Self-adaptive grinding tool for vertical crankshaft

A self-adaptive, crankshaft technology, applied in grinding machines, manufacturing tools, grinding racks, etc., can solve the problems of unable to guarantee the grinding amount of the crankshaft surface, ignoring the influence of the crankshaft force, and frequently adjusting the displacement, so as to prevent rigid contact, Effect of reducing axial force and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

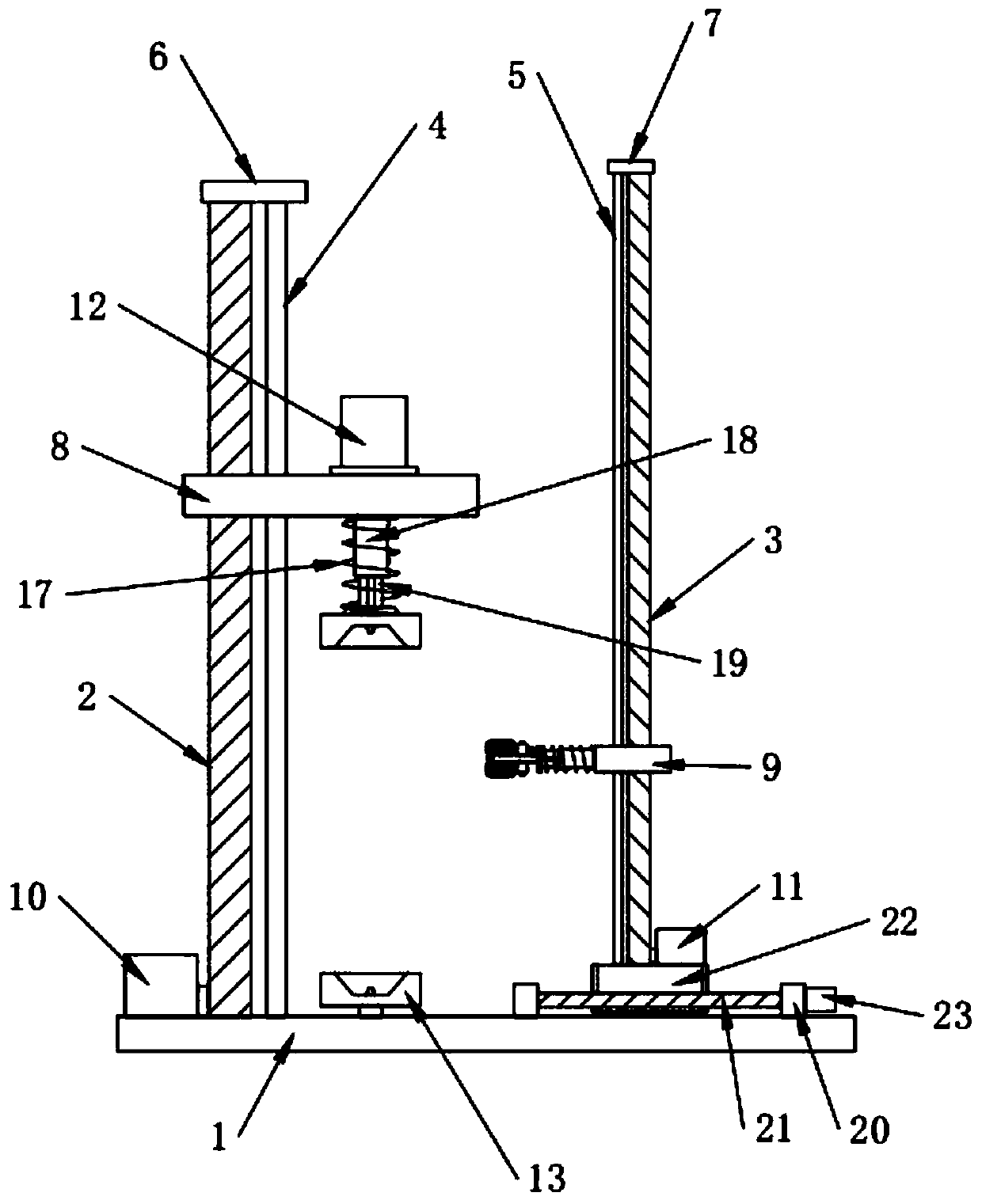

[0051] Such as Figure 1 to Figure 5 As shown, an adaptive grinding tool for a vertical crankshaft includes a positioning device for vertically clamping the crankshaft and a grinding device on one side thereof for adapting to the profile of the crankshaft.

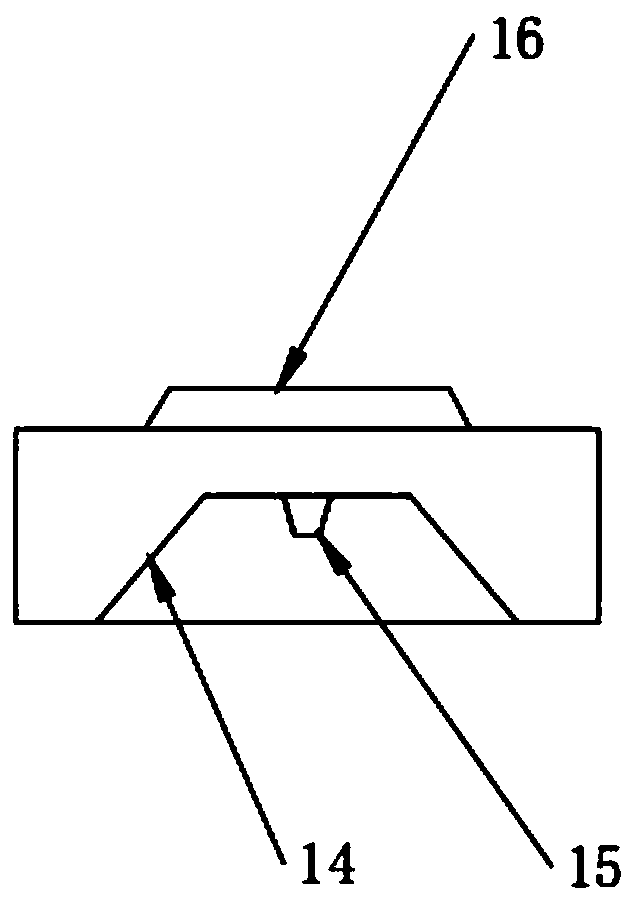

[0052] The positioning device is provided with a fixing mechanism for centering the crankshaft.

[0053] The positioning device is also provided with a buffer mechanism for buffering and clamping the crankshaft.

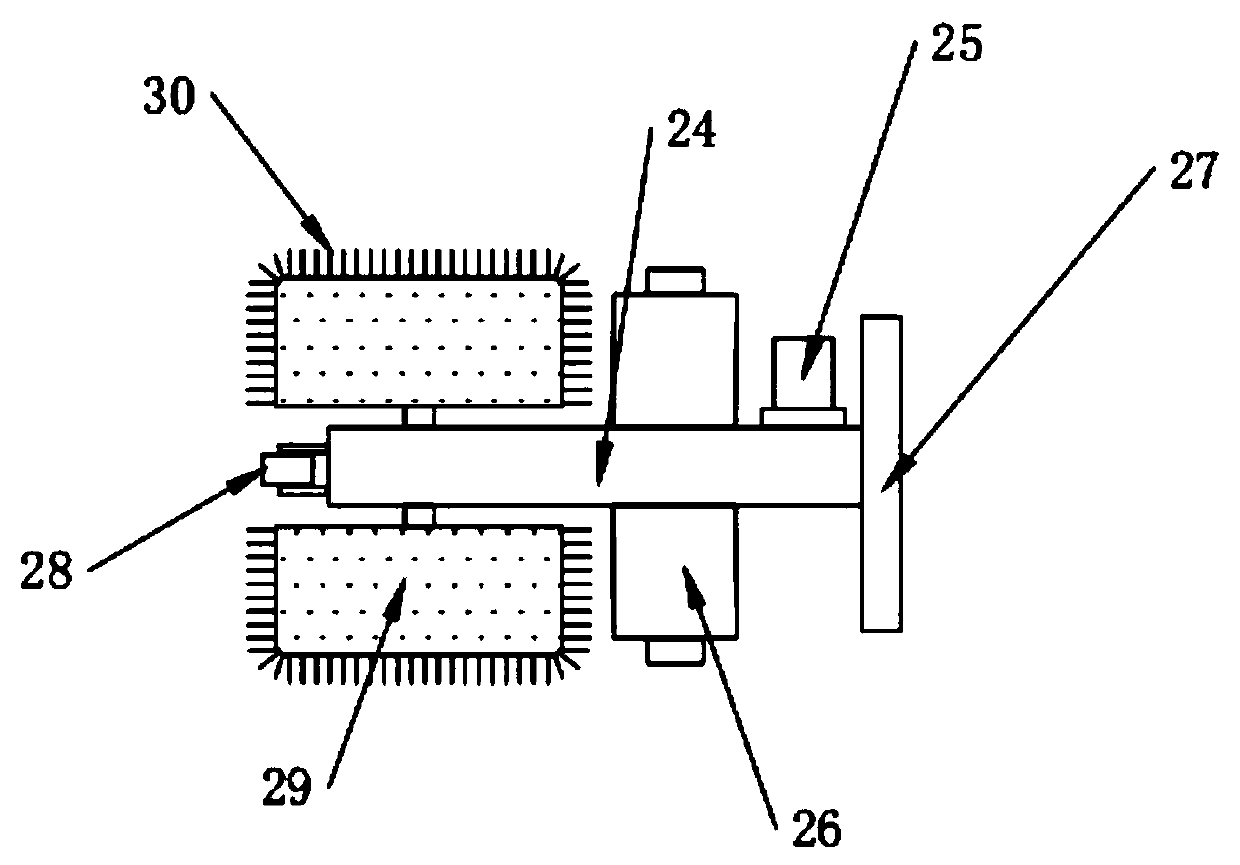

[0054] The grinding device includes a grinding mechanism that performs reciprocating self-adaptive motion along the horizontal direction.

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com