Solidification/forming/heat treatment integrated preparation method of carbon fiber metal laminate curved surface piece

A fiber metal laminate and metal laminate technology, which is applied in metal laminate products, chemical instruments and methods, lamination and other directions, can solve the problems of easy failure of components, instability and wrinkling, low shear strength, etc. The effect of good surface quality, avoiding rigid contact and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

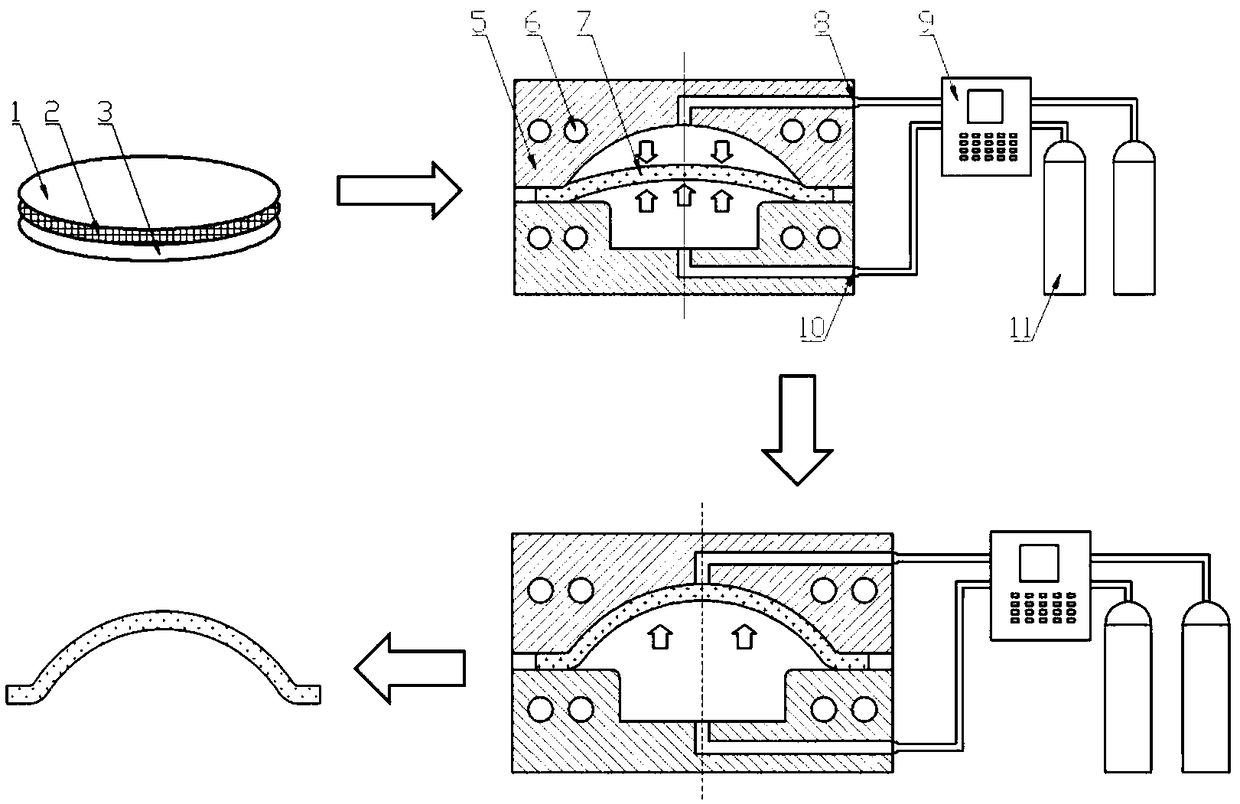

[0023] The invention provides a solidification / forming / heat treatment integrated preparation method of a carbon fiber metal laminate curved part, which comprises the following steps:

[0024] (1) The carbon fiber resin composite material and the aluminum alloy plate are alternately laminated to obtain a laminated fiber metal laminate; the bottom layer and the top layer of the laminated fiber metal laminate are both aluminum alloy plates;

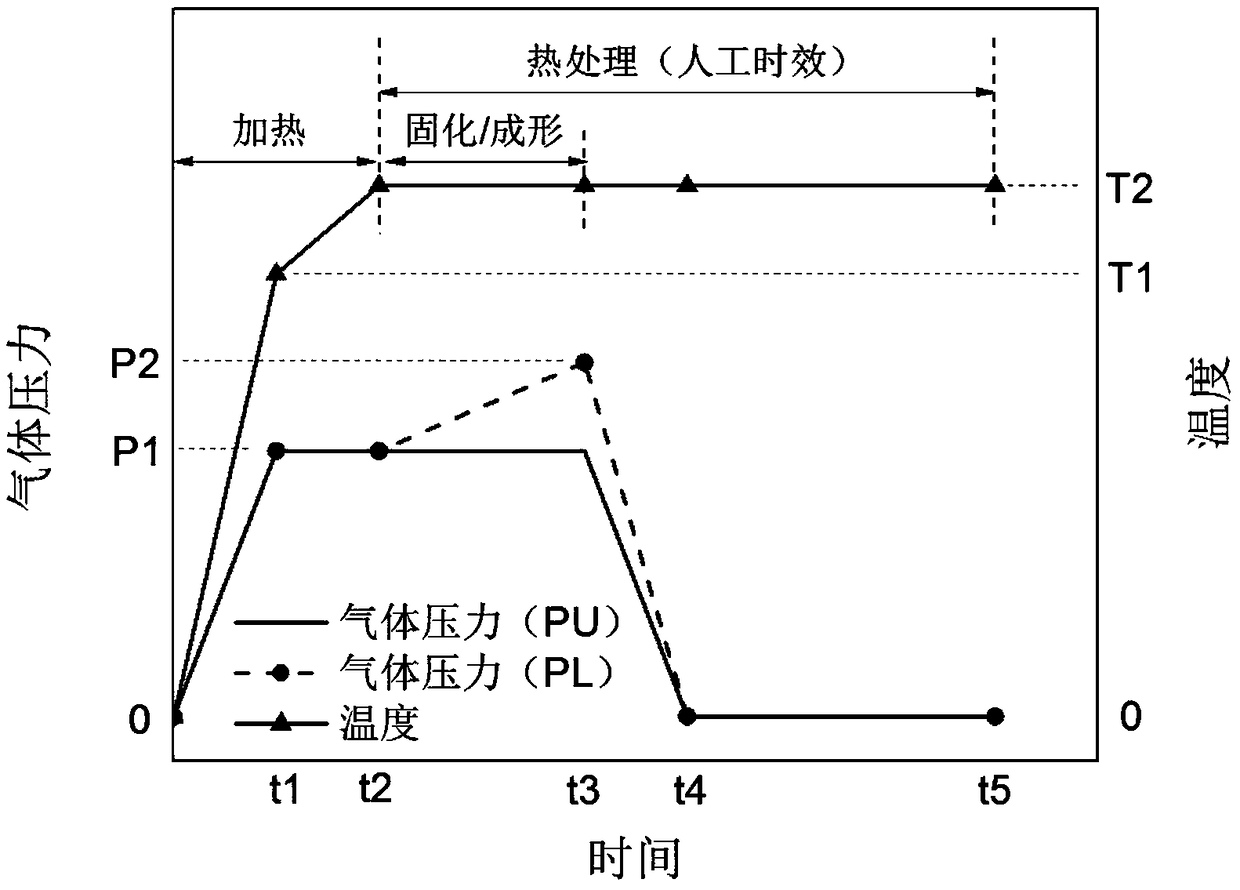

[0025] (2) Raise the temperature of the laminated fiber metal laminate obtained in the step (1) to 80-100°C, and at the same time subject the laminated fiber metal laminate to one level of double-sided pressing; the direction of the double-sided pressing is non-curing The normal direction of the fiber metal laminate and the lower surface; the pressure applied to the upper surface and the lower surface is equal, 15-20 MPa, to obtain a softened fiber metal laminate;

[0026] (3) Heating the softened fiber metal laminate obtained in step (2) to 120-14...

Embodiment 1

[0063] The solid solution 2219 aluminum alloy plate (thickness 0.8mm, diameter 180mm) and carbon fiber composite material (thickness 0.2mm, diameter 175mm) are alternately stacked and placed, from bottom to top: aluminum alloy plate, carbon fiber composite material, aluminum alloy plate , Lay an adhesive film between the aluminum alloy plate and the carbon fiber composite material to obtain a non-cured fiber metal laminate (total thickness 1.8mm, diameter 180mm, thickness-to-diameter ratio 0.01). The carbon fiber composite material is carbon fiber impregnated with resin, wherein the carbon fiber is a T300 orthogonal woven cloth, and the resin material is a bisphenol A epoxy resin.

[0064] Spray the mold release agent on the mold, place the non-cured fiber metal laminate in the mold, close the mold and apply a blank holder force, the blank holder force value is 20t;

[0065] The mold is heated to 85°C by heating resistor, and the upper and lower inlet pipes are fed with high-pressu...

Embodiment 2

[0071] The solid solution 2219 aluminum alloy plate (thickness 0.8mm, diameter 180mm) and carbon fiber composite material (thickness 0.4mm, diameter 175mm) are alternately stacked, from bottom to top: aluminum alloy plate, carbon fiber composite material, aluminum alloy plate , Carbon fiber composite material, aluminum alloy plate, an adhesive film is placed between the aluminum alloy plate and the carbon fiber composite material to obtain a non-cured fiber metal laminate (total thickness 3.8mm, diameter 180mm, thickness to diameter ratio 0.02). The carbon fiber composite material is carbon fiber impregnated with resin, wherein the carbon fiber is a T500 orthogonal woven cloth, and the resin material is an amino epoxy resin.

[0072] Spray the mold release agent on the mold, and place the non-cured fiber metal laminate in the mold, close the mold and apply a blank holder force, the blank holder force value is 40t;

[0073] The mold is heated to 90°C by heating resistance, and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com