Pre-charge spraying desulfurization and dust removal device

A technology for desulfurization, dust removal, and preloading, which is applied to combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to effectively control the discharge of fine particles, the removal efficiency of fine particles is not high enough, and it is difficult to meet high-efficiency control. To achieve the effect of good desulfurization and dust removal, low cost and synchronous removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

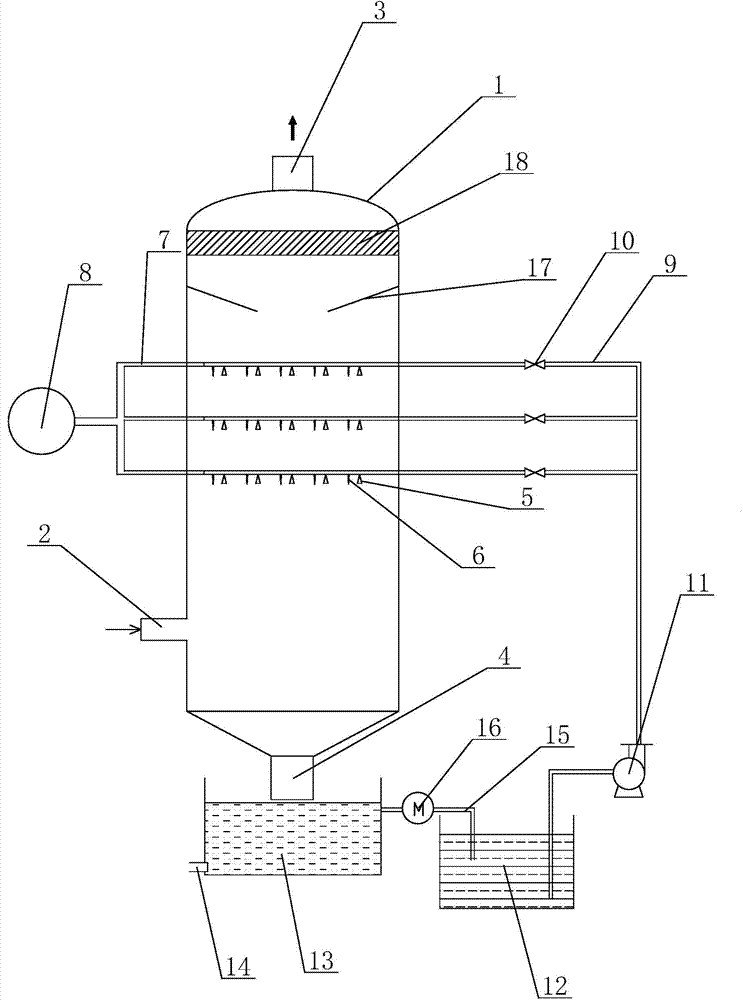

[0014] see figure 1 as shown, figure 1 It is a structural schematic diagram of the pre-charged spray desulfurization and dust removal device provided in Embodiment 1 of the present invention.

[0015] In this embodiment, a pre-charged spray desulfurization and dust removal device includes a tower body 1, the tower body 1 is divided into a cylindrical section and a conical section, the conical section is arranged below the cylindrical section, and the cylindrical section The bottom of the tower is connected with an air inlet pipe 2, the top of the cylindrical section is connected with an exhaust pipe 3, the bottom of the tapered section is connected with a liquid outlet pipe 4, and a plurality of Spray head 5, and the front end of each shower head 5 is equipped with pre-charged needle 6 on the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com