Method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater

A technology for desulfurization wastewater and ammonia nitrogen wastewater, which is applied in gaseous effluent wastewater treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., and can solve problems such as unsuitable desulfurization wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

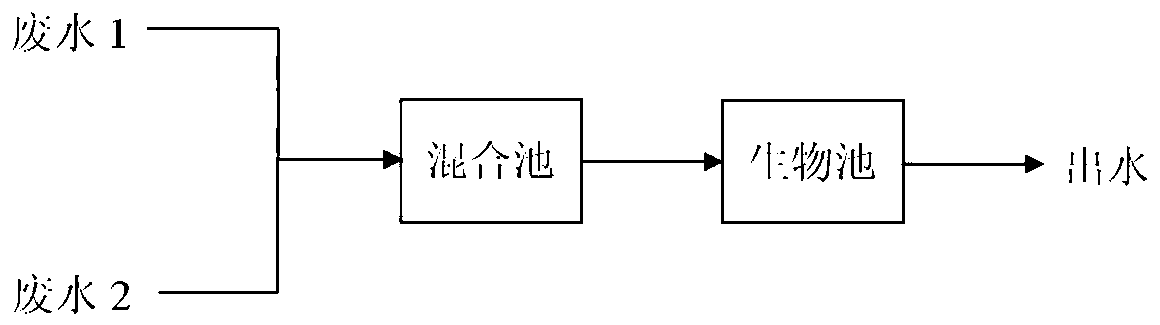

Method used

Image

Examples

Embodiment 1

[0025] A chemical fertilizer factory in Henan uses coal-fired boilers to provide steam during the production process, and correspondingly produces SO 2 Flue gas, after the flue gas is desulfurized by the wet sodium process, it produces a large amount of Na 2 SO 4 The concentration of desulfurization wastewater is about 645mg / L. The ammonia nitrogen wastewater generated during the nitrogen fertilizer production process has an ammonia nitrogen concentration of 160 mg / L. The two kinds of wastewater are confluent to a mixing tank through the sewage pump for stirring and homogenization. After the wastewater is mixed, the NH 4 + -N: SO 4 2- = 1.7:1 (molar ratio). The main process conditions controlled by the mixing tank are: pH 7.5, temperature 30°C. The activated sludge is inoculated in the biological reaction tank, and the activated sludge contains 27% Candidatus Kuenenia , 24% Anammoxo-globus sulfate and 23% of Bacillus benzoevorans population , Introduce homogeneous...

Embodiment 2

[0027] In a lead-zinc smelting enterprise, during the process of production, a large amount of medium and low concentration SO is produced due to the smelting of non-ferrous metal ores. 2 The exhaust gas, after being desulfurized by the wet sodium process, produces Na 2 SO 4 The desulfurization wastewater has a sulfate concentration of 445 mg / L; in the process of producing ammonium sulfate in its supporting nitrogen fertilizer plant, a large amount of high ammonia nitrogen wastewater is produced, with an ammonia nitrogen concentration of about 130 mg / L. The two kinds of wastewater are confluent to a mixing tank through the sewage pump for stirring and homogenization. After the wastewater is mixed, the NH 4 + : SO 4 2- = 2:1 (molar ratio). The main process conditions controlled by the mixing tank are: pH 8.5, temperature 28°C. Activated sludge is inoculated in the biological reaction tank, and the activated sludge contains 26% Candidatus Kuenenia , 24% Anammoxo-globus ...

Embodiment 3

[0029] A sewage treatment plant that receives sulfur-containing wastewater has a sulfate concentration of about 130mg / L, an ammonia nitrogen concentration of 50mg / L, and NH 4 + : SO 4 2- =2.5:1 (molar ratio). The main process conditions controlled by the reactor are: pH 7.5, temperature 30°C. Activated sludge is inoculated in the biological reaction tank, and the activated sludge contains 24%Candidatus Kuenenia , 21% of Anammoxo-globus sulfate and 20% of Bacillus benzoevorans population , The simulated wastewater was introduced into the reactor, and after starting the bioreactor, the hydraulic retention time was controlled to be 8h, and the concentration of activated sludge was 8g / L. After water quality monitoring and analysis, the concentration of ammonia nitrogen in the effluent water is 5 mg / L, the concentration of sulfate is 30 mg / L, and the removal rates of ammonia nitrogen and sulfate are 90% and 77%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com