Treatment method for synchronously removing total phosphorus and nickel in wastewater

A treatment method and technology for wastewater, applied in the fields of metallurgical wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of complicated operation, difficult to implement, long process, etc., to shorten the process flow, compact and efficient process, reduce The effect of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

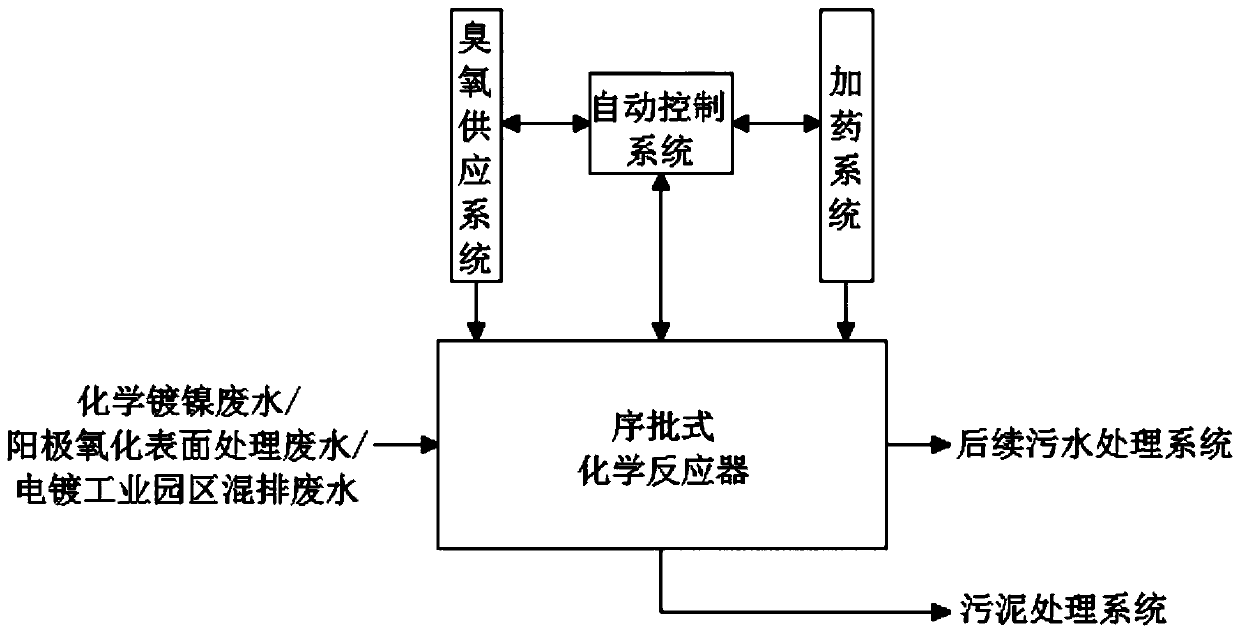

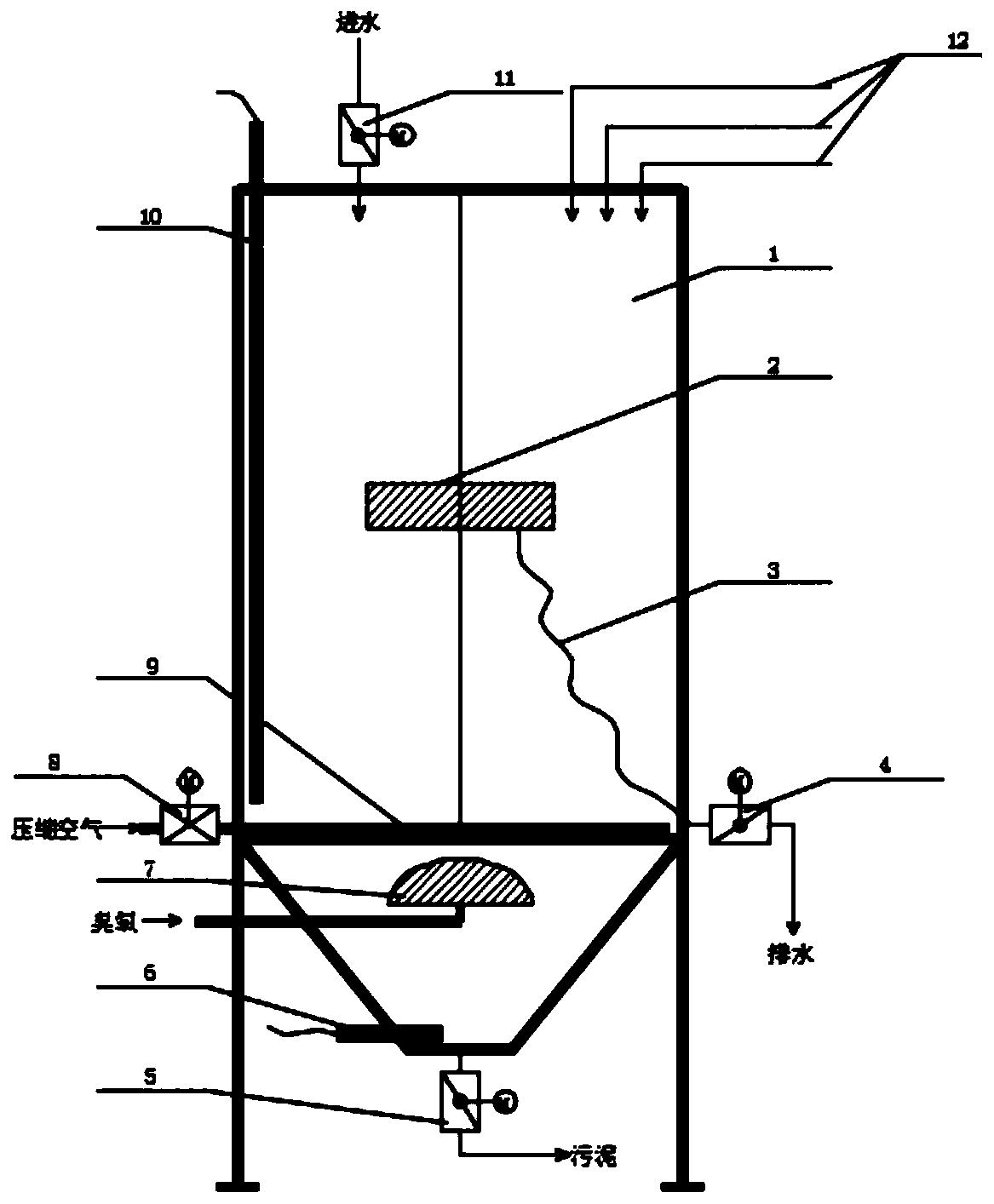

[0029] Such as figure 1 As shown, the present invention is a treatment method for synchronous removal of total phosphorus and nickel in wastewater, which mainly includes a sequencing batch chemical reactor, an ozone supply system, a dosing system and an automatic control system.

[0030] (1) The wastewater enters the sequencing batch chemical reactor, and the hypophosphite, phosphite and pyrophosphite in the wastewater are oxidized to orthophosphate by ozone, and the complexed nickel is broken at the same time, and then the pH value is adjusted by adding alkali After 11.0 to 11.5, add coagulants and coagulants to strengthen coagulation and sedimentation, the supernatant is discharged into the subsequent sewage treatment system, and the sediment is discharged into the sludge treatment system. Ozone oxidation and decompression, pH adjustment, enhanced coagulation reaction, precipitation, drainage and sludge discharge are all completed in the sequencing batch chemical reactor acc...

Embodiment 11

[0038] a. Take a printed circuit board chemical waste nickel cleaning wastewater as raw water, raw water quality total phosphorus = 87.000mg / L, nickel = 23.300mg / L;

[0039] b. The dosage of ozone is 0.100kgO 3 / t, the ozone oxidation time is 1.0h;

[0040] c. After adding NaOH to adjust the pH to 11.5, add PAC100mg / L and APAM0.5mg / L with a molecular weight of 9 million, react for 15min; let it settle for 1.0h;

[0041] d. Total phosphorus in the treated effluent = 0.090mg / L, nickel = 0.080mg / L.

Embodiment 12

[0043] a. Take an anodized surface treatment cleaning wastewater as raw water, raw water quality total phosphorus = 1.250mg / L, nickel = 26.660mg / L;

[0044] b. The dosage of ozone is 0.050kgO 3 / t, the ozone oxidation time is 1.0h;

[0045] c. Dosing Ca(OH) 2 After adjusting the pH to 11.5, add 100mg / L of PAC and 0.5mg / L of APAM with a molecular weight of 9 million, and react for 15min; let it settle for 1.0h;

[0046] d. Total phosphorus in the treated effluent = 0.110mg / L, nickel = 0.088mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com