Disposable paper tableware production process

A production process, one-off technology, applied in the direction of machining/deformation, etc., can solve the problems of protruding linear creases on its surface, and achieve the effects of comfortable use, high aesthetics, and low cost of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

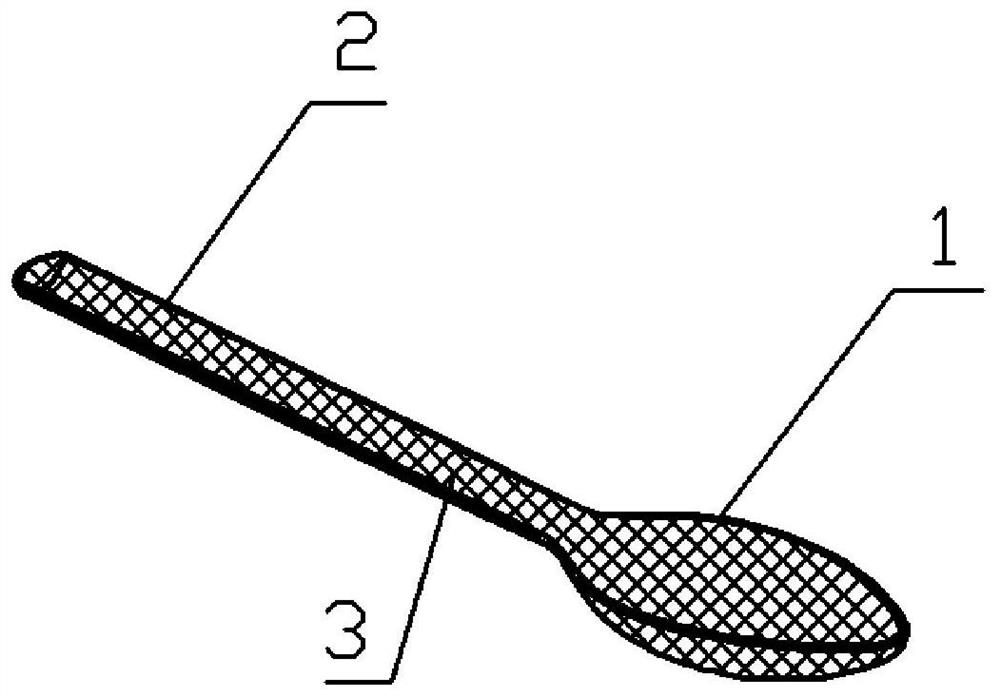

Image

Examples

Embodiment 1

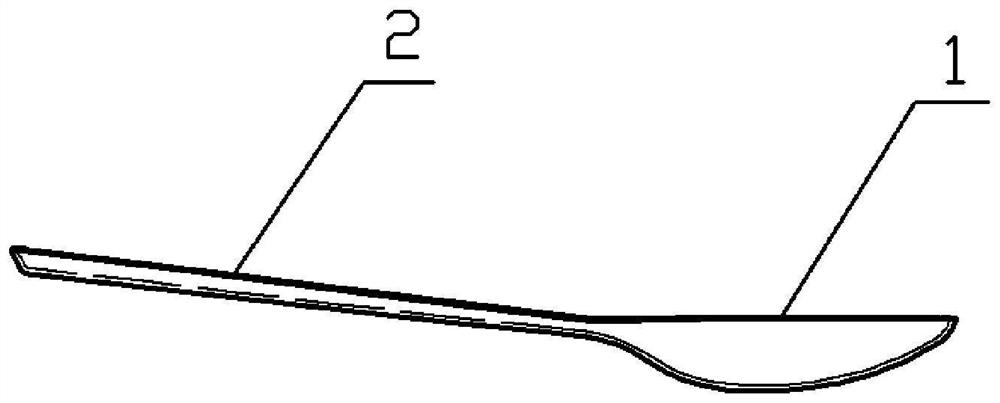

[0037] A production process of disposable paper spoons,

[0038] S1 paper feeding (feeding), the paper thickness is 1mm.

[0039] S2 cleaning and sterilization.

[0040] S3

[0041] a) Put the paper blank into the forming space of the stamping die of the spoon, wherein the corresponding part of the stamping die and the spoon holding part is the forming surface of the holding part, and the corresponding part of the stamping die and the handle part of the spoon is the forming surface of the holding part (using The upper and lower molds, the molding surface is the upper and lower inner cavity surfaces), the cavity surrounded by the forming surface of the receiving part is concave (corresponding to the convex surface of the upper cavity, and the concave surface of the lower cavity), the cavity surrounded by the forming surface of the handle part It is curved (corresponding to the convex surface of the upper chamber and the depression of the lower chamber surface), embossed protr...

Embodiment 2

[0045] The difference between Embodiment 2, Embodiment 3, Embodiment 4, Embodiment 5 and Embodiment 1 lies in the parameters of embossing protrusions. The relevant parameters are shown in Table 1.

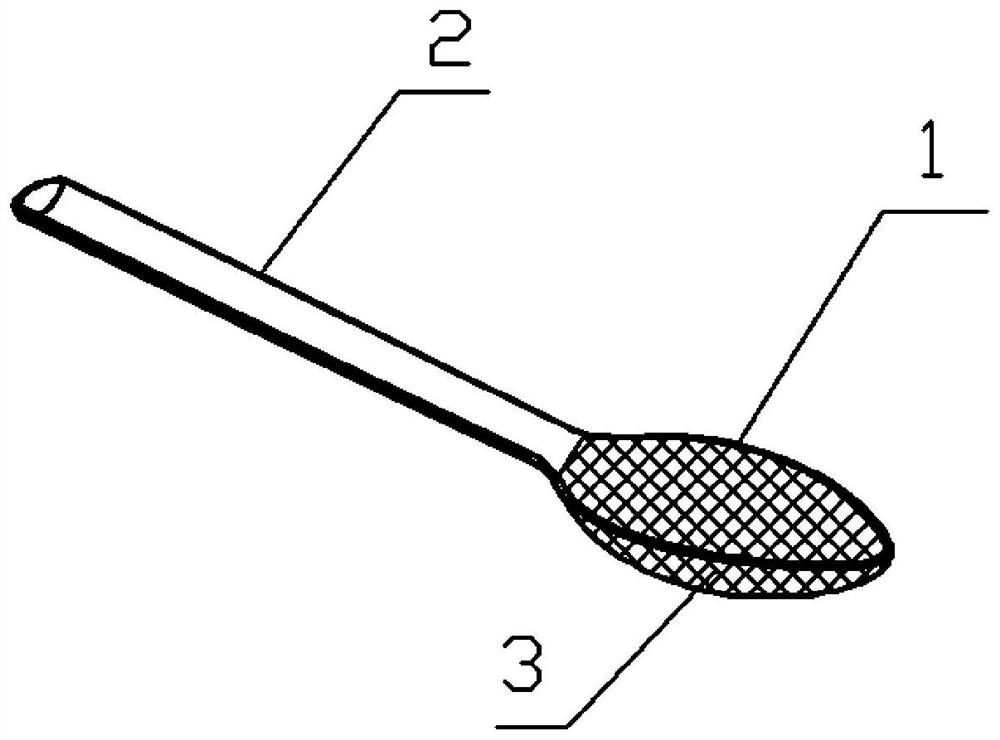

Embodiment 6

[0047] like figure 2 The difference between the illustrated embodiment 6 and the embodiment 5 lies in that only several embossed protrusions are distributed on the forming surface of the receiving portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com