Gas lifting alternative circulation flow composite filter material filter pool

A technology of alternating cycle and composite filter material, which is applied in the direction of aerobic process treatment and sustainable biological treatment. It can solve the problems of limited application, large water flow resistance, easy deposition of carriers, etc., and achieves simple start-up and management, stable working state, The effect of high volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

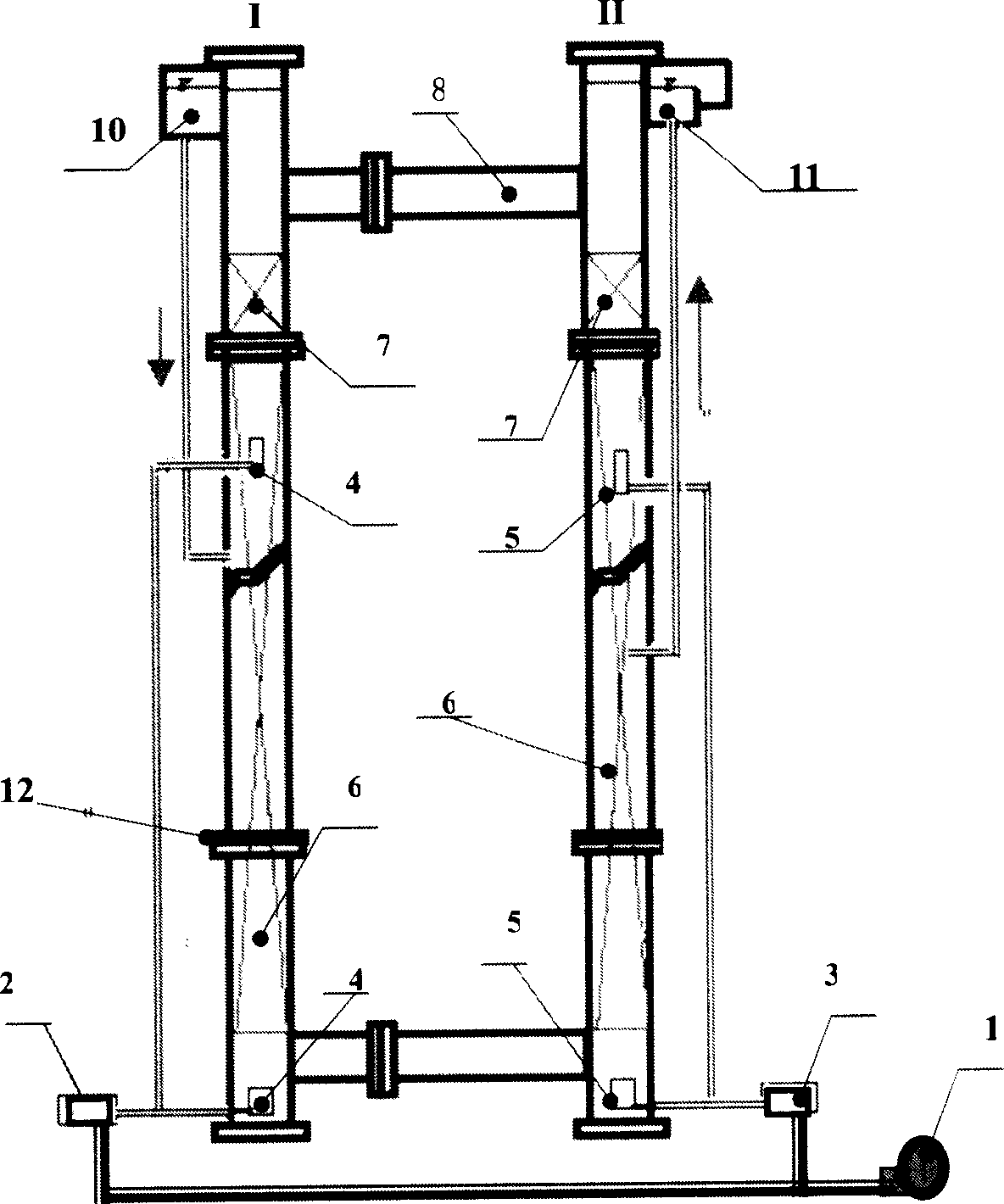

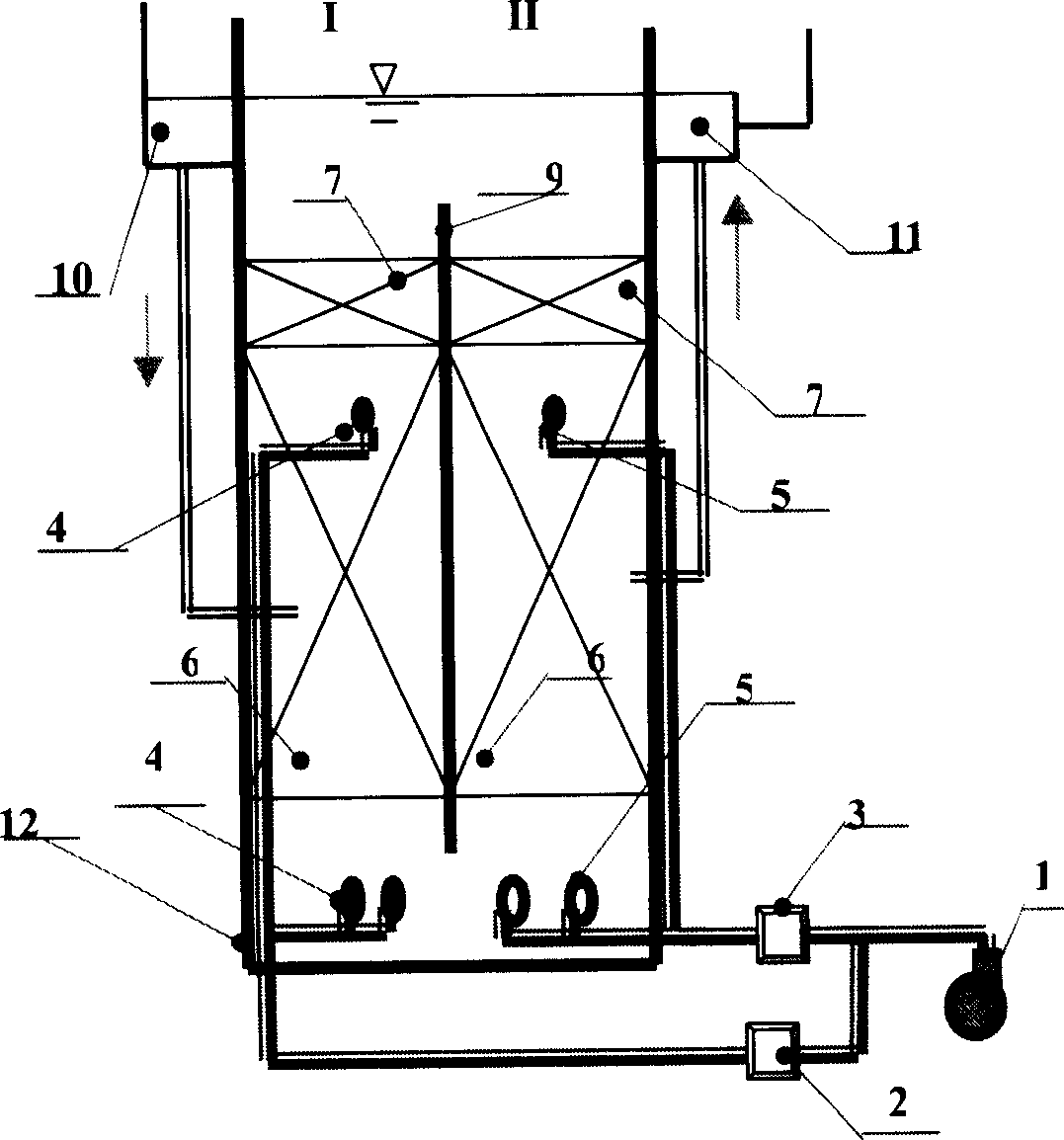

[0013] Embodiment 1: A kind of external circulation structure gas-lifting alternating circulation flow composite filter material filter, the total height of the filter tower 12 is 6.5m, the inner diameter of the empty tower is 0.75m, the hydraulic retention time is 4 hours, and the sewage treatment capacity is 700L / h. Based on the elevation of the tower bottom as 0.0m, the elevations of the inlet and outlet pipes at the opening of the tower body are 3.3 and 2.7m respectively, the diameter of the horizontal pipe 8 is 0.5m, the elevation of the centerline of the upper horizontal pipe is 5.80m, and the elevation of the centerline of the lower horizontal pipe is 0.42m ; The diameter of the granular filter material is 3-8mm, the elevation of the upper edge is 5.2m, and the floor height is 0.5m. The suspended filter material 6 is a semi-soft filler with a layer height of 3.5m and a length of each suspension cable of 1.75m. The plane direction is 1.5 times the original standard, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com