Ultrafiltration membrane and preparation method thereof

A technology of ultrafiltration membrane and conversion method, which is applied in the preparation of microspheres, chemical instruments and methods, membranes, etc., can solve problems affecting ultrafiltration performance, destroying ultrafiltration membrane structure, and affecting practical applications, etc., and achieves low mass transfer resistance , simple operation, high load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

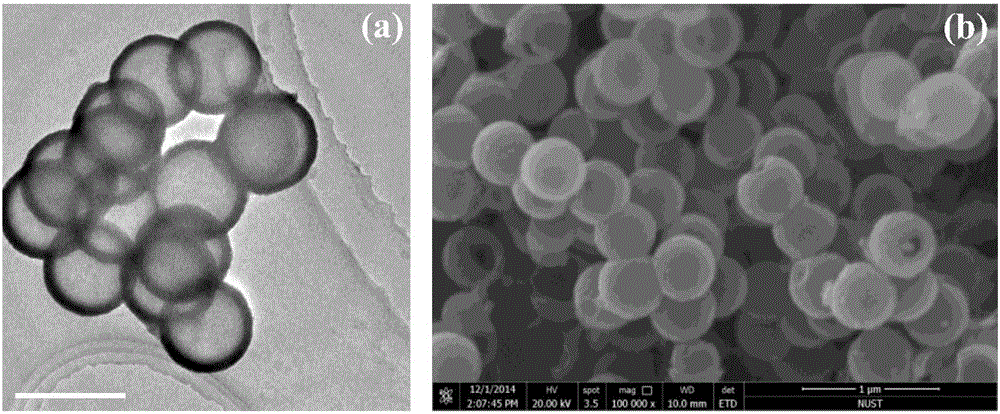

[0048] Step 1, Synthesis of Nanoporous Hollow Beads

[0049] In this embodiment, the synthesized porous hollow hydrated zirconia spheres are selected as the nanoporous hollow spheres.

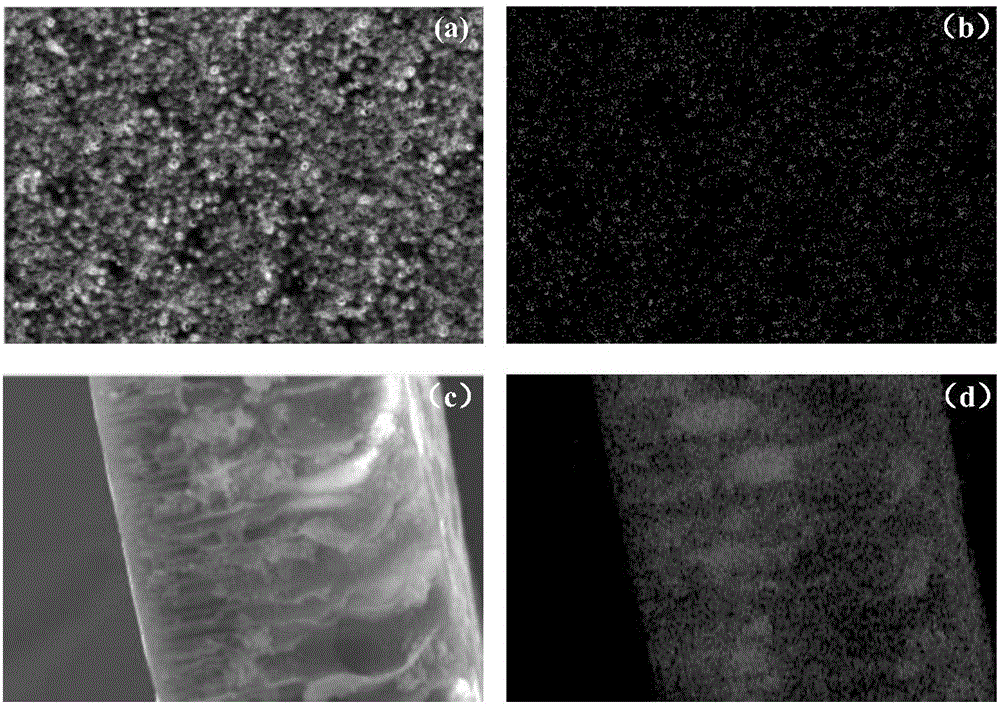

[0050] The preparation of porous hollow hydrated zirconia balls is divided into four steps. The first step is to prepare SiO 2 For small balls, add 18mL of ammonia water and 49.5mL of distilled water into 32.5mL of absolute ethanol, stir for half an hour, then add a mixture of 9ml of tetraethyl orthosilicate and 91ml of absolute ethanol, and continue magnetic stirring for 8h After the reaction is completed, the reaction solution is centrifuged, washed alternately with distilled water and ethanol, and the operation is repeated three times, and the product is dispersed in 320mL of absolute ethanol; in the second step, 1mL of distilled water and 0.75g of Brij- 35. After stirring for 2 hours, a mixed solution containing 4.5 mL of zirconium n-butoxide and 45.5 mL of absolute ethanol was added ther...

Embodiment 2

[0066] Step 1, Synthesis of Nanoporous Hollow Beads

[0067] In this embodiment, synthetic porous hollow carbon spheres are selected as nanoporous hollow spheres.

[0068] Add 1.04g of 25wt% CTAC to a mixed solution containing 19mL of distilled water, 0.1mL of ammonia water and 5mL of absolute ethanol, stir for half an hour, add 0.2g of resorcinol, and continue stirring for half an hour. 0.72 mL of tetraethyl orthosilicate and 0.28 mL of formaldehyde solution were added to the above mixed solution, and the reaction was stirred at 30° C. for 24 h. After the reaction, the solid was obtained by centrifugation and dried at 80° C. for 12 hours. The dried solid was calcined at 200° C., 350° C., 500° C., and 600° C. for 2 h under the protection of nitrogen, and then calcined at 800° C. for 5 h. Finally, porous hollow carbon spheres are obtained. In this example, a large number of spherical particles with a hollow structure were synthesized with a particle size of about 200-300 nm....

Embodiment 3

[0080] Step 1, Synthesis of Nanoporous Hollow Beads

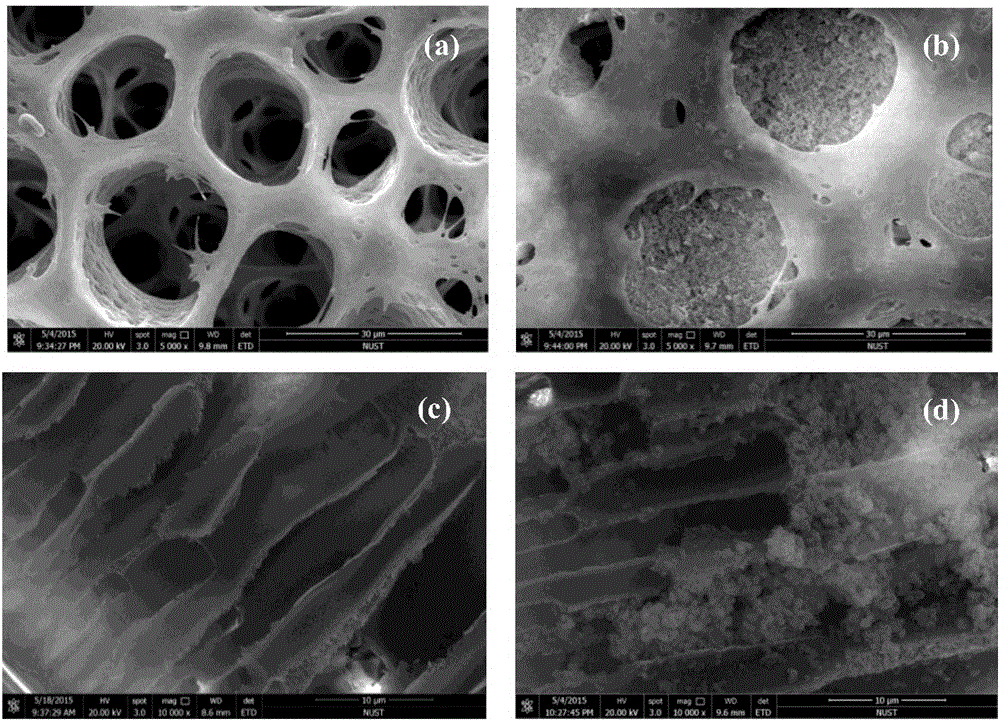

[0081] In this embodiment, synthetic porous hollow ferric oxide balls are selected as nanoporous hollow balls.

[0082] The porous hollow Fe3O4 balls were synthesized by a one-step hydrothermal method. 2mmol ferric chloride, 4mmol sodium citrate and 6mmol urea were dissolved in 40mL distilled water, then 0.3g polyacrylamide was added and stirred until completely dissolved. The obtained solution was transferred to a polytetrafluoroethylene-lined reactor and reacted at 200° C. for 12 h. After cooling to room temperature, it was centrifuged to obtain a black solid, which was washed alternately with water and absolute ethanol, and dried under vacuum conditions to finally obtain porous hollow ferric oxide balls. In this example, a large number of spherical particles with a hollow structure were synthesized with a particle size of about 200-300 nm.

[0083] Step 2, the preparation of PES ultrafiltration membrane

[0084] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com