Electrocatalytic oxidation-biochemical coupling method for treating high-salinity high-concentration organic wastewater

A technology for electrocatalytic oxidation and organic wastewater, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. The effect of electrolysis energy consumption and efficient recycling

Active Publication Date: 2019-03-26

南通寰宇博新化工环保科技有限公司

View PDF16 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Commonly used physical and chemical methods mainly include ion exchange method, membrane separation method, incineration method, evaporation method, and Fenton oxidation method, etc.; however, ion exchange method and membrane separation method are easy to cause membrane clogging, and their use is limited because of high cost; The incineration method has certain requiremen

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

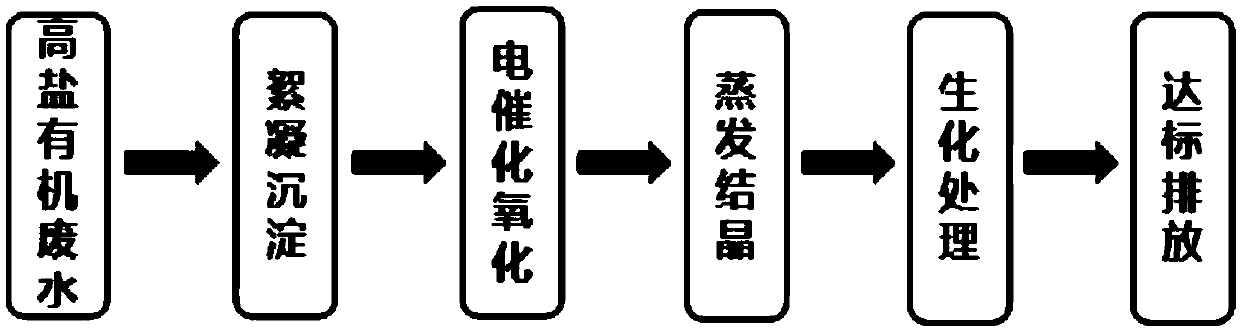

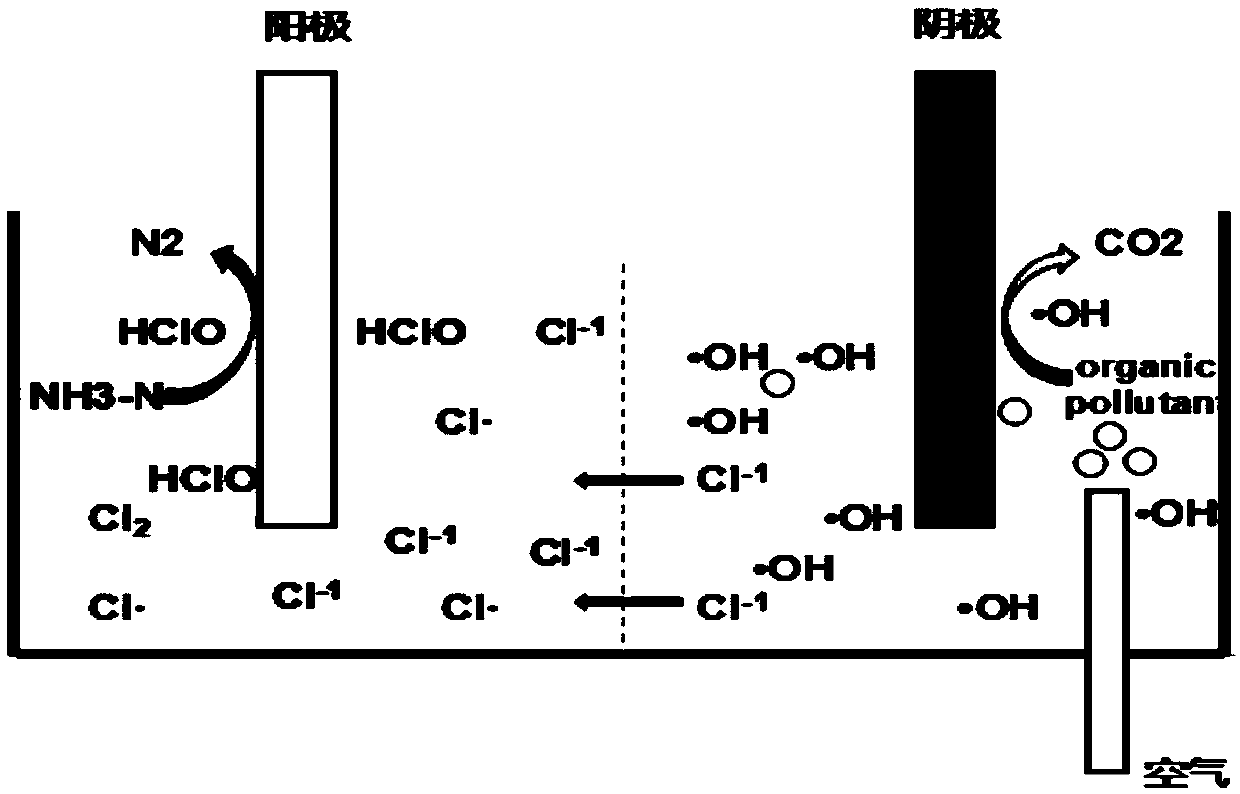

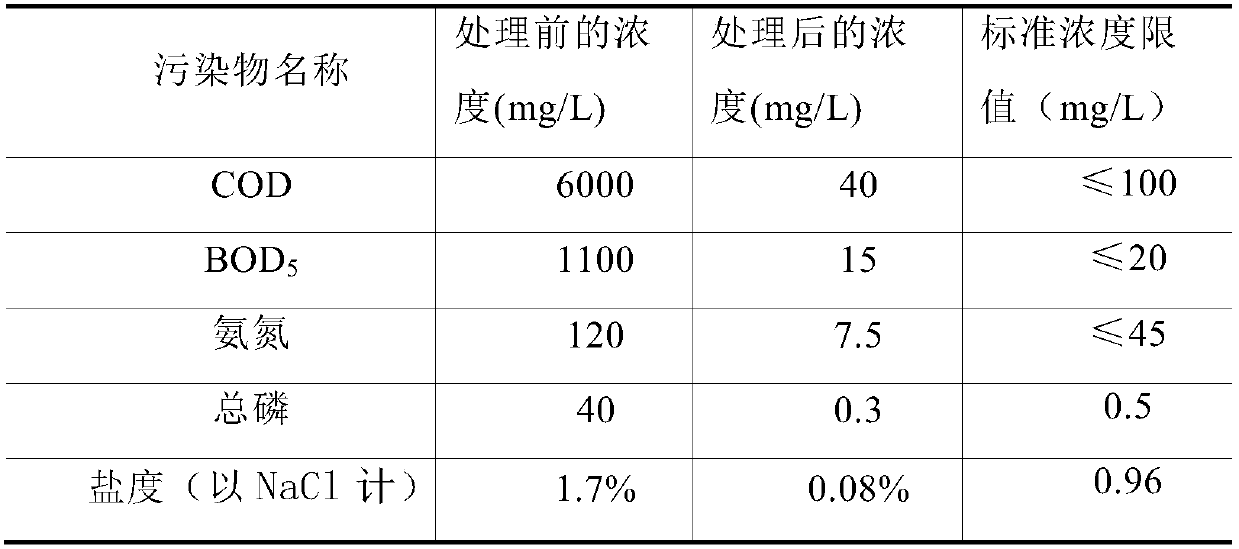

The invention discloses an electrocatalytic oxidation-biochemical coupling method for treating high-salinity high-concentration organic wastewater and relates to the technical field of sewage treatment. The method comprises the following steps: pretreating high-salinity high-concentration organic wastewater and discharging first-stage organic wastewater; treating the first-stage organic wastewaterin an electrocatalytic oxidation mode and discharging second-stage organic wastewater; biochemically treating the second-stage organic wastewater until the second-stage organic wastewater reaches a standard and is discharged. According to the method disclosed by the invention, electrocatalytic oxidation and a biochemical treatment technology are coupled, so that high-efficient treatment on the high-salinity high-concentration organic wastewater is achieved; furthermore, in an electrocatalytic oxidation process, the characteristic that the concentration of chlorine ions in the high-salinity organic wastewater is high is fully utilized, high-efficient reclamation on the chlorine irons is achieved, and the chlorine ions are activated into chlorine activity free radicals when electrified to degrade pollutants.

Description

technical field [0001] The invention relates to the technical field of sewage treatment, in particular to a method for electrocatalytic oxidation-biochemical coupling treatment of high-salt and high-concentration organic wastewater. Background technique [0002] With the development of society and economy, the demand for water resources has increased rapidly, and problems such as water resource pollution have become increasingly serious. my country's high-salt organic wastewater accounts for 5% of the total wastewater, and is still growing at a rate of 2% per year. If high-salt wastewater is discharged directly without treatment, it will destroy the ecological environment of the soil and bring greater pressure to the water environment. Although the country has issued relevant policies and regulations for water environment protection to control sewage discharge and strengthen environmental governance, the treatment effect and efficiency of high-salt wastewater are very limit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/14C02F101/30C02F103/32C02F101/38

CPCC02F9/00C02F1/048C02F1/4672C02F1/52C02F1/76C02F1/763C02F1/722C02F1/725C02F3/302C02F2101/306C02F2101/30C02F2101/38C02F2103/32

Inventor 邹建平周志刚汪月华秦元成罗胜联江训恒李飞

Owner 南通寰宇博新化工环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com