Culture method and culture method for aerobic granular sludge

A technology of aerobic granular sludge and cultivation method, which is applied in chemical instruments and methods, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. Poor stability and other problems, to achieve the effect of synchronous removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

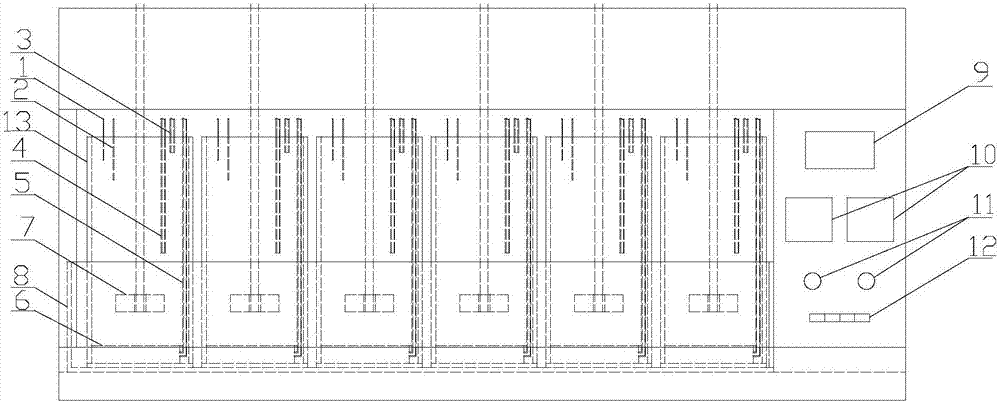

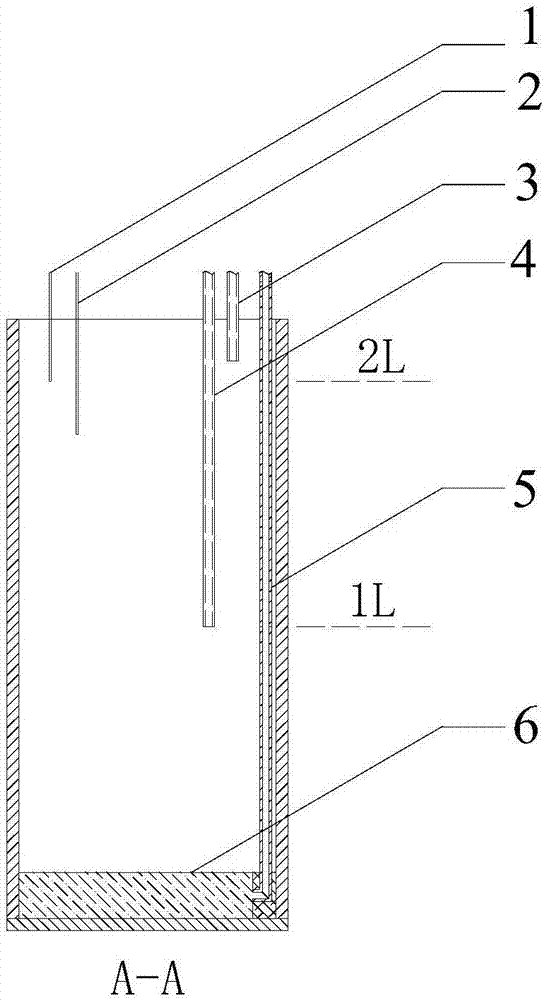

[0059] Example 1: Exploration of adding inert substrate PAC / sepiolite to aerobic granular sludge cultivation

[0060] The invention utilizes PAC as an inert substrate to quickly cultivate aerobic granular sludge. In this embodiment, the control group is set as an RC reactor without adding an inert substrate, an RP reactor with PAC added, and an RPS reactor for PAC / sepiolite combination, and the rest of the operating conditions are the same to construct a device described in the invention. The reactor 13 in the device has an inner diameter of 12 cm, an effective volume of 2 L, a ratio of height to diameter of 2:1, and a volume exchange rate of 50%. The feed water of the reactor adopts artificial synthetic wastewater to simulate domestic sewage, and the specific components are: CH 3 COONa, 513mg·L -1 , the organic load is 1.0kgCOD / (m 3 d); NH 4 Cl, 153 mg L -1 ;KH 2 PO 4 , 40.6mg·L -1 ;K 2 HPO 4 , 46.3mg·L -1 Na 2 EDTA, 38.2mg·L -1 ;CaCl 2 , 100mg·L -1 ;MgSO 4 2H...

Embodiment 2

[0086] Example 2, the enhanced biological phosphorus and nitrogen removal of the aerobic granular sludge cultivated by PAC / sepiolite combination.

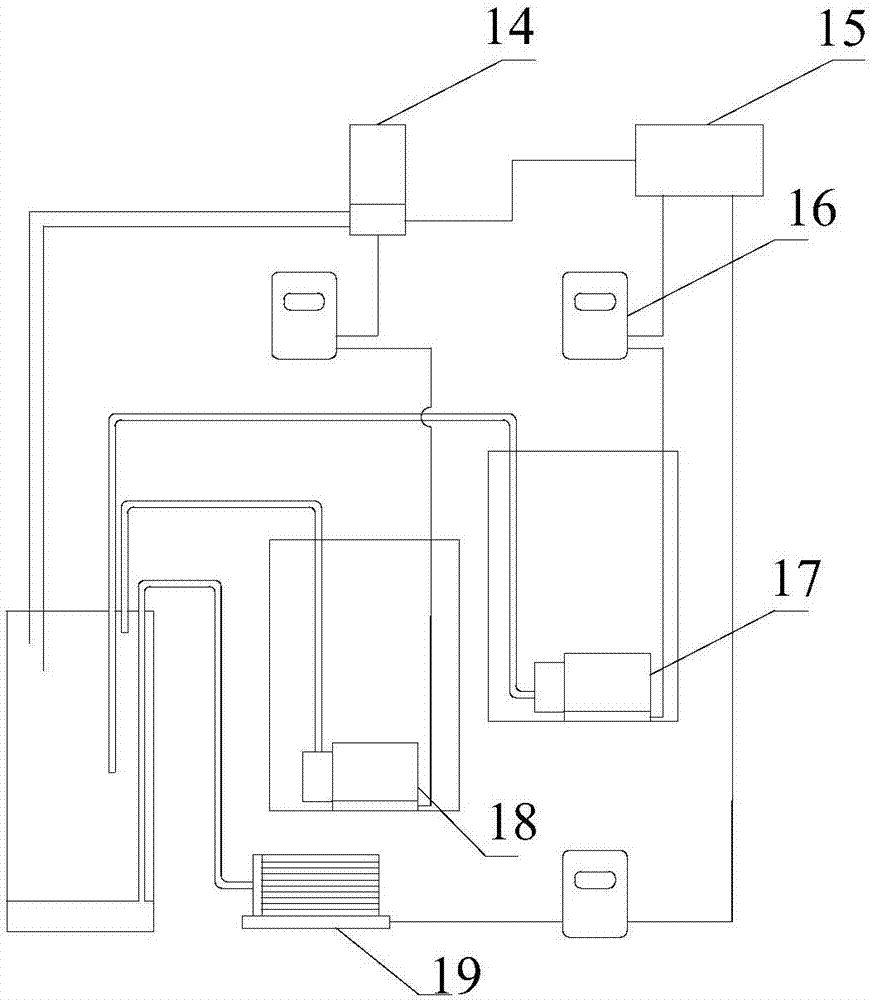

[0087] According to the synthetic wastewater formula in Example 1 as the reactor feed water, the SBR reactor adopts the anaerobic-aerobic alternate operation mode in Example 1 during the process of cultivating granular sludge, and runs for 4.8 hours per cycle, 5 a day and night The cycle includes 1 minute of water inflow, 99 minutes of anaerobic, 160 minutes of aerobic, initial sedimentation time of 20 minutes, 1 minute of water outlet, 7 minutes of idle time, a total of 6 stages, each stage can be regulated by a time controller.

[0088] like Figure 9a , Figure 9b , during the sludge cultivation process, the three reactors for TP and PO 4 3- The removal rate of -P is basically about 99%, and the effluent index is better than the first-class A standard of "Pollutant Discharge Standards for Urban Sewage Treatment Plants". In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com