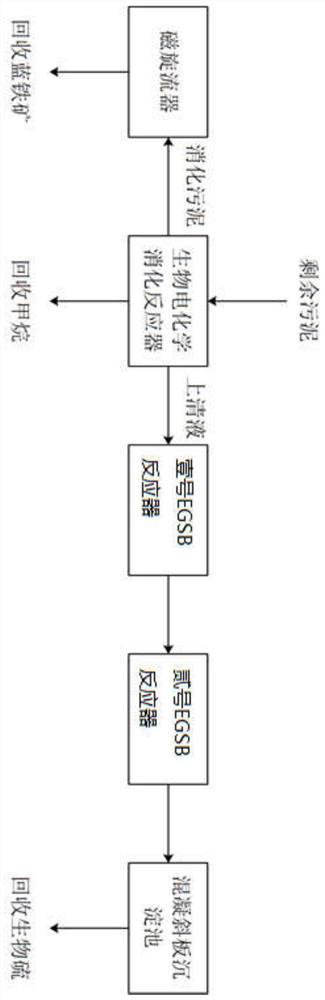

Process for producing methane and blue iron ore and recovering sulfur through anaerobic digestion of bioelectrochemical sludge

A bioelectrochemical and anaerobic digestion technology, applied in the field of sludge anaerobic treatment, can solve the problems of inability to remove ammonia nitrogen, affecting the efficiency of anaerobic digestion, and inconvenient operation and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

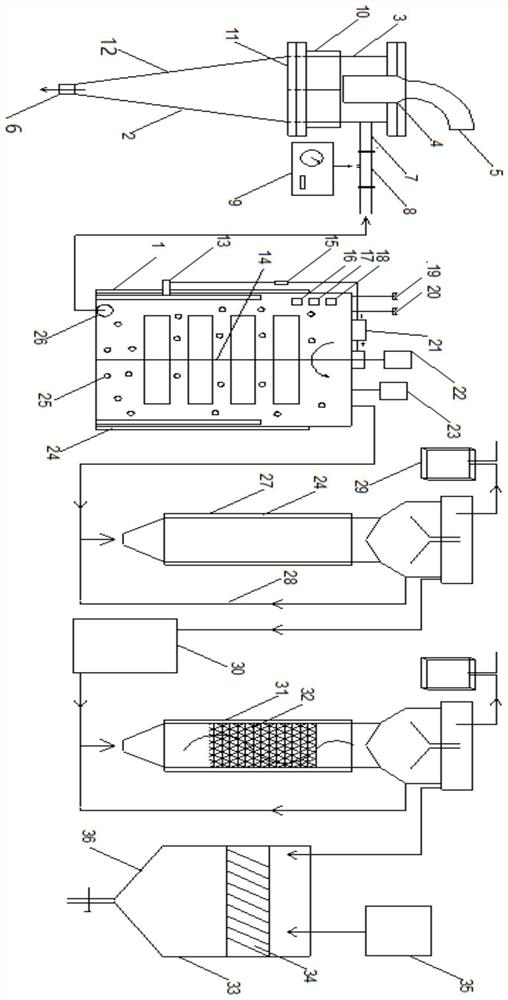

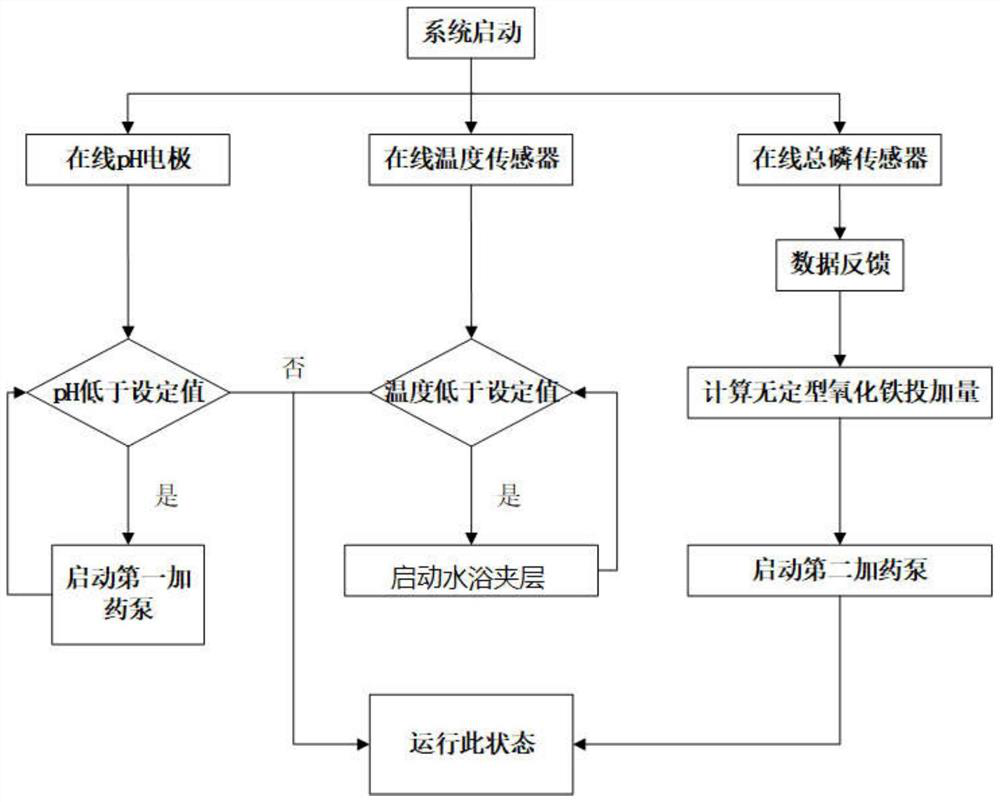

[0044] The remaining sludge enters the bioelectrochemical digestion reactor 12, the power supply 21 and the top motor 22 are turned on, the stainless steel rotating shaft 14 acts as an anode and agitator at the same time, and the external stainless steel cathode 13 and the anode made of the stainless steel rotating shaft 14 constitute a biological Electrochemistry promotes mesothermal anaerobic digestion of sludge. After three stages of hydrolysis and fermentation, hydrogen production, acetic acid production, and methane production, the sludge cells rupture, and the organic matter released by the rupture becomes methane gas and other soluble supernatants. The methane produced to The biogas collector 23 at the top of the reactor collects; after the mesophilic anaerobic digestion is completed, the blue iron ore system is started, and the power supply 21 is turned off. According to the PLC control system composed of the online pH electrode 16, the online temperature sensor 17, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com