Applications of nanometer iron-palladium double-metal composite material, method for removing nitrates and phosphates in water, and subsequent treatment method

A composite material and nano-iron technology, which is applied in the field of environmental functional composite materials, can solve the problems of incomplete removal of nitrate, inability to remove nitrate and phosphate at the same time, a large amount of high concentration, etc., to achieve efficient reduction, easy operation, and selection sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

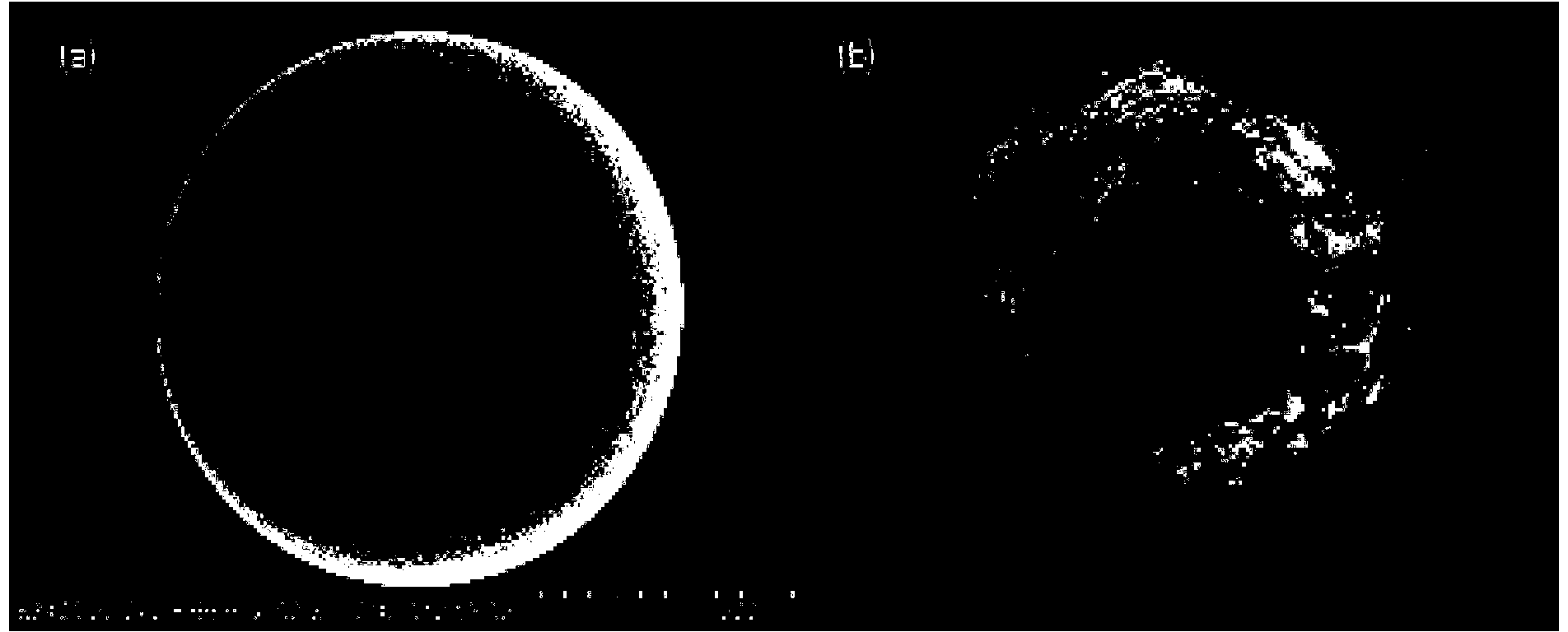

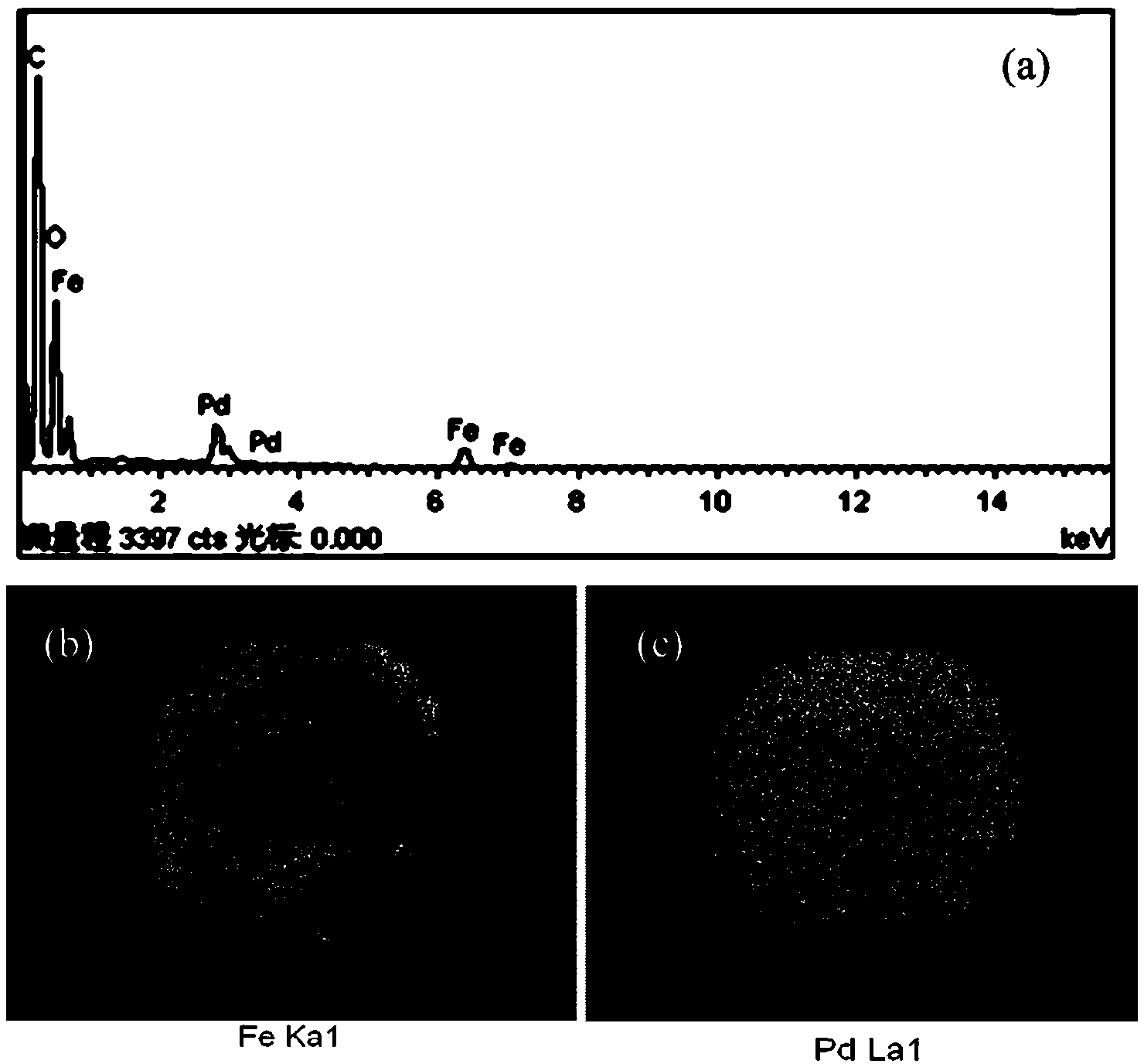

[0039] A method for preparing a loaded nano-iron-palladium bimetallic composite, the steps of which are:

[0040] (a) 1g resin carrier DOWEX TM Add M4195 to 500mL containing Fe 3+ solution, where Fe 3+ The mass concentration is 2g / L, Fe 3+ The pH value of the solution was 2, shaken in a constant temperature shaking incubator at 30°C for 24 hours, and the carrier material was taken out to obtain Fe-chelated 3+ carrier material;

[0041] (b) the chelated iron taken out in step (a) has Fe 3+ The carrier material, added to 200mL containing Pd 2+ solution, where Pd 2+ The mass concentration is 300mg / L, Pd 2+ The pH value of the solution is 2, shake in a constant temperature shaking incubator at 30°C for 10 hours, and take out the secondary load carrier material;

[0042] (c) Put the secondary load carrier material obtained in step (b) into a three-necked flask, add dropwise 200mL of a mass concentration of 1% sodium borohydride solution, stir and react for 2 hours, then che...

Embodiment 2

[0049] With embodiment 1, difference is: the resin carrier in the step (a) is changed into DOWEX TM XFS43084, Fe 3+ The solution was changed to Fe 2+ solution, Fe 2+ The mass concentration is 5g / L, Fe 2+ The pH value of the solution was 4, and shaken in a constant temperature shaking incubator for 20 hours at 30 ° C; the Pd in step (b) 2+ The mass concentration is 700mg / L, Pd 2+ The pH value of solution is 4, shakes 8 hours in constant temperature vibration incubator under 30 ℃, and sodium borohydride solution mass concentration is 5% in step (c), the hydrochloric acid solution concentration in step (1) is 100mmol / L, other Conditions remain the same, after 2 hours of reaction, the removal rate of phosphate in water is 100%, the removal rate of nitrate is 96%, the selectivity of nitrogen in the reduction product is 87%, and no metal ion is detected during the reaction. After repeated use for 3 times, the removal rate of phosphate is 90%, the removal rate of nitrate is 92...

Embodiment 3

[0051] With embodiment 1, difference is: in the step (a) Fe 3+ The mass concentration is 1g / L, Fe 3+ The pH value of solution is 3, shakes 10 hours in constant temperature vibration incubator under 30 ℃, and sodium borohydride solution mass concentration is 0.5% in the step (c); The pH value of the nitrate solution in the step (i) is adjusted to 8. Other conditions remain unchanged, after 3 hours of reaction, the removal rate of phosphate in the water body is 96%, the removal rate of nitrate is 99%, the selectivity of nitrogen in the reduction product is 85%, and there is no metal ion in the reaction process Check out. After repeated use for 3 times, the removal rate of phosphate is 92%, the removal rate of nitrate is 88%, and the selectivity to nitrogen in the reduction product is 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com