Multicomponent bacterial cellulose composite filter film as well as preparation method and application thereof

The technology of bacterial cellulose membrane and bacterial cellulose is applied in the field of multi-component bacterial cellulose composite filter membrane and its preparation, which can solve the problems that powder nanomaterials are not easy to recover, and it is difficult to load nanoparticles in large quantities, and achieves easy recovery, Contaminant-synchronized, high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method for multicomponent bacterial cellulose composite filter membrane, comprising the following steps:

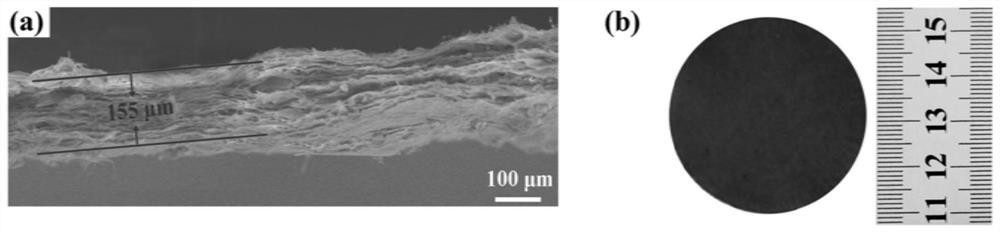

[0031] Step 1, cutting the entire bacterial cellulose film purchased through commercial means into small pieces, and then breaking the cut bacterial cellulose film into short-fiber bacterial cellulose slurry; wherein, every 1g of the bacterial cellulose After the slurry was sufficiently dried, 3.36 mg of dry bacterial cellulose could be obtained.

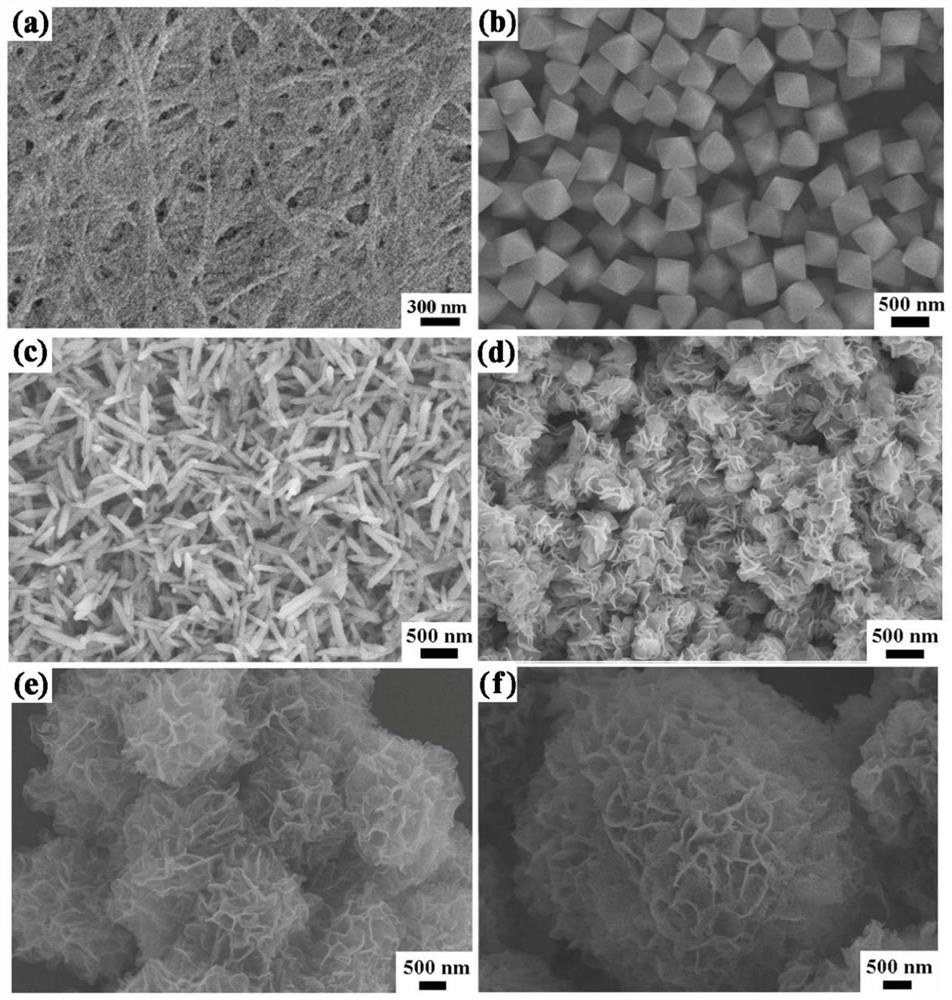

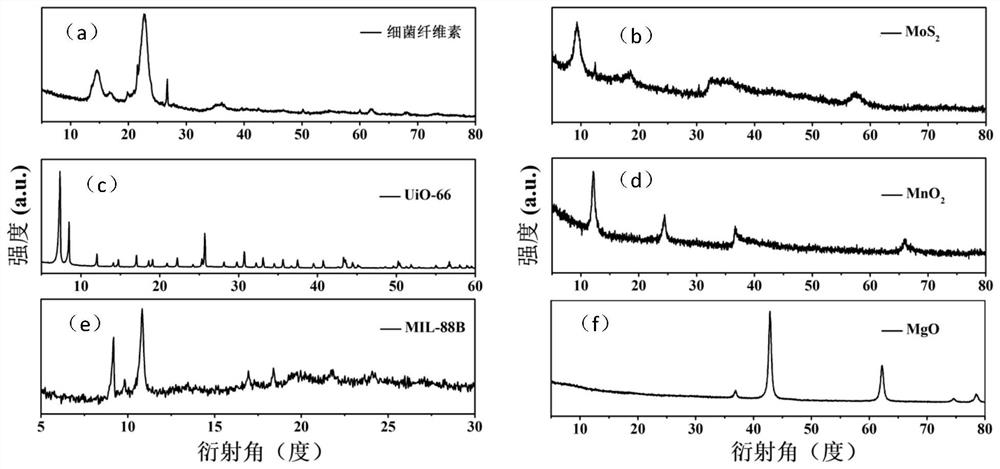

[0032] Step 2, the metal organic framework material UiO-66 powder, metal organic framework material MIL-88B powder, MoS 2 Powder, MnO 2 Powder, MgO powder, and the bacterial cellulose slurry are mixed together, and fully stirred evenly, and then vacuum filtration is directly performed without adding a flocculant, thereby preparing a wet multi-component bacterial cellulose composite filter membrane (the Multi-component bacterial cellulose composite filter membrane containing UiO-66, MIL-88B, MoS 2 , MnO ...

Embodiment 1

[0051] A kind of multi-component bacterial cellulose composite membrane, its preparation method comprises the following steps:

[0052] Step A, cutting the whole bacterial cellulose membrane purchased by commercial means into 2mm (long) * 2mm (wide) * 2mm (high) bacterial cellulose membrane fragments, then cutting the bacterial cellulose membrane fragments Use a high-speed crusher to crush to obtain a uniform bacterial cellulose slurry; 3.36 mg of dried bacterial cellulose can be obtained after every 1 g of the bacterial cellulose slurry is fully dried.

[0053] Step B, UiO-66 powder, MIL-88B powder, MoS 2 Powder, MnO 2 Synthesis of powder and MgO powder: 0.45mmol ZrCl 4 , 0.45mmol terephthalic acid and 4.5mmol acetic acid were dissolved in 30mL DMF, hydrothermally reacted at 120°C for 24h, washed with DMF and ethanol, and dried in vacuum at 60°C to obtain UiO-66 powder. 1mmol FeCl 3 ·6H 2 O and 1 mmol of terephthalic acid were dissolved in 10 mL of DMF, and then 2 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com