Dynamic allocation logistics conveying auxiliary device

An auxiliary device and dynamic distribution technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of reduced service life of the conveyor belt, uneven distribution, easily damaged materials, etc., to achieve balanced flow of object transmission, avoid rigid contact, and prolong the life of the conveyor belt. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

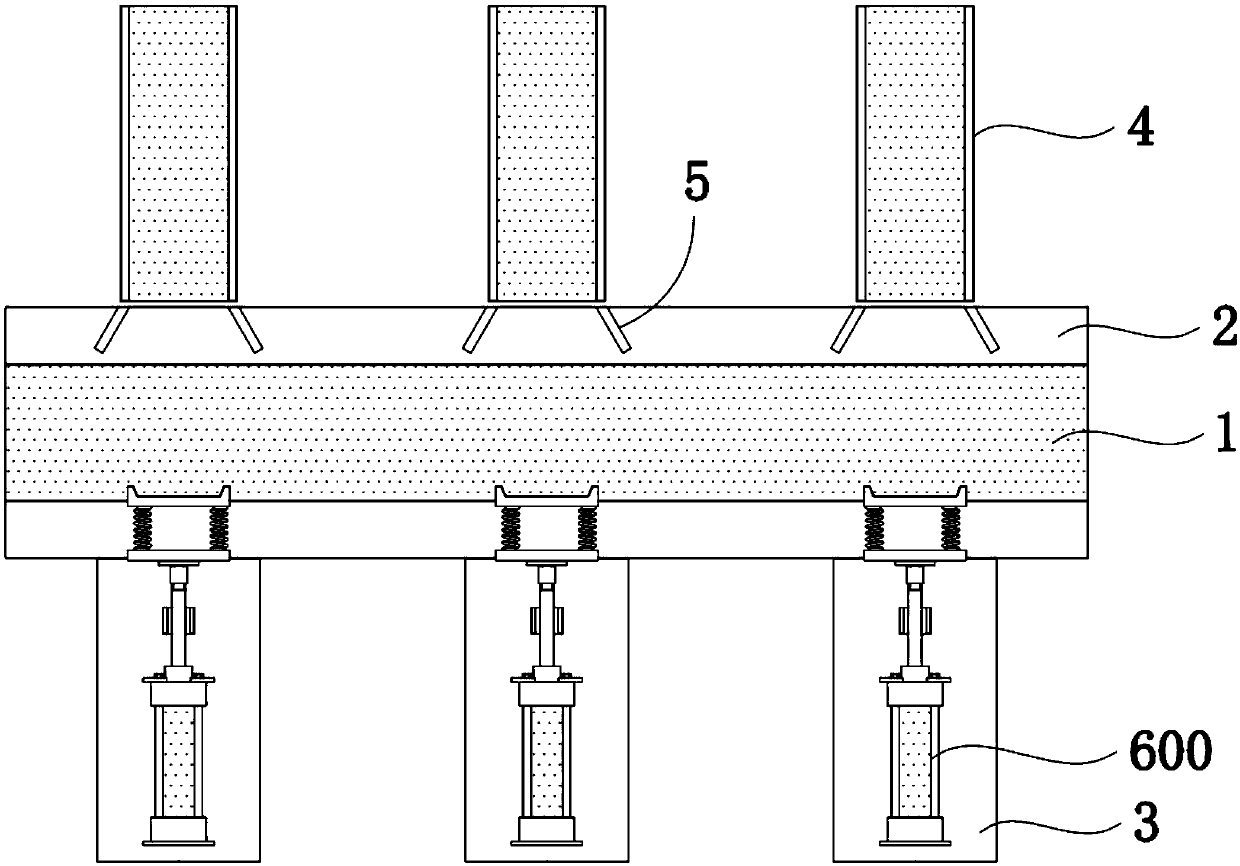

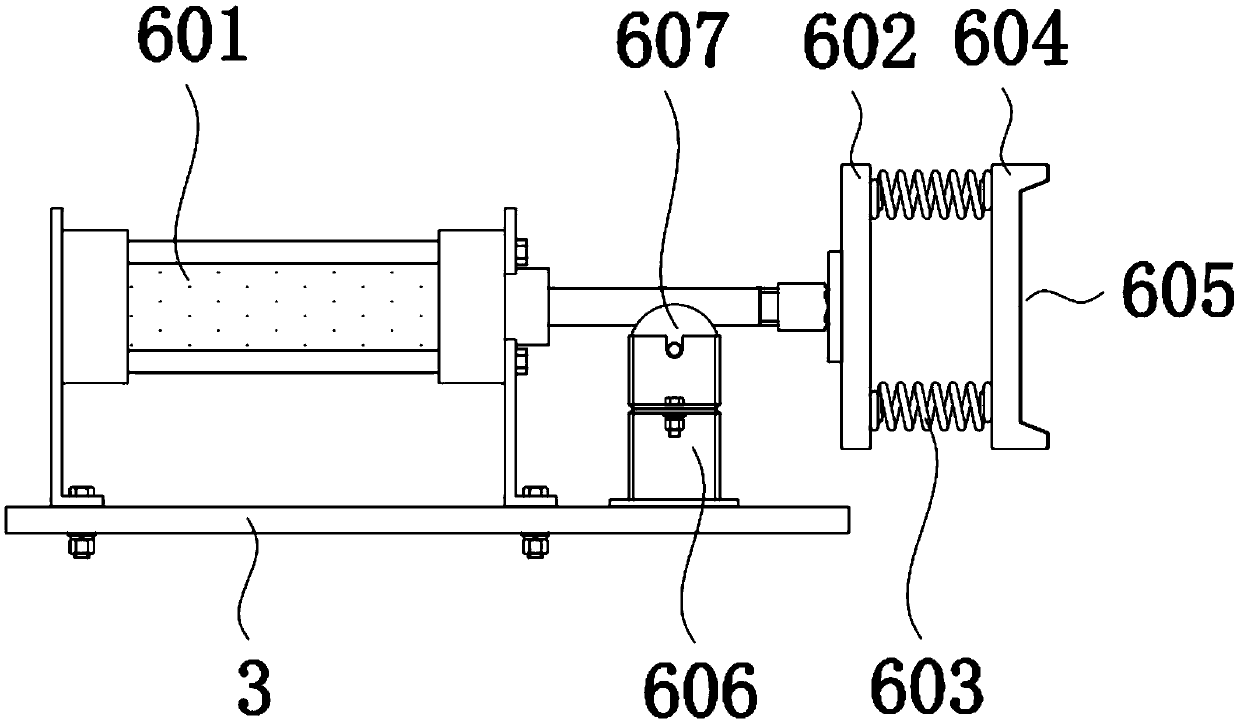

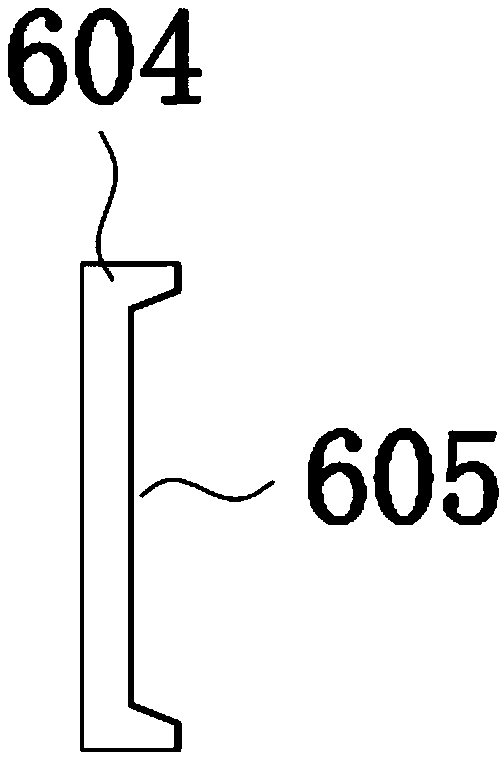

[0020] First implementation: see Figure 1-3 , the present invention provides a technical solution: an auxiliary device for logistics transportation, including a main conveyor belt 1 and several auxiliary conveyor belts 4, one side of the main conveyor belt 1 is provided with an inclined surface 2, and the auxiliary conveyor belt 4 is set at the bottom of the slope 2, and the slope 2 is provided with a material stopper 5 corresponding to the auxiliary conveyor belt 4. The inclination angle of the slope 2 can be designed according to the actual situation, so that the material can slide along the slope 2 to the auxiliary conveyor belt Conveyor belt 4 gets final product, and the other side of described main conveyer belt 1 is provided with several main support platforms 3, and described main support platform 3 is installed with height detection and material pushing integrated structure 600, and described height detection and material pushing The integrated structure 600 and the a...

no. 2 approach

[0027]The second embodiment: as shown in claim 1, a dynamic allocation of logistics delivery auxiliary device, including a main conveyor belt 1 and three auxiliary conveyor belts 4 and a dynamic distribution control system, one side of the main conveyor belt 1 is set There is an inclined surface 2, the auxiliary conveyor belt 4 is arranged at the bottom of the inclined surface 2, and the inclined surface 2 is provided with a material blocking plate 5 corresponding to the auxiliary conveyor belt 4, and the other side of the main conveyor belt 1 Three main support platforms 3 are provided, and a height detection and material pushing integrated structure 600 is installed on the main supporting platform 3. The height detection and material pushing integrated structure 600 is correspondingly arranged with the auxiliary conveyor belt 4. The material integrated structure 600 includes a cylinder 601, the output end of the cylinder 601, that is, the cylinder piston rod is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com