Efficient nitrogen and phosphorus removal method for sewage properties-classified treatment in highway service area

A technology for quality-based treatment, nitrogen and phosphorus removal, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large footprint and large carbon source dosage , high chemical costs and other issues, to achieve the effect of reducing carbon dioxide, reducing aeration, and high nitrogen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

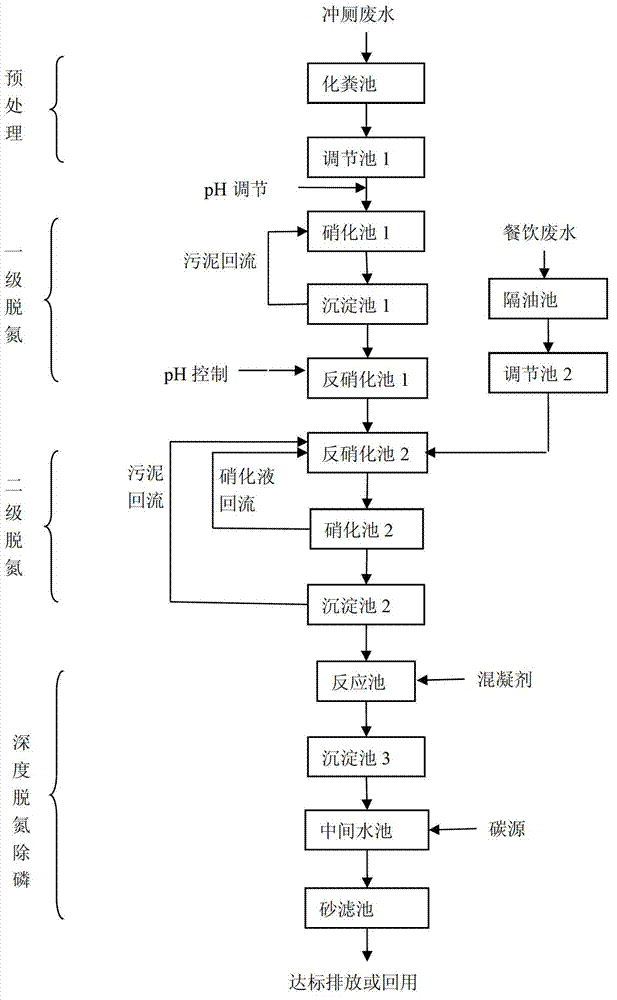

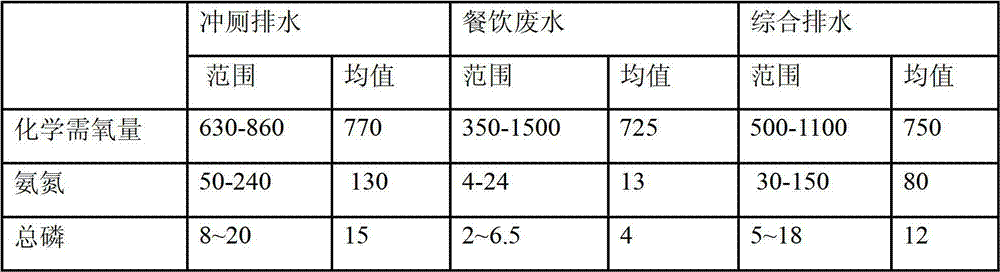

[0036] The wastewater from the expressway service area is collected separately from toilet flushing wastewater, catering wastewater and other wastewater. The toilet flushing wastewater enters the septic tank, and the septic tank wastewater flows into the regulating tank 1 by itself, while other wastewater also enters the regulating tank 1, with a residence time of 24h. The catering wastewater enters the conditioning tank 2 through the grease trap for a stay time of 24h. The wastewater from the regulating tank 1 enters the nitrification tank 1 for a residence time of 6h, and the dissolved oxygen is controlled to be 1.0mg / L. The wastewater from the nitrification tank 1 enters the sedimentation tank 1 for precipitation, the sludge in the sedimentation tank 1 returns to the nitrification tank 1, and the supernatant enters the denitrification tank 1. Add NaOH and NaHCO in denitrification tank 1 3 Adjust the pH to 8.2, fill the denitrification tank 1 with elastic fillers, and an ana...

Embodiment 2

[0041] The wastewater from the expressway service area is collected separately from toilet flushing wastewater, catering wastewater and other wastewater. The toilet flushing wastewater enters the septic tank, the septic tank wastewater flows into the regulating tank 1 by itself, and the catering wastewater enters the regulating tank 2 through the grease trap. At the same time, other wastewater also enters the regulating tank 2. The wastewater from the regulating tank 1 enters the nitrification tank 1, and the dissolved oxygen is controlled at 3.0 mg / L to fully oxidize the ammonia nitrogen into nitrate. The wastewater from the nitrification tank 1 enters the sedimentation tank 1, the sludge of the sedimentation tank 1 returns to the nitrification tank 1, and the supernatant enters the denitrification tank 1. NaOH is added to the denitrification tank 1 to adjust the pH, and the effluent from the denitrification tank 1 enters the denitrification tank 2. Both denitrification tank ...

Embodiment 3

[0046] The wastewater from the expressway service area is collected separately from toilet flushing wastewater, catering wastewater and other wastewater. The toilet flushing wastewater enters the septic tank, the septic tank wastewater flows into the regulating tank 1 by itself, and the catering wastewater enters the regulating tank 2 through the grease trap. At the same time, other wastewater also enters the regulating tank 2. The effluent from the regulating tank 2 enters the denitrification tank 1 and the denitrification tank 2 at the ratio of 70% and 30% respectively. Among them, the wastewater from the regulating tank 1 enters the nitrification tank 1, and the dissolved oxygen is controlled to be 2.0 mg / L, and the residence time is 6 hours to partially oxidize the ammonia nitrogen into nitrate. The wastewater from the nitrification tank 1 enters the sedimentation tank 1, the sludge of the sedimentation tank 1 returns to the nitrification tank 1, and the supernatant enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com