Static load detection equipment for concrete beam

A static load detection, concrete beam technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as mistakes, and achieve the effect of improving accuracy, convenient vertical adjustment, and not easy to make errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

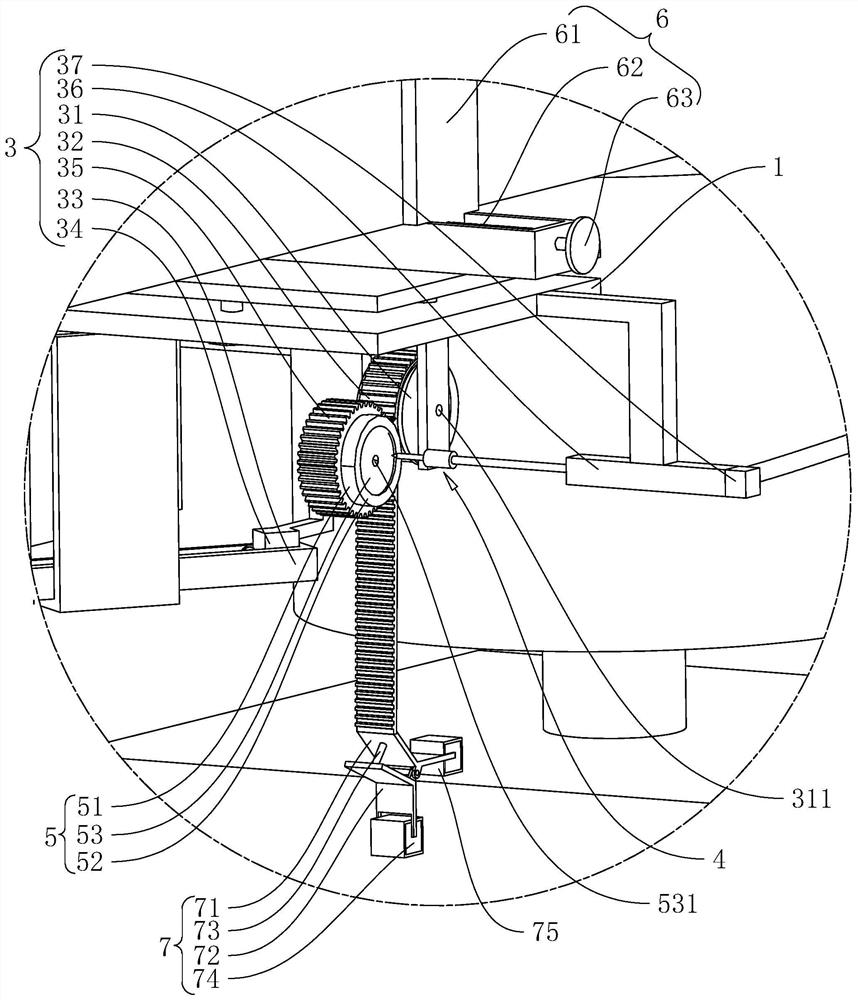

[0039] The following is attached Figure 2-7 The application is described in further detail.

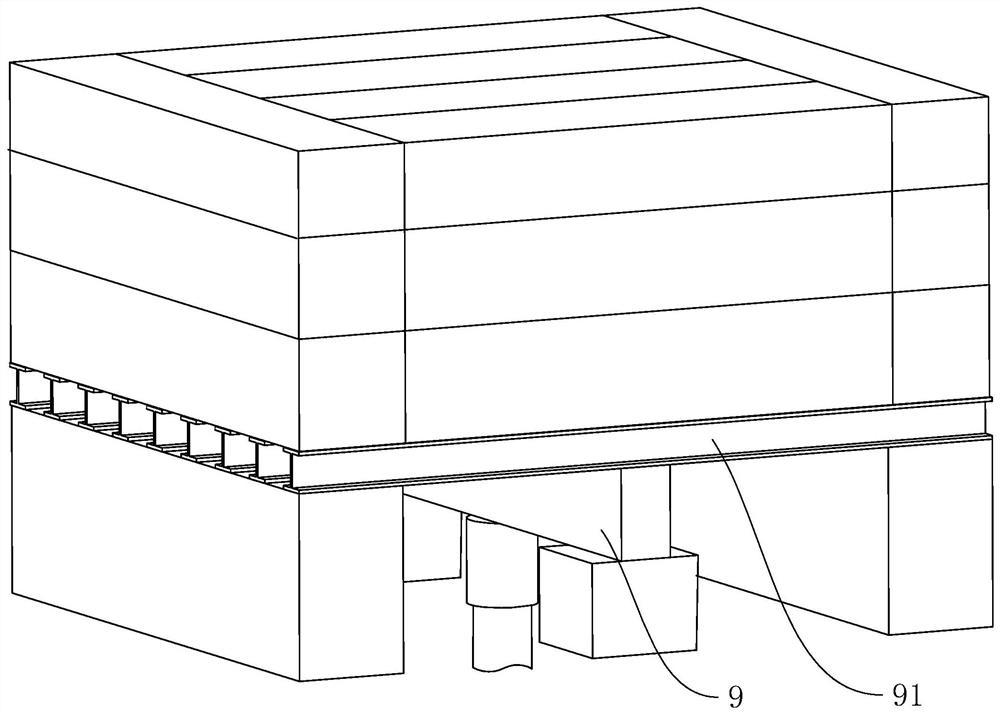

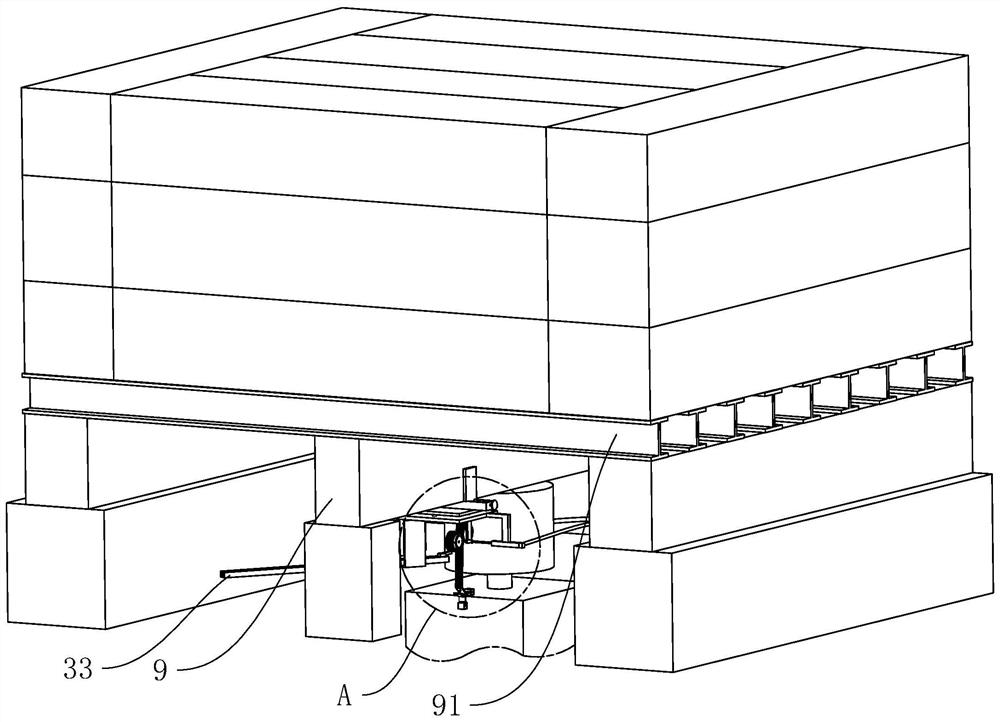

[0040] When carrying out the static test, at first a hydraulic jack is placed on the top wall of the test pile, and then a main beam 9 will be horizontally erected through the concrete block directly above the jack, and the upper end of the jack is fitted against the bottom wall of the main beam 9, Then eight secondary beams 91 are erected above the main beam 9, and the eight secondary beams 91 are parallel to each other and are all attached to the top wall of the main beam 9. On the top wall of the secondary beam 91, a certain number of concrete counterweights are stacked to complete the process. Counterweight, then connect an oil pump to the jack, start the oil pump to drive the jack to work, and the jack applies pressure to the test pile step by step for static test.

[0041] The embodiment of the present application discloses a static load testing device for concrete beams, refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com