Magnetically-separable multiplex photo-catalyst, and preparation method and application thereof

A composite light and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reduced loading and photocatalytic activity, poor thermal stability, weak binding ability, etc. Light wavelength response range, good magnetic properties, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

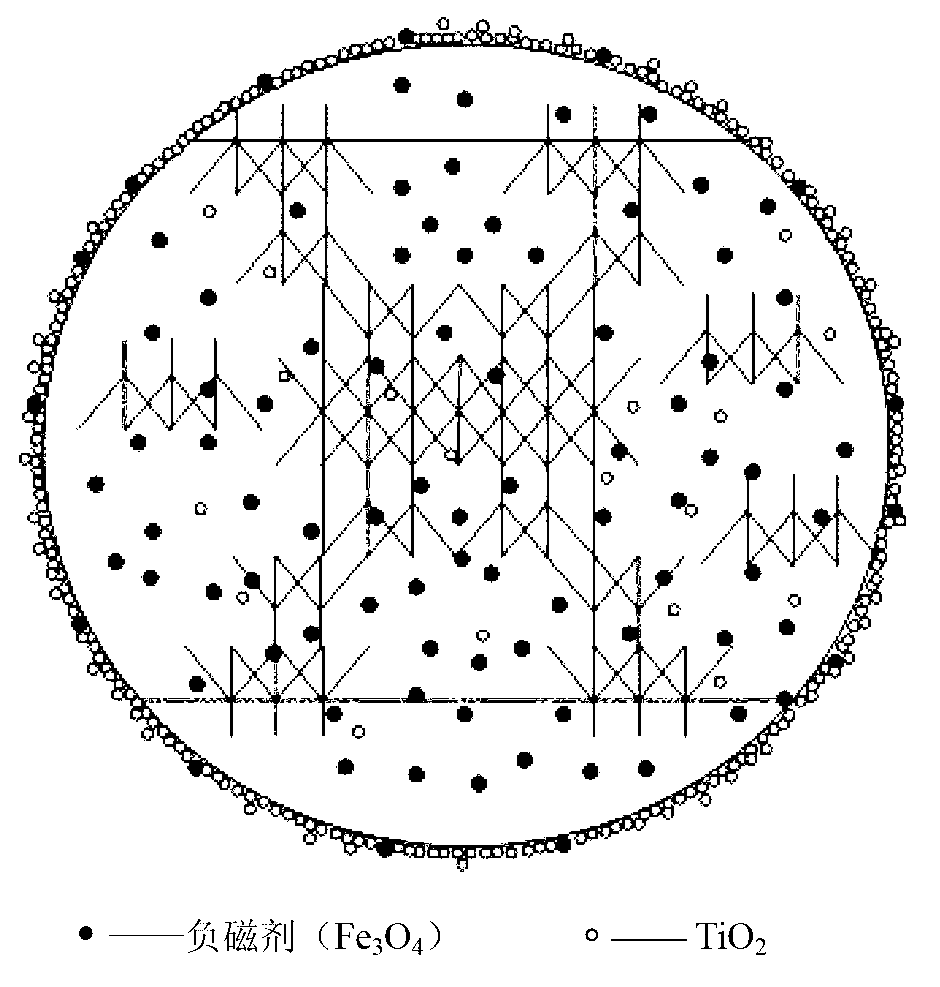

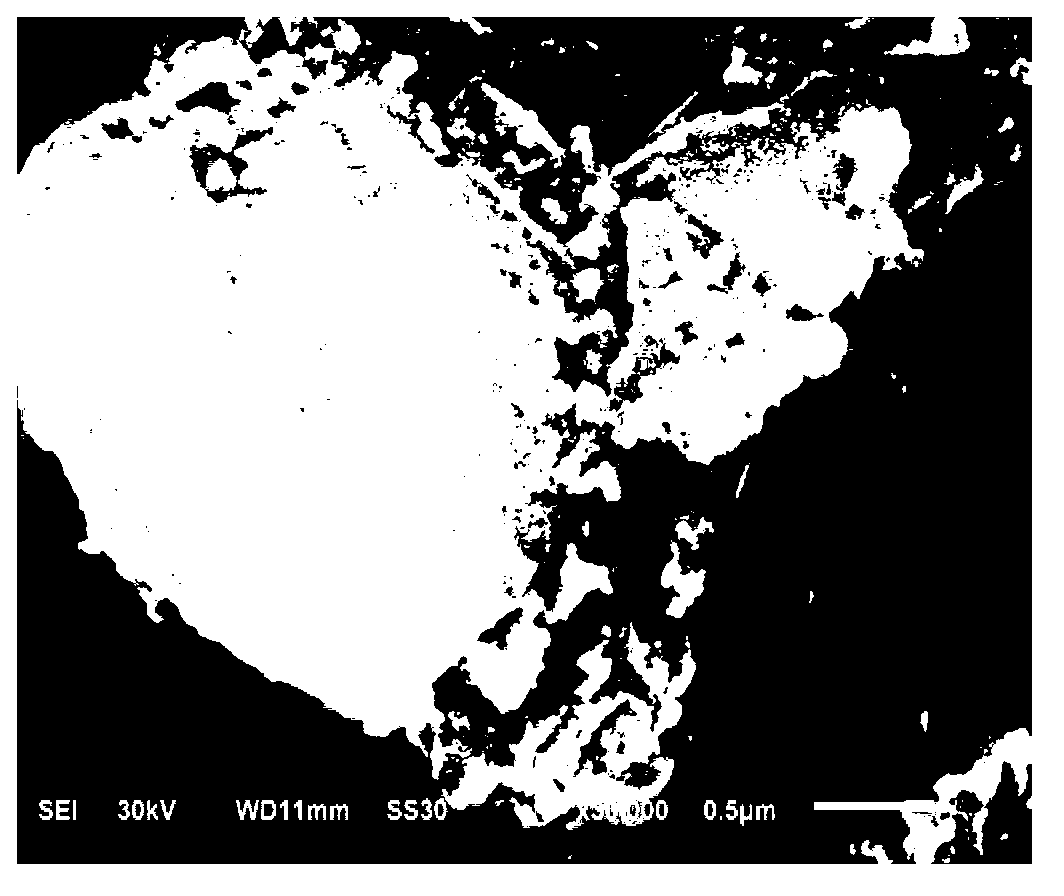

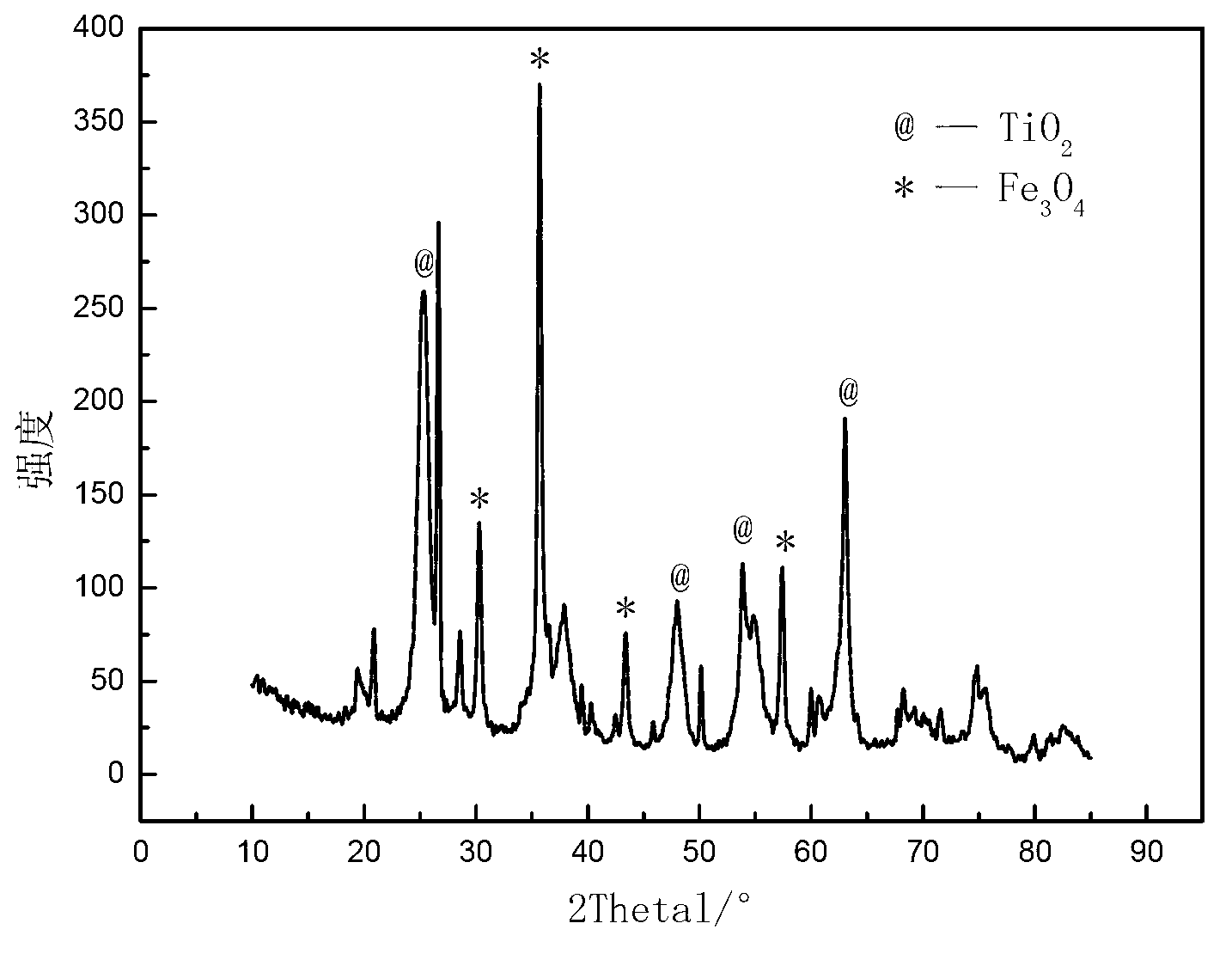

[0032] (1) Preparation of composite photocatalyst: 11.83g FeCl 3 ·6H 2 Dissolve O in 100ml of distilled water, add 10g of sepiolite raw soil (passed through 80 mesh sieve) in a water bath at 60°C, stir rapidly for 30min, then add 6.95g of FeSO 4 ·7H 2O powder, then add concentrated ammonia water dropwise to adjust the pH value of the solution to about 9.0, continue to stir for 1 hour and then age for 1 hour. Pass through a 80-mesh sieve to obtain magnetic sepiolite. Dissolve 20ml of butyl titanate in 20ml of absolute ethanol, add 2ml of anhydrous acetic acid, mix well, then add 6.804g of the above-prepared magnetic sepiolite powder, stir and react for 30min to obtain liquid A; Add 2ml of deionized water to the water ethanol, and adjust the pH to 2~3 with 1:1 nitric acid to obtain liquid B; then, slowly drop liquid B into liquid A, and stir rapidly for 60 minutes (the mixed liquid changes from sol to gel ), then left to age for 24 hours, the resulting gel was washed, dried ...

Embodiment 2

[0035] (1) Preparation of composite photocatalyst: First, the preparation process of magnetic sepiolite is the same as that in Example 1. Then, dissolve 20ml of butyl titanate in 20ml of absolute ethanol, add 2ml of anhydrous acetic acid, mix evenly, add 6.804g of magnetic sepiolite powder, and stir rapidly for 30min to obtain liquid A; Add 2ml of deionized water, and then use 1:1 nitric acid to adjust the pH to 2~3 to obtain liquid B; then, slowly drop liquid B into liquid A, stir and react rapidly for 60 minutes (the mixed liquid changes from sol to gel), Then stand and age for 24 hours; the obtained gel is washed, dried at 60° C., calcined at 300° C., ground, and passed through an 80-mesh sieve to obtain a composite photocatalyst.

[0036] (2) Performance test of the composite photocatalyst applied to the simultaneous removal of heavy metals and organic matter in water: Cr(Ⅵ) and 2,4-DCP coexist in wastewater, and their concentrations are 40mg / L and 40mg / L, respectively. F...

Embodiment 3

[0038] The composite photocatalyst was repeatedly applied to the performance test of simultaneous removal of heavy metals and organic matter in water: Cr(Ⅵ) and 2,4-DCP coexisted in wastewater, and their concentrations were 20mg / L and 80mg / L, respectively. First adjust the pH value of the wastewater to 2, then add TiO 2 A composite photocatalyst with a loading capacity of 20.22% was added at a dosage of 2 g / L. The dark reaction was performed for 30 minutes, followed by a light reaction for 75 minutes. Magnetic separation was performed after the reaction, and the supernatant was taken to analyze Cr(Ⅵ) and 2,4 in the solution. -The remaining concentration of DCP, the recovered composite photocatalyst was washed several times with distilled water, dried at 60°C, ground, passed through an 80-mesh sieve, and applied again to the refractory wastewater treatment where Cr(Ⅵ) and 2,4-DCP coexist , the process is the same as above. It can be seen from the experimental results that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com