Large-diameter motor stator structure and mounting method thereof

A technology of motor stator and installation method, applied in electromechanical devices, manufacturing motor generators, magnetic circuit shape/style/structure, etc., can solve the problems of low utilization rate of enameled wire winding, easy damage of coil insulation layer, inconvenient coil, etc. , to achieve the effect of convenient winding, high slot full rate and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

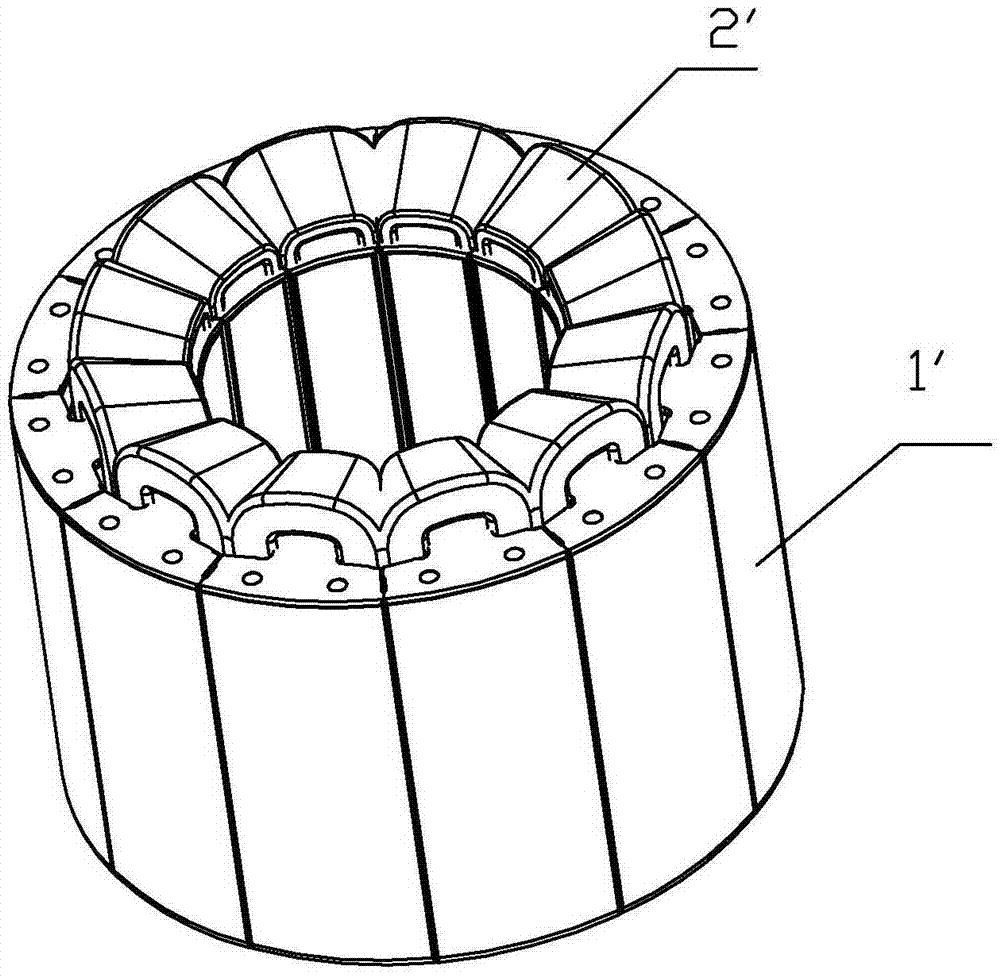

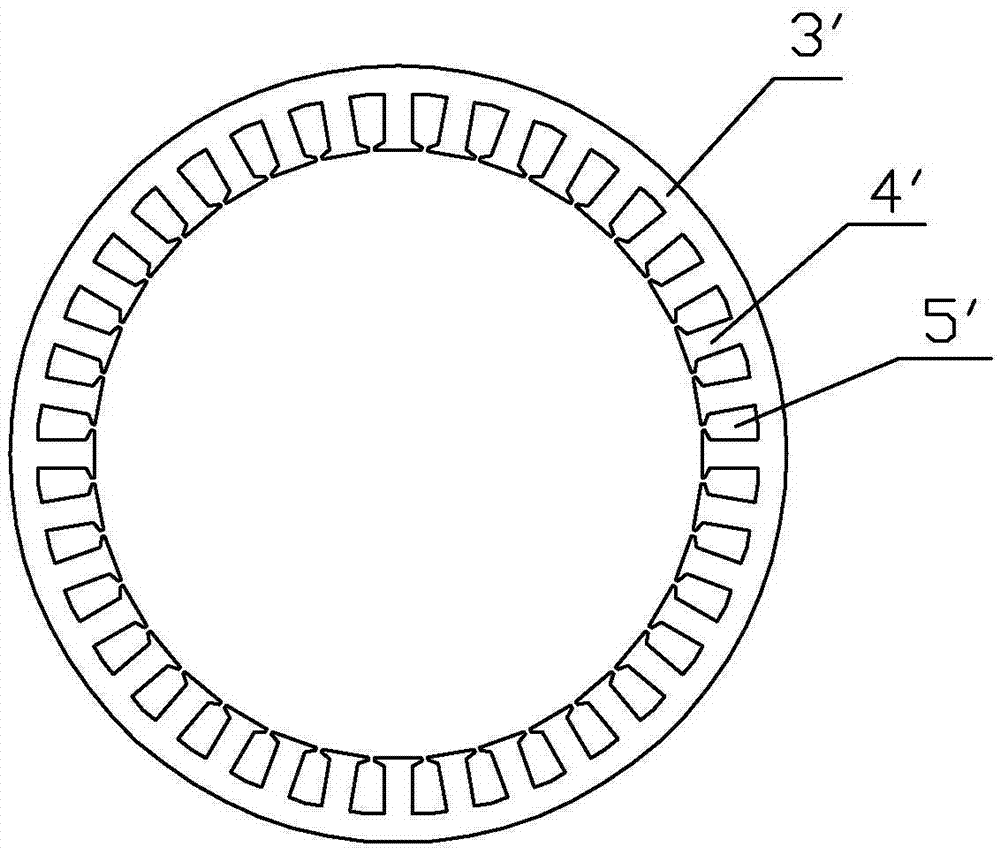

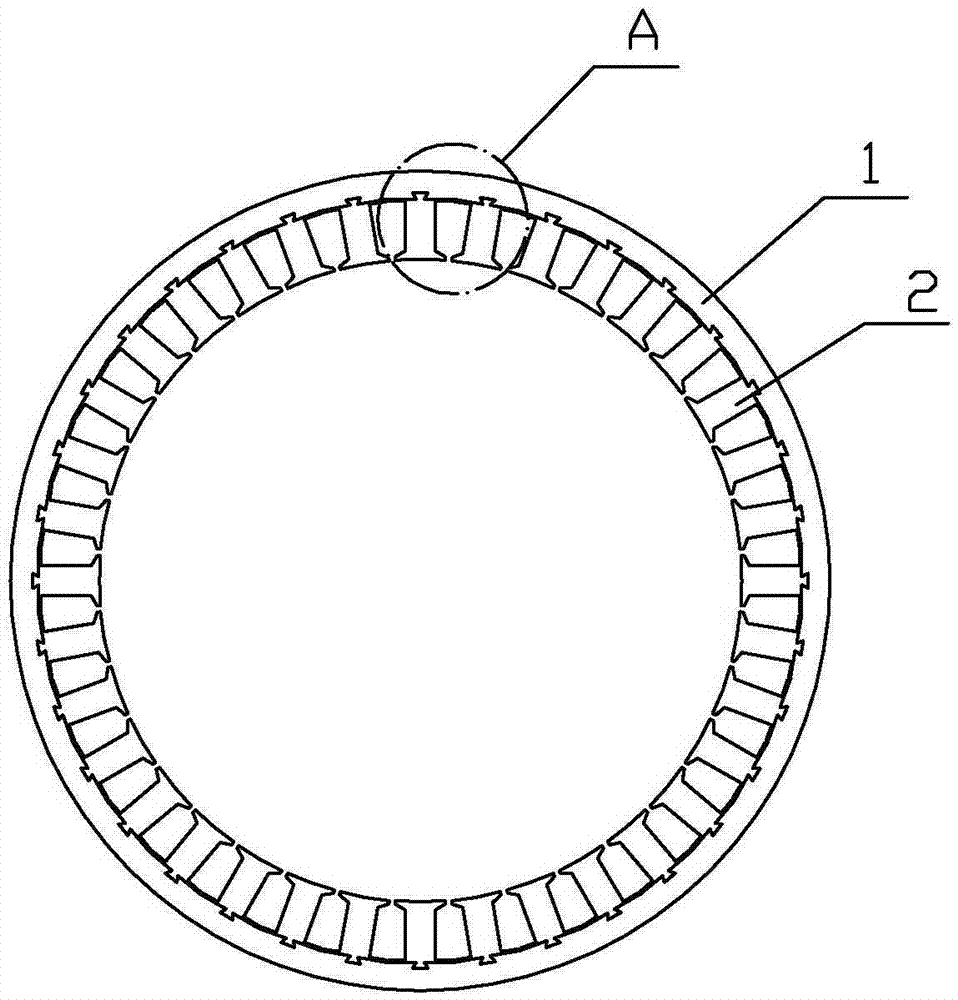

[0024] Embodiment: the large-diameter motor stator structure of the present embodiment, such as image 3 , Figure 4 As shown, it includes a stator core and an enameled wire winding 8, and the stator core includes a yoke body 1 and a plurality of teeth 2 connected to the yoke body 1, such as Figure 5 As shown, the yoke body 1 is in the shape of a tube, and the inner surface of the yoke body 1 has a plurality of slots 3 uniformly distributed along the circumference of the yoke body. The tooth body and the yoke body are two separate and discrete parts. There is a card head 4 matching the card slot 3. In this embodiment, the card slot 3 is a dovetail groove, and the card head 4 is a dovetail tenon head. The dovetail groove extends along the length of the yoke body 1, and the dovetail tenon head extends along the length of the tooth body 2. The connection between the tooth body 2 and the yoke body 1 is realized by embedding the dovetail tenon into the dovetail groove. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com