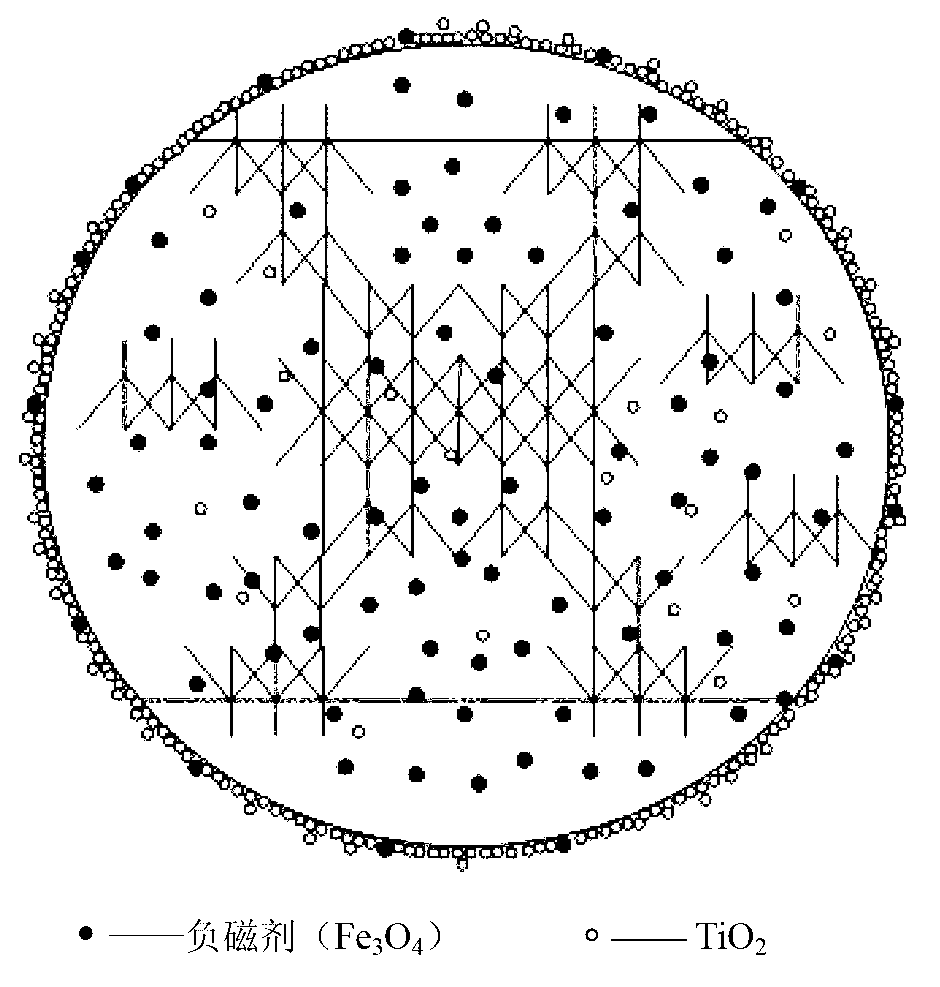

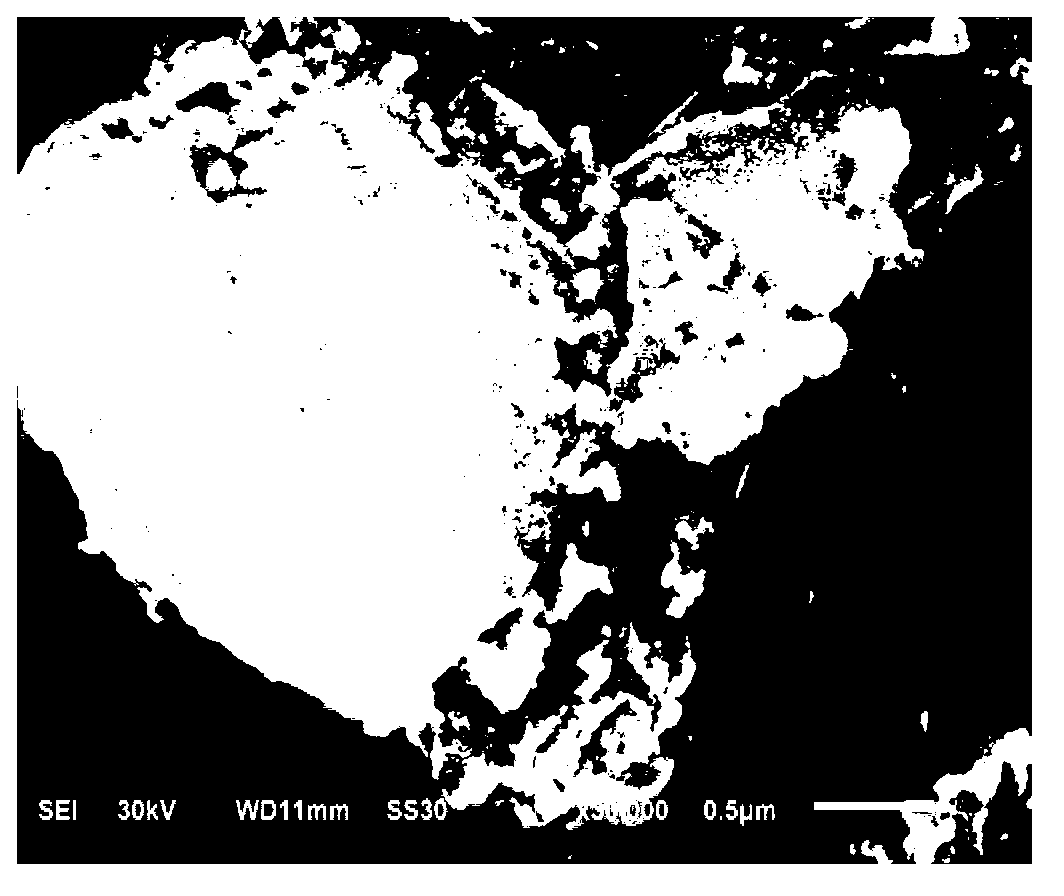

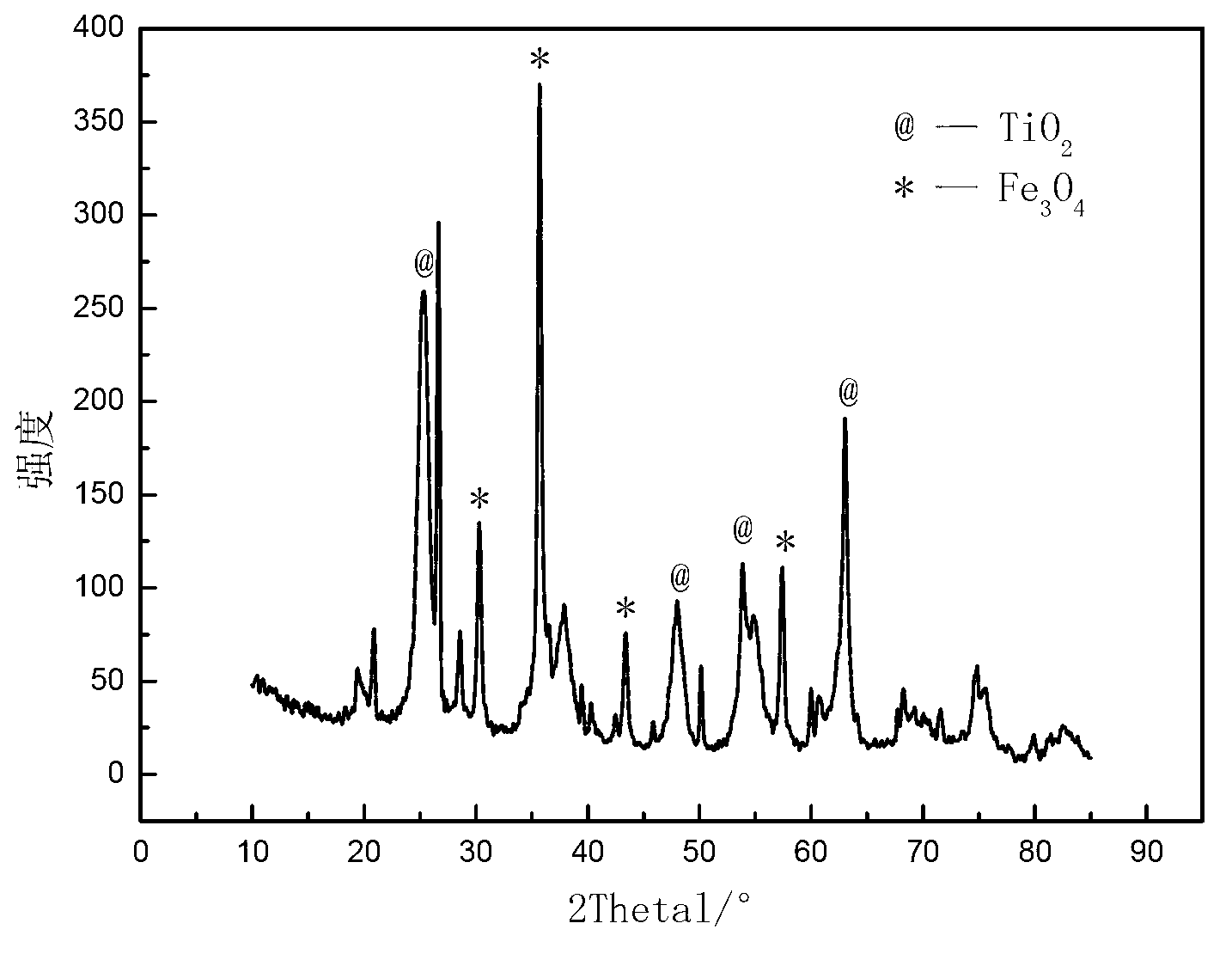

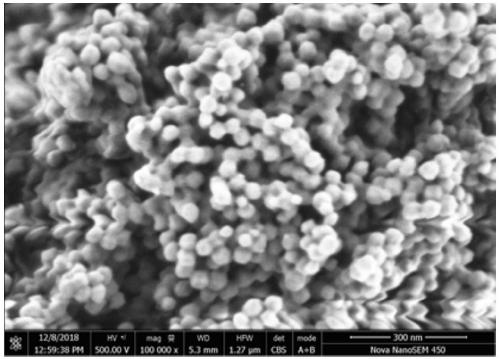

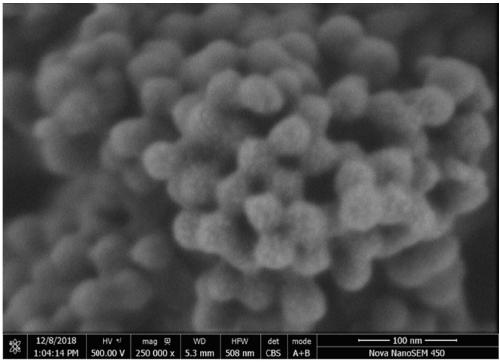

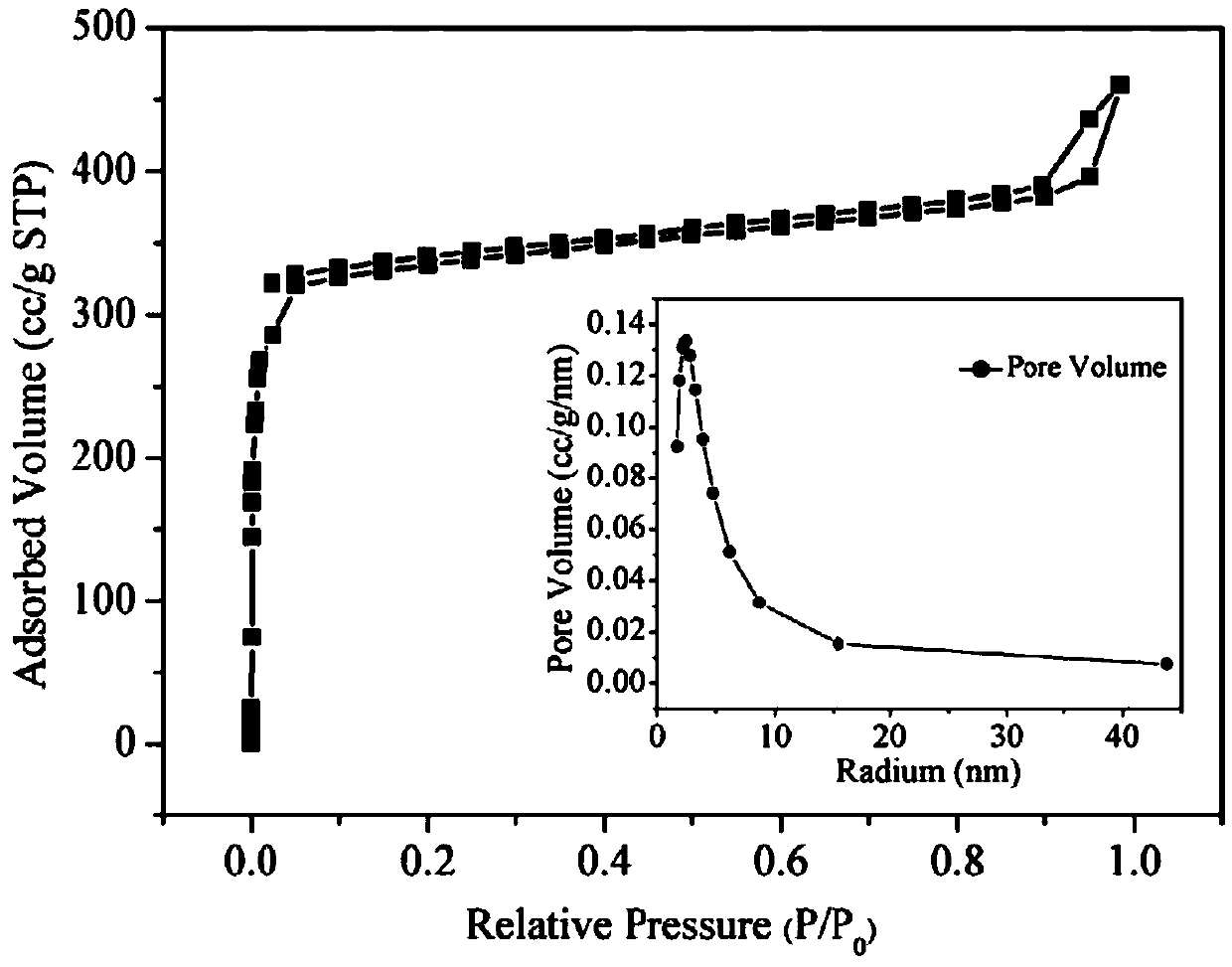

Magnetically-separable multiplex photo-catalyst, and preparation method and application thereof

InactiveCN103071502ARich sourcesLow priceWater/sewage treatment by irradiationWater contaminantsMagnetic separationEthanol

The invention discloses a magnetically-separable multiplex photo-catalyst, and a preparation method and an application thereof. The preparation method is characterized in that the preparation method comprises the steps that Fe3O4 columns enter interlayers, hole channels and the surface of natural sepiolite soil in a supporting manner with a chemical method to ensure that the natural sepiolite soil achieves negative magnetism; butyl titanate is dissolved in absolute ethyl alcohol; anhydrous acetic acid is dropwise added and serves as a hydrolytic inhibitor; then magnetic sepiolite is added and stirred, and reacts to form a liquid A; distilled water is added to absolute ethyl alcohol to form a solution; a pH value of the solution is adjusted to 2-3 with nitric acid at a ratio of 1:1; a liquid B is obtained, then dropwise added to the liquid A slowly, and stirred quickly, reacts for 30-60min, and is subjected to standing and aging for 12-24h to form gel; the gel is washed, subjected to magnetic separation, dried, calcined and ground, and passes through an 80-mesh sieve; and the multiplex photo-catalyst is obtained. The multiplex photo-catalyst is good in adsorbability and photocatalytic activity, wide in response range of an optical wavelength, and magnetically-separable, and can be applied to treatment of heavy metal Cr(VI) and organic 2,4-DCP (2,4-Dichlorophenol) coexisting degradation-resistant waste water.

Owner:XIANGTAN UNIV

Bifunctional group MOFs material and preparation method and application thereof

ActiveCN109608655ASolve the unsatisfactory regeneration effectSolve the secondary pollution of regenerantOther chemical processesAlkali metal oxides/hydroxidesRegenerative processPollutant

The invention discloses a bifunctional group MOFs material and a preparation method and application thereof, and belongs to the field of sewage treatment of nanometer composite functional materials. For the problems that existing MOFs materials cannot simultaneously remove anion and cation pollutants in water, the regeneration rate after adsorption is low, the regeneration effect is not ideal, andsecondary pollution is easily caused in the regeneration process, the bifunctional group MOFs has a carboxylic acid functional group and a tertiary amine group at the same time and can simultaneouslyremove anions and cations in the water; after adsorption is completed, the material is treated at a certain temperature, and the purposes of environmental protection and regeneration can be achieved.The preparation method is simple in process, easy to operate, environmentally friendly and free of pollution.

Owner:NANJING UNIV

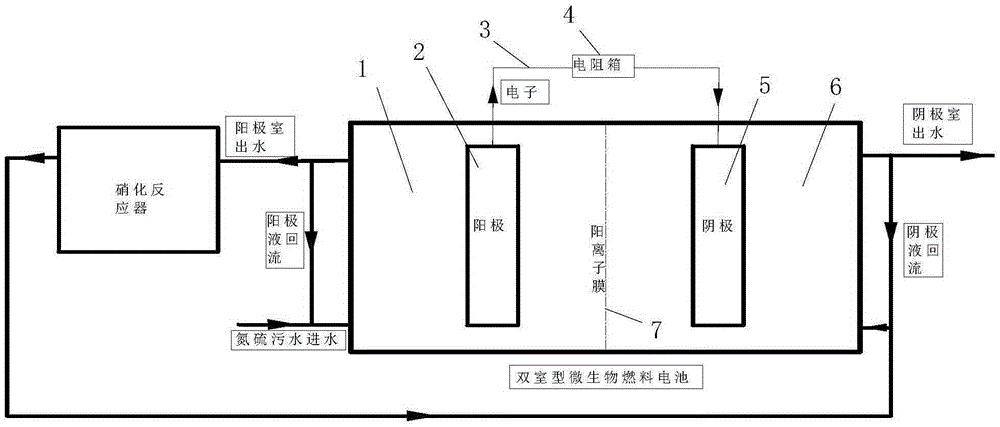

Synchronous sewage denitrification and desulphuration method for microbial fuel cell

ActiveCN105406096ARecyclable electricityLow running costTreatment by combined electrochemical biological processesSpecific water treatment objectivesElectron donorNitration

The invention provides a synchronous sewage denitrification and desulphuration method for a microbial fuel cell. The synchronous sewage denitrification and desulphuration method comprises the following specific steps: constructing a double-chamber type microbial fuel cell and setting a nitration reactor outside the microbial fuel cell; firstly pumping sewage containing sulfides and ammonia nitrogen into an anode chamber of the microbial fuel cell, eliminating sulfur pollution by utilizing self-power generation electrochemical action and microbial metabolism and transmitting generated electrons to a cathode through an external circuit; firstly enabling anode effluent of the microbial fuel cell to pass through the external nitration reactor so as to oxidize the ammonia nitrogen into nitrate nitrogen, and then enabling the anode effluent to enter a cathode chamber of the microbial fuel cell; removing nitrogen pollution by using the electrons transmitted from the external circuit as electron donors through microorganisms inside the cathode chamber; and generating a current in the external circuit in the process that the electrons are transmitted to the cathode through the external circuit from the anode so as to realize electric energy recycling. According to the method, synchronous denitrification and desulphuration of sewage containing nitrogen and sulfur is realized through the microbial fuel cell, and the method has the advantages of saving additional chemical agents, recycling electric energy and the like.

Owner:WUHAN UNIV OF TECH

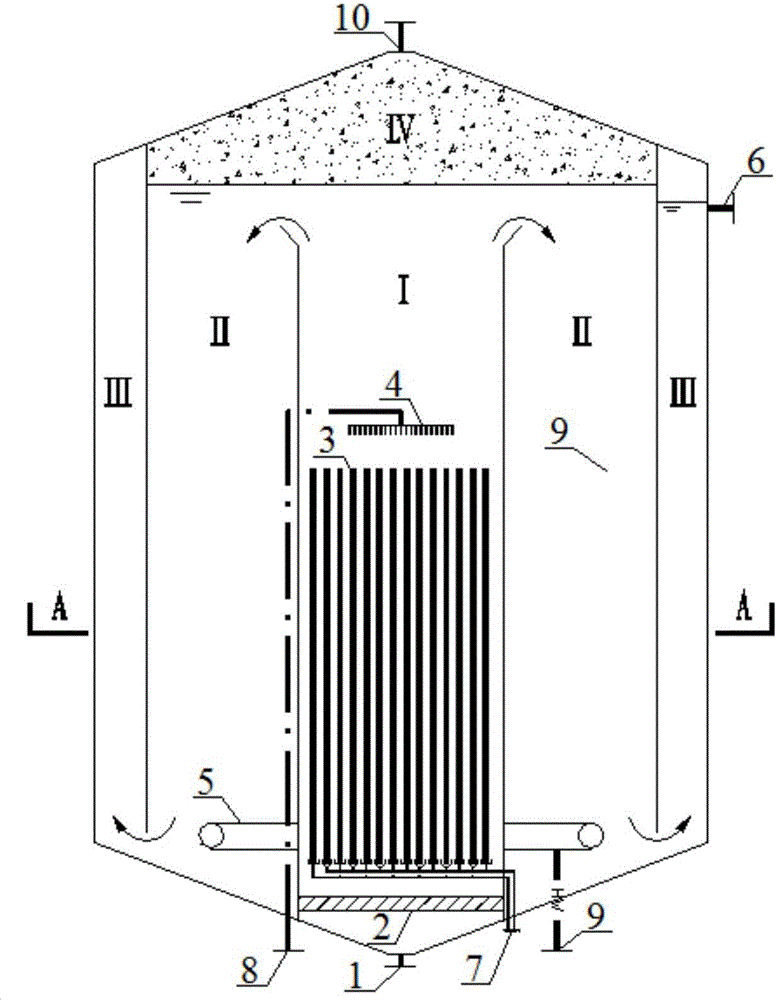

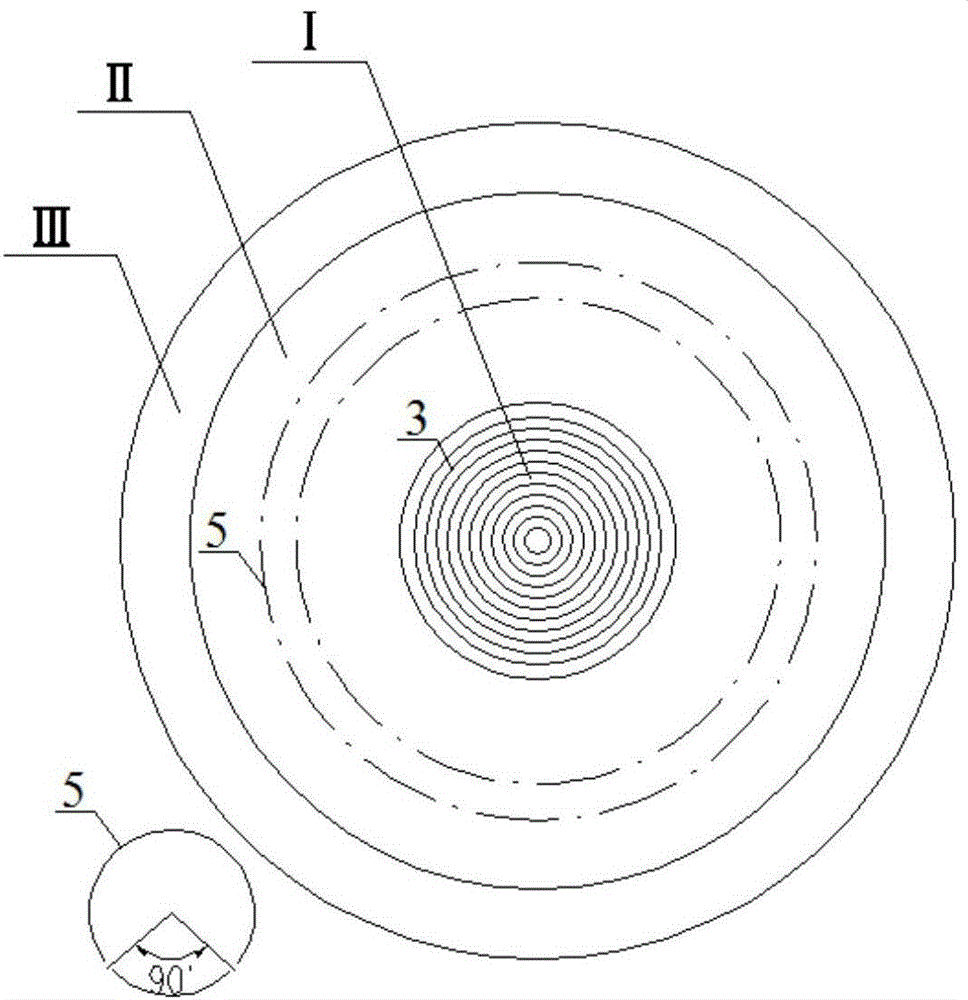

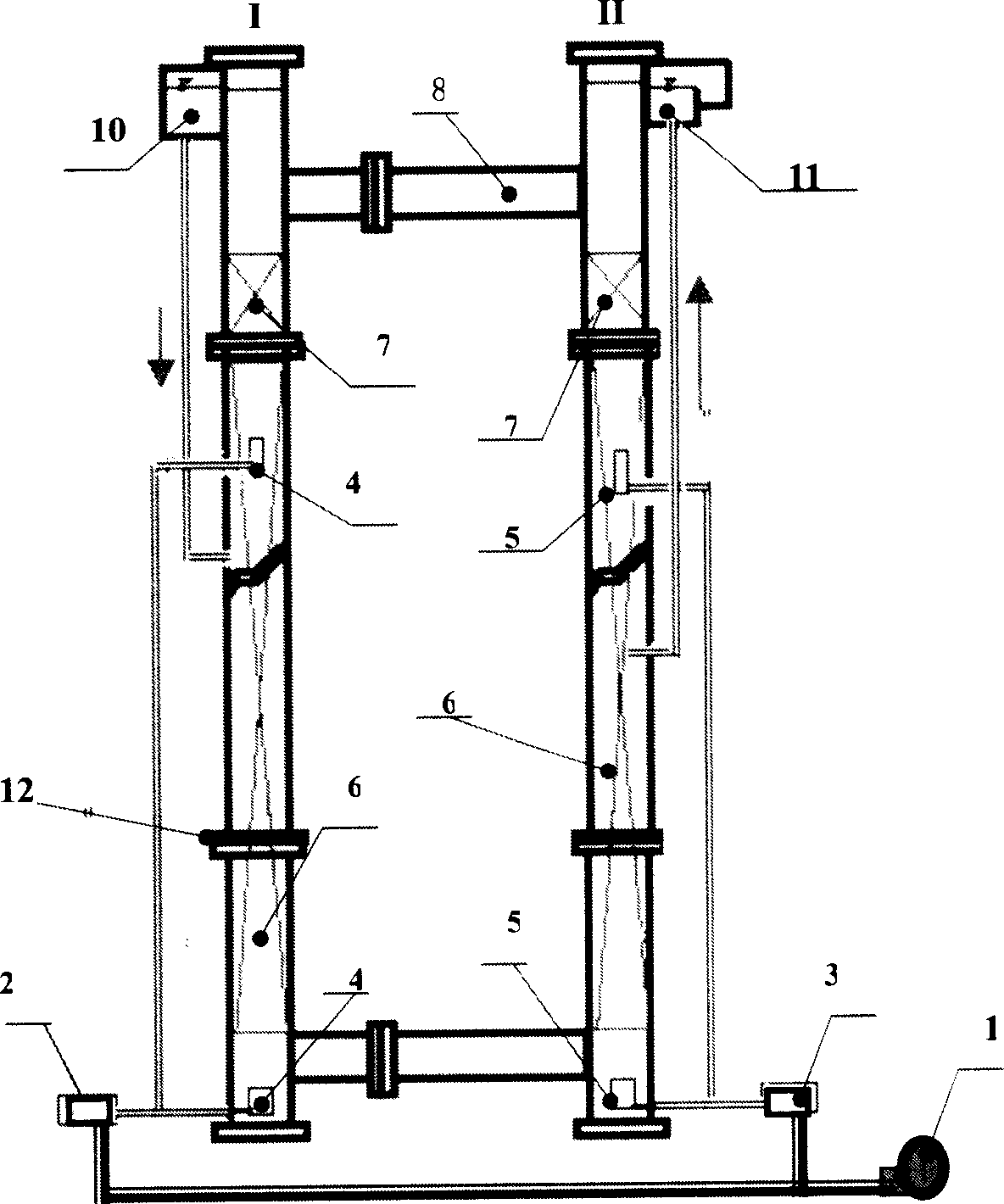

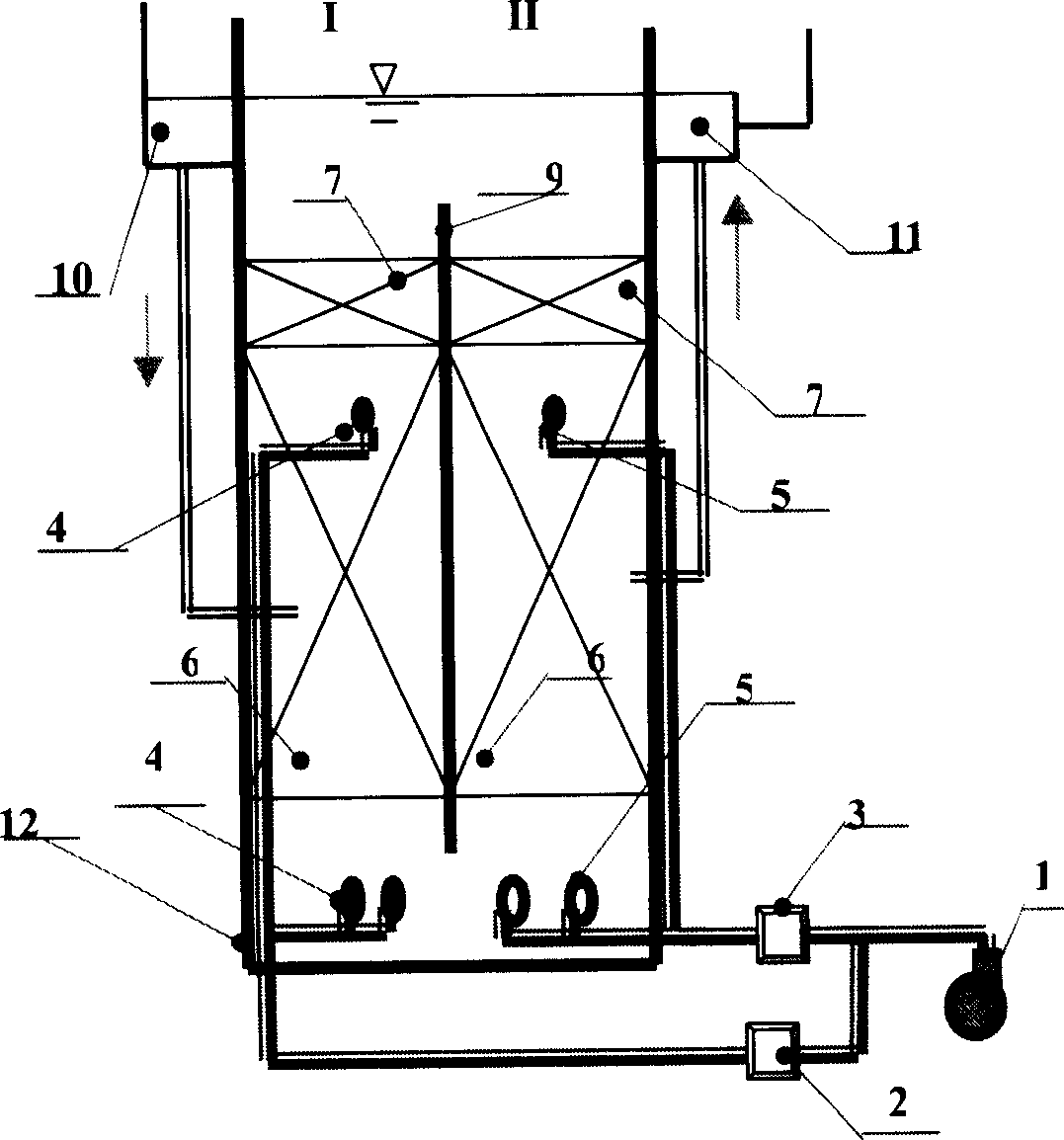

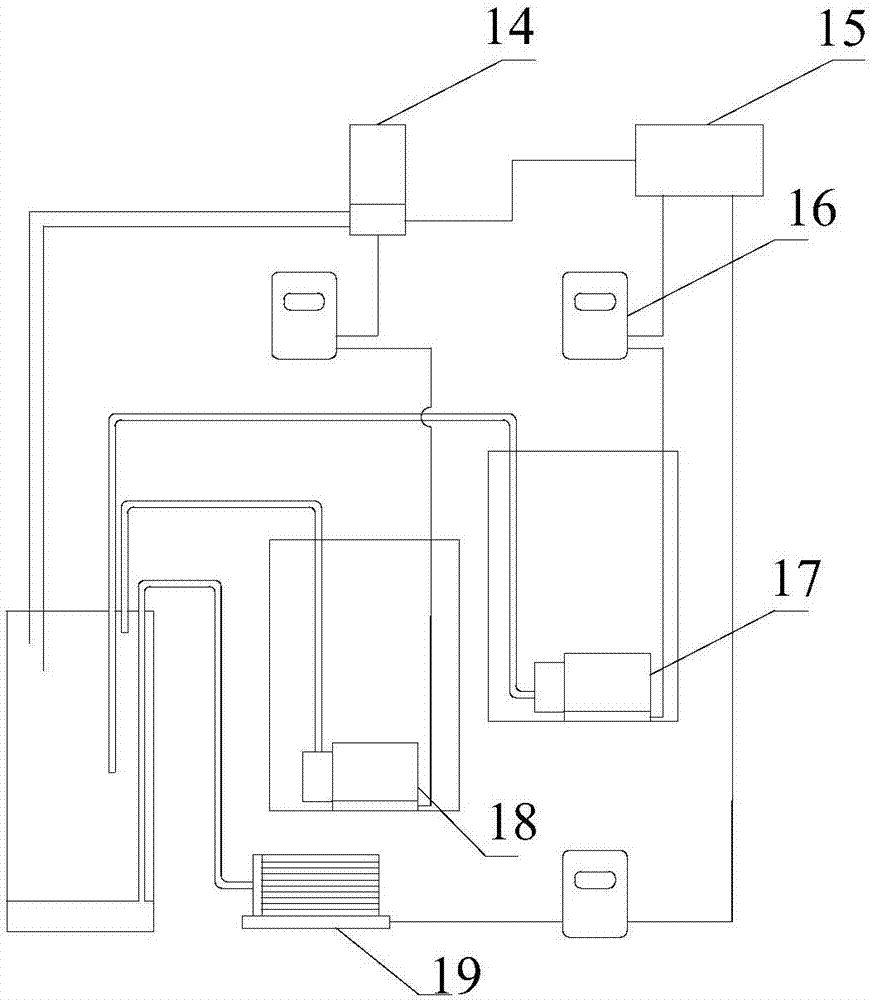

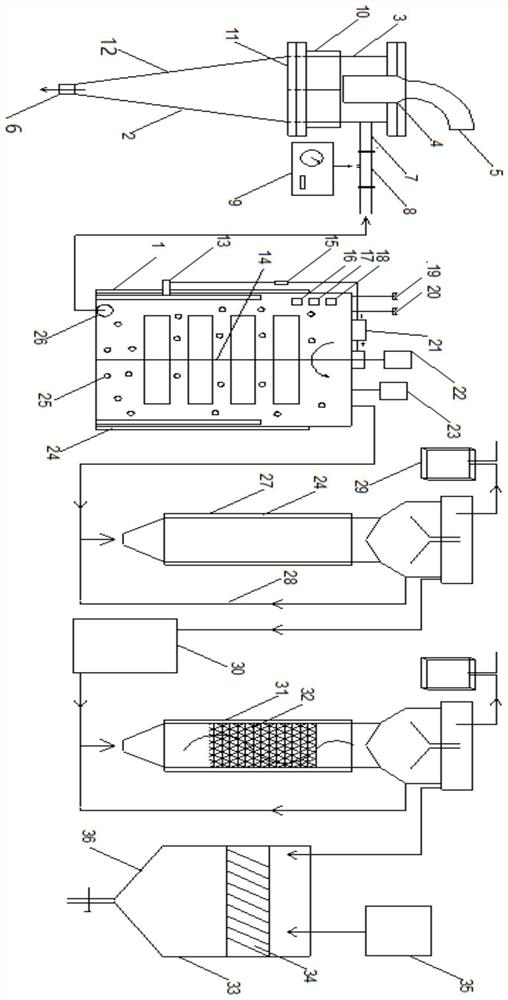

Gas lifting alternative circulation flow composite filter material filter pool

InactiveCN1821120ASync removalWith processing functionTreatment using aerobic processesSustainable biological treatmentWater resourcesWater flow

The present invention provides a kind of air lifting circular flow filter with composite filter material, and belongs to the field of high efficiency bioreactor for water resource protection. The filter has both outer circulation structure and inner circulation structure, switching valve for alternate air supply to two aerators so as to obtain altered circular flow, and composite filter material operating alternately in the ascending area and the descending area to optimize operation environment. It operates in a biomembrane plus filtering process to eliminate organic matter and ammonia nitrogen simultaneously. The present invention is superior in management and treating effect, and may become new generation of bioreactor to replace available aerobic biofilter and air-lift circular fluidizing bed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

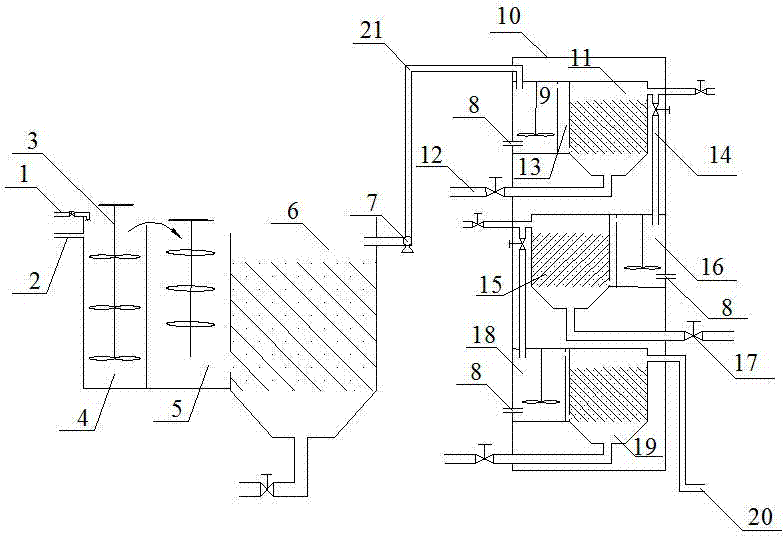

Multistage countercurrent reaction integration technology and device for synchronous removal of a plurality of heavy metal ions

ActiveCN104326595AHigh reducing activityQuick responseWater treatment compoundsWater contaminantsWastewaterHeavy metals

The invention relates to an integration technology for synchronous removal of a plurality of heavy metal ions by use of structure state iron; pretreated heavy metal wastewater is introduced into a structure state iron-vertical multistage reaction system, the suitable reactor stage is adopted according to properties of the wastewater and kinds and concentrations of heavy metals in the wastewater; a medicament and the wastewater are fully contacted and mixed for reaction in a mixing reaction pool in the manner of countercurrent mixing, then the solution enters into a sedimentation tank of a reactor of the stage to achieve solid-liquid separation; after separation, the supernatant is detected, until the supernatant achieves discharge standard, the effluent is discharged; if the effluent does not achieve the discharge standard, the effluent continues to enter into a reactor of next stage for repeated wastewater treatment, until the effluent achieves the discharge standard; the medicament is the structure state iron. The structure state iron-vertical multistage reaction system includes a rapid mixing pool, a slow mixing pool, a pretreatment sedimentation tank and a multistage pretreatment reactor, has the advantages of simple operation, capability of continuously performing multi-stage reaction, small occupation area, high treatment efficiency, and short reaction time, can simultaneously remove the heavy metals, reduces the application cost, and has promotion and application prospect.

Owner:TONGJI UNIV

Method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater

ActiveCN108191050ARealize synchronous removalSync removalWater contaminantsWaste water treatment from gaseous effluentsActivated sludgeElectron donor

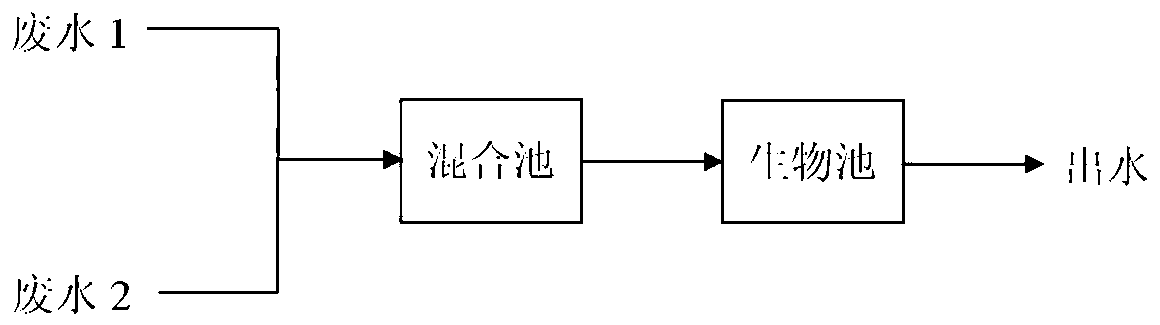

A method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater comprises steps as follows: (1) flue gas desulfurization wastewater containing sulfateand ammonia-nitrogen wastewater are guided into a mixing tank to be mixed; (2) the pH and the temperature of mixed wastewater are adjusted in the mixing tank; (3) firstly, a biological reaction tank is inoculated with cultured activated sludge, the mixed wastewater is introduced from the mixing tank, microorganisms in the activated sludge take ammonia nitrogen as an electron donor in the biological reaction tank, sulfate is reduced to elemental sulfur, besides, ammonia nitrogen is oxidized into nitrogen, and synchronous removal of sulfur and nitrogen is realized. The problems that the water quality of the flue gas desulfurization wastewater hardly reaches the standard after treatment with conventional physical and chemical methods, the biodegradability is poor and biological treatment is difficult are solved, and co-treatment of two kinds of wastewater is realized.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

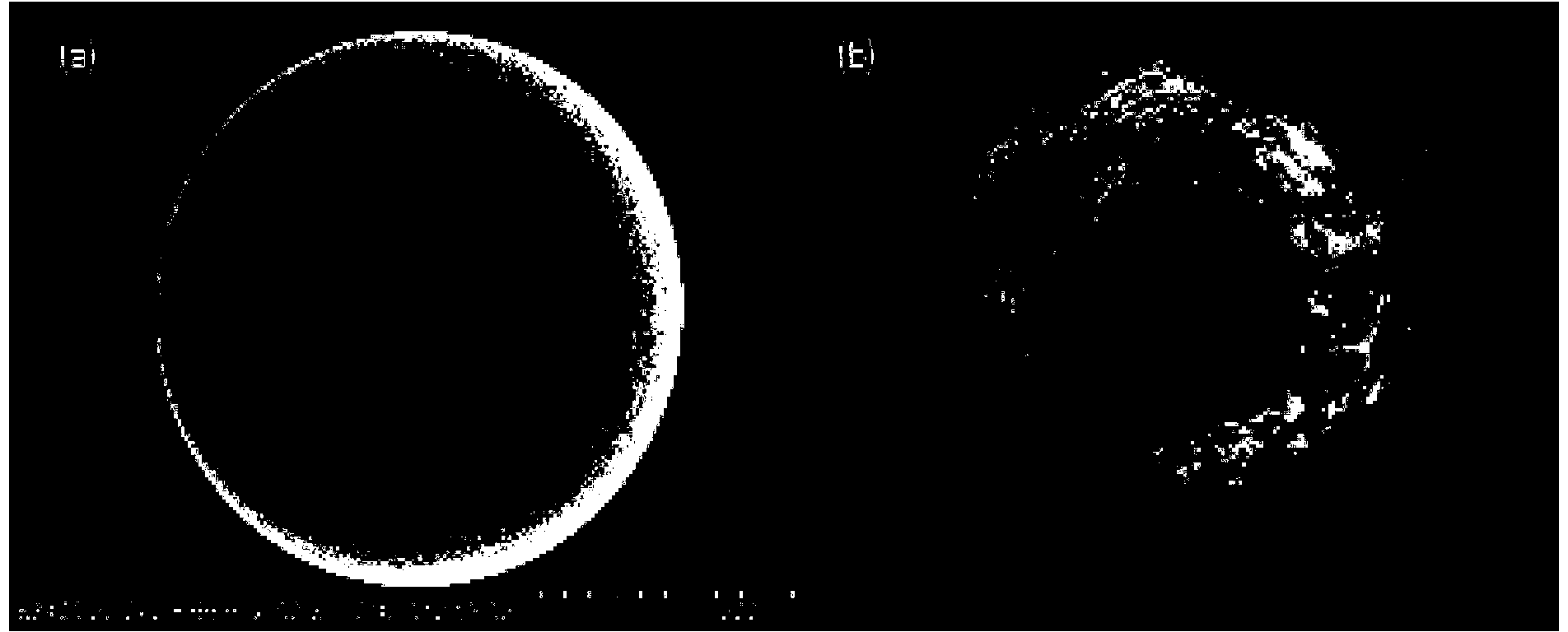

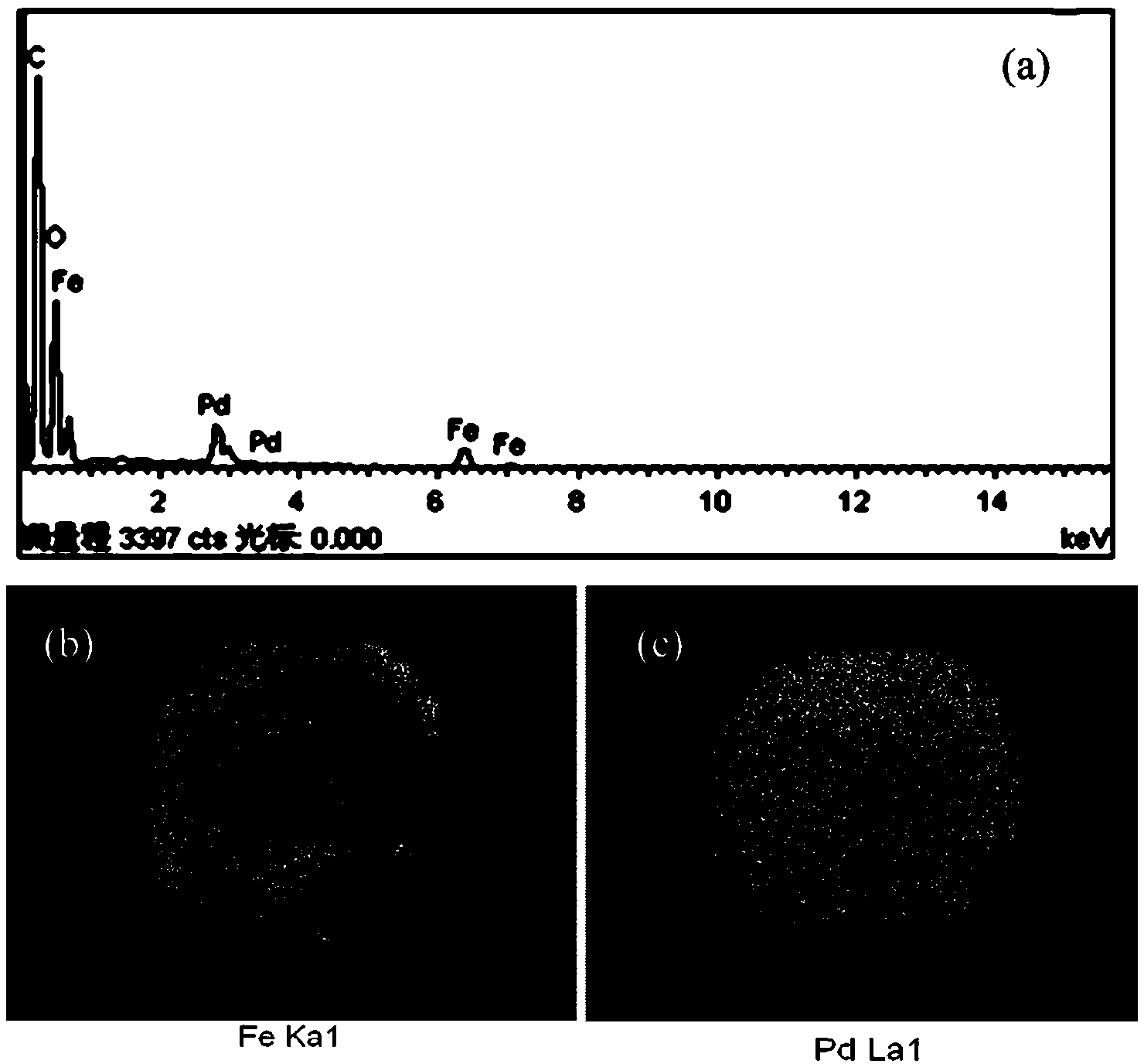

Applications of nanometer iron-palladium double-metal composite material, method for removing nitrates and phosphates in water, and subsequent treatment method

ActiveCN104386794AAvoid Excessive DissolutionAvoids the need to use hydrogen as a reducing agentOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPhosphateAcid washing

The present invention discloses applications of a nanometer iron-palladium double-metal composite material, a method for removing nitrates and phosphates in water, and a subsequent treatment method, and belongs to the field of environmental function composite materials. The preparation method of the loaded nanometer iron-palladium double-metal composite material comprises: respectively and sequentially loading Fe<3+> or Fe<2+> and Pd<2+> on a chelating resin containing the nitrogen pyridyl functional group in a chelating manner, adopting a NaBH4 solution to reduce the iron-palladium double-metal ion loaded on the resin, and carrying out vacuum drying to obtain the loaded iron-palladium double-metal composite material, wherein nitrates and phosphates in water can be synchronously removed, and the nitrate is reduced into the nitrogen gas. In addition, the hydrochloric acid solution is adopted to treat the failure loaded iron-palladium double-metal composite material, such that the composite material being subjected to the acid washing treatment can be recycled. According to the present invention, the nitrate removing efficiency and the phosphate removing efficiency are high, metal ion dissolution and other secondary pollution problems do not exist, the composite material can be reused, the operation condition is simple, and advantages of economy, environmental protection and the like are provided.

Owner:NANJING UNIV

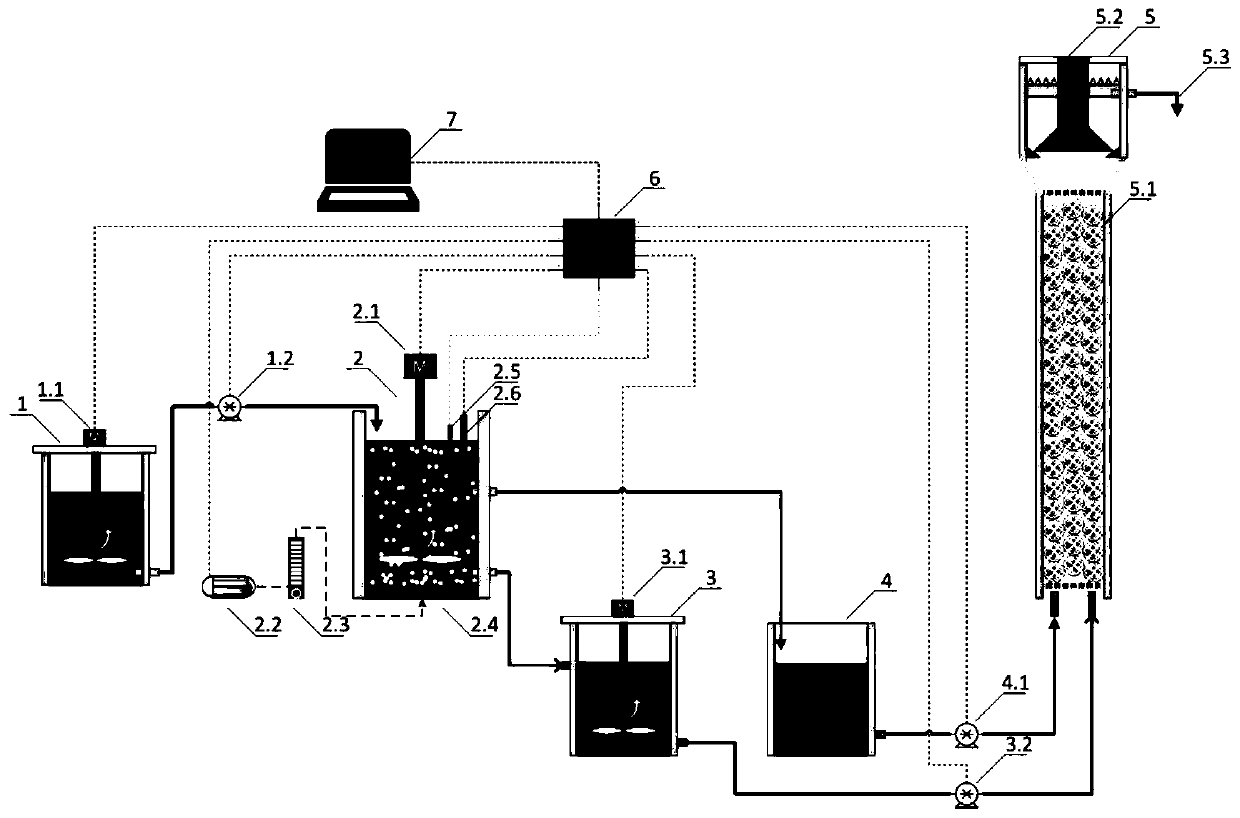

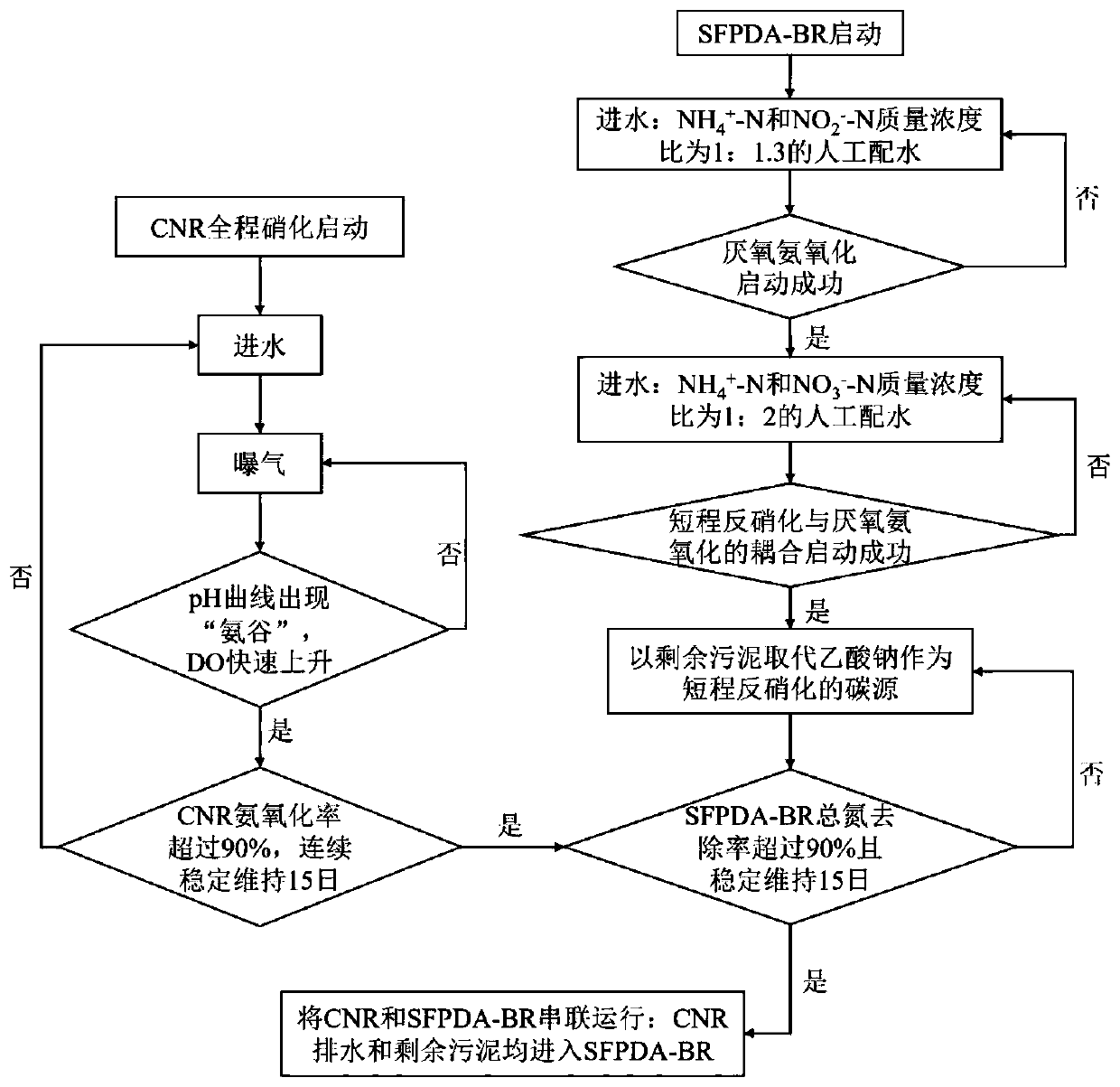

Method for treating high ammonia-nitrogen wastewater by complete nitrification-sludge fermentation coupling short-cut denitrification/anaerobic ammoxidation biofilm technology

ActiveCN110372095APromote growthAvoid churnWater treatment parameter controlSpecific water treatment objectivesAutomatic controlAutomated control system

The invention discloses a method for treating high ammonia-nitrogen wastewater by complete nitrification-sludge fermentation coupling short-cut denitrification / anaerobic ammoxidation biofilm technology, and belongs to the field of sewage sludge treatment. A device includes an original water tank, a complete nitrification reactor (CNR), an intermediate pool, a mud storage pool, a sludge fermentation coupling short-cut denitrification / anaerobic ammoxidation biofilm reactor (SFPDA-BR) and an automatic control system. The sludge fermentation coupling short-cut denitrification / anaerobic ammoxidation biofilm reactor is provided with a padding ball, a three-phase separator and other devices. The method includes the steps that the high ammonia-nitrogen wastewater with 200-400 mg / L concentration ofNH4<+>-N firstly enters the CNR from the original water tank for complete nitrification, the CNR drains the water to the intermediate pool, the CNR discharges mud to mud storage pool, the water of the intermediate pool and the mud of the mud storage pool are together fed into the SFPDA-BR, and sludge fermentation, short-cut denitrification and anaerobic ammoxidation denitrification are simultaneously conducted. The method is suitable for advanced treatment of the high ammonia-nitrogen wastewater, the denitrification process does not require an external carbon source, and finally, the aims ofcarbon source development, short-cut denitrification and anaerobic ammoxidation coupling in sludge are realized.

Owner:BEIJING UNIV OF TECH

Method for removing carbon, nitrogen and phosphorus in sewage cooperatively

InactiveCN102092851AReduce demandReduce aeration energy consumptionTreatment with aerobic and anaerobic processesSequencing batch reactorPhosphate

The invention provides a method for removing carbon, nitrogen and phosphorus in sewage cooperatively. The method comprises the following specific steps: nitrite type denitrifying dephosphatation floating sludge and anammox biofilms are commonly placed in an anaerobic-anoxic composite sequencing batch reactor (SBR); under an anaerobic condition, nitrite type denitrifying dephosphatation bacteria are used to remove organic carbon in sludge and release phosphate through decomposition for the following excessive phosphorus-uptake; under an anoxic condition, anammox bacteria are used to remove ammonia nitrogen and nitrite in sewage and nitrite type denitrifying dephosphatation bacteria are used to remove nitrite and nitrate and uptake excessive phosphorus to form sludge with rich phosphorus; and after the mud-water separation of the precipitation period, the residual sludge with rich phosphorus is discharged to achieve the aim of dephosphorization. The method of the invention utilizes the synergy of nitrite type denitrifying dephosphatation bacteria and anammox bacteria in the same reactor to realize that carbon, nitrogen and phosphorus in the sewage with low organic carbon and high nitrogen and phosphorus can be removed simultaneously; and the method has the advantages of low carbon source demand, low aeration energy consumption and the like.

Owner:WUHAN UNIV OF TECH

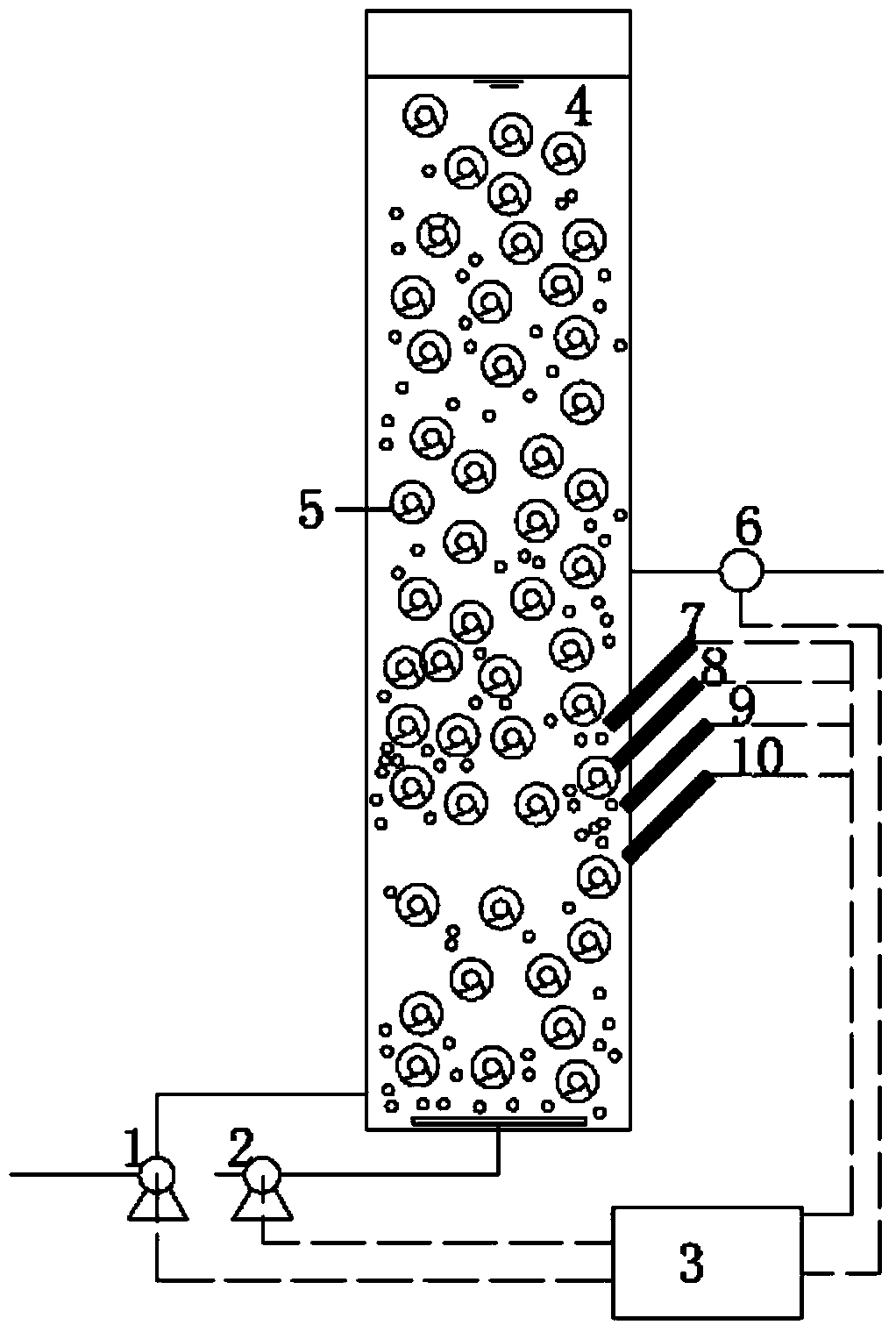

Sequencing batch reactor, method for culturing biological membrane on sequencing batch reactor and method for treating sewage by utilizing sequencing batch reactor

ActiveCN103864207ACompact structureReduce energy consumptionWater contaminantsSustainable biological treatmentBatch reactorSequencing batch reactor

The invention discloses a sequencing batch reactor which comprises a reactor body, a sensor, a regulator and a filler. The regulator regulates the working state of the reactor body according to the signal of the sensor; the diameter of the filler is 2-5 cm, the specific area is 180-250 m<2> / m<3>, and the total volume accounts for 30%-80% of the total volume of the reactor body. A method for culturing a biological membrane on the sequencing batch reactor comprises the following steps of firstly inoculating aerobiotic active sludge into the sequencing batch reactor; then pumping sewage into the sequencing batch reactor, and then introducing air; and finally precipitating to obtain the needed biological membrane. A method for synchronously removing nitrogen, phosphorus and organic substances which are contained in the sewage comprises the following steps of firstly pumping the sewage into the sequencing batch reactor; then standing for reaction, and then carrying out aeration treatment; finally discharging precipitations. The sequencing batch reactor disclosed by the invention can be used for synchronously removing the nitrogen, the phosphorus and the organic substances which are contained in the sewage and has the advantages of compact structure and low energy consumption. The method for culturing the biological membrane can obtain the light yellow biological membrane of 0.5-2 mm.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

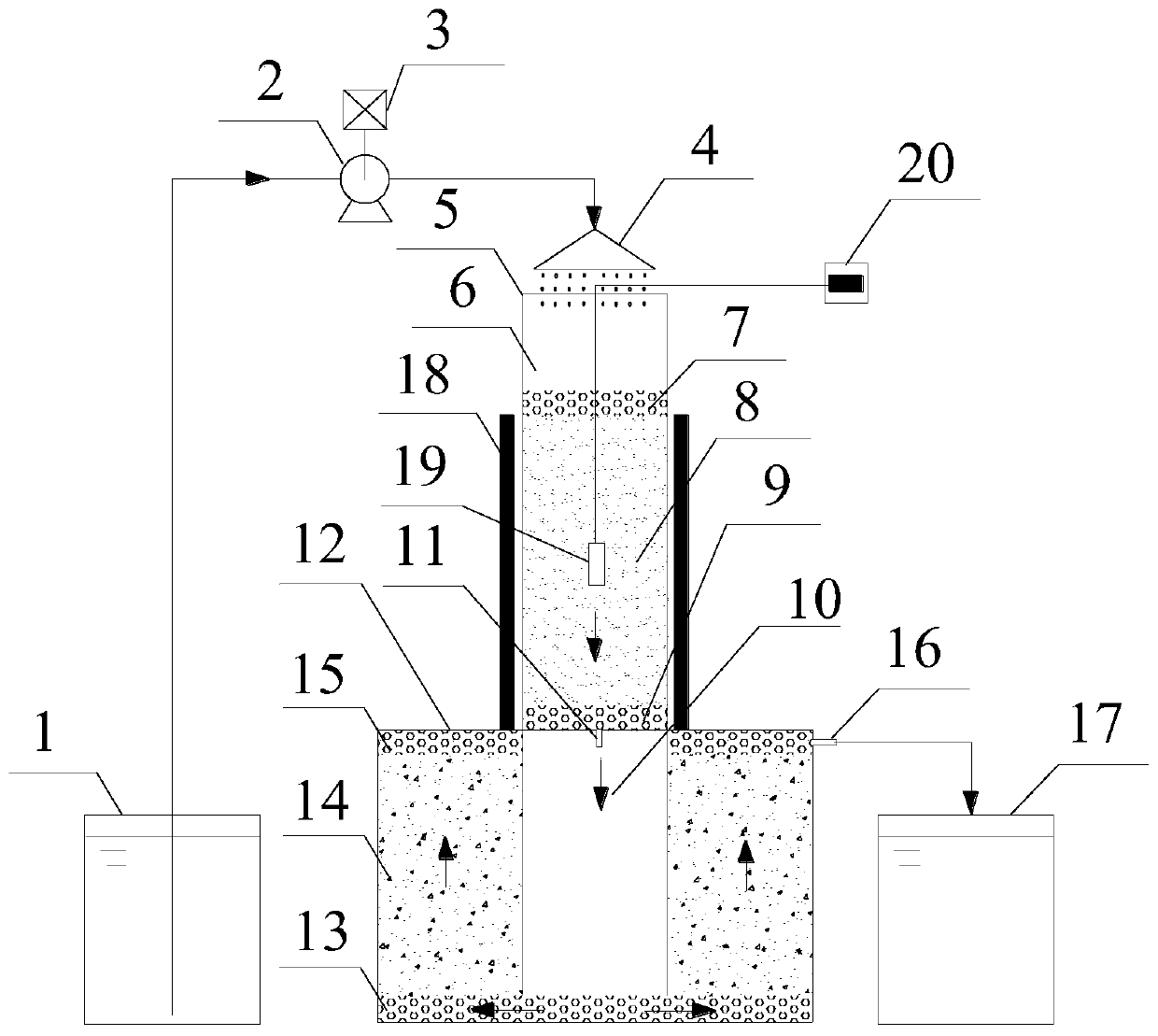

Double-tank artificial rapid infiltration system and method used for high-efficiency denitrification of sewage with low C/N ratio

PendingCN110127955AShort startup timeStart fastWater contaminantsWater/sewage treatmentSludgeSmall footprint

The invention discloses a double-tank artificial rapid infiltration system and method used for high-efficiency denitrification of sewage with a low C / N ratio. The system comprises a water inlet box, an artificial rapid infiltration tank 1, an artificial rapid infiltration tank 2 and a water outlet box; a magnetic field is arranged in the artificial rapid infiltration tank 1, the artificial rapid infiltration tank 1 is inserted into the artificial rapid infiltration tank 2, and the bottom of the artificial rapid infiltration tank 1 communicates with the artificial rapid infiltration tank 2; andthe sewage passes through the water inlet box, and passes through a water distribution zone, a gravel zone 1, a filter material zone 1, a gravel zone 2, a water collection zone, a gravel zone 3, a filter material zone 2 and a gravel zone 4 in sequence, and treated water enters the water outlet box. According to the method provided by the invention, the magnetic field is added in the artificial rapid infiltration tank 1, and through repeated fluctuation of water inflow and fall drying time and coordinated regulation and control of the magnetic field, integrated partial short-cut nitrificationand anaerobic ammonia oxidation denitrification are realized; and the system and method provided by the invention have the advantages of short starting time, high denitrification efficiency, no production of excess sludge, low operating costs, simple convenient and flexible operation, a small floor space and no secondary pollution.

Owner:CHENGDU TECHCAL UNIV

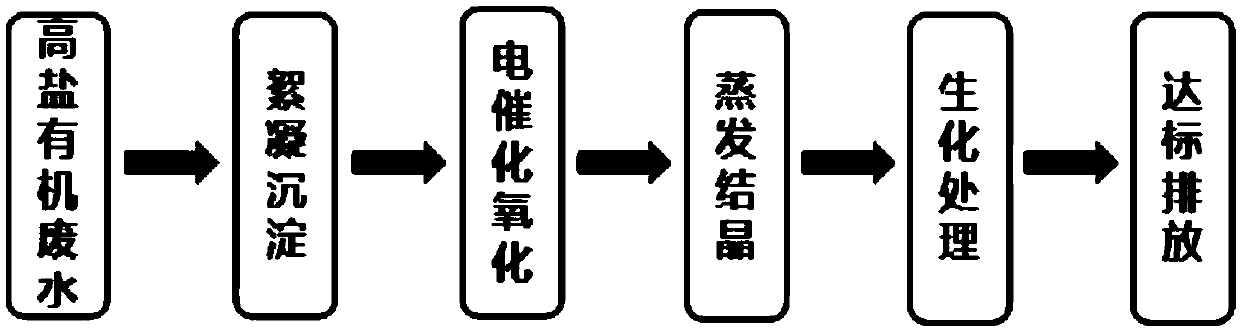

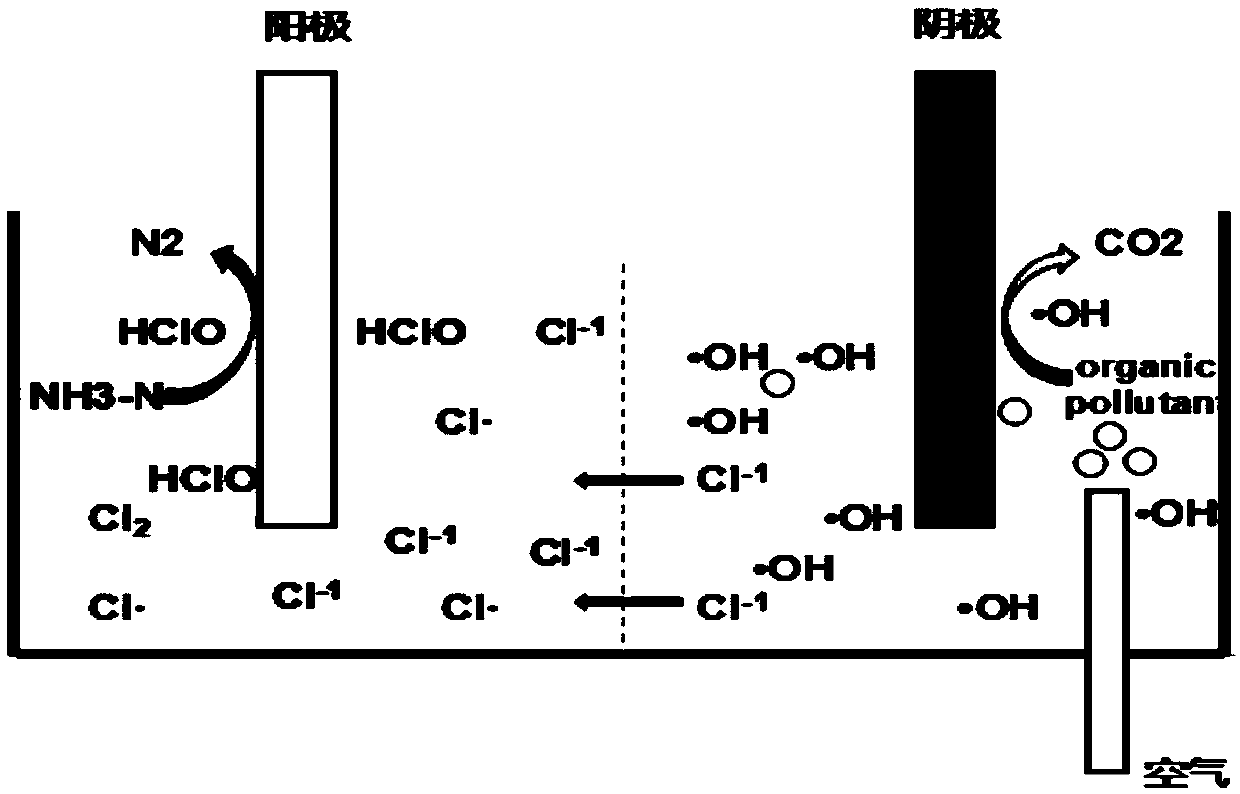

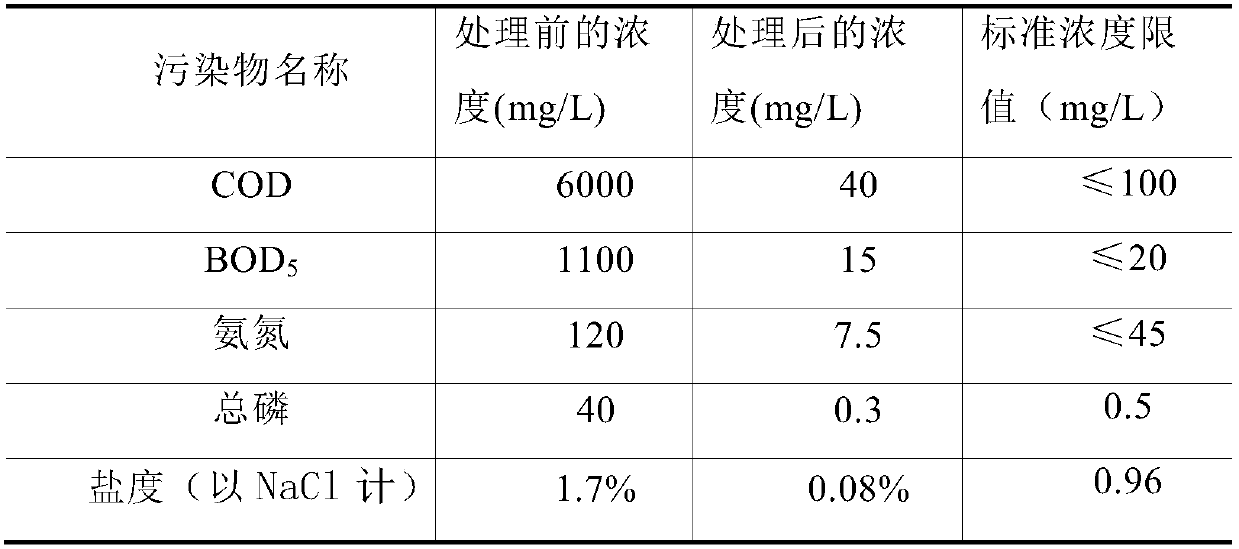

Electrocatalytic oxidation-biochemical coupling method for treating high-salinity high-concentration organic wastewater

ActiveCN109516641AEfficient processingReduce electrolysis energy consumptionWater contaminantsMultistage water/sewage treatmentIonPollutant

Owner:南通寰宇博新化工环保科技有限公司

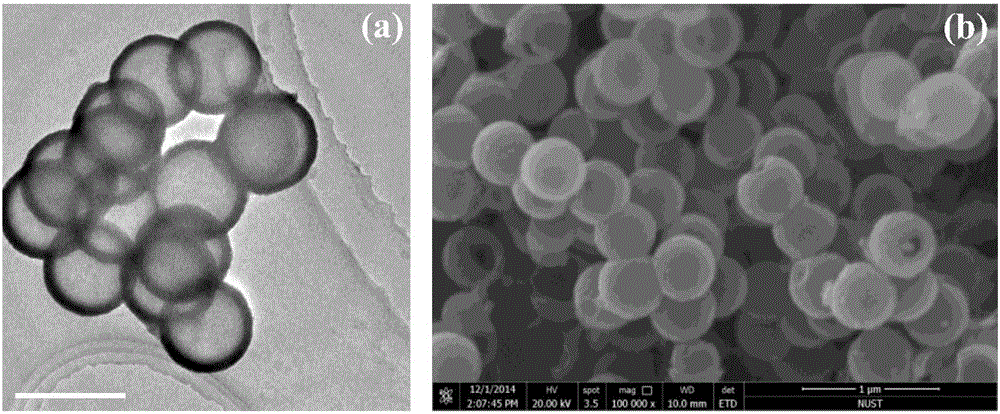

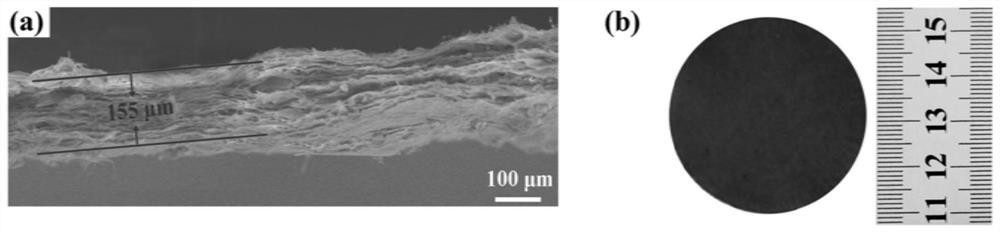

Ultrafiltration membrane and preparation method thereof

ActiveCN106794431AGood removal effectIncrease loadMembranesSemi-permeable membranesPolymer scienceUltrafiltration

An ultrafiltration membrane and a preparation method thereof are provided. The ultrafiltration membrane comprises a cavity composed of a sulfone-based polymer film matrix and an organic polymer encapsulation layer, wherein the cavity comprises nano-adsorbent. The preparation method comprises following steps: (1) synthesis of nano-adsorbent;(2)preparing the sulfone-based polymer film matrix by immersion-sedimentation phase transformation method; (3) filling from the bottom of the sulfone-based polymer film matrix with the nano-adsorbent, and using organic polymer to encapsulate after filling to obtain a multifunctional ultrafiltration membrane.

Owner:NANJING UNIV OF SCI & TECH

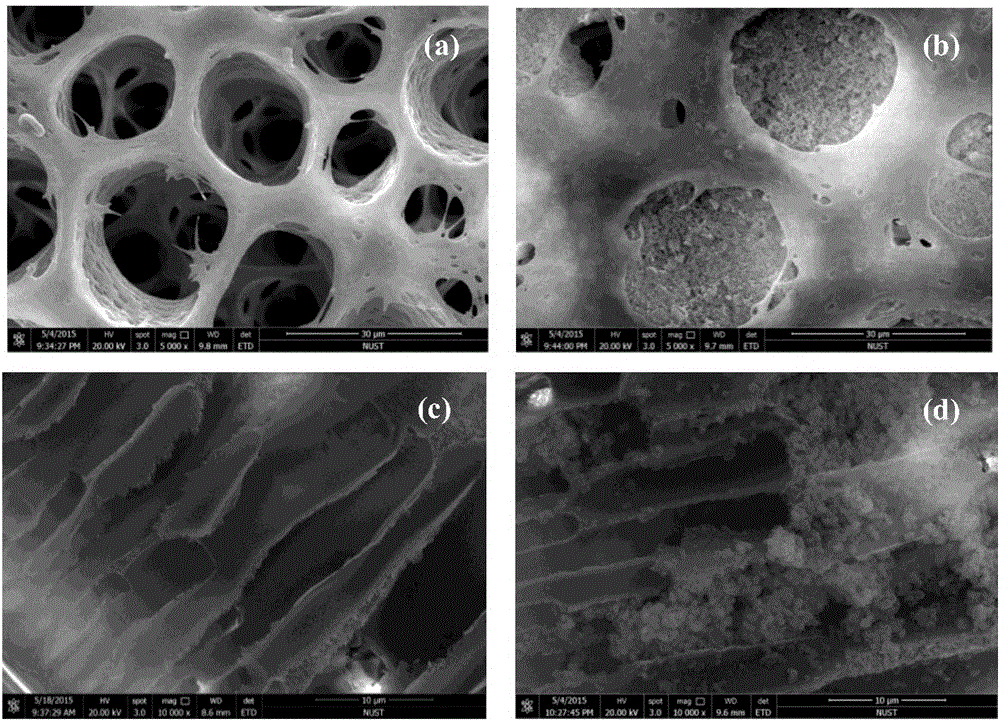

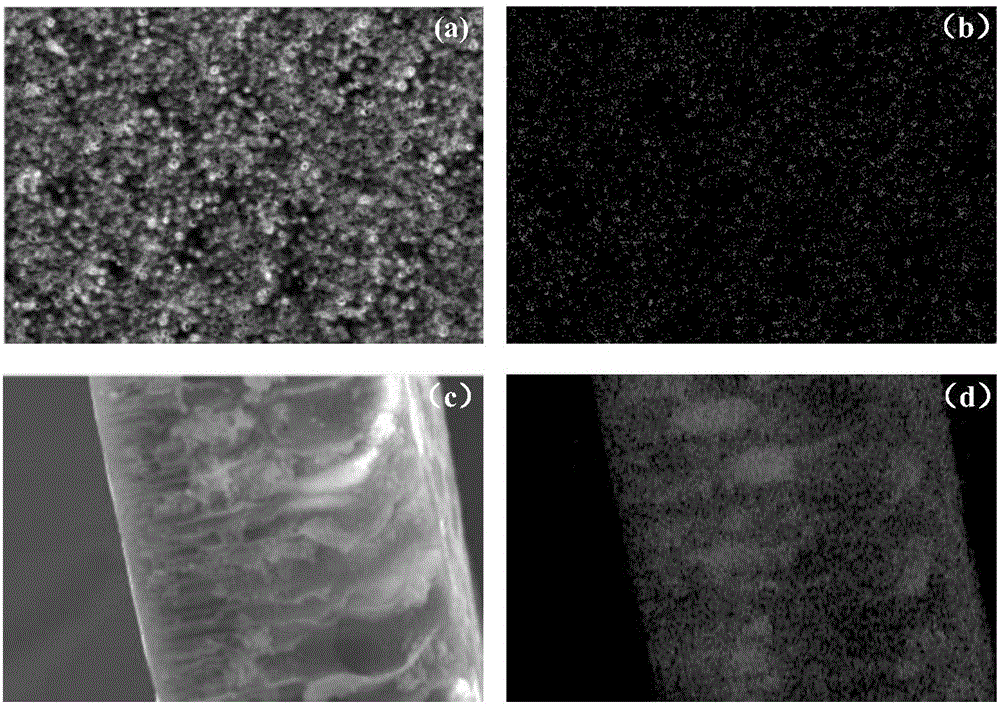

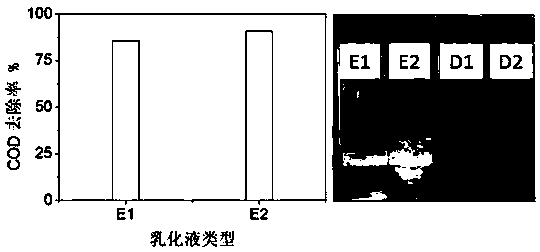

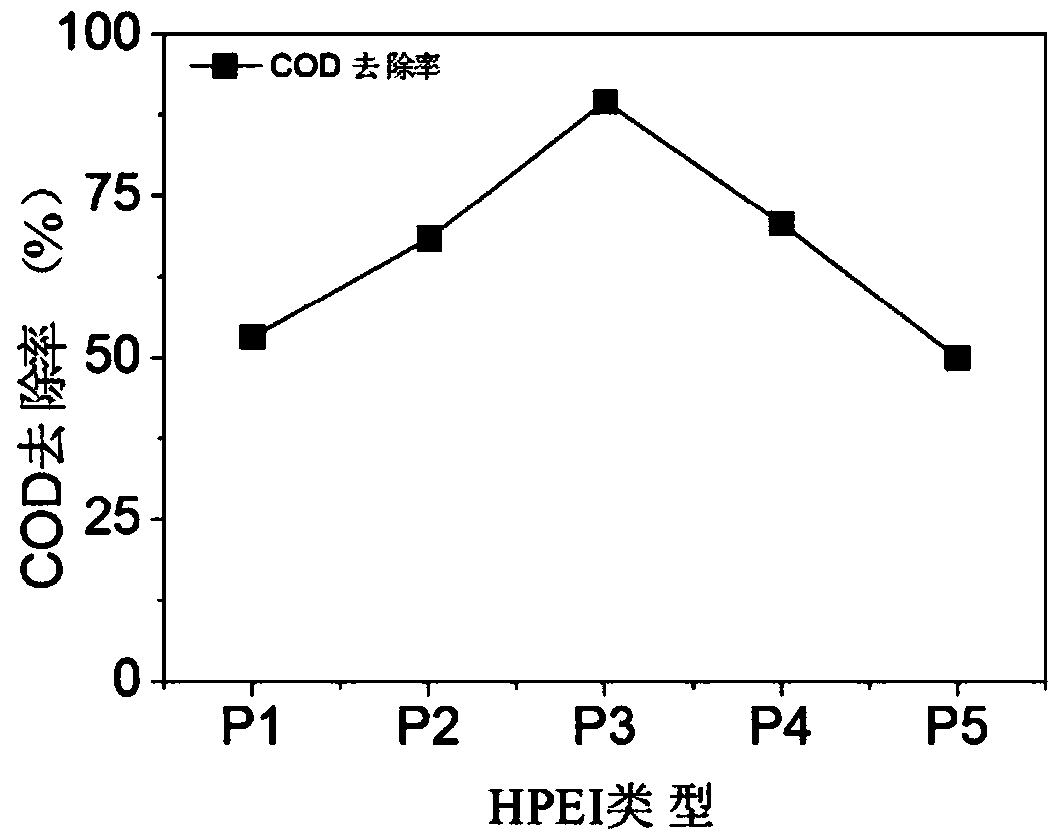

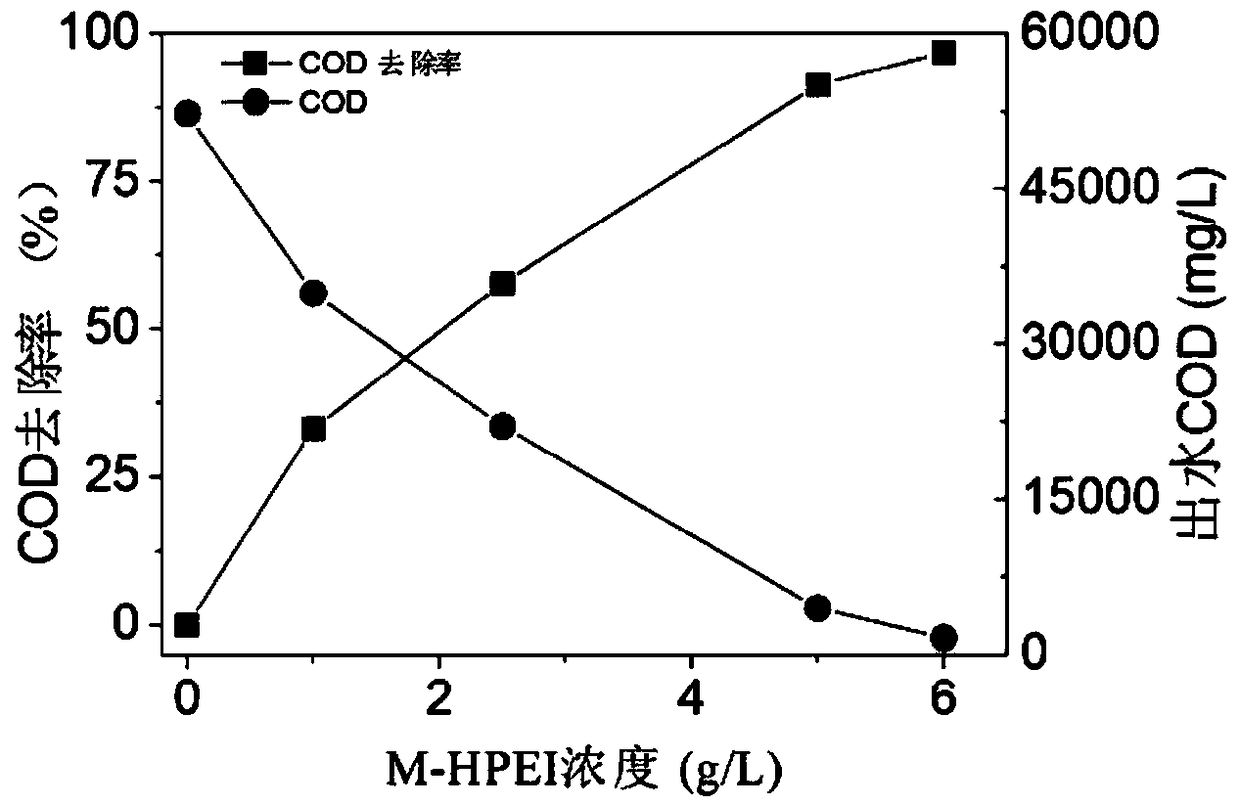

Amino-rich magnetic nanoparticle demulsifier preparation and application method thereof in treating waste emulsion

InactiveCN109350998AOvercoming rateOvercome the defect of large amount of sludge flocNon-miscible liquid separationDemulsifierEffective action

The invention relates to an amino-rich magnetic nanoparticle demulsifier preparation and an application method thereof in treating a waste emulsion. Magnetic nanoparticle demulsifier makes polyethyleneimine branched molecules fixed to the surface of a magnetic core, and a large number of effective action sites are provided for the emulsion. The method for treating the waste emulsion particularly comprises the steps that a magnetic nanoparticle demulsifier suspension is added in the waste emulsion, the mixture is fully mixed to be uniform, and oil-water separation is conducted by means of a magnetic field. By means of the simple method, the novel magnetic nanoparticle demulsifier is synthesized, efficient and rapid demulsification of emulsions with different compositions and properties is achieved, the operation condition is simple, the application range is wide, and industrial application is easy. The treatment scheme is particularly suitable for the waste emulsion generated in the machining process.

Owner:TONGJI UNIV

Pre-charge spraying desulfurization and dust removal device

InactiveCN103480263ASync removalGood effect of desulfurization and dust removalCombination devicesSulfur dioxideEngineering

The invention discloses a pre-charge spraying desulfurization and dust removal device which is applied to the technical field of coal-fired flue gas desulfurization and dust removal. The pre-charge spraying desulfurization and dust removal device comprises a tower body, wherein the bottom of the tower body is connected with a gas inlet pipe and a liquid outlet pipe, and the top of the tower body is connected with a gas exhaust pipe correspondingly; a plurality of spraying heads are arranged in the tower body; a pre-charge needle is arranged at the front end of each spraying head and is connected with a high-voltage power supply through a cable; a high-pressure air pipeline is connected to a spraying pipe of the spraying heads and is connected with a high-pressure air compressor; the spraying heads are connected with an absorption liquid pipeline; a valve is arranged on the absorption liquid pipeline and is connected with an absorption liquid conveying pump; the absorption liquid conveying pump is connected with an absorption liquid preparation pool through a pipeline; a demister is arranged above the spraying heads. The pre-charge spraying desulfurization and dust removal device can be used for synchronously removing sulfur dioxide and fine particulate matters in coal-fired flue gas, and is high in efficiency and low in cost.

Owner:JIANGSU OU CHAO ENVIRONMENTAL TECH

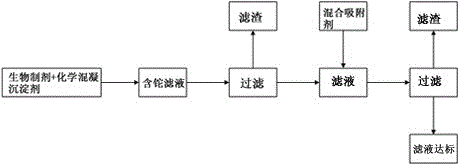

Deep treatment method for thallium-containing wastewater of electronic product manufacturing and metallurgical process

InactiveCN105884132AReduce processing costsEffluent water quality is stable and up to standard dischargeWater contaminantsTreatment involving filtrationIonHeavy metals

The invention discloses a deep treatment method for thallium-containing wastewater of an electronic product manufacturing and metallurgical process. The method disclosed by the invention is used for treating the wastewater, of which the initial thallium content is lower than 1.6mg / L, and comprises the following specific steps: (1) dosing a biological preparation to the thallium-containing wastewater generated from the electronic product manufacturing and metallurgical process, carrying out a reaction for 15 to 30 minutes, and then, carrying out standing; (2) dosing a chemical coagulation precipitant into the wastewater, adjusting the pH of the wastewater to 10 to 12 during coagulative precipitation, carrying out a reaction for 15 to 30 minutes, and then, carrying out filtration; (3) adding a coagulation adsorbent into the filtrate obtained in the step (2), carrying out a stirred reaction for 15 to 30 minutes, and then, carrying out filtration, thereby obtaining the thallium-containing wastewater which can be discharged after reaching standard. The method disclosed by the invention can also be used for synchronously treating other heavy-metal ions contained in the thallium-containing wastewater. According to the method, the method can be implemented through carrying out reforming on the existing facilities, the cost of investment can be reduced greatly, the process is simple, the operation is stable, and the application prospect of industrialization is broad.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Sludge treatment filler and preparation method thereof

InactiveCN106517506AEasy to passSync removalTreatment with anaerobic digestion processesActivated sludgeTalc

The invention discloses sludge treatment filler and a preparation method thereof. The filler is prepared from components in parts by mass as follows: 15-25 parts of ceramsite, 13-15 parts of talc powder, 6-8 parts of organic matter, 6-8 parts of humic acid, 15-25 parts of limestone, 6-10 parts of gypsum, 6-8 parts of basalt particles, 1-3 parts of a porous suspension, 10-12 parts of Mengmoli pumice, 10-12 parts of fly ash, 13-15 parts of activated sludge and 1-2 parts of an oxidizing agent. Electron and proton transfer is promoted by using a porous carrier with conductivity, and organic pollutants and nitrogen-containing pollutants in sewage can be synchronously and efficiently removed.

Owner:钦州市高新技术产业服务中心

Culture method and culture method for aerobic granular sludge

InactiveCN107986432APromote formationExtend build timeTreatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorActivated sludge

The invention relates to a culture method and a culture device for aerobic granular sludge. The culture method for the aerobic granular sludge particularly comprises the following steps of inoculatingactive sludge in a reactor, adding PAC (Polyaluminum Chloride) and sepiolite, and mixing the active sludge; pumping artificial synthetic wastewater into the reactor by utilizing a water intake device, and culturing the aerobic granular sludge through an SBR (Sequencing Batch Reactor) treatment process. The culture device is used for solving problems that the start time is long, the running is unstable, the impact load resisting ability is weak and sludge is easily disintegrated, and the like, in a culture procedure of the aerobic granular sludge, can be used for enhancing biological phosphorus removal, and has advantages of synchronous denitrogenation and phosphorus removal function, stable running, wide raw material source, simple operation and the like.

Owner:WUHAN UNIV OF TECH

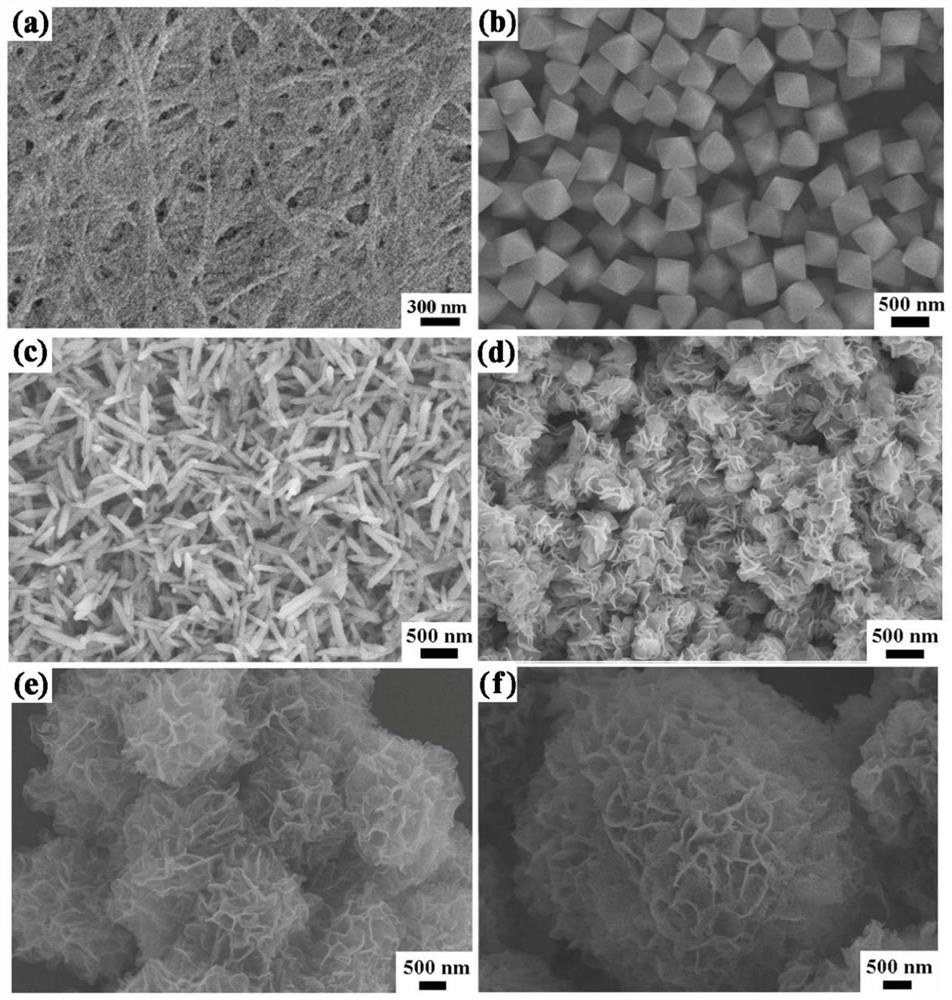

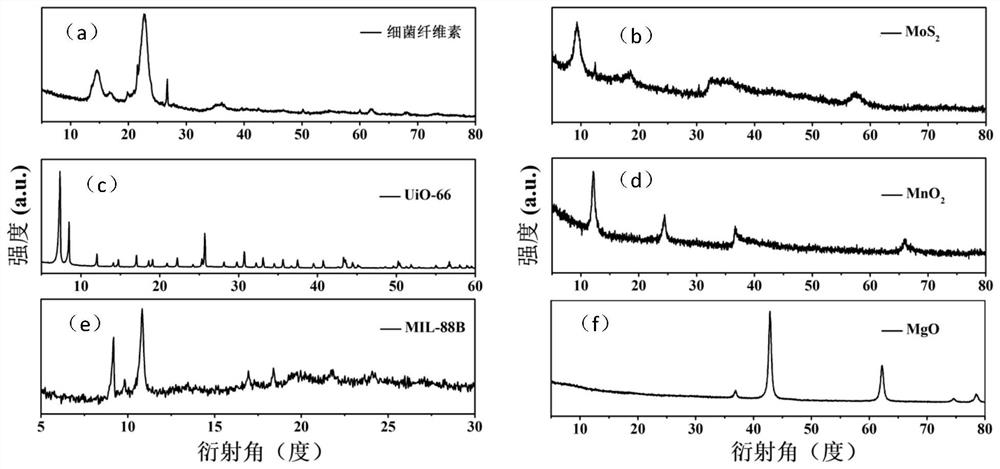

Multicomponent bacterial cellulose composite filter film as well as preparation method and application thereof

ActiveCN113398771ATake advantage of hydrogen bondingSave resourcesMembranesSemi-permeable membranesMercuric ionPhosphate

The invention discloses a multicomponent bacterial cellulose composite filter film and a preparation method and application thereof, and the preparation method comprises the following steps: crushing a bacterial cellulose film to prepare bacterial cellulose slurry; and mixing UiO-66 powder, MIL-88B powder, MoS2 powder, MnO2 powder, MgO powder and the bacterial cellulose slurry together, and carrying out vacuum filtration, so as to obtain the wet multicomponent bacterial cellulose composite filter film. The multicomponent bacterial cellulose composite filter film can be used as an adsorbent for removing phosphate, arsenate, mercury ions, bisphenol A, lead ions and cadmium ions in a water body. The problem that a composite filter film prepared by an in-situ growth method is difficult to load a large number of nano particles is solved, the defect that a powder nano material is difficult to recycle is overcome, the adsorption performance of the nano particles of each component can be comprehensively exerted, and synchronous and efficient removal of various pollutants in the combined polluted water body is realized.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

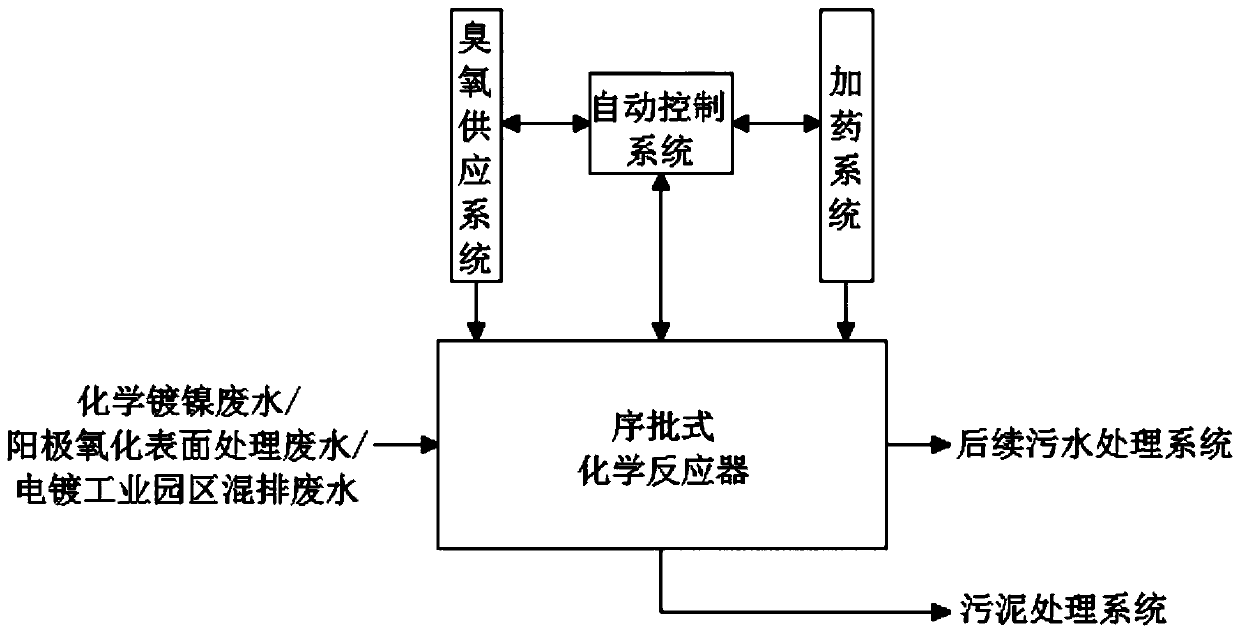

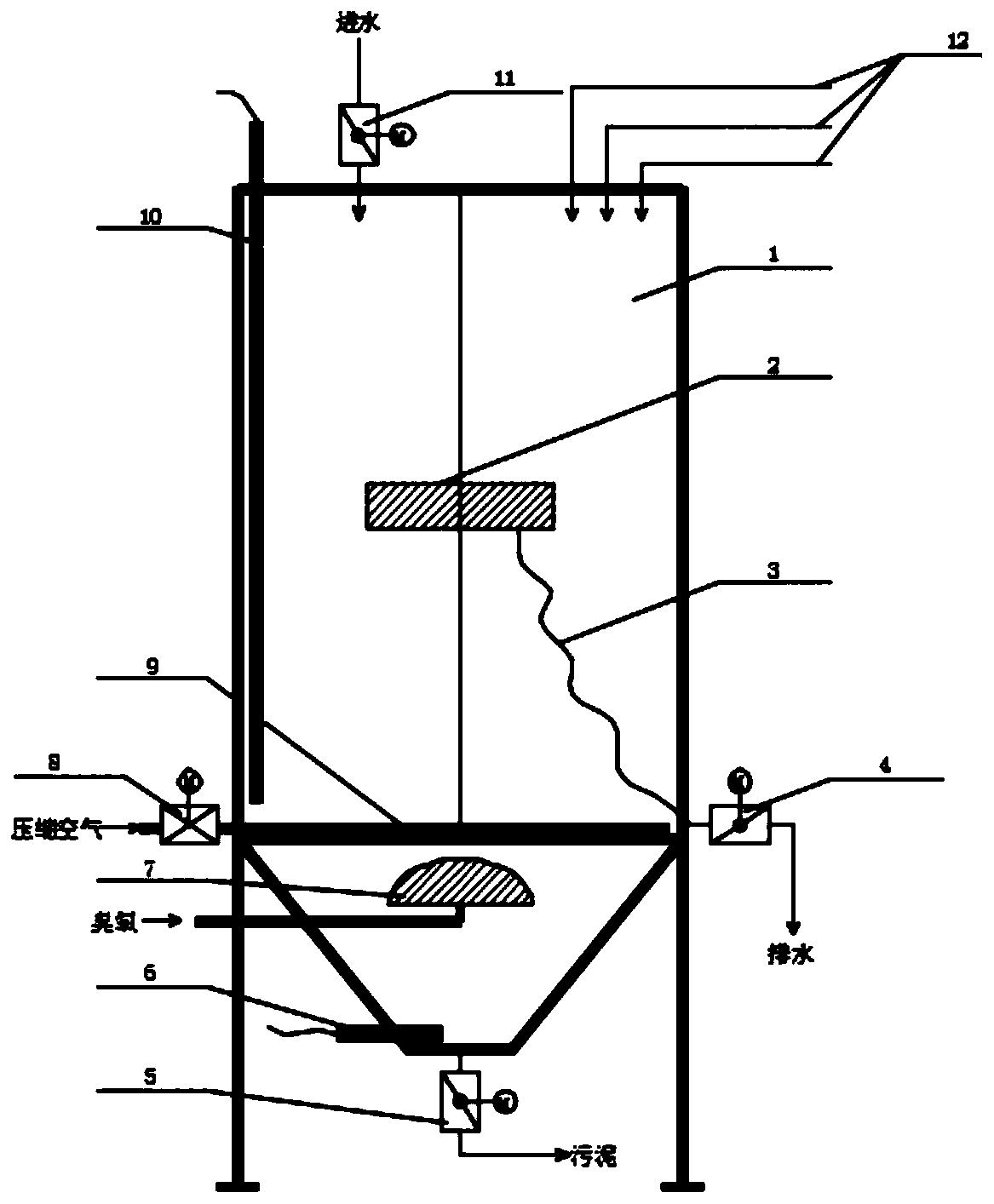

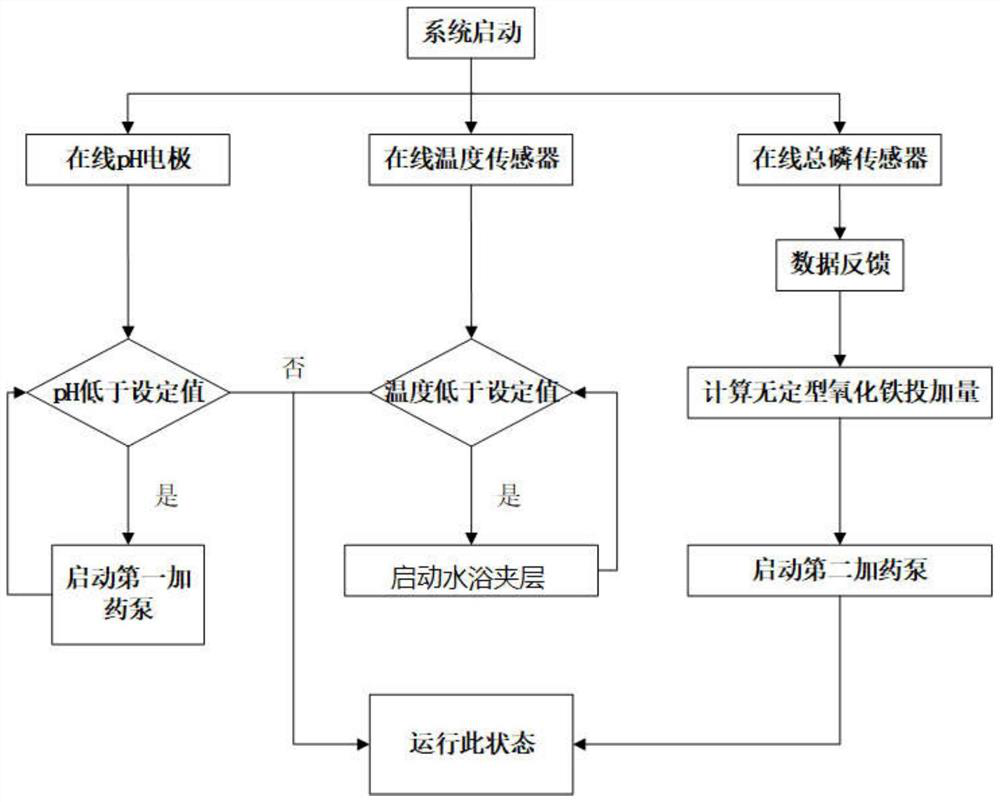

Treatment method for synchronously removing total phosphorus and nickel in wastewater

PendingCN111186935ASync removalThe process is compact and efficientWater treatment parameter controlWater contaminantsPhosphorous acidO-Phosphoric Acid

The invention discloses a treatment method for synchronously removing total phosphorus and nickel in wastewater. A device used in the method mainly comprises a sequencing batch chemical reactor, an ozone supply system, a dosing system and an automatic control system. Wastewater enters the sequencing batch chemical reactor; hypophosphite radicals, phosphite radicals and pyrophosphite radicals in the wastewater are oxidized into orthophosphate radicals by utilizing ozone; meanwhile, complex nickel is subjected to complex breaking, and then alkali is added to adjust a pH value to 11.0-11.5; a coagulant, a coagulant aid and other chemical agents are added for enhanced coagulating sedimentation; a supernatant is discharged into a subsequent sewage treatment system; and sediments are dischargedinto a sludge treatment system. According to the method, the hypophosphite radicals, the phosphite radicals and the pyrophosphite radicals in the wastewater are fully oxidized into the orthophosphateradicals by utilizing ozone, complex nickel breaking is synchronously completed, and total phosphorus and nickel are synchronously and efficiently removed in the same reactor, so total phosphorus andnickel after treatment of short-process chemical nickel-plating wastewater, anodic oxidation surface treatment wastewater and mixed discharge wastewater of an electroplating industrial park stably reach discharge standards.

Owner:SOUTH CHINA UNIV OF TECH

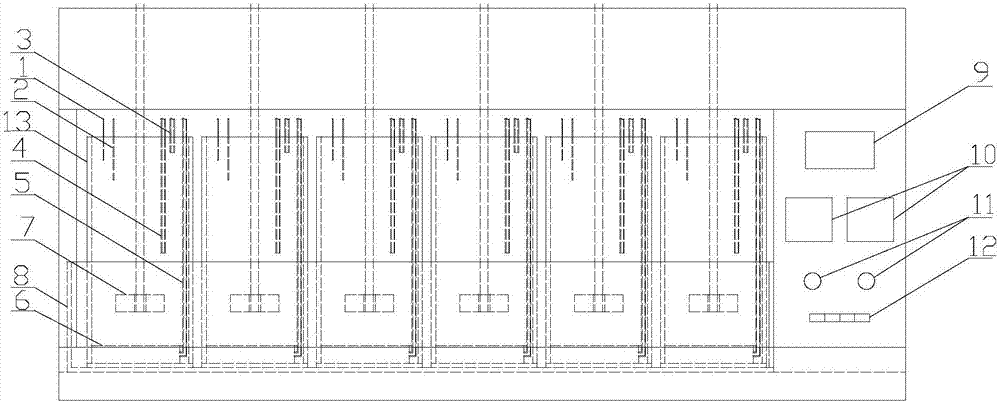

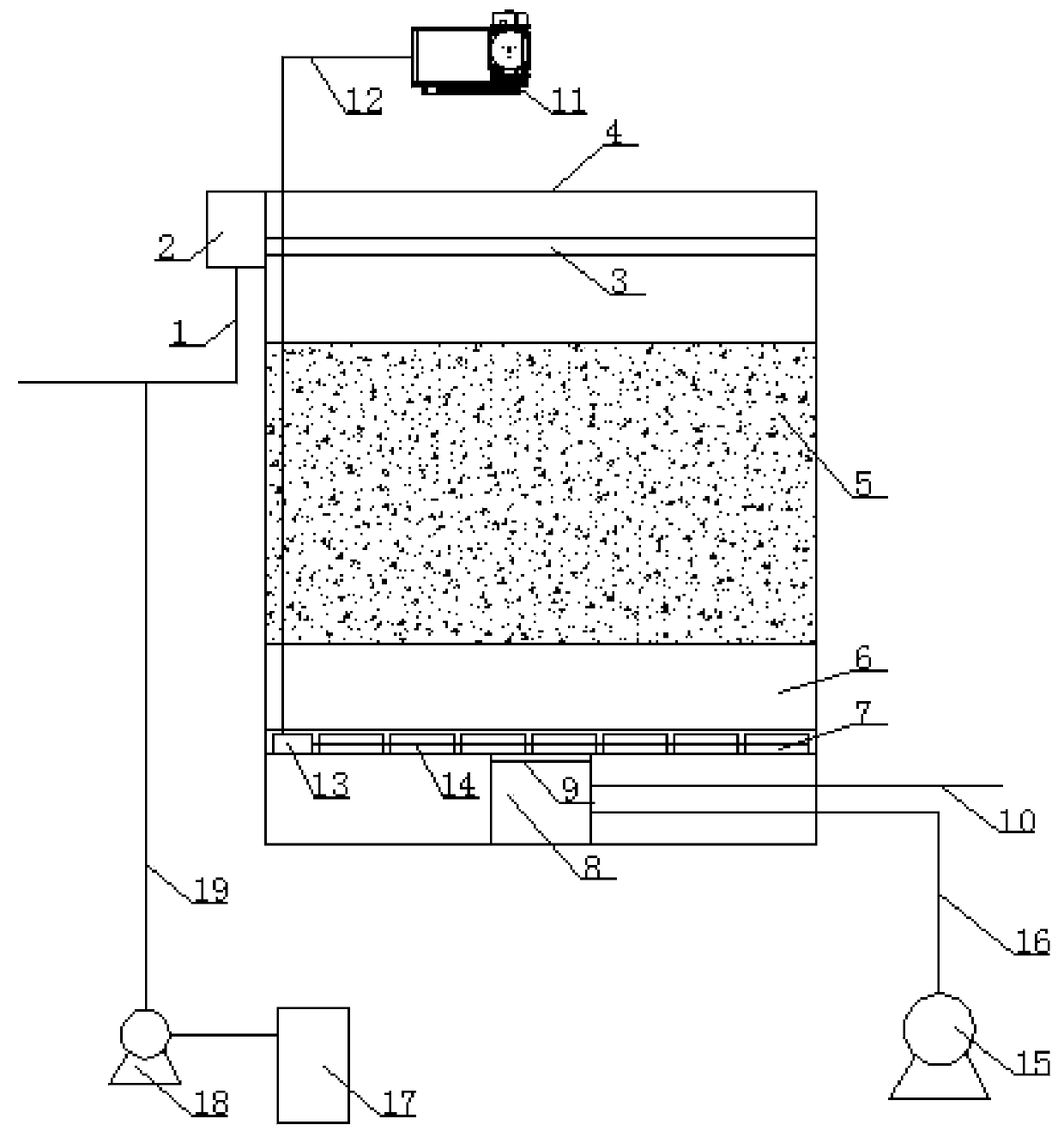

Novel denitrification deep bed filter tank reaction system

PendingCN110240270ANo maintenanceNo consumable partsWater contaminantsTreatment with anaerobic digestion processesBrickWater quality

The invention discloses a novel denitrification deep bed filter tank reaction system. The novel denitrification deep bed filter tank reaction system comprises a denitrification deep bed filter tank composed of a water inlet system, a biological filter material, sewage special-purpose water distribution gas distribution filter bricks, a gas water distribution chamber, a water outlet pipe, a backwashing system, and a carbon source adding system; a plurality of functions are achieved; a plurality of purposes can be achieved using one tank; synchronous removing is adopted to reach TN, SS, and TP three water quality index standards; the quality of discharged water is better than first grade A discharge standard or special discharge value limit standard in <Discharge standard of pollutants for municipal wastewater treatment plant> (GB18918-2002); incomplete denitrification at winter low temperature conditions is avoided; adding of a certain amount of carbon source into the denitrification deep bed filter tank plays an important role in stable reachment of TN standard, and TN discharge standard which is gradually strict in the further is achieved, and TN is ensured to be equal to or lower than 8mg / L.

Owner:盖格环境技术(杭州)有限公司

Method of treating coal mine wastewater by synergy of sulfate-reducing bacteria and spontaneous combustion gangue

ActiveCN108623017ALow costStrong applicabilityWaste water treatment from quariesBiological water/sewage treatmentCoal gangueChemistry

A method of treating coal mine wastewater by synergy of sulfate-reducing bacteria and spontaneous combustion gangue belongs to the field of wastewater treatment and comprises: screening spontaneous combustion gangue samples to obtain spontaneous combustion gangue powder having particle size of 0.074-0.600 mm, and drying; with wastewater sediment as activated sludge, performing enrichment culture with Postgate medium in an anaerobic environment to obtain an SRB (sulfate-reducing bacteria) strain in logarithmic phase, and centrifuging to obtain an SRB suspension; adding the spontaneous combustion gangue powder and the SRB suspension into Postgate medium having no Fe2+, sealing the liquid, culturing in a thermostatic vibrating culture tank at 30-35 DEG C for 5-7 days to obtain a sulfate-reducing bacteria and spontaneous combustion gangue sample, adding the sulfate-reducing bacteria and spontaneous combustion gangue sample into coal mine wastewater at 30-35 DEG C, and performing wastewatertreatment. The method that treats coal mine wastewater by synergy of microorganisms and spontaneous combustion gangue can help reduce environment pollution due to coal mine wastewater and solve the coal gangue piling problem and has a good application prospect.

Owner:LIAONING TECHNICAL UNIVERSITY

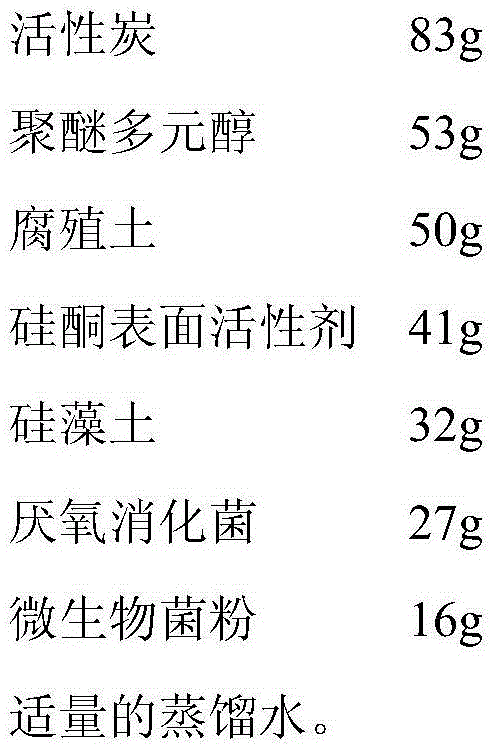

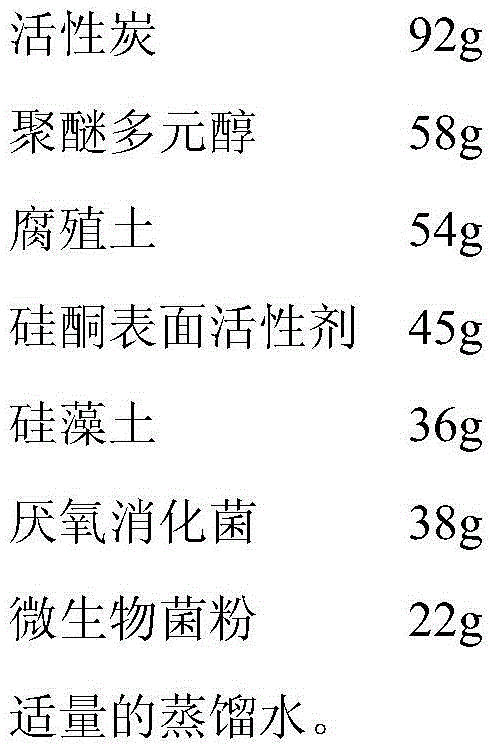

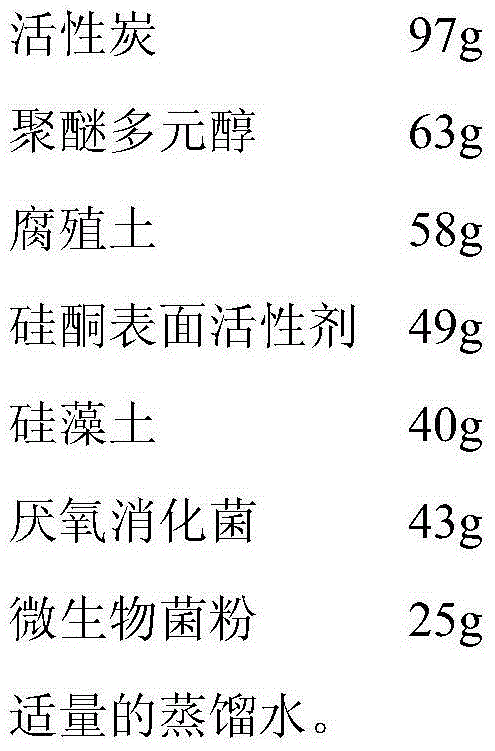

Efficient filler for sewage treatment

InactiveCN104671402ASync removalEfficient removalTreatment with anaerobic digestion processesActivated carbonPolyol

The invention provides an efficient filler for sewage treatment. The efficient filler is prepared from the following components including activated carbon, polyether polyol, muck, a silicone surfactant, diatomite, anaerobic digestion bacteria, microorganism bacterium powder and distilled water. A preparation scheme of the efficient filler comprises the following steps: weighing the polyether polyol, the muck, the silicone surfactant and the diatomite according to a ratio, mixing with water, stirring with a low speed by virtue of a stirrer, and slowly adding the activated carbon after weighing in a mixed liquid; and increasing the stirring speed until the mixed liquid and the activated carbon are fully mixed, and adding the anaerobic digestion bacteria and the microorganism bacterium powder after weighing.

Owner:QINGDAO HAOTAI WATER

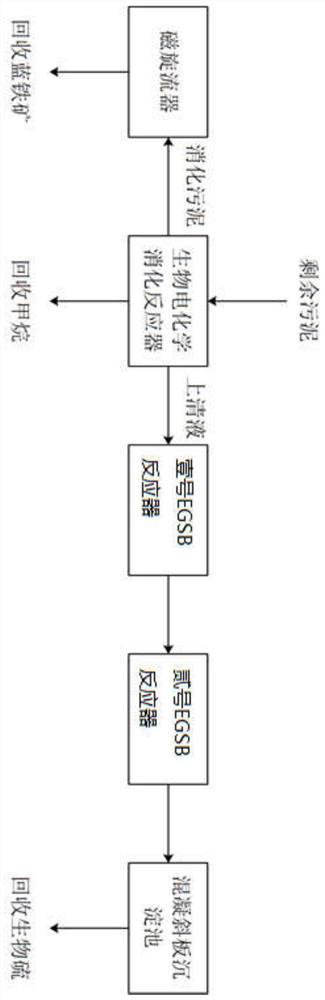

Process for producing methane and blue iron ore and recovering sulfur through anaerobic digestion of bioelectrochemical sludge

ActiveCN112811755ASync removalStable in natureWater/sewage treatment by electrochemical methodsGas production bioreactorsCoupling reactionAmmonia

The invention discloses a process for producing methane and blue iron ore and recovering sulfur through anaerobic digestion of bioelectrochemical sludge, and belongs to the field of anaerobic treatment of sludge. The process comprises a bioelectrochemical digestion reactor, a first EGSB reactor, a second EGSB reactor, a coagulation inclined plate sedimentation tank and a magnetic cyclone; wherein the two ends of the bioelectrochemical digestion reactor are communicated with the magnetic cyclone and the first EGSB reactor respectively, one end of the first EGSB reactor is communicated with an adjusting tank, one end of the adjusting tank is communicated with the second EGSB reactor, and one end of the second EGSB reactor is communicated with a V-shaped recovery tank. According to the invention, the technologies of producing the blue iron ore through anaerobic digestion of the sludge, reducing sulfate, performing sulfur autotrophic denitrification and performing anaerobic ammonia oxidation are integrated to treat residual sludge and digest supernate of the sludge, and the blue iron ore and biological sulfur are recycled; in addition, the sludge is subjected to anaerobic digestion to produce methane and generate blue iron ore, and nitrogen and sulfur are simultaneously removed through the autotrophic denitrification reaction and the anaerobic ammonia oxidation coupling reaction.

Owner:SHANGHAI BI ZONE ENVIRONMENTAL EQUIP & ENG

Novel ammonia nitrogen biotreatment device

InactiveCN102874924ASync removalEasy to handleWater contaminantsTreatment with aerobic and anaerobic processesFacultative lagoonIon exchange

The invention discloses a novel ammonia nitrogen biotreatment device comprising raw water supply equipment, raw water treatment equipment and water outlet equipment, which are connected in sequence, wherein the raw water treatment equipment comprises a water distributor, a facultative layer and an aerobic layer; the water distributor is connected with the raw water supply equipment; the facultative layer is perpendicularly mounted at the lower end of the water distributor; the aerobic layer is perpendicularly mounted at the lower end of the facultative layer; the aerobic layer is connected with the water outlet equipment; the facultative layer is uniformly filled with zeolite; and the aerobic layer is uniformly filled with clinoptilolite. The novel ammonia nitrogen biotreatment device comprehensively utilizes the measures of adsorption, ion exchange, biodegradation and the like, can synchronously remove pollutants such as CODcr, ammonia nitrogen, suspended matters and feculence, and has a good treatment effect as well as the advantages of long service life, energy conservation, low operation cost, small occupied area, labor conservation and the like.

Owner:广东金明环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com