Electrolysis induction and ozone floatation integrated device

An ozone flotation and ozone technology, which is used in oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc. , water additives are difficult to degrade and other problems, to achieve the effect of convenient remote control and unattended operation, reduced operating skills, and low requirements for supporting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

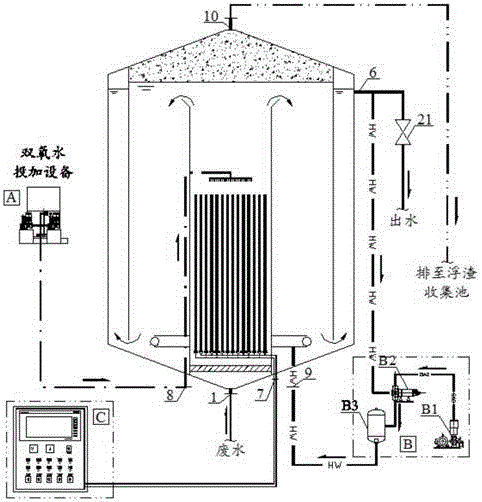

[0029] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

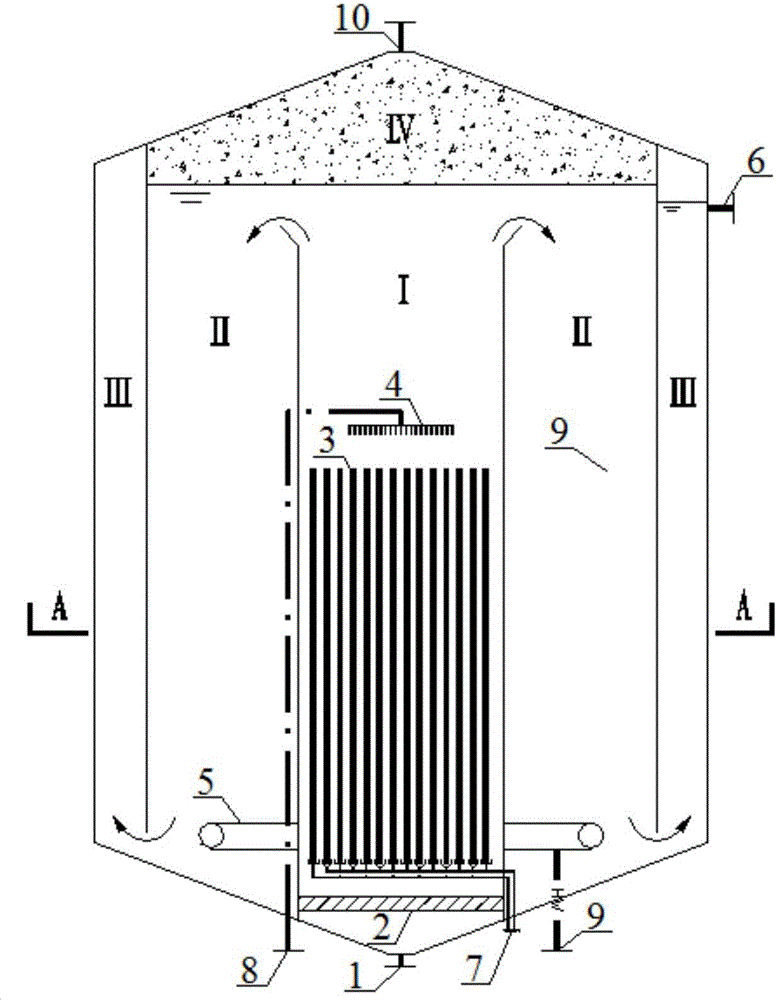

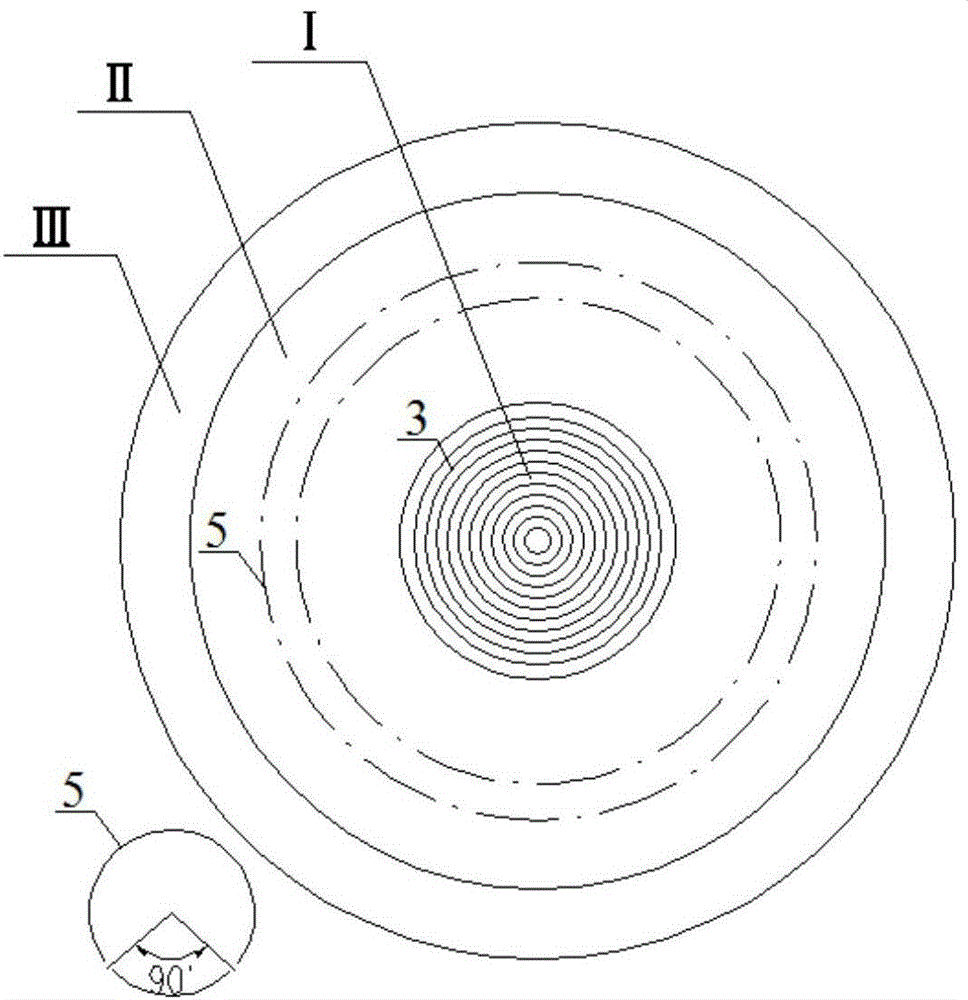

[0030] Such as figure 1 with figure 2 As shown, an integrated electrolysis-induced ozone flotation device of the present invention includes the following four functional modules:

[0031] Electric flocculation core tube I, the wastewater completes the destabilization and coagulation of colloids, emulsified oil, etc., and hydrogen peroxide is added to the upper part of the tube to form a Fenton oxidation system with iron ions entering the water to oxidize the organic matter in the water and change the electric flocculation. The charge characteristics of the body surface make it easy to be closely combined with microbubbles;

[0032] Ozone flotation / catalytic oxidation zone II, connected to the top of the electro-flocculation core tube I, the wastewater forms an ozone catalytic oxidation system of ozone / hydrogen peroxide / iron ions in it to further oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com