Bifunctional group MOFs material and preparation method and application thereof

A bifunctional group, tertiary amine group technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the structural damage of ZIF-8 adsorbent, heavy metal cations and harmful Anion removal and regeneration does not have problems such as evaluation research and stability degradation, so as to improve the efficiency and success rate of synthesis and preparation, solve the secondary pollution of regenerant, and the preparation process is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

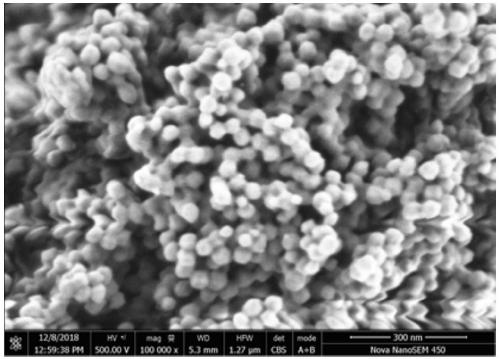

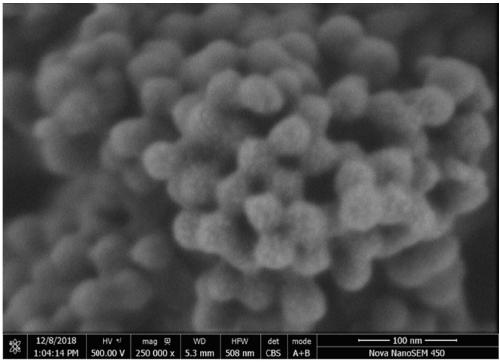

[0044] First, the preparation method of carboxyl-functionalized ZIF-8 (ZIF-8-COOH) is as follows: Weigh 2.933 g of zinc nitrate hexahydrate and 6.489 g of 2-methyl-1H-imidazole-4,5-dicarboxylic acid, Then add 200ml of methanol solution and stir vigorously for 2h, then centrifuge and wash 3 times with methanol and deionized water respectively, then vacuum dry at 40°C for 24h to obtain a white powder of ZIF-8-COOH functionalized in situ with carboxyl group (such as figure 1 shown), with carboxyl functional groups.

[0045] The preparation steps of the bifunctional group MOFs material in this example are as follows:

[0046] Step 1: Grind the ZIF-8-COOH material. After the grinding is completed, add 0.5g of ZIF-8-COOH and 0.25g of DMAEA into 10ml of ethanol solution and stir evenly (the mass of ZIF-8-COOH and DMAEA The ratio is 2:1), then slowly add 0.01g of AIBN (the amount of AIBN accounts for 1.3% of the total mass fraction of MOFs and DMAEA), stir at 50°C for 12h, and obtain...

Embodiment 2

[0057] The preparation steps of ZIF-8-COOH in this example are the same as those in Example 1.

[0058] In this embodiment, the bifunctional group MOFs material (ZIF-8-COOH / R 2 N) The preparation steps are as follows:

[0059] Step 1: Grind the ZIF-8-COOH material. After the grinding is completed, add 0.5g ZIF-8-COOH and 1gDMVBA to 20ml of ethanol solution and stir evenly (the mass ratio of ZIF-8-COOH to DMVBA is 2: 4), then slowly add 0.15g AIBN (the amount of AIBN accounts for 10% of the total mass fraction of MOFs and DMVBA), stir at 55°C for 12h, and obtain precursor A after the ethanol is completely volatilized;

[0060] Step 2: Put the precursor A in an oven at 65°C for 12 hours to dry, and obtain the modified bifunctional group MOFs material after heating.

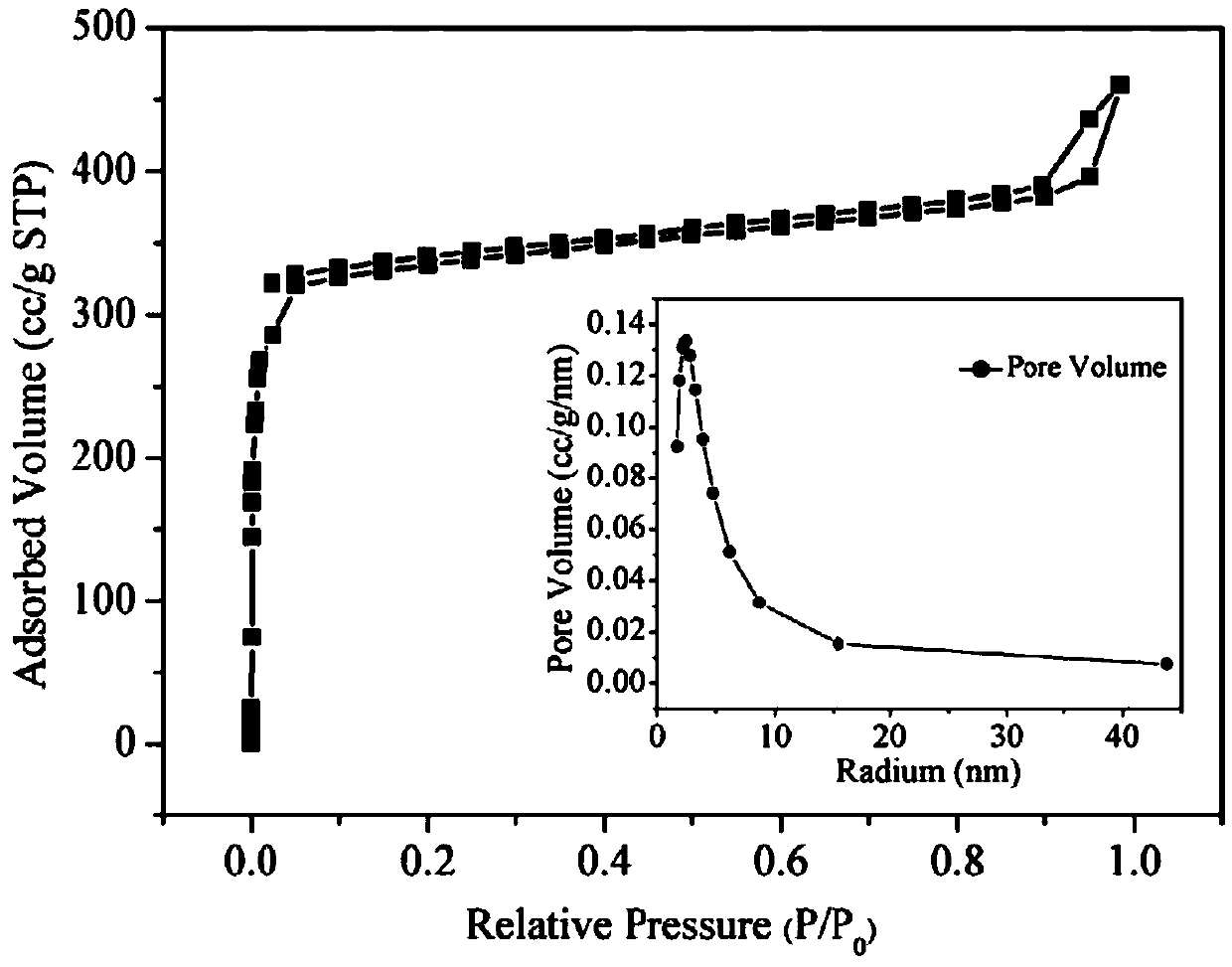

[0061] The bifunctional group MOFs material prepared in this example (ZIF-8-COOH / R 2 N), the specific surface area is 800m 2 / g; mesopore average pore diameter is 0.95nm; pore volume is 0.45cm 3 / g; the molar r...

Embodiment 3

[0068] The preparation steps of ZIF-8-COOH in this example are the same as those in Example 1.

[0069] In this embodiment, the bifunctional group MOFs material (ZIF-8-COOH / R 2 N) The preparation steps are as follows:

[0070] Step 1: Grind the ZIF-8-COOH material. After the grinding is completed, add 0.5g of ZIF-8-COOH and 0.5g of DMAEA into 15ml of ethanol solution and stir evenly (the mass of ZIF-8-COOH and DMAEA The ratio is 1:1), then slowly add 0.05g of AIBN (the amount of AIBN accounts for 5% of the total mass fraction of MOFs and DMAEA), stir at 70°C for 12h, and obtain the precursor A after the ethanol is completely volatilized;

[0071] Step 2: Put the precursor A in an oven at 70°C to dry for 6 hours, and obtain the modified bifunctional group MOFs material (ZIF-8-COOH / R 2 N).

[0072] The bifunctional group MOFs material prepared in this example (ZIF-8-COOH / R 2 N), the specific surface area is 900m 2 / g; mesopore average pore diameter is 1.05nm; pore volume is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Mesopore average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com