Patents

Literature

66results about How to "Quickly put into production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

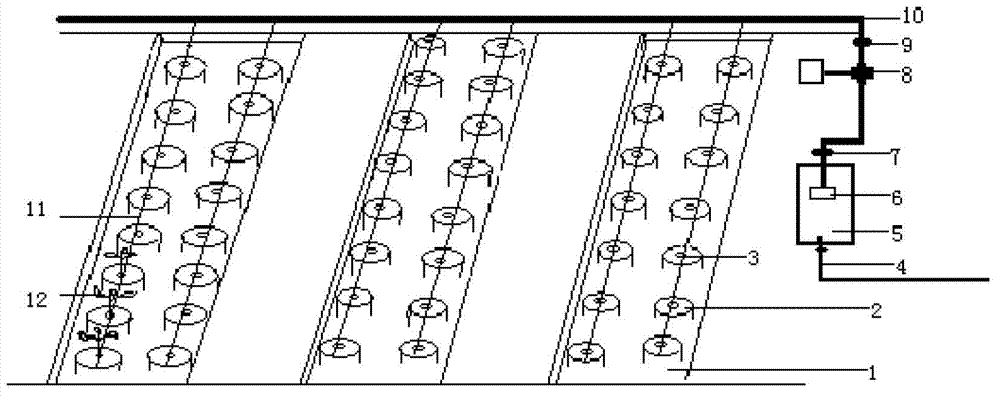

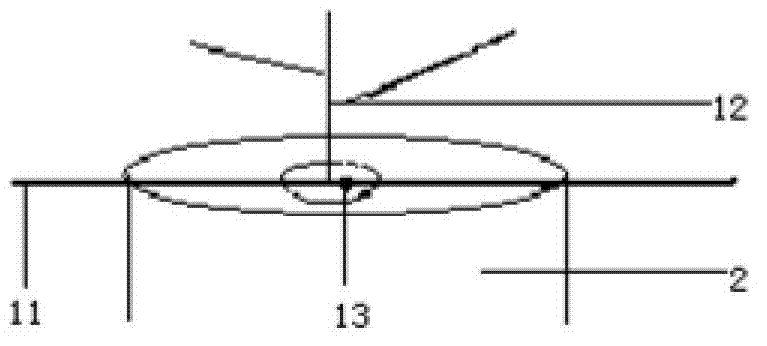

Bag culture system for large-scale production of solanaceous vegetables

InactiveCN102783402AIncrease productionImprove qualityAgriculture gas emission reductionCultivating equipmentsDiseaseDrip irrigation

A bag culture system for large-scale production of solanaceous vegetables comprises a plurality of culture troughs, a plurality of culture bags, a water inlet pipe, a reservoir, a water pump, a fertilizing device, a filter, a drip irrigation main pipe, a plurality of drip irrigation branch pipes and a plurality of emitters. The culture troughs are formed in parallel on the floor of a solar greenhouse by recessing. Two rows of upright culture bags are disposed in each culture trough. The reservoir is located inside the greenhouse. The water pump is disposed in the reservoir, and an outlet of the water pump is connected with a liquid inlet end of the drip irrigation main pipe. An outlet end of the fertilizing device is connected with a liquid inlet end of the drip irrigation main pipe. The filter is disposed on the drip irrigation main pipe. The rear of the drip irrigation main pipe is arranged above one ends of the culture troughs. One drip irrigation branch pipe is disposed above each row of culture bags, and one ends of the drip irrigation branch pipes are connected with the drip irrigation main pipe simultaneously. Each drip irrigation branch pipe is provided with the emitters, while each emitter is above a round hole of each culture bag. The bag culture system has the advantages that production environment can be improved, water and fertilizer can be economized, utilization rate of fertilizer is increased, spread of soil-borne diseases is avoided, and the like.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

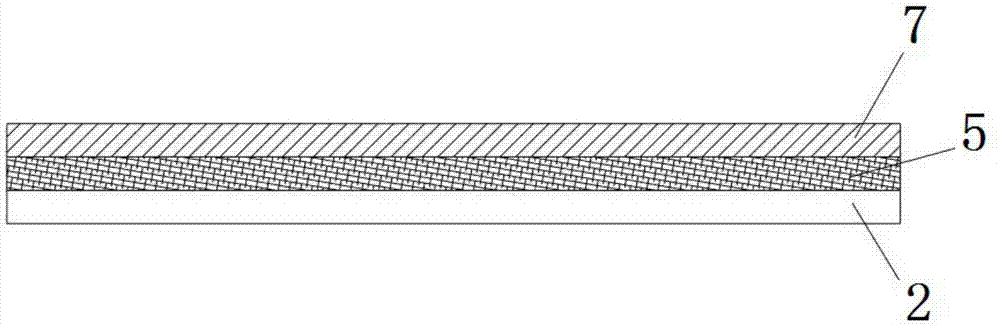

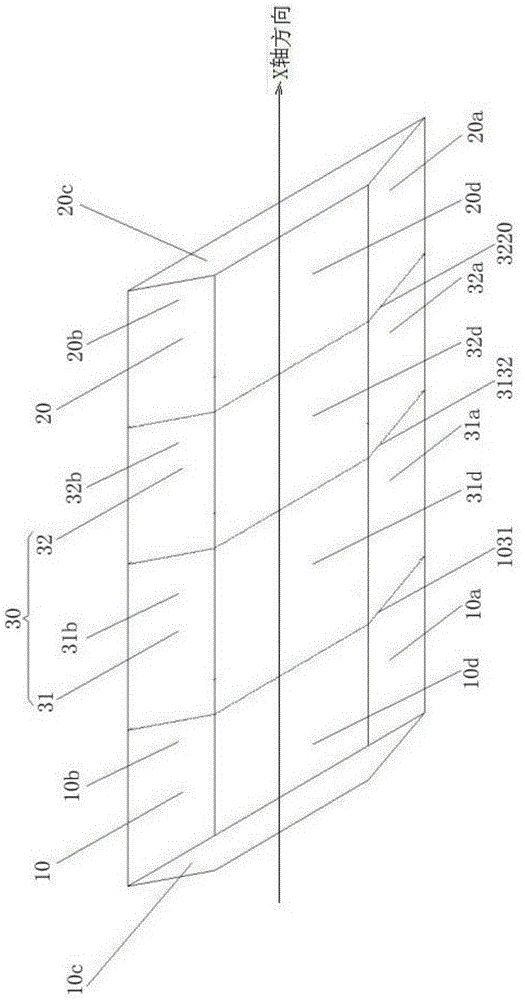

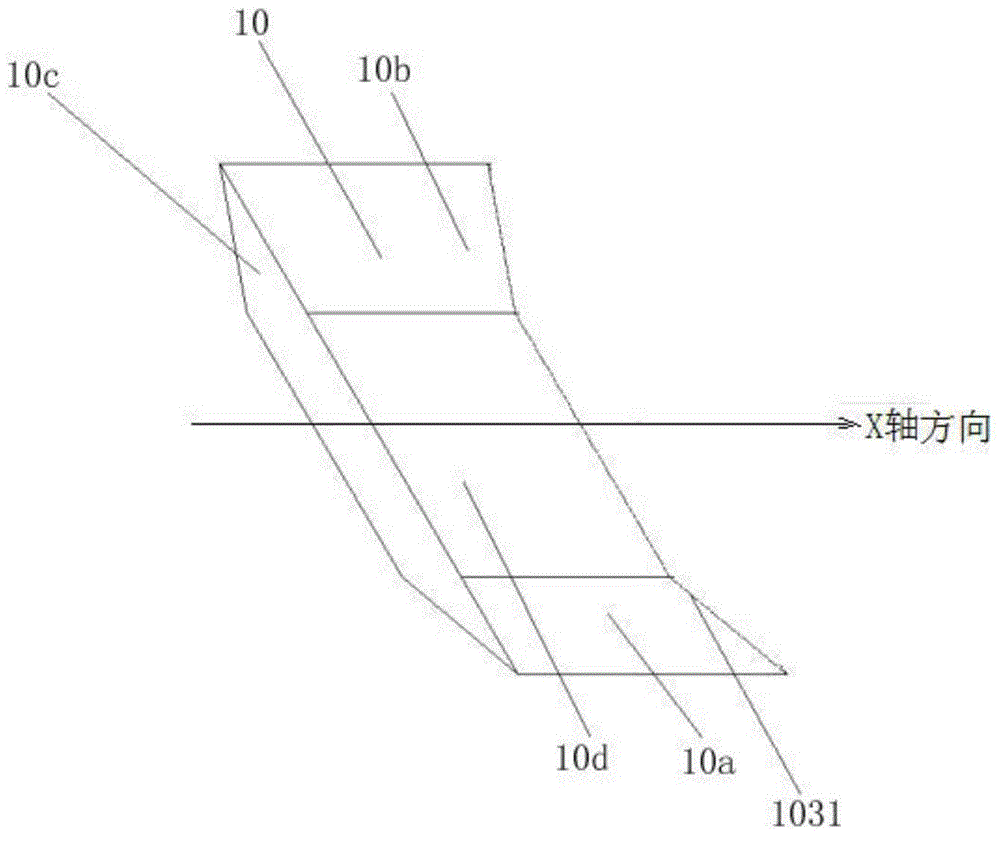

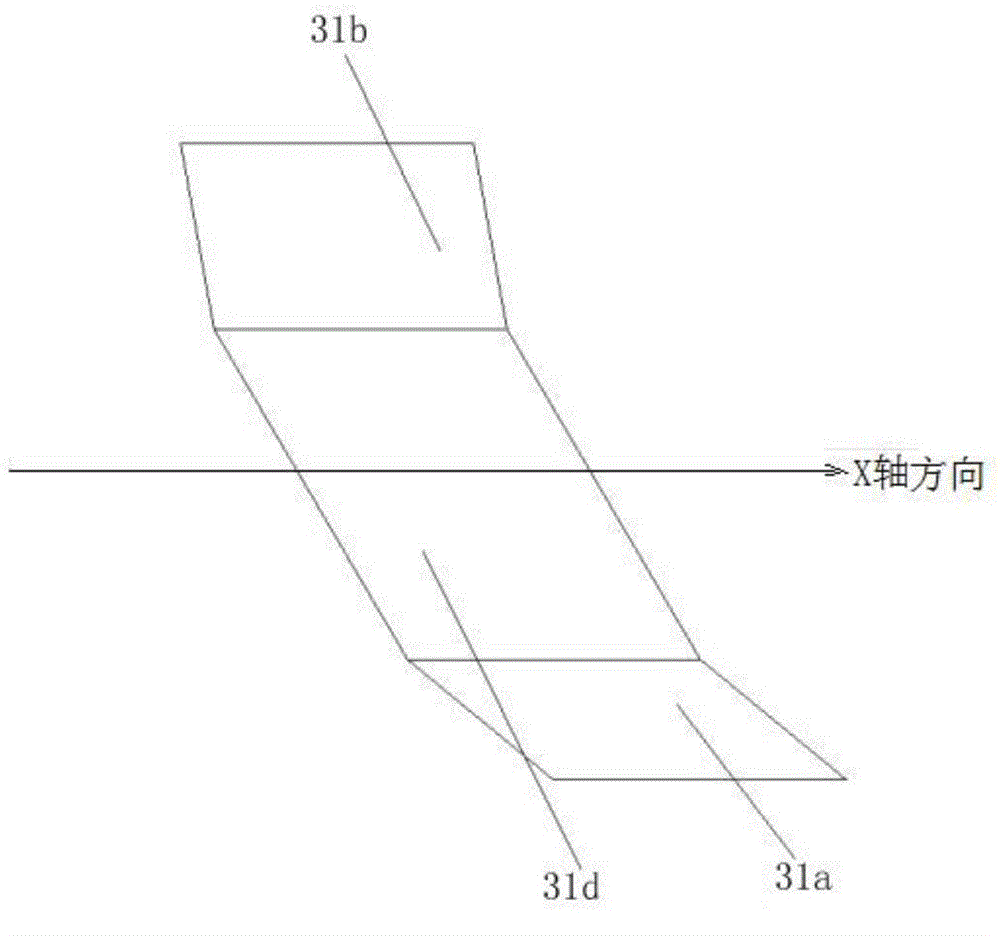

Sarcandra glabra facial mask base fabric, preparation method and preparation system

InactiveCN105437637AGood effectHas a natural antibacterial effectLayered productsEnvironmental resistanceCarding

The invention discloses a sarcandra glabra facial mask base fabric, a preparation method and a preparation system. The sarcandra glabra facial mask base fabric comprises three layers of fiber webs including a functional layer fiber web, a liquid storage layer fiber web and a protection layer fiber web, wherein the functional layer fiber web, the liquid storage layer fiber web and the protection layer fiber web are twisted and fixedly connected to a whole after being twisted and reinforced by spunlace; the functional layer fiber web is a parallel fiber web; the liquid storage layer fiber web is a fiber web formed by random carding by a condensing roller; the protection layer fiber web adopts non-woven cloth; the functional layer fiber web, the liquid storage layer fiber web and the protection layer fiber web are superposed from top to bottom, then are twisted and compounded by spunlace according to a working procedure of front prewet spunlace, one front spunlace, one back spunlace and two front spunlace, and are dried and wound to form the sarcandra glabra facial mask base fabric. The sarcandra glabra facial mask base fabric disclosed by the invention is high in skin-friendliness, antibacterial property, shape retention and liquid lock performance, can be completely degraded, is high in production efficiency and low in cost, and can meet the requirements on greening, ecology, environment protection and health.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

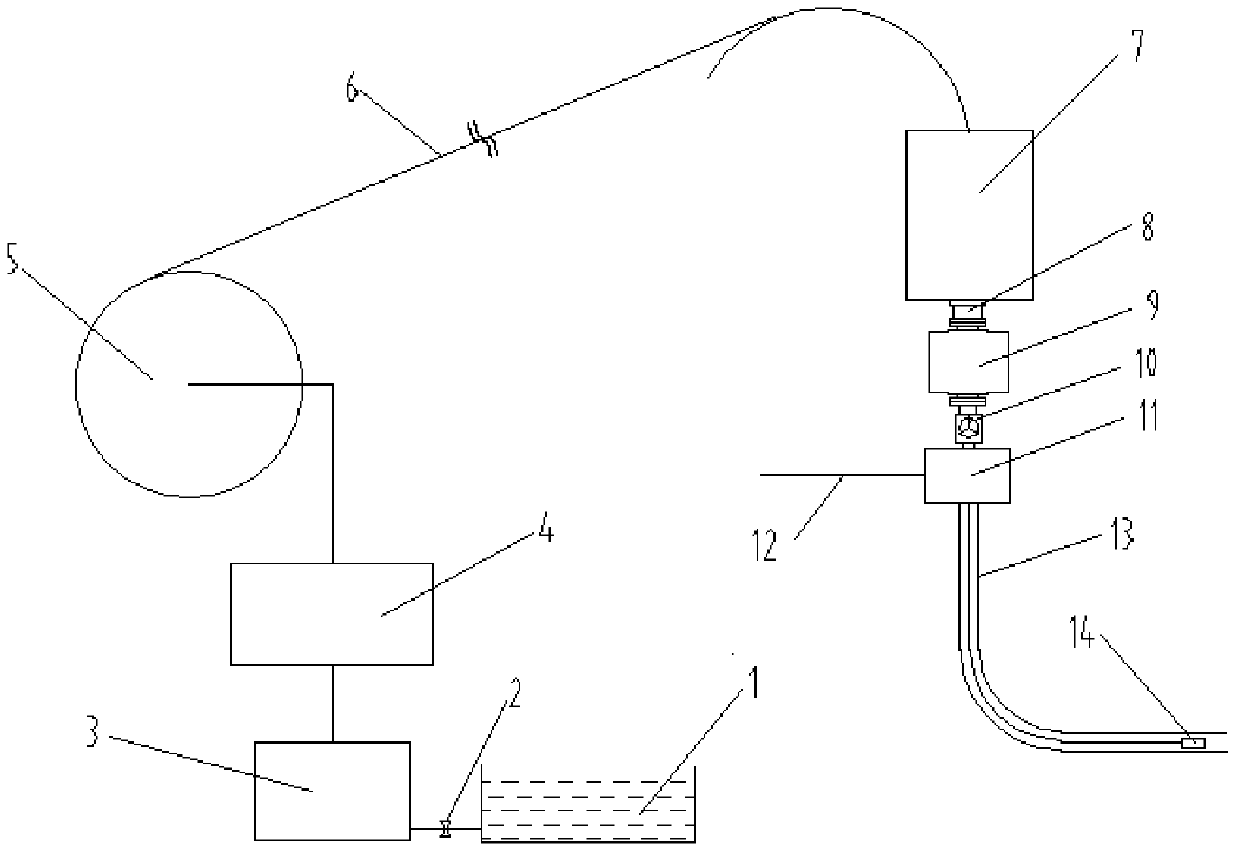

Abrasive perforating unblocking method and device for coiled tubing

InactiveCN105569619ATo achieve the purpose of connecting the channelQuickly put into productionFluid removalAbrasive blastingLine tubing

The invention provides an abrasive perforating unblocking method and device for coiled tubing. The device comprises a liquid tank, a skid-mounted sand mixing unit, high-pressure pumping-in equipment, coiled tubing equipment and an ejector, wherein a sand carrying liquid is stored in the liquid tank, and an input pipe of the skid-mounted sand mixing unit is connected with the liquid tank; an input end of the high-pressure pumping-in equipment is connected with an output pipe of the skid-mounted sand mixing unit; the coiled tubing equipment is wound with the coiled tubing, and a high-pressure inlet of the coiled tubing equipment is connected with an output end of the high-pressure pumping-in equipment through a pipe; the high-pressure inlet is communicated with the coiled tubing; the ejector is connected onto the coiled tubing. According to the unblocking method, the ejector is lowered into a pipe column for operation by the aid of the unblocking device. According to the method and the device, abrasive perforating can be performed on pipe columns with smaller inner diameters, a production channel is communicated, and production of oil-gas wells is recovered.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

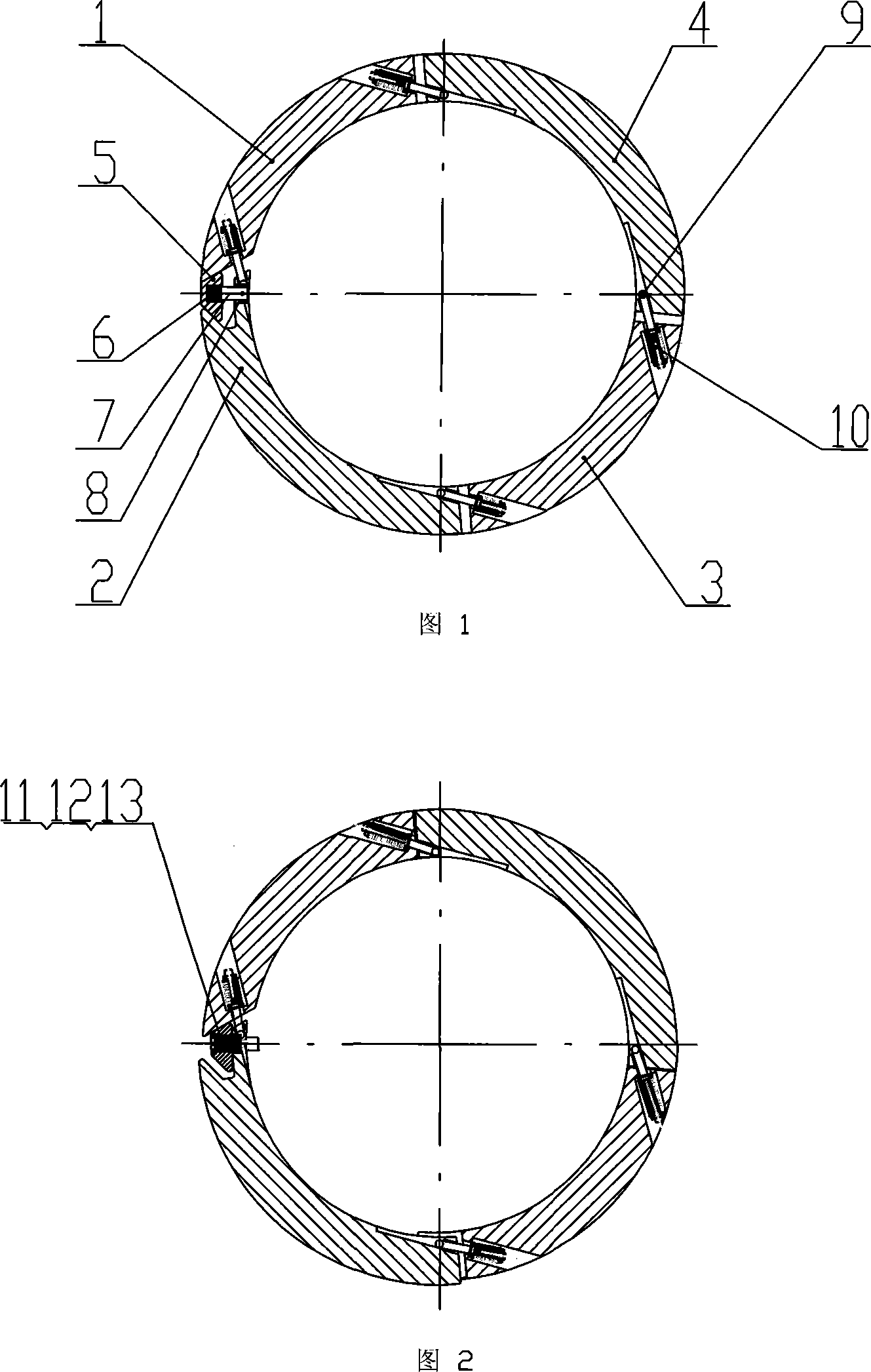

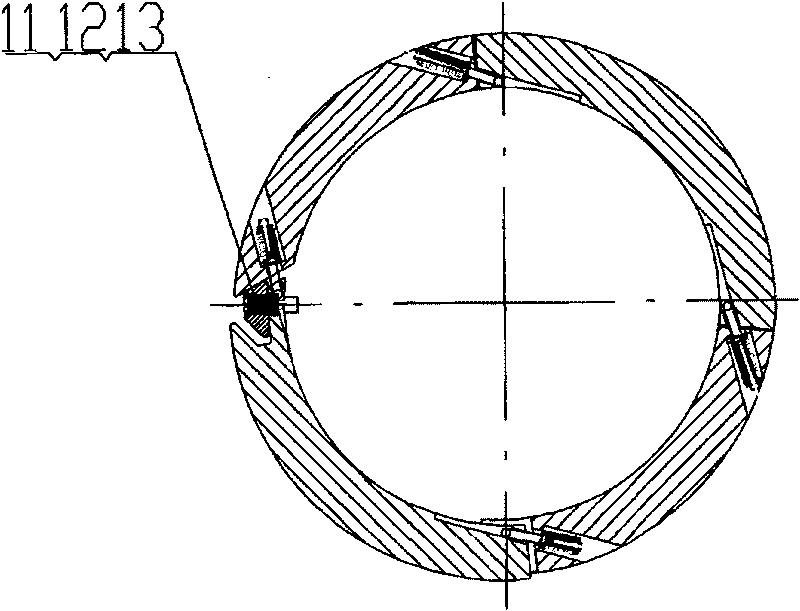

Coiling machine sleeve barrel with wrench jaw

The invention relates to a recoiler sleeve provided with a gate, comprising more than 3 sector-shaped boards. By being connected with bolts, the sector-shaped boards are connected into a whole with disk springs on the joint position. The invention is characterized in that a gate is arranged between two boards of the sector-shaped boards; the gate position also comprises a gate slide block, a gate slide block jack system and a gate slide block resetting device. The clamp slide block is matched with the gate and as the diameter expanding and shrinking of the recoiler sleeve is pushed out and back to and fro through the gate under the action of the gate slide block resetting device, the tightening and opening of the gate is realized. The invention realizes rolling up belt coils with different internal diameters on one recoiler, which enhances the utilization rate and production efficiency of the equipment and has dramatic economic benefit.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

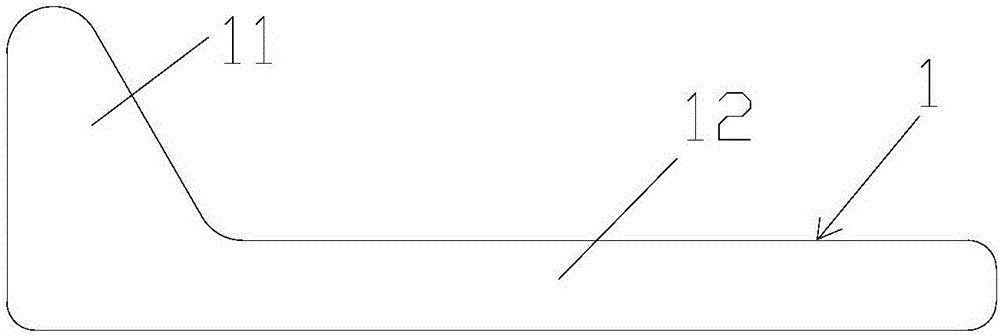

Method for producing flat bulb steel

ActiveCN105690045AIncrease the cross-sectional areaLow costExtrusion diesEngineeringUltimate tensile strength

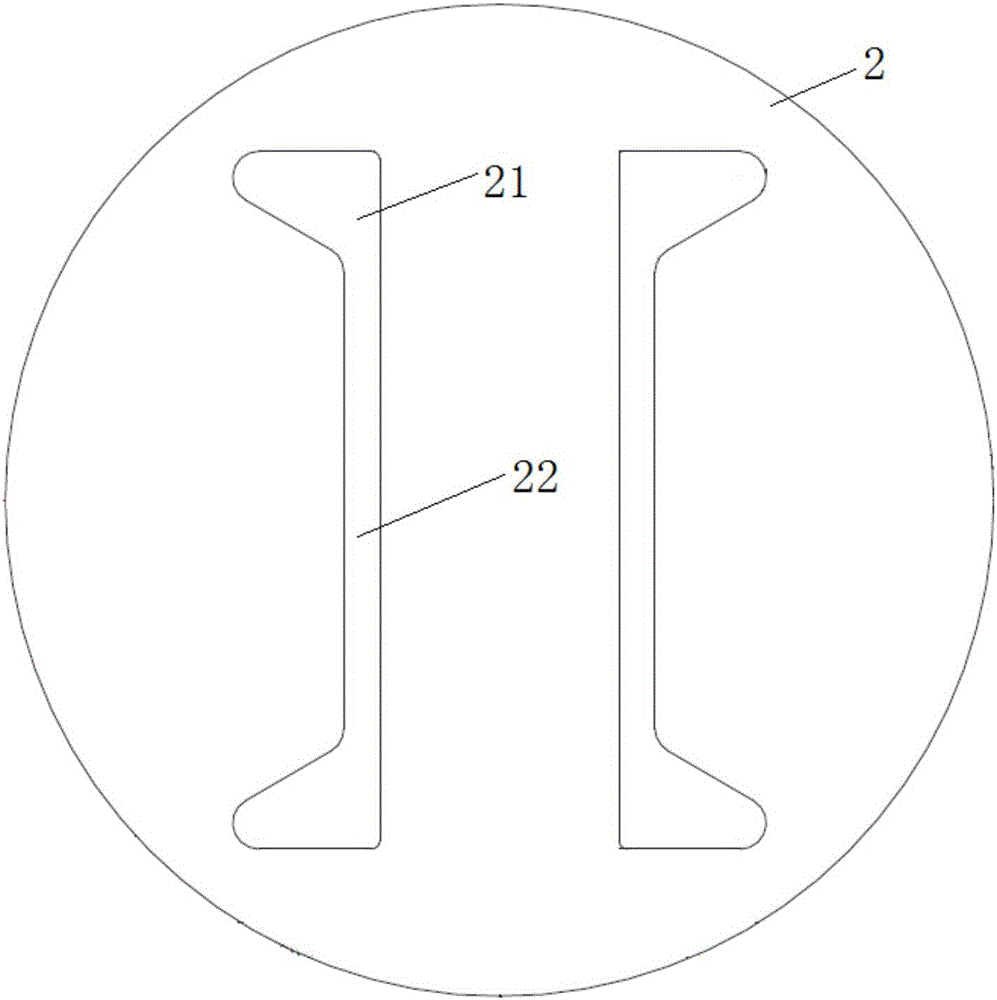

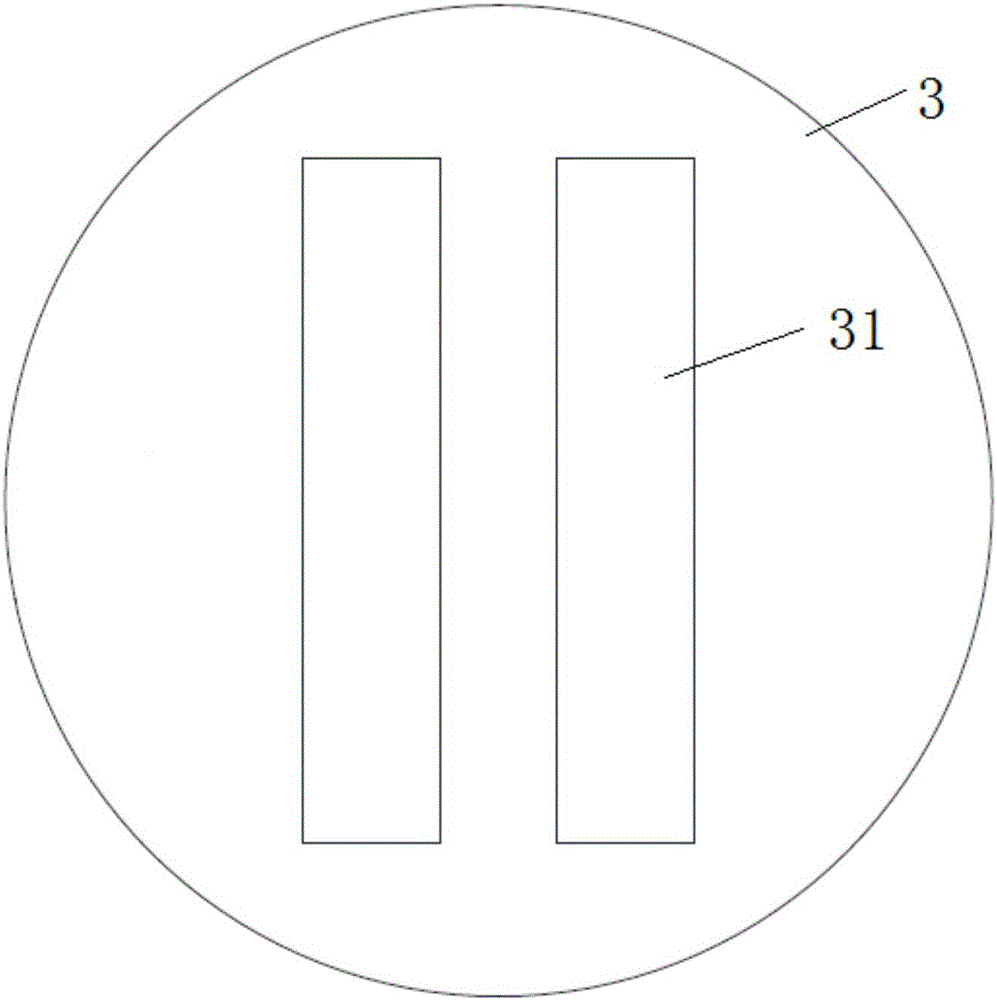

The invention discloses a method for producing flat bulb steel. Hot extrusion equipment comprises an extrusion cylinder and an extrusion mold (2) which are mutually connected; flat bulb steel hole patterns of the extrusion mold (2) comprise a web hole pattern (22) and bulb hole patterns (21) at the two ends of the web hole pattern (22), accordingly, a rod is extruded to form a flat bulb steel blank provided with two bulbs (11) by the flat bulb steel hole patterns, one of the bulbs (11) is cut off, and the flat bulb steel (1) is produced. By designing the flat bulb steel hole patterns into a form with the two bulb hole patterns and one web hole pattern, the area of the cross section of the flat bulb steel hole patterns can be increased, accordingly, required extrusion drive force is reduced, existing hot extrusion equipment can be applied to extrusion machining of materials with higher strength, the increase in cost caused by equipment improvement is avoided, the production cost can be lowered, the improvement work is simple and easy to implement, and the flat bulb steel can be quickly put into production.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Preparation method of polyether-type polyurethane sponge with flame-retardant function

The invention belongs to the technical field of polyurethane sponge. The invention discloses a preparation method of polyether-type polyurethane sponge with a flame-retardant function. The preparation method comprises the steps of preparing materials, mixing the materials, stirring, feeding, foaming, carrying out the after-treatment and the like, and in the material preparation process, raw materials such as first polyether polyalcohol, second polyether polyalcohol, third polyether polyalcohol, butyl rubber, a first catalyst, a second catalyst, silicone oil, water, a foaming agent, MDI isocyanate, flame-retardant additive, chain extender and the like. The preparation method of the slow-resilience polyether-type polyurethane sponge is simple in process, high in production efficiency, capable of being produced by utilizing the existing equipment, and capable of being rapidly put into production; and the slow-resilience polyether-type polyurethane sponge prepared by virtue of the preparation method in the invention has good slow resilience and excellent flame retardant property.

Owner:德清舒华泡沫座椅有限公司

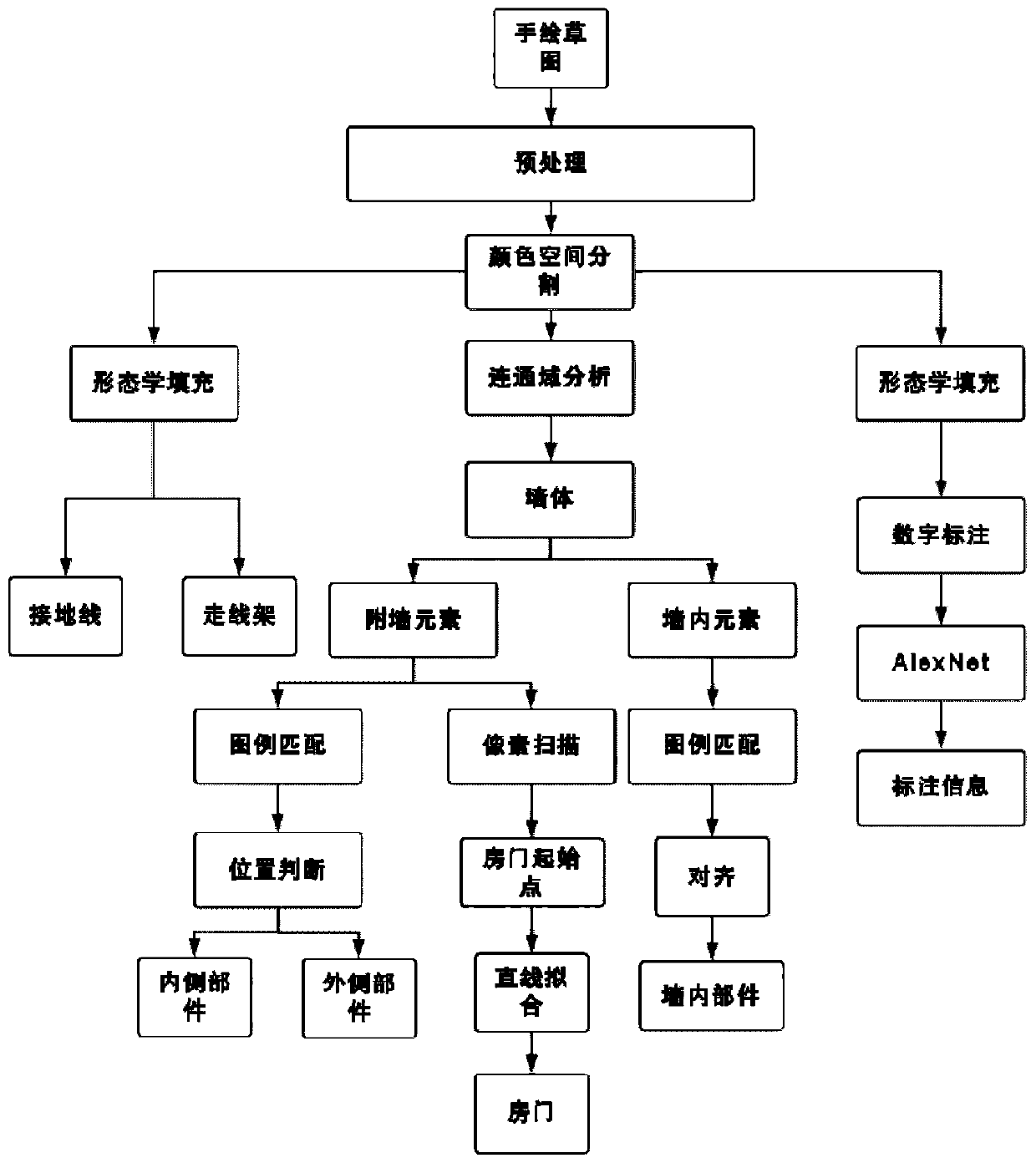

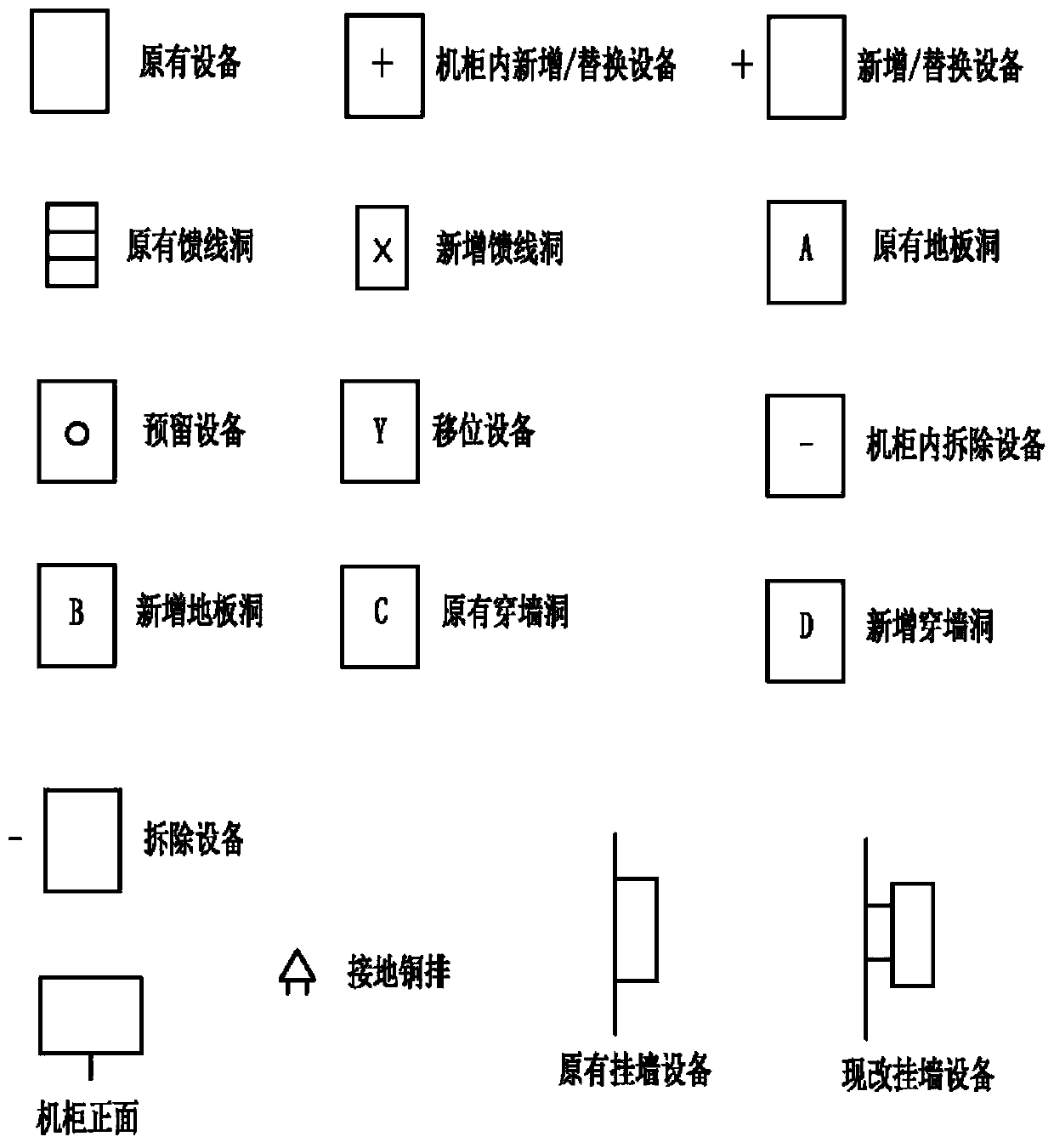

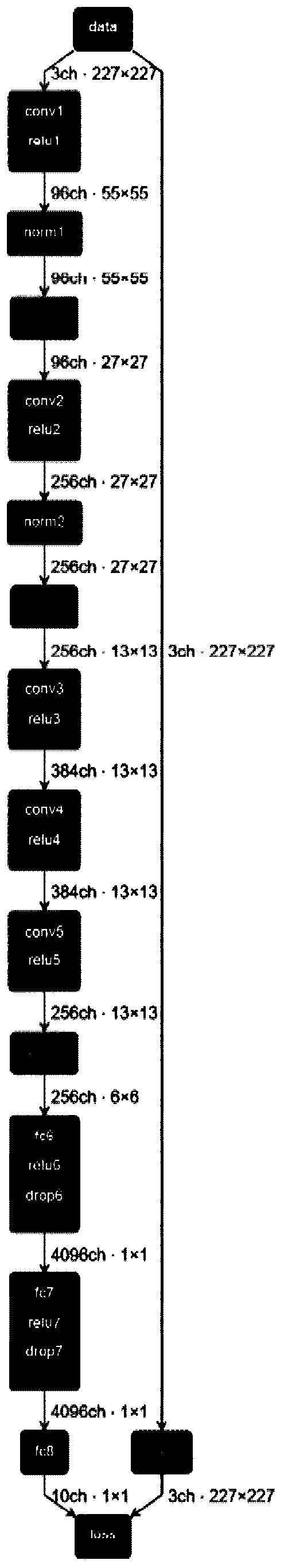

Machine room sketch identification method and device based on legend library

ActiveCN110598634AEasy to enterImprove normativeCharacter and pattern recognitionGraphicsPattern recognition

The invention provides a machine room sketch identification method and device based on a legend library, and the method is characterized in that the method comprises the following steps: formulating asketch drawing standard, building a standard legend library, and carrying out the regularization constraint of the drawing of a machine room sketch; obtaining sketch data; performing hierarchical segmentation on the whole image in the machine room sketch to obtain a component diagram of the machine room sketch; performing matching identification by utilizing a standard legend library so as to realize detection and identification of the machine room sketch components; carrying out reasonable position constraint on the machine room sketch component; and performing parameterized output of results. The machine room sketch recognition method and device based on the legend library have the advantages that the standard graph recognition result matched with the input sketch can be output quicklyand accurately in real time, therefore a more visual reference basis is provided for designers to conduct quick design after the designers combine a sketch exploration report.

Owner:山东文多网络科技有限公司

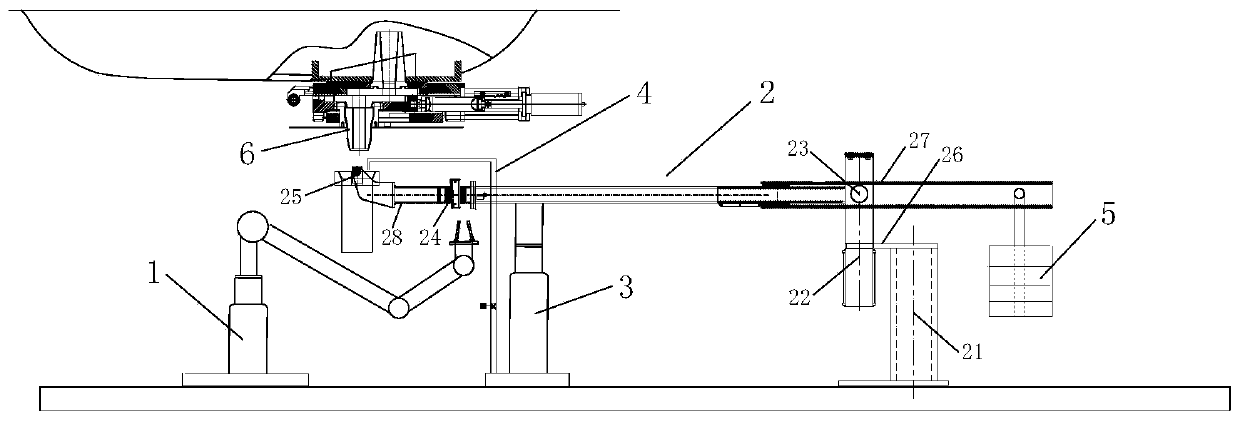

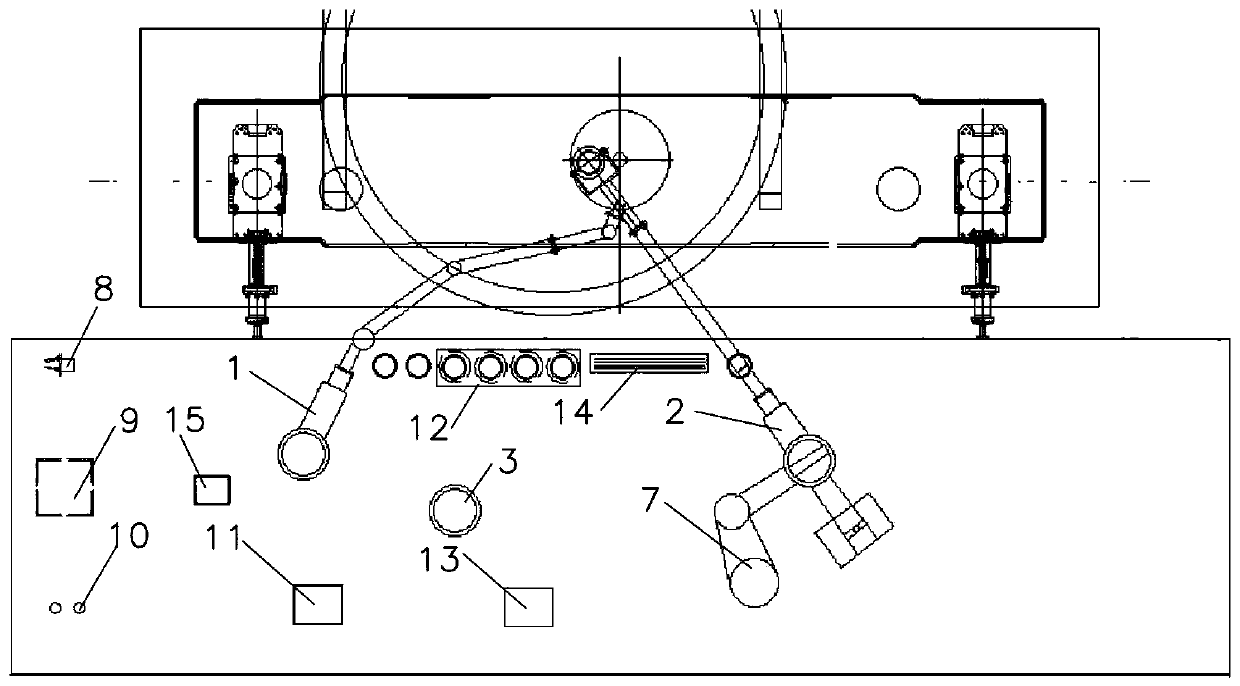

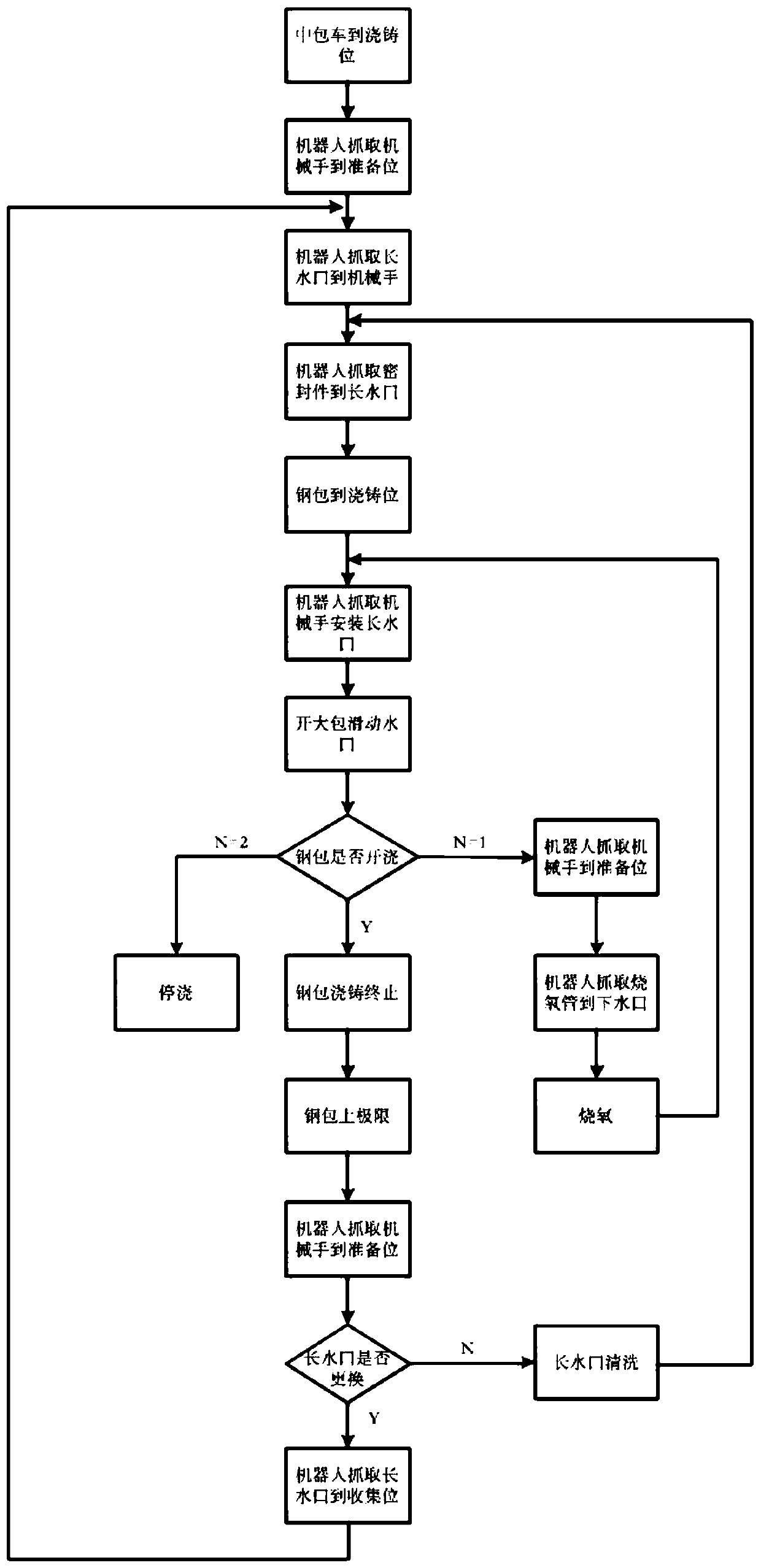

Unmanned system and operation method of steel ladle casting area

ActiveCN111168051AEnsure health and safetyReduce investmentMelt-holding vesselsCasting parameters measurement/indication devicesRobot handEngineering

The invention relates to an unmanned system and operation method of a steel ladle casting area. The method comprises the steps that a mechanical arm is prepared, wherein a robot grabs the mechanical arm from a mechanical arm standby station, the mechanical arm is placed into a fixed bayonet of a locating pile, and the mechanical arm is released; a long nozzle is prepared, wherein the robot takes out the long nozzle from a long nozzle storage device, the long nozzle approaches a mechanical arm long nozzle backing ring according to the set position, the position of the long nozzle is finely adjusted through a robot vision recognition system and a mechanical arm recognition mark, and then the long nozzle is placed into the long nozzle backing ring; a sealing part is mounted, wherein the sealing part is grabbed by the robot from a sealing part storage device and is placed into the long nozzle; and the long nozzle is mounted, wherein after a steel ladle rotates in place, the mechanical armis grabbed by the robot to drive the long nozzle and a lower nozzle to be aligned, the long nozzle is mounted in, the robot retreats, and the mechanical arm supports the long nozzle and presses the lower nozzle all the time. The unmanned system and operation method have the advantages that the mechanical arm and the robot cooperate to replace manual operation, and operations of long nozzle replacement, tundish molten steel temperature measuring and sampling, tundish covering agent adding and steel ladle oxygen pipe burning are completed.

Owner:ANGANG STEEL CO LTD

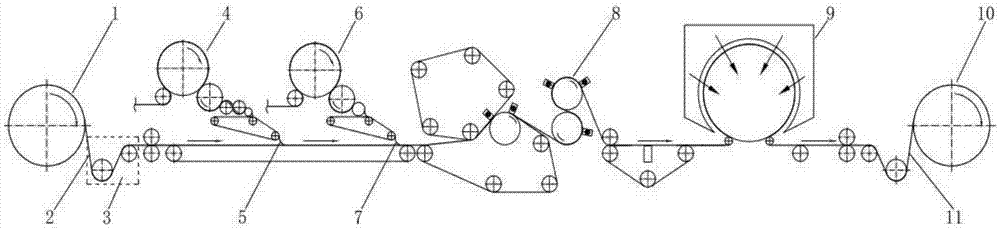

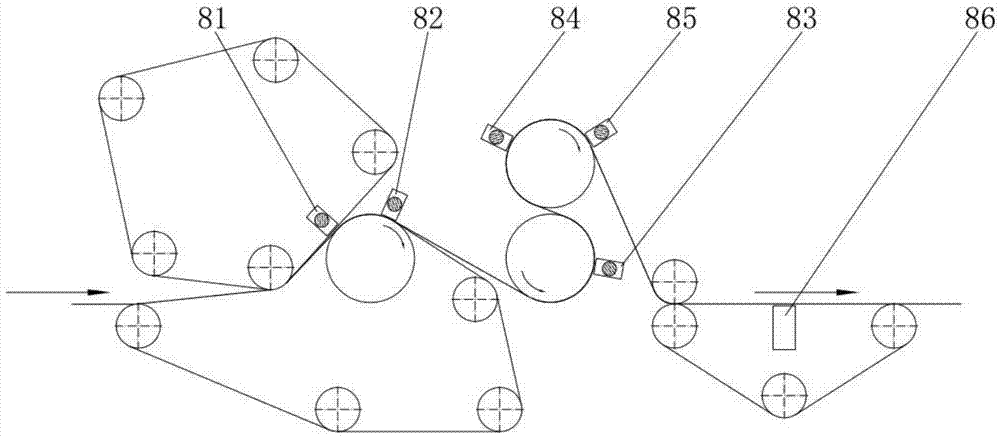

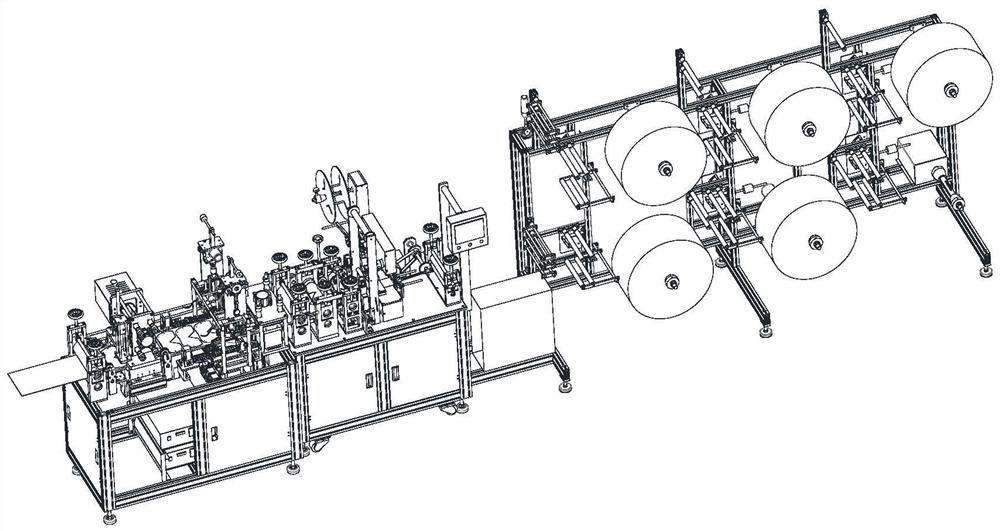

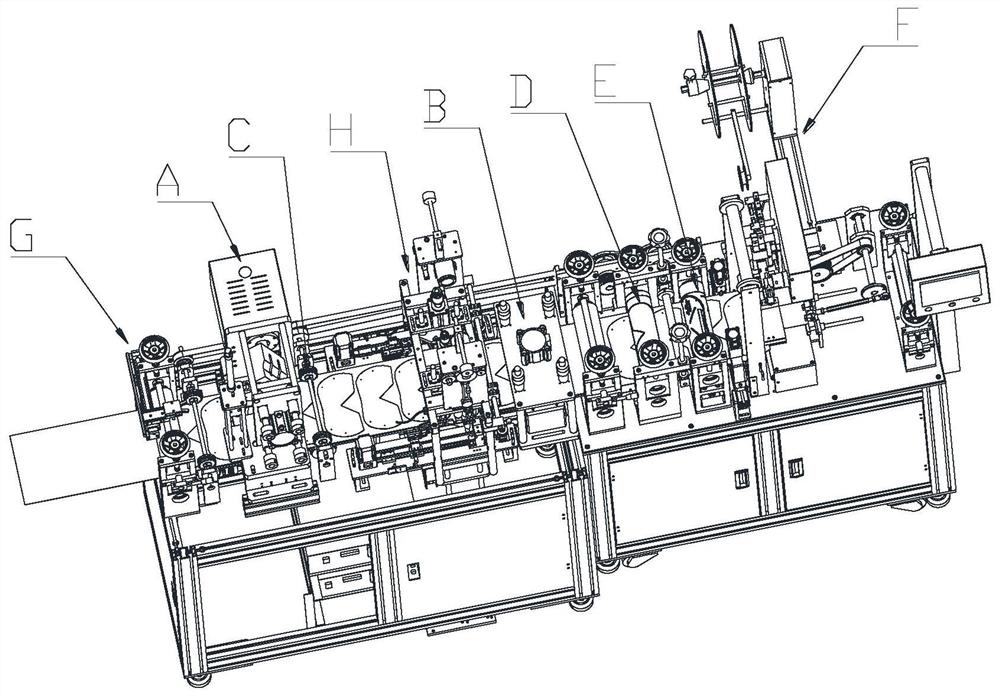

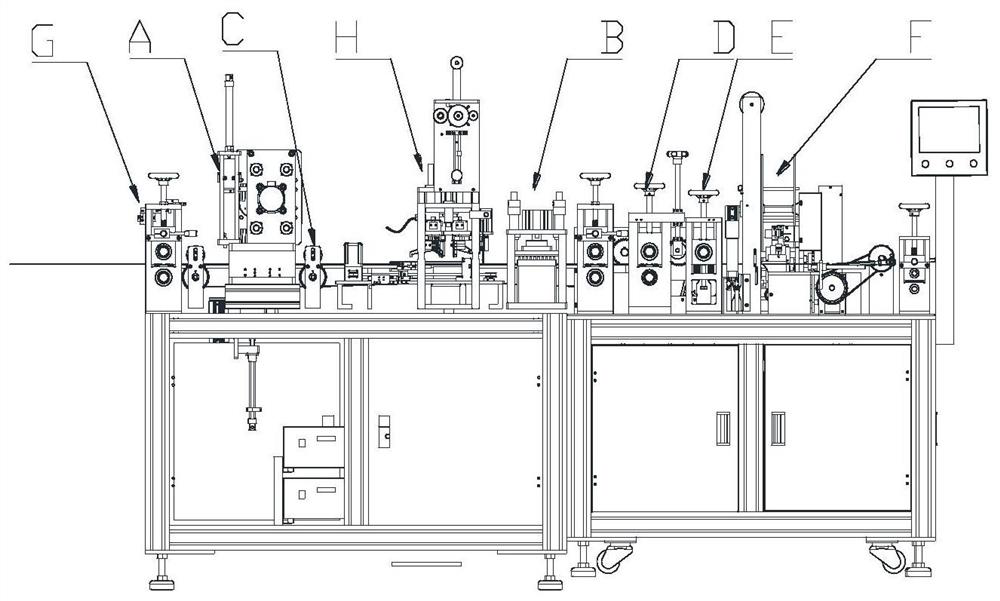

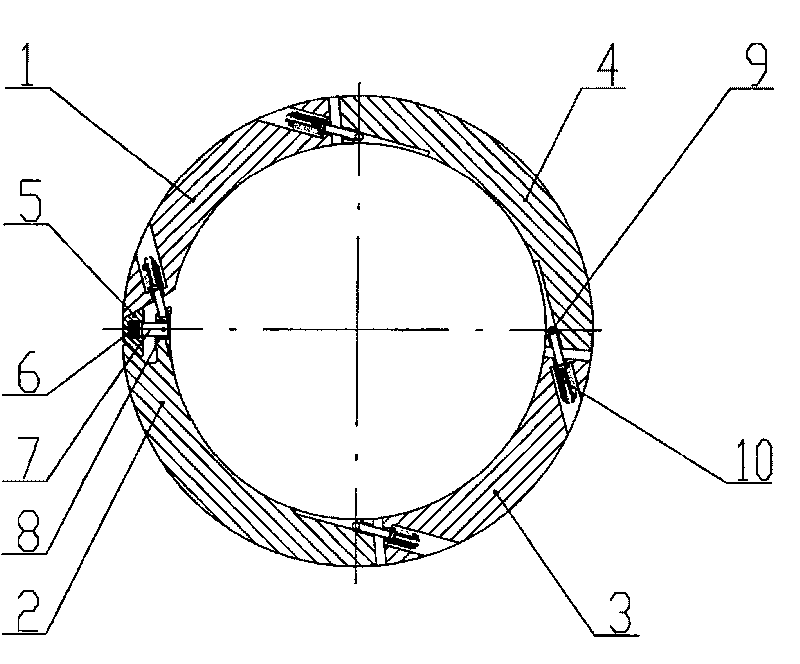

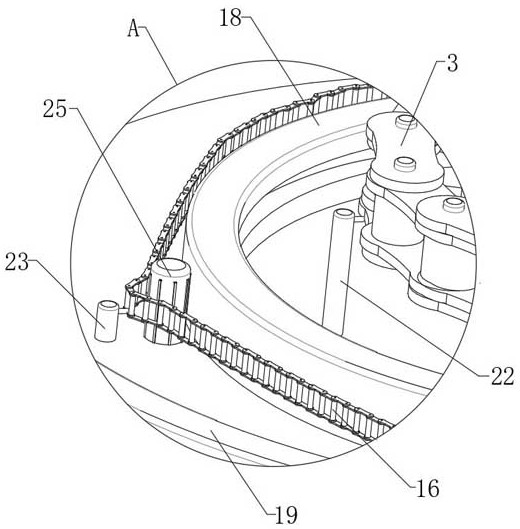

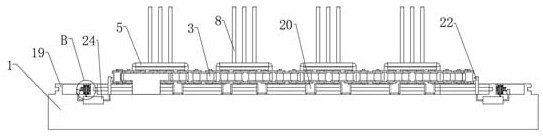

Full-automatic production equipment and process for vertical folding mask

PendingCN111657604AReduce difficultyQuickly put into productionProtective garmentClothes making applicancesKnurlingEngineering

The invention discloses full-automatic mask production equipment and process for a vertical folding mask. The equipment comprises a feeding module, a nose bridge line imbedding module, a knurling module, an edge cutting module, an ear line welding module, an edge sealing module and a waste traction module which are arranged in sequence. The edge cutting module is adjacently arranged at a downstream station of the knurling module, a mask base body formed by compounding multiple layers of cloth is knurled by the knurling module and then enters the edge cutting module in a flat state, a mask bodycut by an edge cutting shaft of the edge cutting module is embedded into the mask base body and is forwards conveyed to a subsequent station along with the mask base body, the ear wire welding moduleis used for welding ear wires to the cut mask body, and the edge sealing module is used for folding the mask body in half and sealing the edge of the mask body, and the equipment further comprises apunching module and a positioning module. The equipment has the advantages of being high in cutting precision, small in debugging difficulty, accurate in positioning, small in size, flexible in station arrangement and the like.

Owner:GUANGDONG INST OF INTELLIGENT MFG

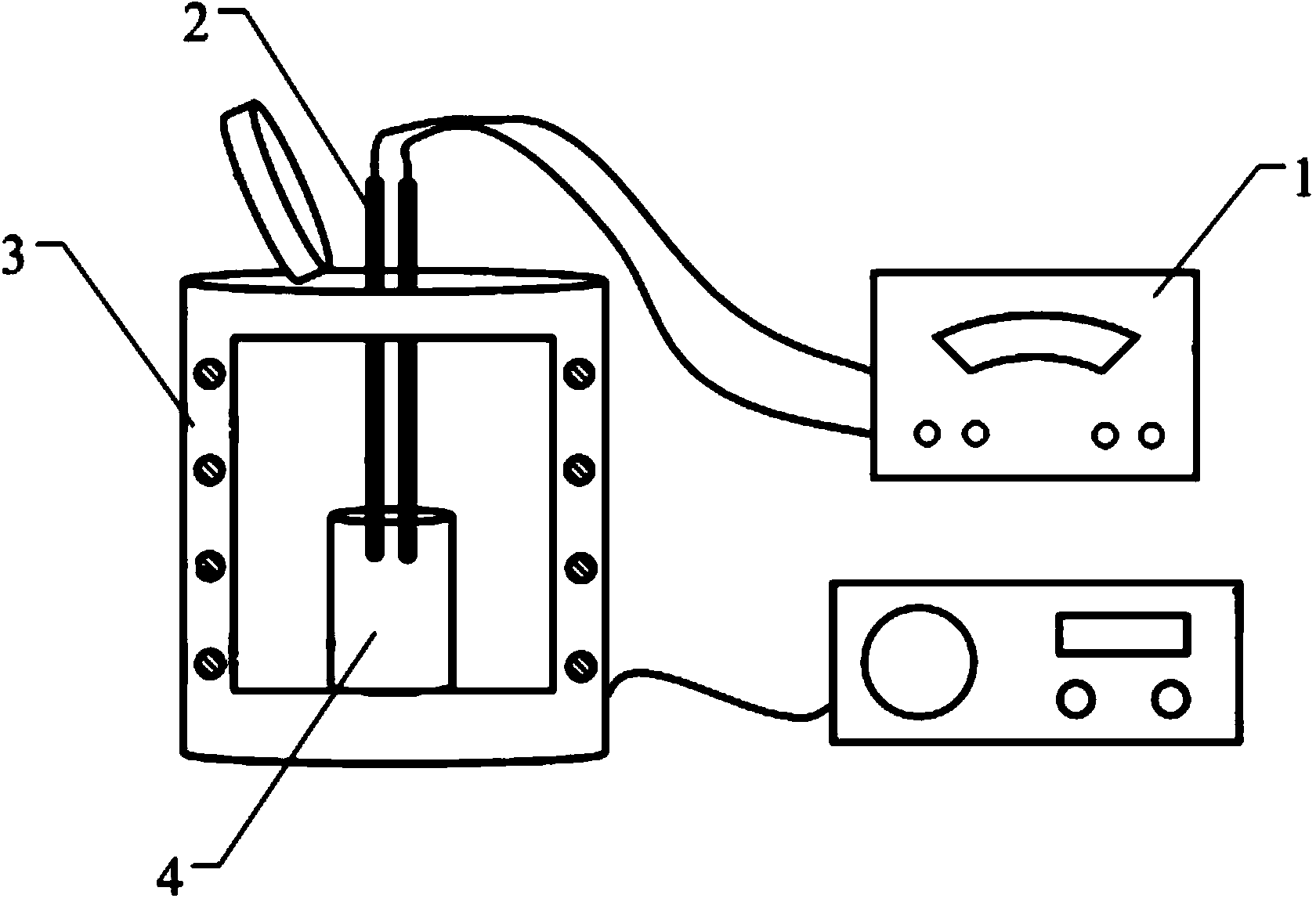

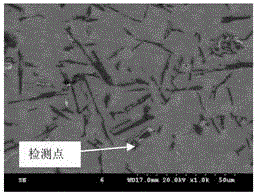

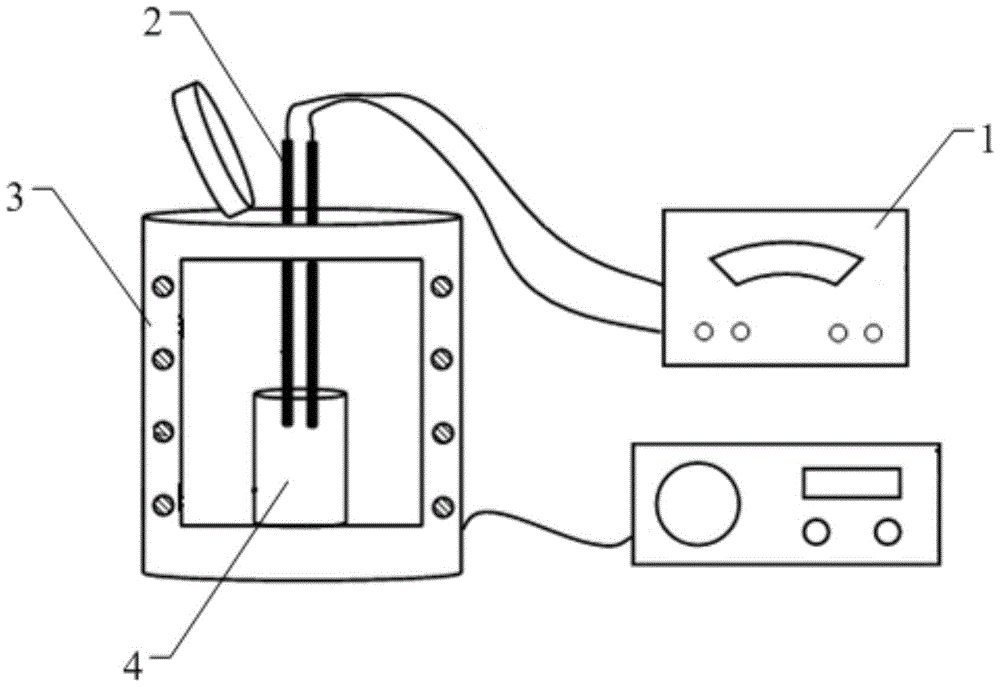

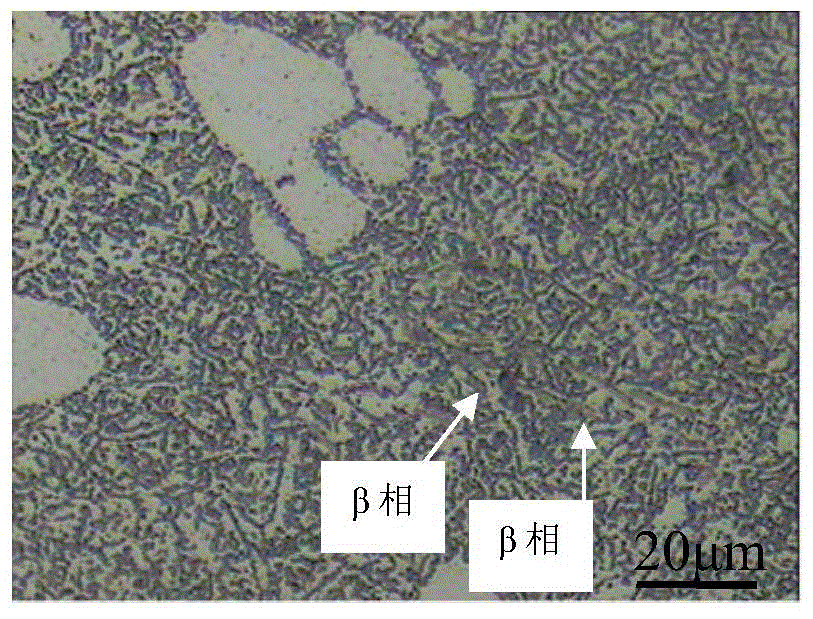

Electric pulse control method and device for iron-rich aluminum-silicon alloy iron phases

InactiveCN103817314AImprove mechanical propertiesHigh tensile strengthSilicon alloyElectrical impulse

The invention discloses an electric pulse control method for iron-rich aluminum-silicon alloy iron phases. The method includes the following steps that step1, iron-rich aluminum-silicon alloy is smelted to obtain iron-rich aluminum-silicon alloy melt, wherein the iron content in the iron-rich aluminum-silicon alloy is 0.5-1.2%, and the silicon content is 9-13%; step2, the iron-rich aluminum-silicon alloy melt is heated to 720 DEG C-760 DEG C, and electric pulse equipment is used for performing electric pulse treatment on the iron-rich aluminum-silicon alloy melt, wherein the electric pulse equipment comprises a pair of pulse electrodes which are inserted into the iron-rich aluminum-silicon alloy melt, in the process of electric pulse treatment, the pulse voltage is 500 V-1200 V, the pulse frequency is 3 Hz-15 Hz, and the continuing time is 10s-60s; step3, the iron-rich aluminum-silicon alloy melt which is subjected to the electric pulse treatment in the step2 is formed in a casting mode. Mechanical properties of the alloy treated through the method are greatly improved, the tensile strength is improved by 8-25%, the ductility is improved by 5-14%, and the invention further provides a device used for implementation of the method.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

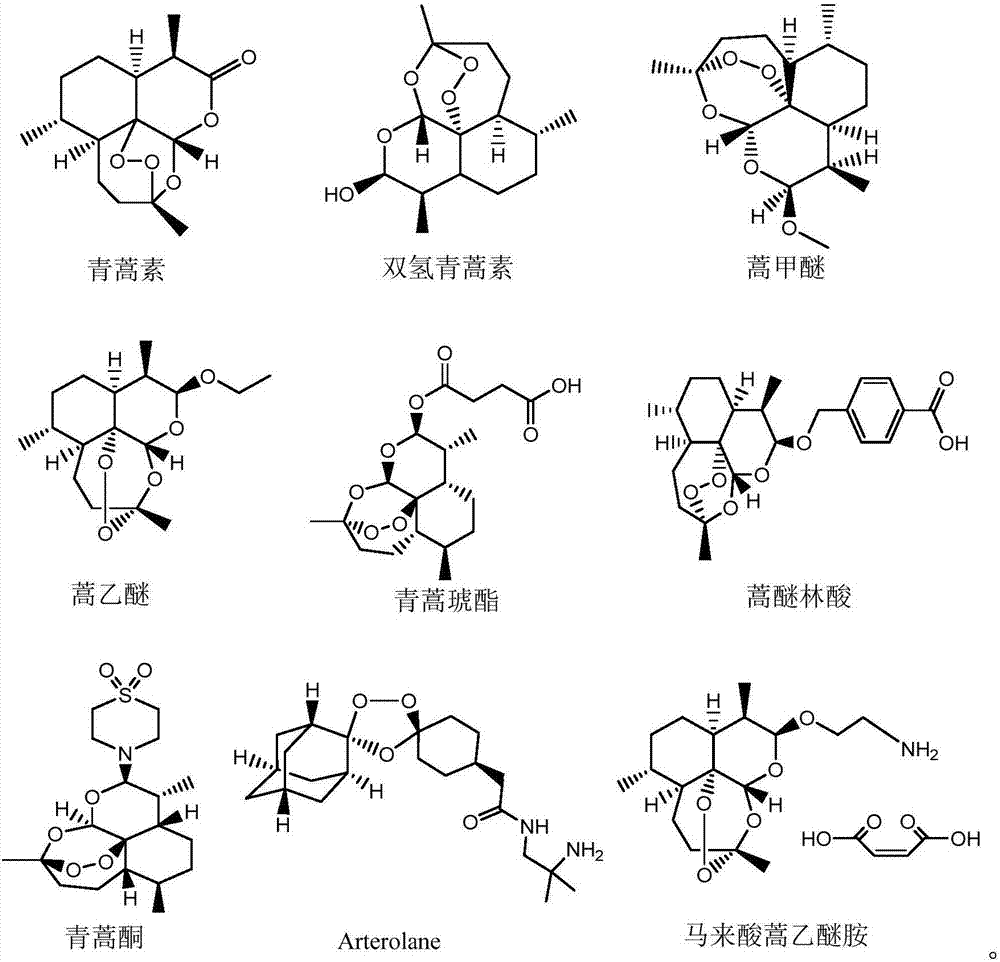

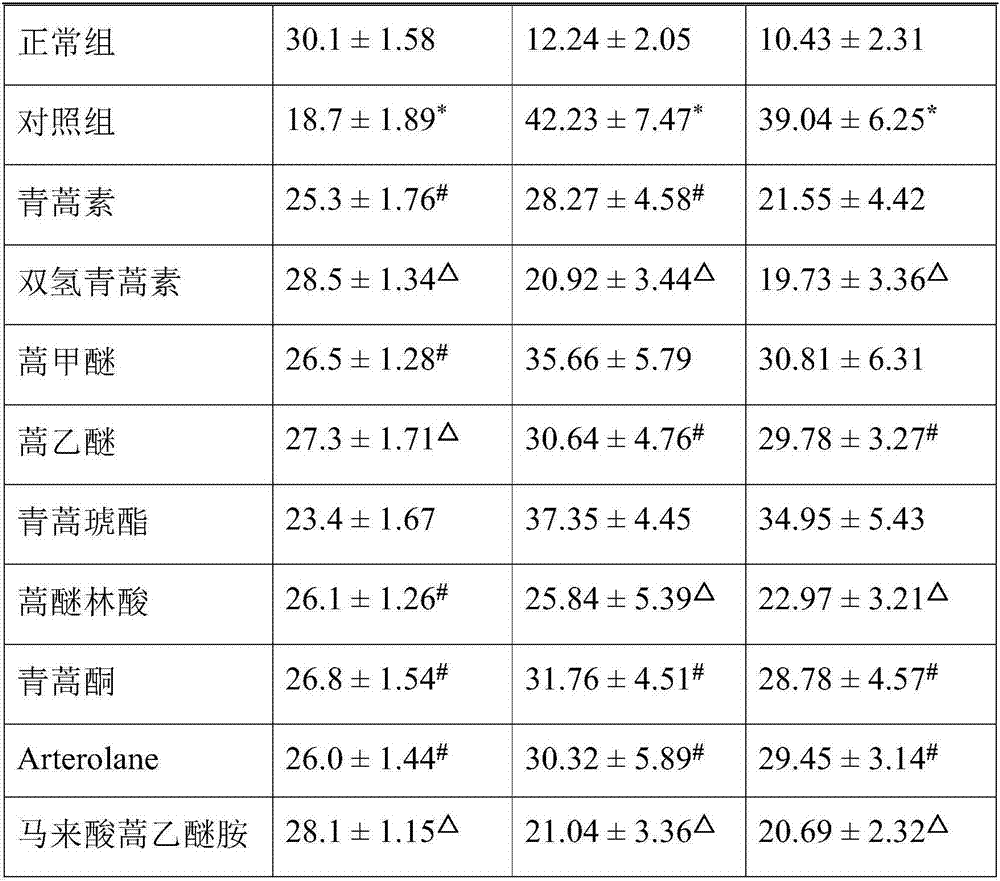

Application of artemisinin derivative in preparation of drugs for treatment or adjuvant therapy of autoimmune thyroid disease

ActiveCN107213149AEasy to synthesizeMature production processOrganic active ingredientsImmunological disordersAutoimmune thyroid diseaseAutoimmune disease

The invention provides an application of an artemisinin derivative in preparation of drugs for treatment or adjuvant therapy of an autoimmune thyroid disease. The artemisinin derivative and a pharmaceutical composition thereof are capable of reducing the content of a thyroglobulin antibody (TGAb) and a thyroid peroxidase antibody (TPOAb), and has a relatively good treatment effect on a Graves disease and chronic lymphocytic thyroiditis (hashimoto's thyroiditis and atrophic thyroiditis) or postpartum thyroiditis.

Owner:NANKAI UNIV

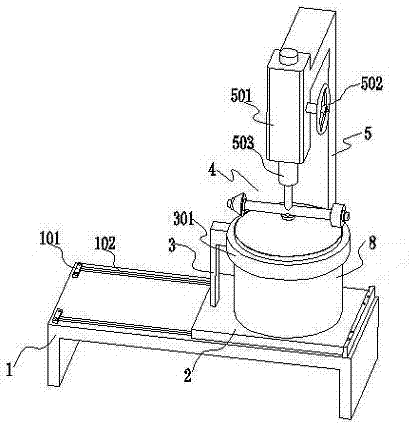

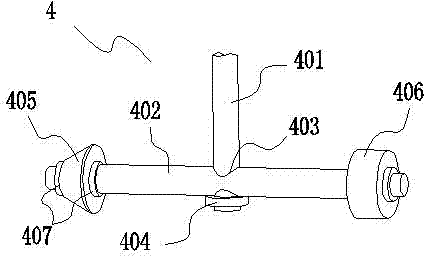

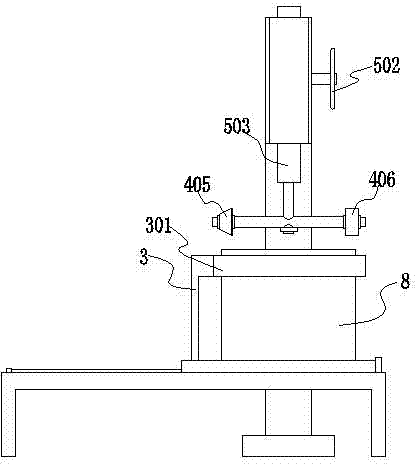

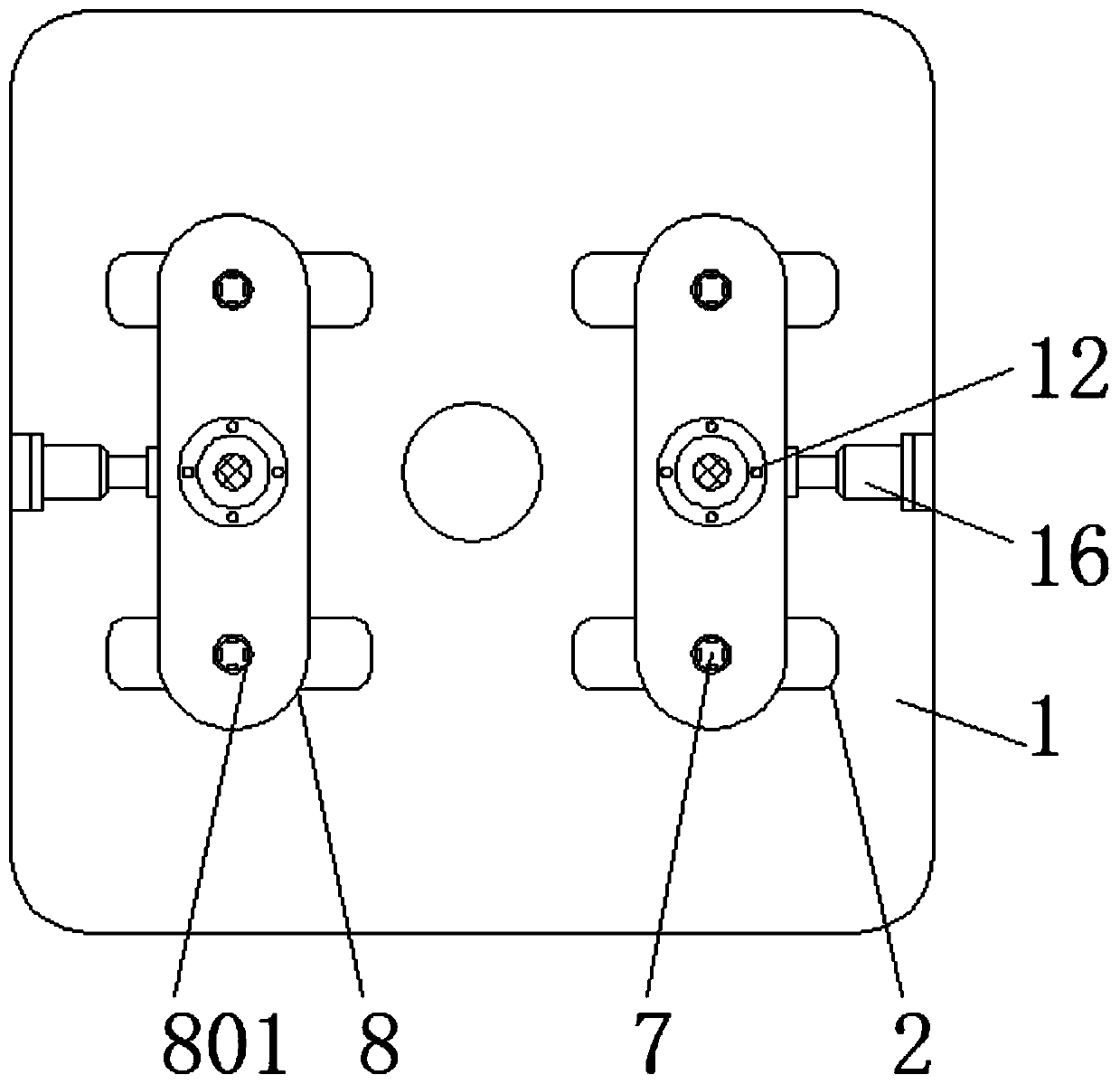

Flanging and patting device for metal thin-walled cylindrical vessels

The invention belongs to the fields of metal material processing and mould manufacturing and discloses a flanging and patting device for metal thin-walled cylindrical vessels. The flanging and patting device comprises a base, a bottom plate is arranged on the base, a support is arranged on the bottom plate, and a support ring is arranged on the support. A moulding body is arranged above the support ring and on a rotary device. The moulding body comprises a rotating shaft connected to the rotary device and a cross bar connected to the lower side of the rotating shaft, and a moulding head and a leveling head are respectively arranged at two ends of the cross bar. The flanging and patting device is simple in mechanism, low in material cost, short in manufacturing circle, applicable to flanging and patting the cylindrical vessels different in size, reduced in mounting time and high in processing speed and production efficiency.

Owner:刘英

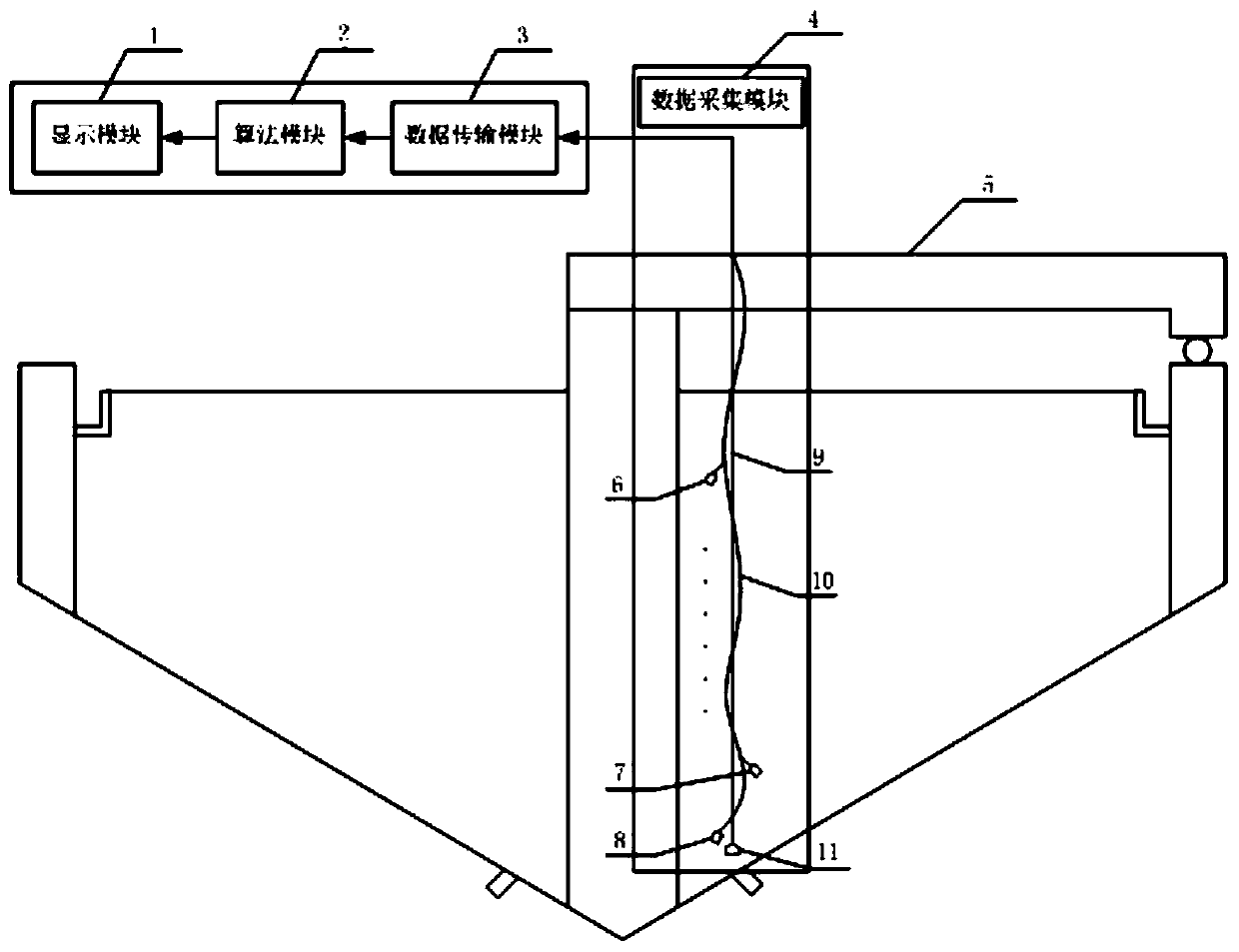

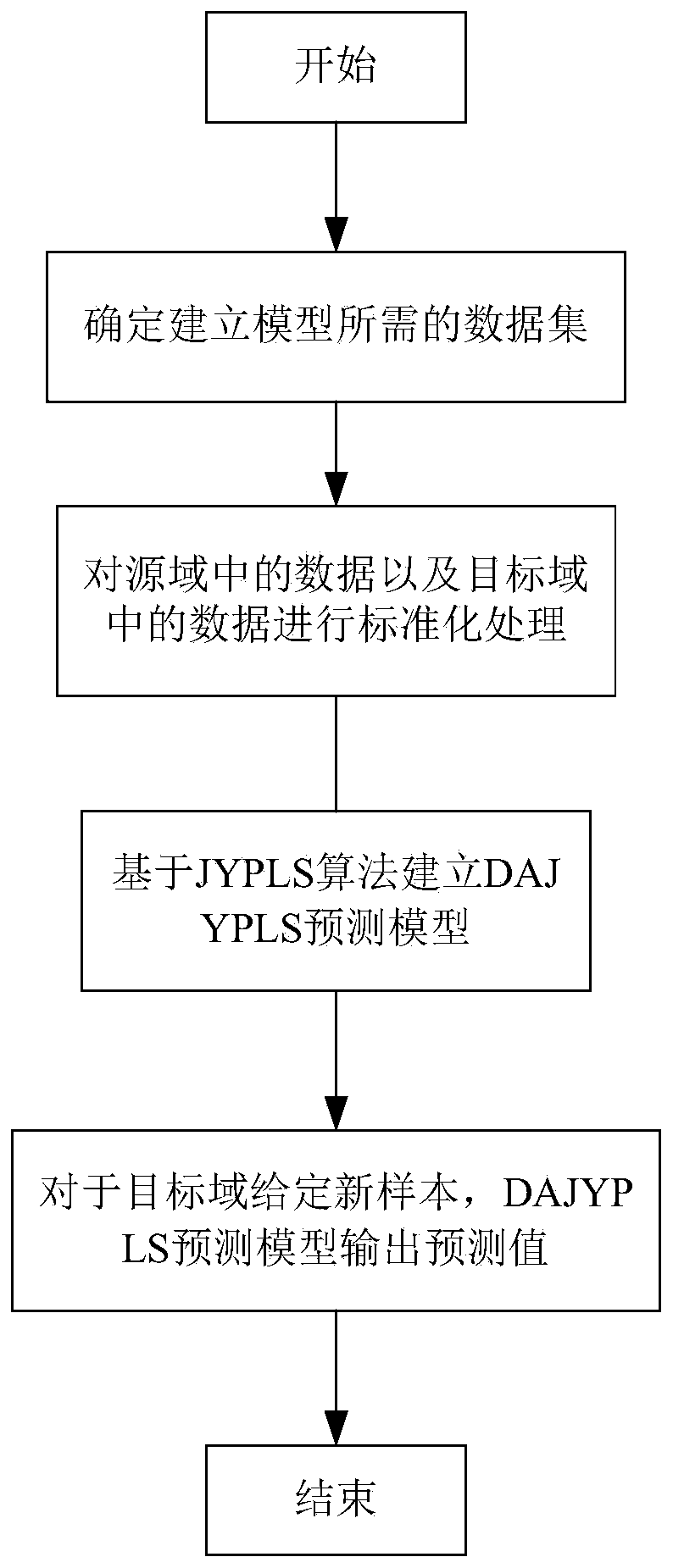

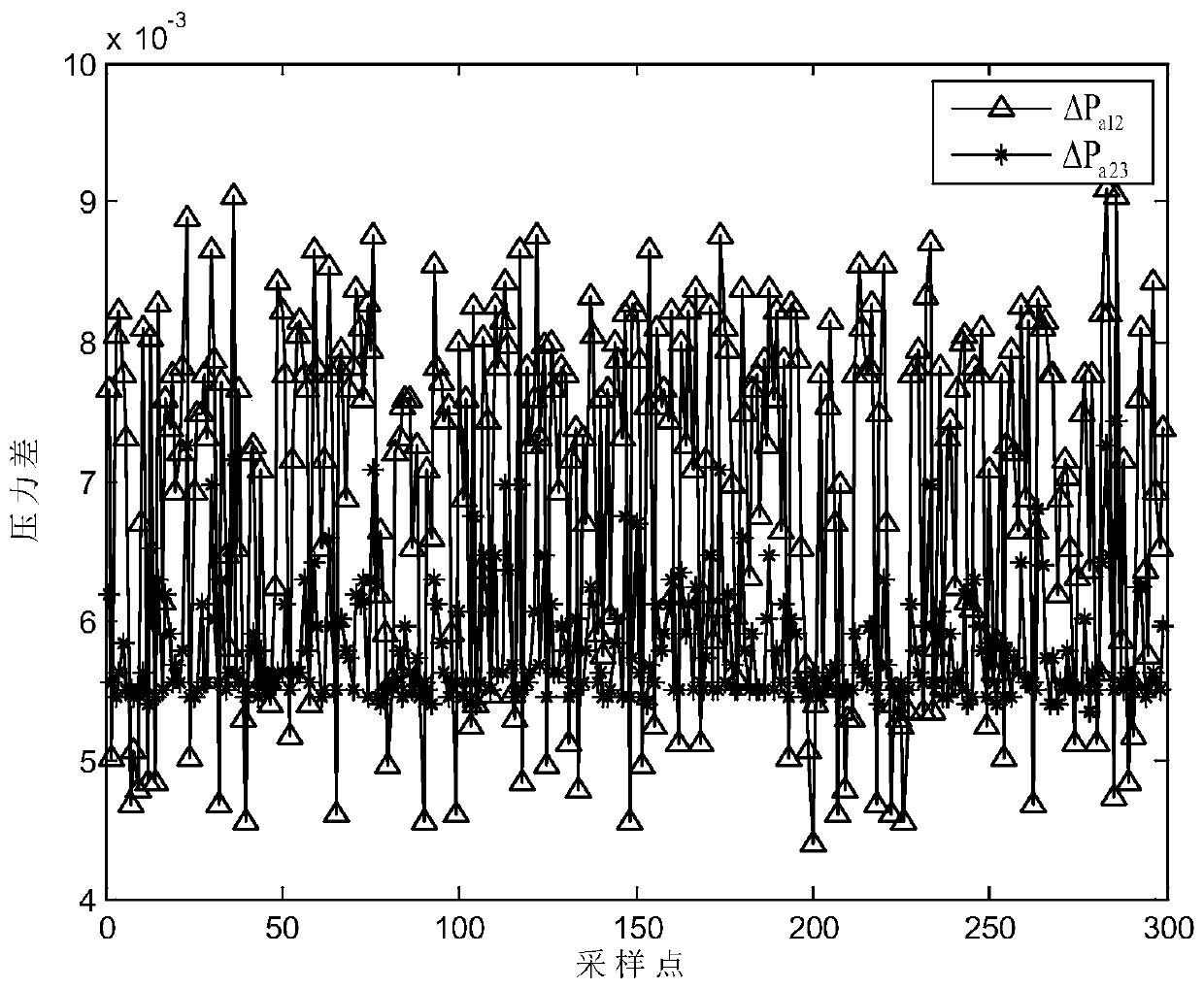

Thickener underflow concentration prediction method based on DAJYPLS algorithm

ActiveCN110276128ALow failure rateSolve problems that are difficult to build predictive modelsForecastingDesign optimisation/simulationFailure rateData set

The invention provides a thickener underflow concentration prediction method based on a DAJYPLS algorithm, and relates to the technical field of hydrometallurgy. The method comprises the following steps: step 1, determining a data set required for establishing a model; 2, performing standardized processing on data in the data set; step 3, establishing a DAJYPLS prediction model based on a JYPLS algorithm; step 4, giving a new sample xnew for the target domain. According to the method, an accurate prediction model can still be established when a small amount of on-site sampling data exists, so that an operator is assisted in control, safe and stable operation of the thickening and dewatering process is guaranteed, comprehensive economic benefits are improved, and meanwhile, the failure rate of the filter press is reduced.

Owner:NORTHEASTERN UNIV

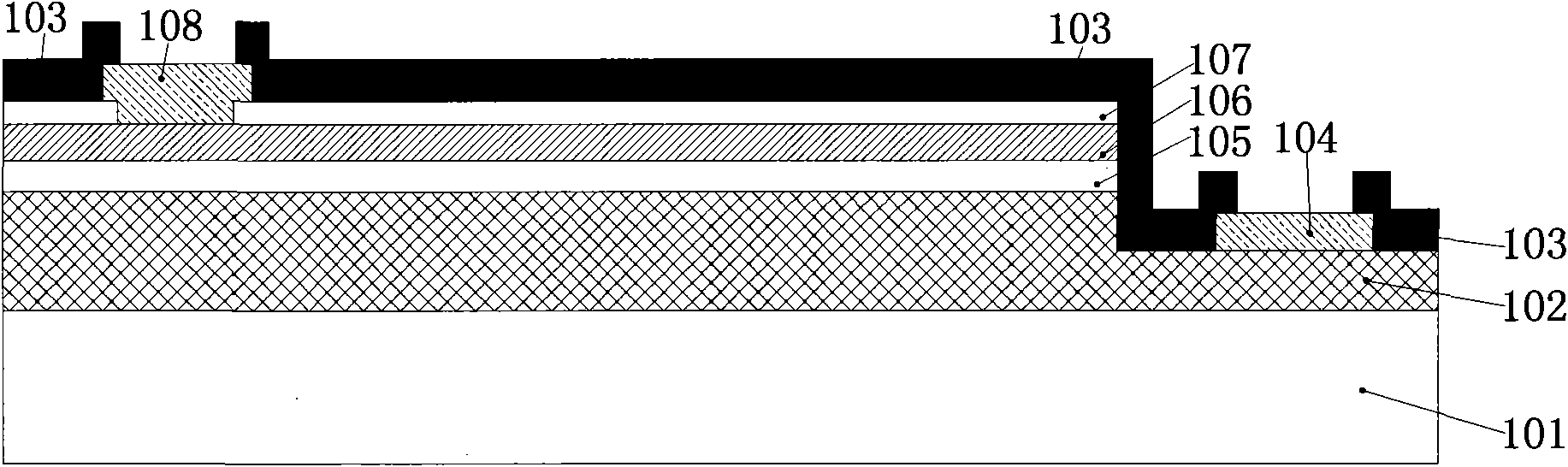

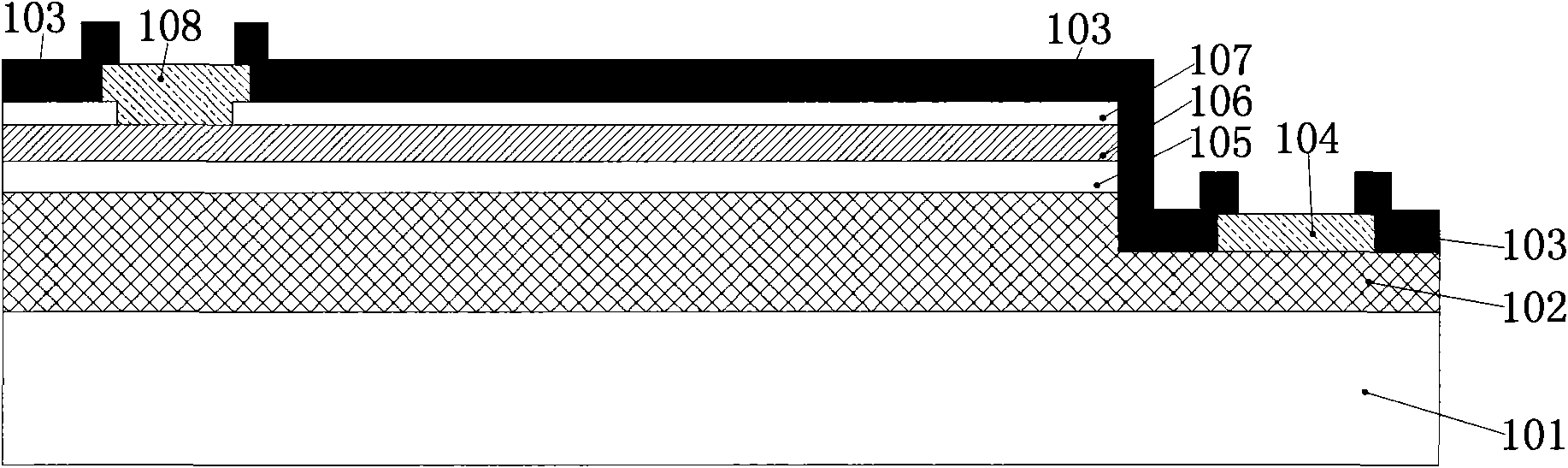

Light-emitting diode with light filtering film and manufacturing method thereof

InactiveCN101937959ALight attenuation is smallGood production compatibilitySemiconductor devicesTransmittanceCoating system

The invention discloses a light-emitting diode with a light filtering film. A gallium-nitride-based light-emitting diode is used for processing P and N electrodes in a normal process, an electron beam evaporation or ion beam sputtering coating system is used for growing a wavelength pass filtering film layer outside P and N electrode areas of the light-emitting diode, and the wavelength pass filtering film layer has a stopping function for short-wavelength light, such as ultraviolet light, and the like and high transmissivity for long-wavelength light. Because short-wavelength light can accelerate the ageing of an LED (Light-Emitting Diode) packaging material, when being packaged, an LED chip with a long wavelength pass filtering film layer structure effectively reduces light decay of the LED, ensures reliability, consistency and service life of the LED, simplifies extended structure design and shortens extended research and development time at the same time.

Owner:HC SEMITEK CORP

Front mold plate of injection molding machine and capable of mounting and fixing mold conveniently

The invention discloses a front mold plate of an injection molding machine and capable of mounting and fixing a mold conveniently. The front mold plate comprises a front mold plate body, a motor and hydraulic cylinders. A locating hole is formed in the middle of the front mold plate body. Sliding blocks are mounted in sliding rails. The outer sides of cross shafts are sleeved with driven gears. Dustproof covers are mounted on the outer sides of mounting plates through bolts. A motor is mounted in the middle of each dustproof cover through bolts. Mounting blocks are integrally arranged on the front portions of screws, and grooves are formed in the rear surfaces of the mounting blocks. The hydraulic cylinders are mounted on the left side and the right side of the rear surface of the front mold plate body through bolts. The front mold plate of the injection molding machine and capable of mounting and fixing the mold conveniently is provided with the screws, the cross shafts and the mounting blocks, in the use process, the screws and the cross shafts are driven by the motors and gears to rotate, and therefore the positions of the mounting blocks are adjusted in cooperation with the sliding blocks, the mounting blocks can clamp and fasten an upper mold seat plate of the mold effectively, and the process that technical staff do mold mounting work through a wrench is not needed.

Owner:沪金(苏州)实业有限公司

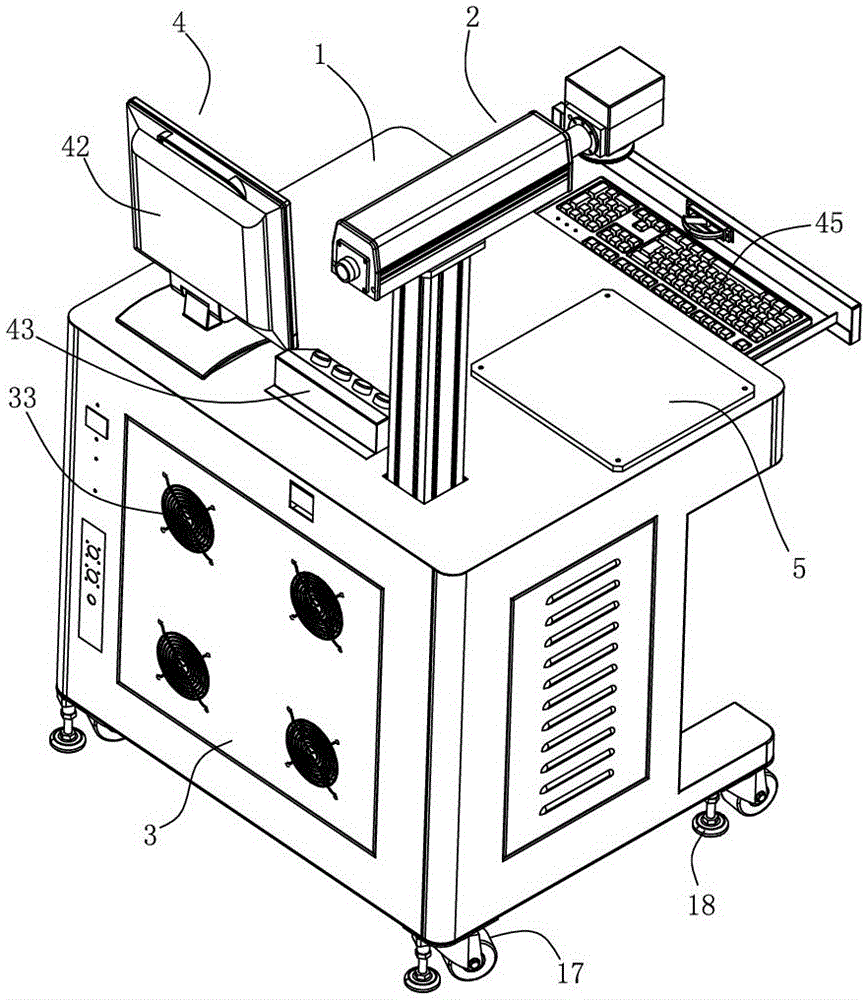

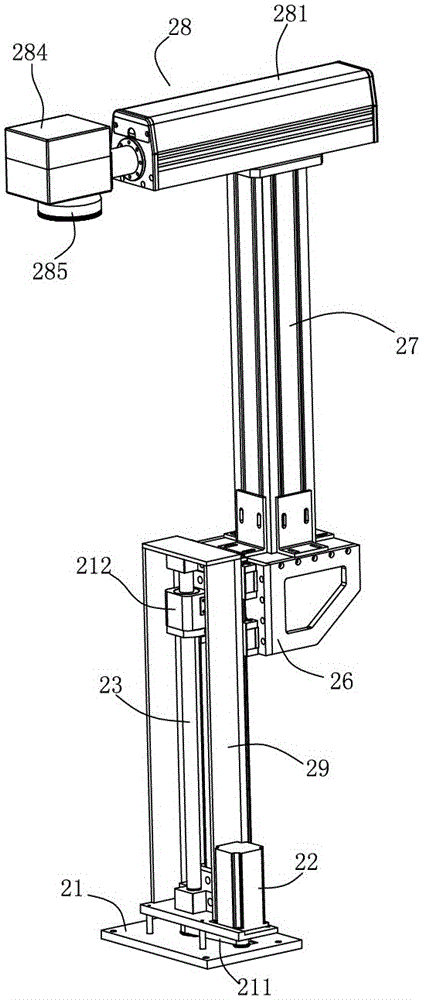

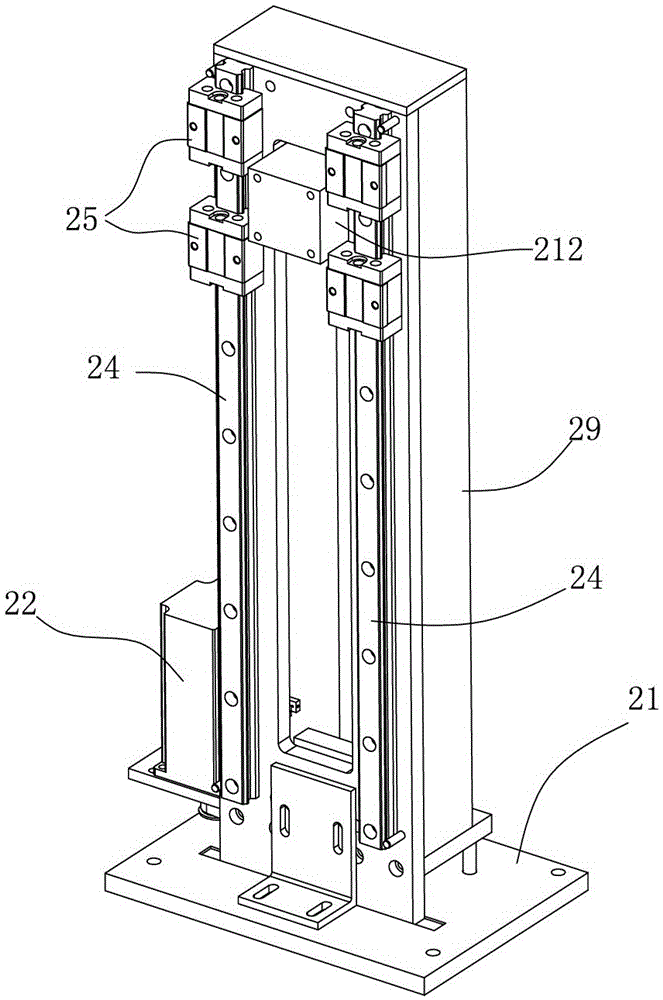

Laser marking machine

InactiveCN106218226AImprove efficiencyImprove securityPrintingWork performanceBiochemical engineering

The invention discloses a laser marking machine. The laser marking machine comprises a machine bench, an automatic focusing and scanning system, a cabinet and an industrial control system. The cabinet is arranged in the machine bench. The industrial control system is electrically connected with the cabinet and the automatic focusing and scanning system. The automatic focusing and scanning system comprises a bottom installation plate, a screw rod, guide rails, slide blocks capable of moving up and down on the rails, an elevating base which is fixedly connected with the slide blocks and is driven by the screw rod to move up and down, a focusing and scanning support arranged on the elevating seat and a focusing and scanning assembly arranged at the top of the focusing and scanning support. The bottom installation plate is fixed in the machine bench. The focusing and scanning assembly is arranged above the machine bench. A work bench is arranged corresponding to the focusing and scanning assembly on the machine bench. The laser marking machine is simple and proper in structure, ingenuous in design, stable and reliable in working performance, high in automation degree, stable and reliable in marking quality, high in precision and efficiency, low in fault rate, and capable of effectively increasing production efficiency of an enterprise and reducing production cost.

Owner:东莞市环亚激光科技有限公司

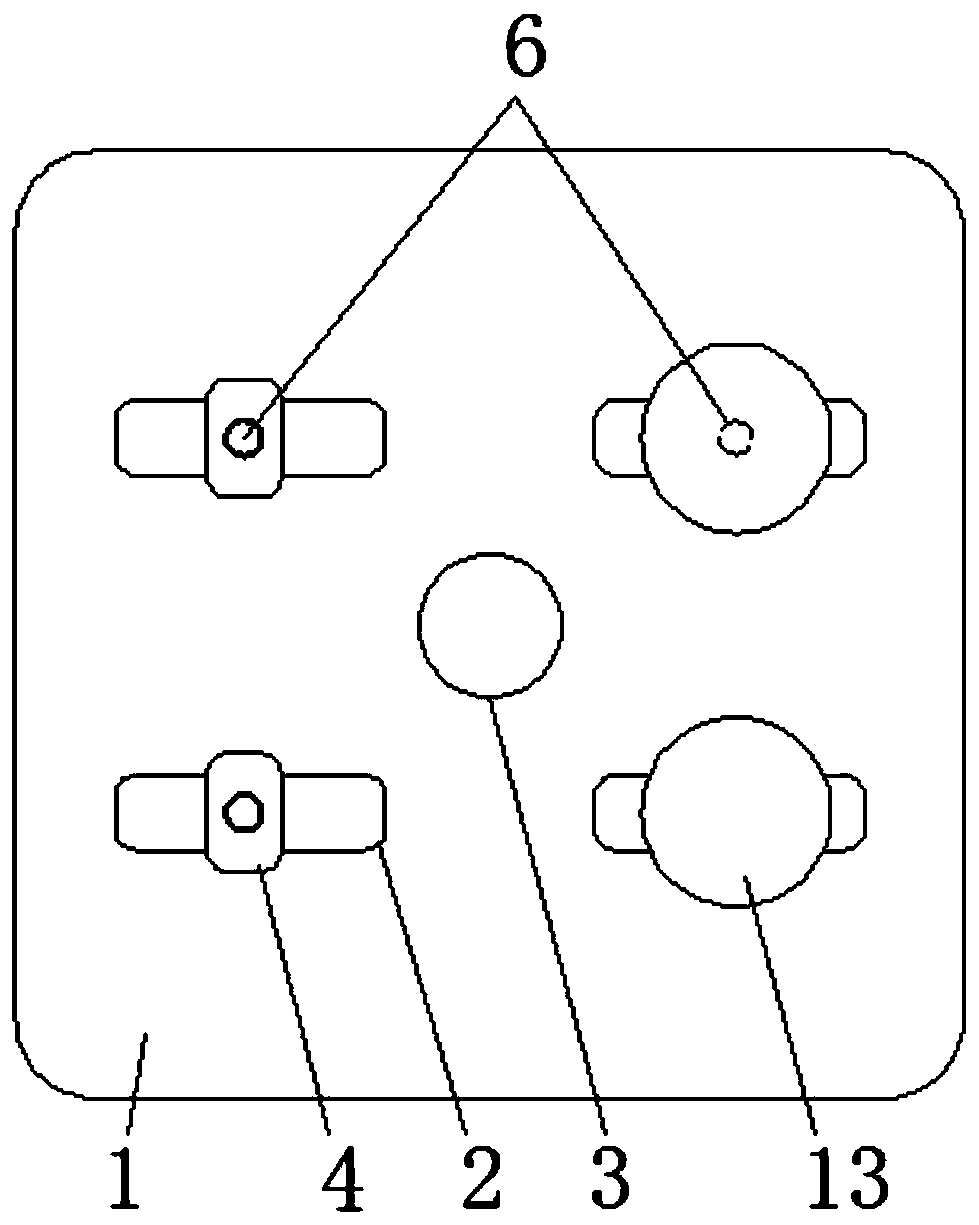

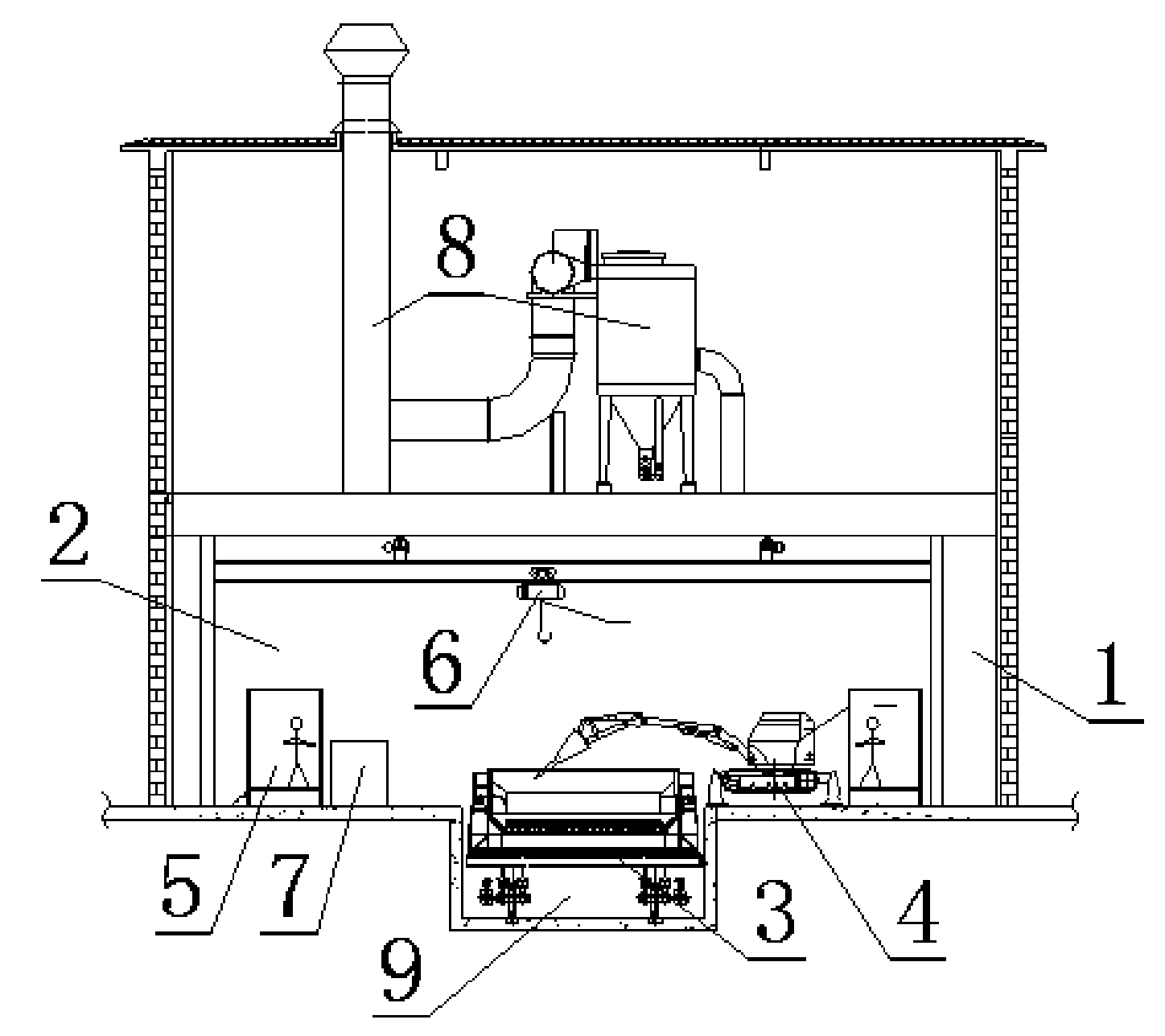

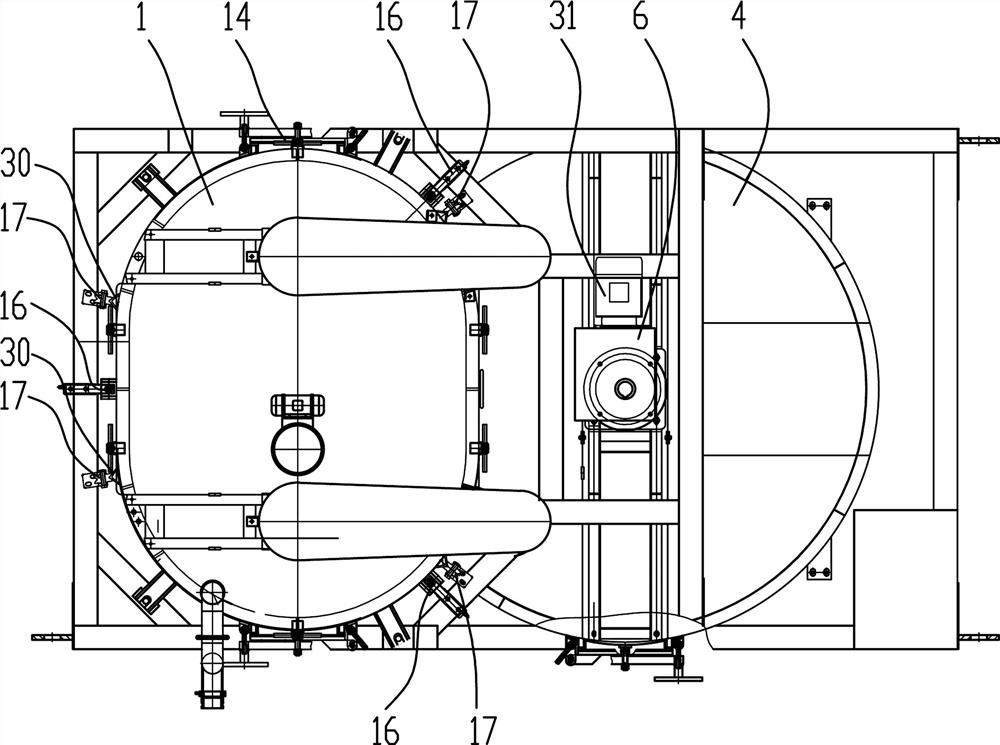

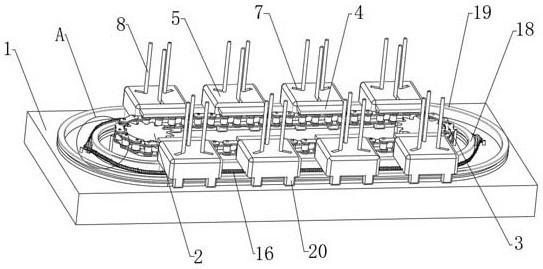

Configuration mode for an electrobath overhaul workshop and a furnace dismounting room

InactiveCN101591789AEasy accessQuickly put into productionIndustrial buildingsRemote controlEngineering

The invention discloses a configuration mode for an electrobath overhaul workshop and a furnace dismounting room. The electrobath overhaul workshop comprises a bath overhaul workshop (1); the furnace dismounting room (2) is arranged inside or outside the bath overhaul workshop (1); the inside of the furnace dismounting room (2) is provided with one or more than one multifunctional remote control planning furnace machines (4), closed control rooms (5) and an underhung cranes (6); and an electric flat bed truck (3) is arranged from a door opening to the furnace dismounting room (2). By the configuration mode, when the electrobath is maintained, the working procedures with large labor intensity and higher dust and noise are finished in the furnace dismounting room during the maintenance, and a dust collecting system is arranged on the top or the lateral surface of the furnace dismounting room, so large amount of dust generated in the process of dismounting cannot be discharged in an inorganization mode, and the influence on the environment is avoided.

Owner:GUIYANG AL-MG DESIGN & RES INST

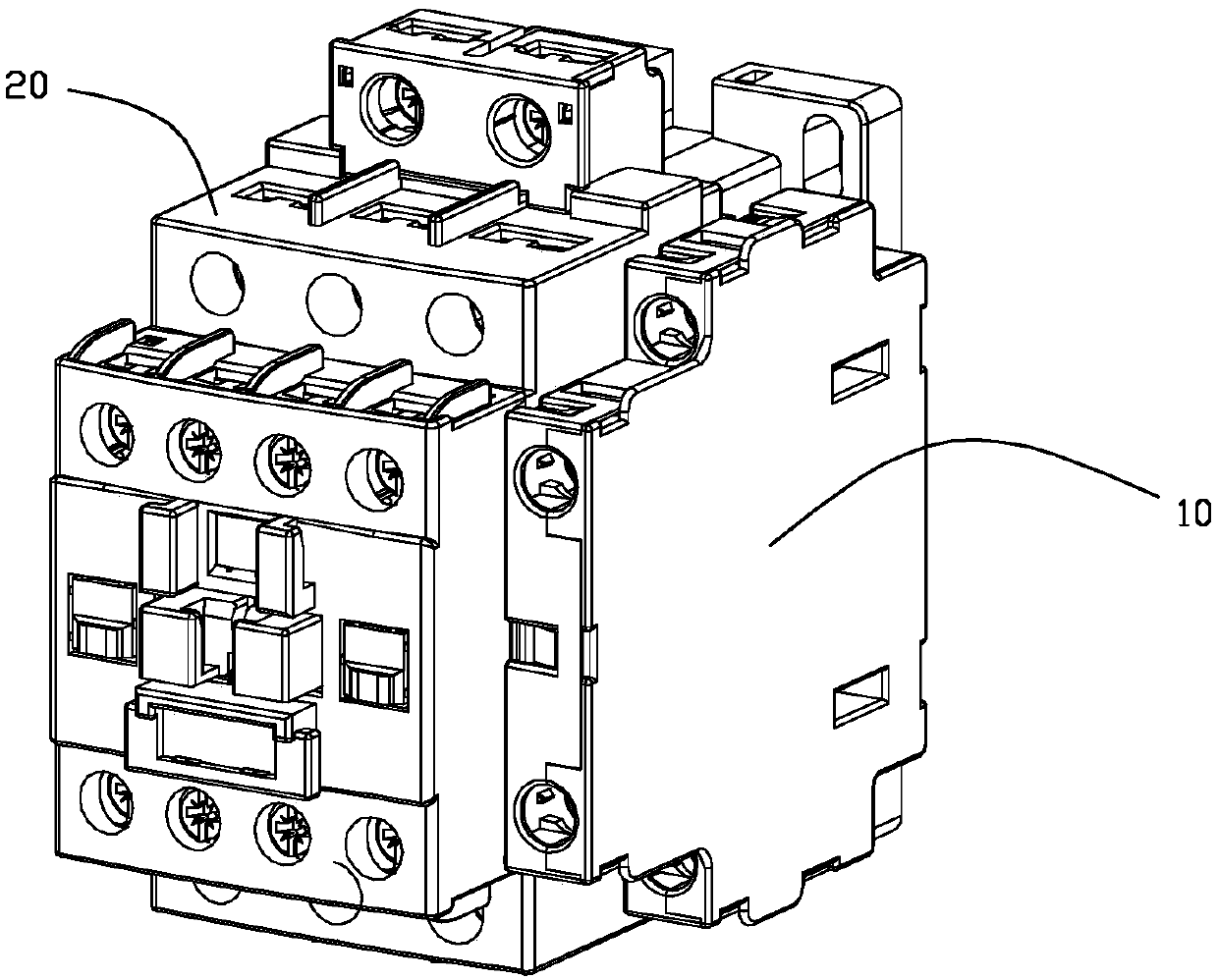

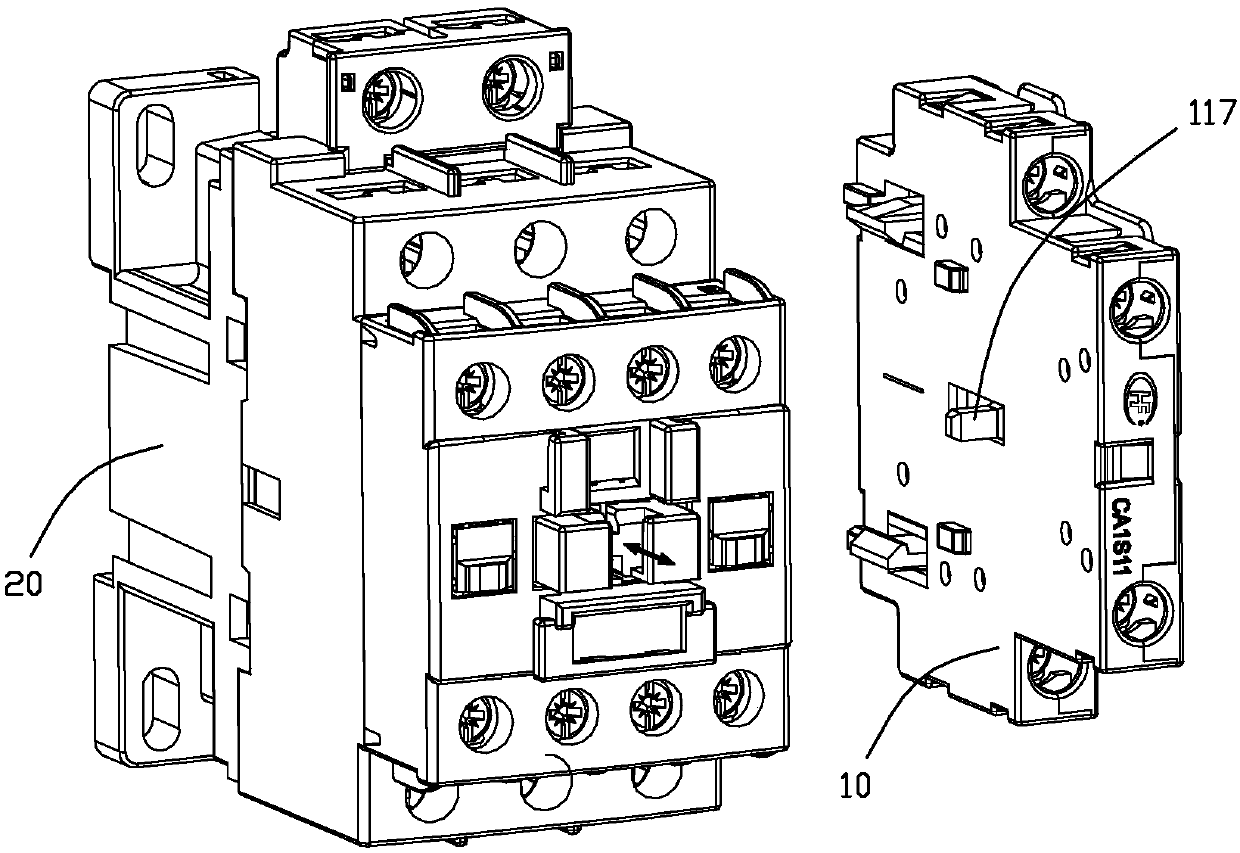

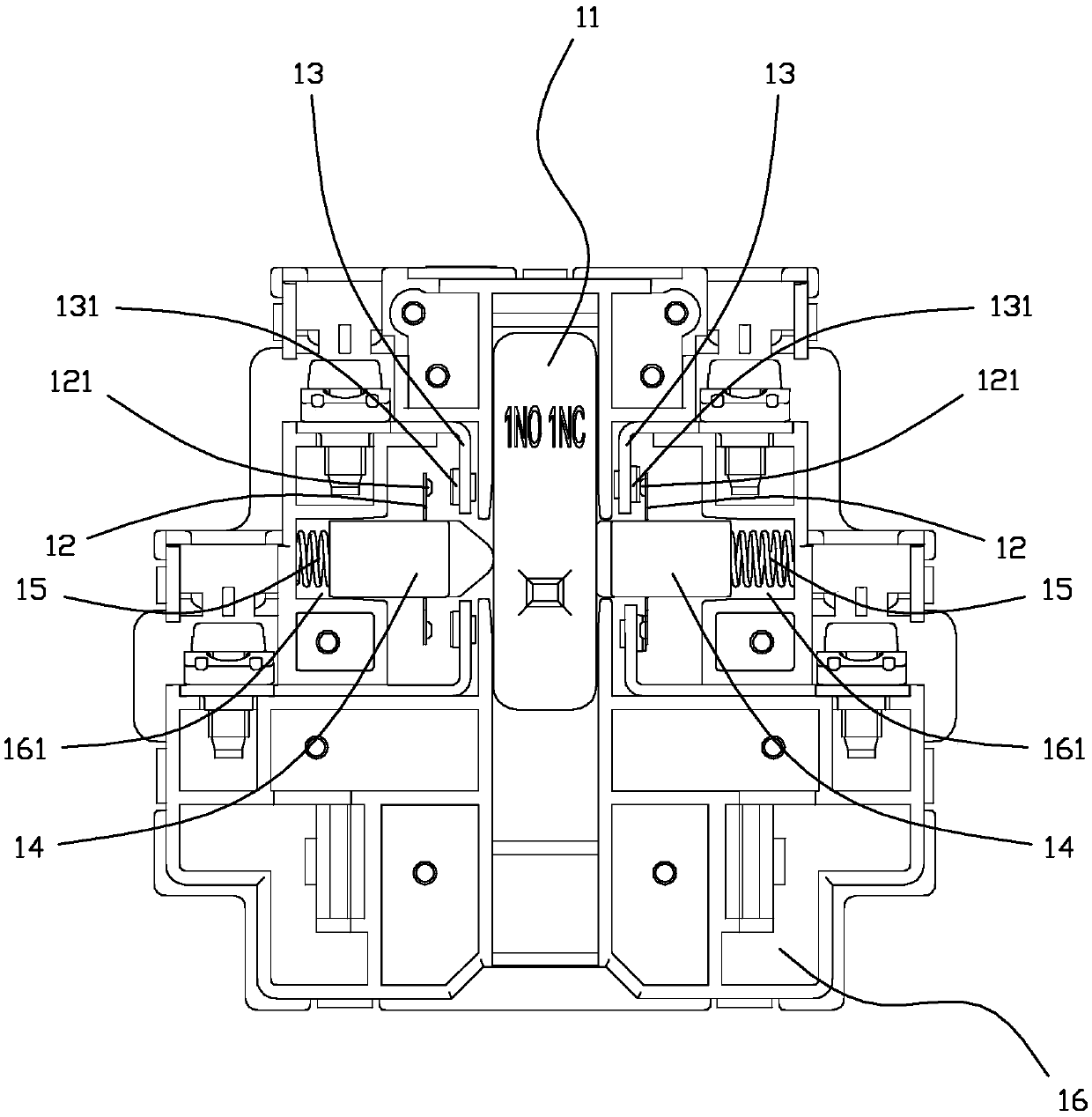

Side-hung auxiliary contact module with contact adhesion self-locking function

PendingCN109585230AEnsure safetyReduce burden and energy consumptionElectromagnetic relay detailsContactorSelf locking

The invention relates to a side-hung auxiliary contact module with a contact adhesion self-locking function; through a sliding rod with a special structure, two sets of moving contacts form an associated mechanical interlocking relation; through the mechanical locking action of the sliding rods, when one set of contacts is closed, the other set of contacts is unconditionally kept open or the two sets of contacts are kept in an closed or disconnected state unconditionally. When a contact adhesion fault occurs on one of the contact systems on one side, and when the moving contact at the fault side cannot be driven by the sliding rod to change the working state, the sliding rod is locked, so that the contact support at the normal end is locked immovably by the sliding rod which is kept at thecurrent position, and therefore the safety is ensured. According to the module, no extra energy is needed for the body contactor basically, so that the state of the sliding rod can be kept, and the burden and energy consumption of the contactor are reduced. According to the module, the sliding rod and the movable contact and the contact support are all in linear motion, only needing to provide asmall movement space for the product, so that it is beneficial to miniaturization, lightening and thinning design of the product.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS

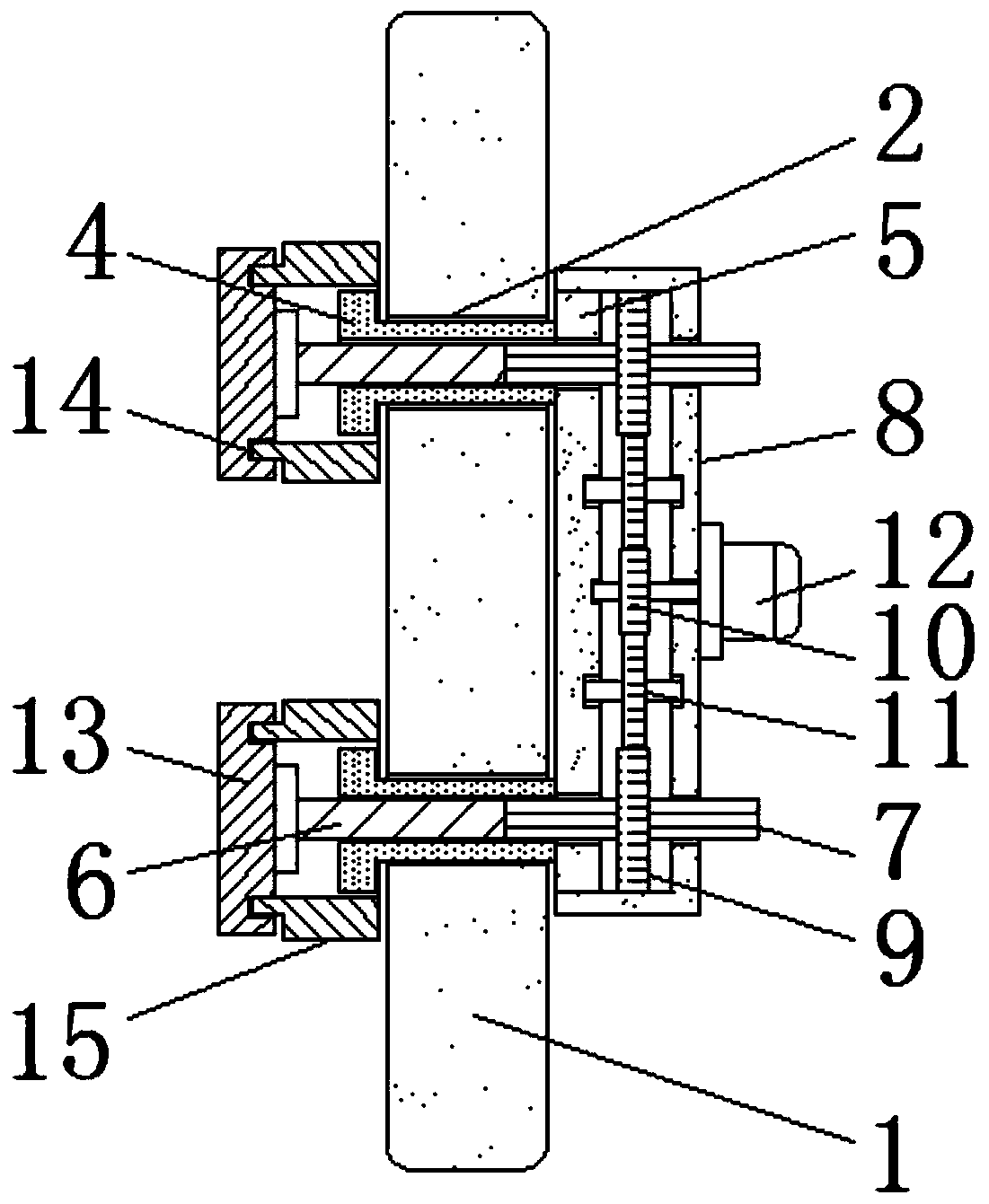

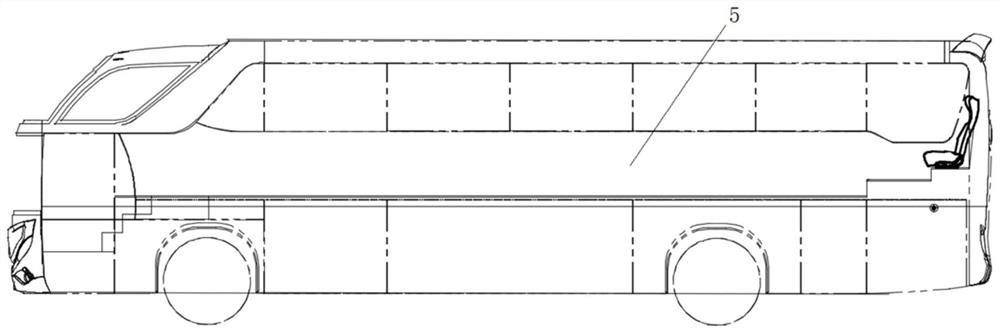

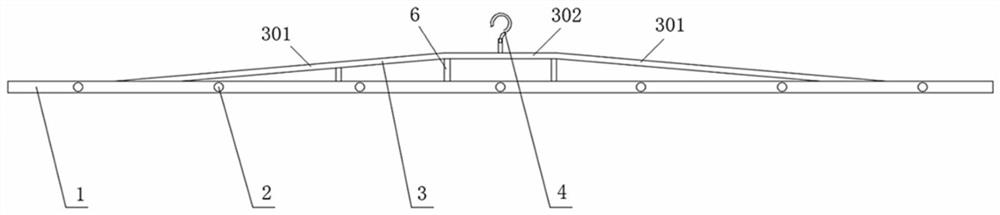

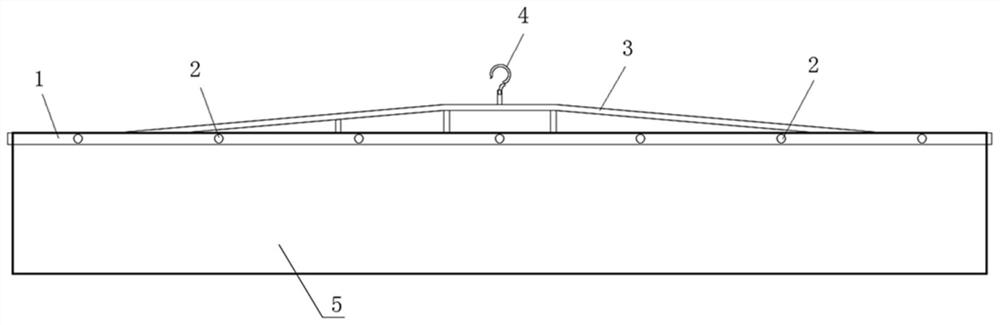

Novel passenger car body tensioning skin lifting device

PendingCN112209213ASimple structureExpensive to solveLoad-engaging elementsCar passengerControl theory

The invention relates to a novel passenger car body tensioning skin lifting device. The novel passenger car body tensioning skin lifting device comprises a main bearing cross beam (1), a hanging bracket cross beam (3) and a hanging hook (4) used for moving by a operating traveling crane and a plurality of electromagnetic chucks (2) used for attracting a car body skin (5); the hanging bracket crossbeam (3) is fixed to the top of the main bearing cross beam (1); the hanging hook (4) is fixed in the central position of the top of the hanging bracket cross beam (3); a hook hole of the hanging hook (4) is arranged in the operating traveling crane; the plurality of electromagnetic chucks (2) are uniformly distributed on the side wall of the main bearing cross beam (1); the plurality of electromagnetic chucks (2) are controlled by the same electromagnetic chuck controller circuit; and the electromagnetic chuck controller circuit comprises a rectifying circuit, a control circuit and a protection circuit. Compared with the prior art, the novel passenger car body tensioning skin lifting device has the advantages of simple operation, cost saving, labor saving, occupied space saving, accuratepositioning and the like.

Owner:SHANGHAI SUNLONG BUS

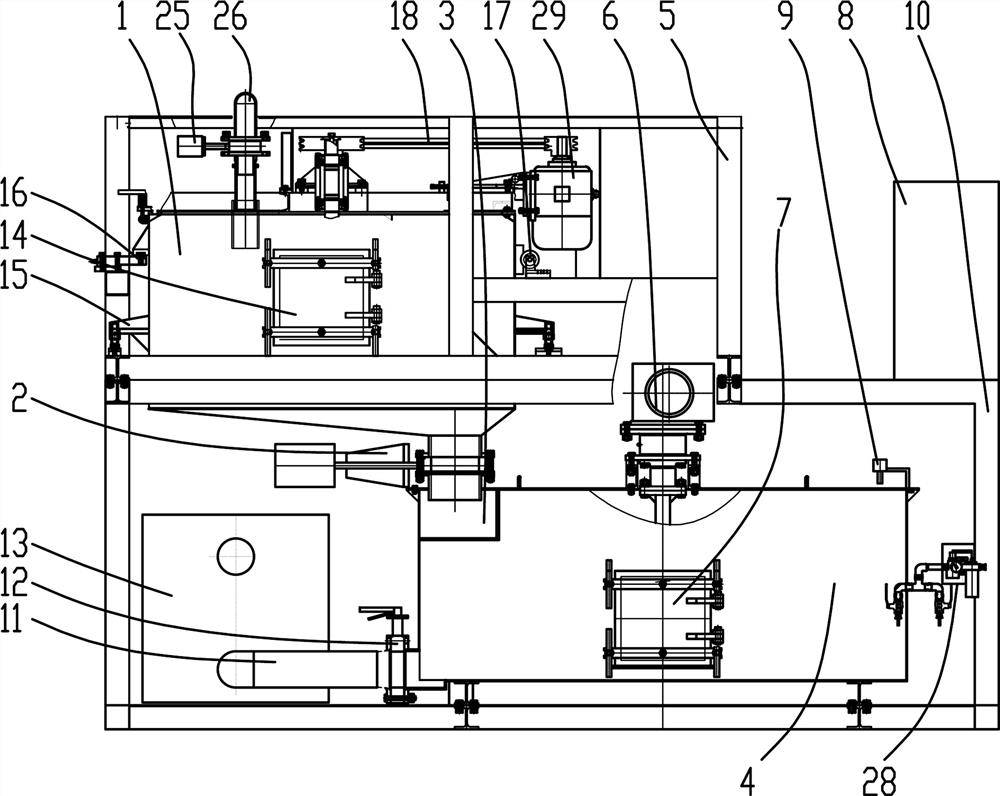

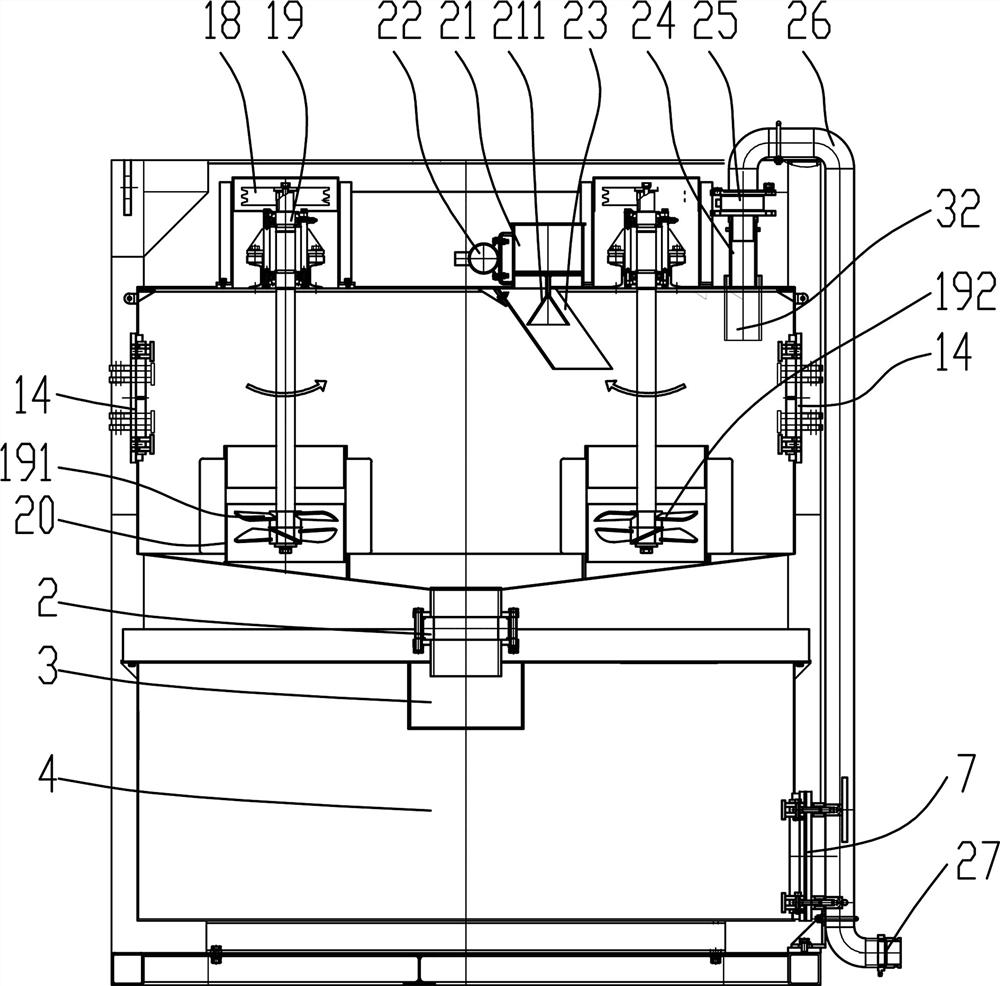

Cement slurry preparing, stirring and conveying integrated system

PendingCN111791367AGuaranteed accuracyQuick connectionMixing operation control apparatusIngredients proportioning apparatusInlet valvePulp and paper industry

The invention provides a cement slurry preparing, stirring and conveying integrated system. The cement slurry preparing, stirring and conveying integrated system comprises a slurry preparing machine and a stirring machine; the slurry preparing machine is located above the stirring machine, and a slurry outlet pipeline of the stirring machine is connected with an inlet of a conveying pump; the slurry preparing machine is supported on an upper frame through a plurality of weighing sensors, a water inlet pipeline is arranged at the top of the slurry preparing machine, an automatic water inlet valve is arranged on the water inlet pipeline, and the water inlet pipeline is movably connected with a liquid inlet in the top of a barrel body of the slurry preparing machine; and a cement feeding holeis further formed in the top of the slurry preparing machine. According to the cement slurry preparing, stirring and conveying integrated system, the slurry preparing machine is stacked above the stirring machine by adopting the modularized frame stacking structure, and the fed cement and water can be accurately weighed, so that the accuracy of the water cement ratio is ensured. The system is convenient to mount and dismount on site, high in slurry preparing precision, high in speed and small in number of operators, and only one operator is needed at least.

Owner:三川德青工程机械有限公司

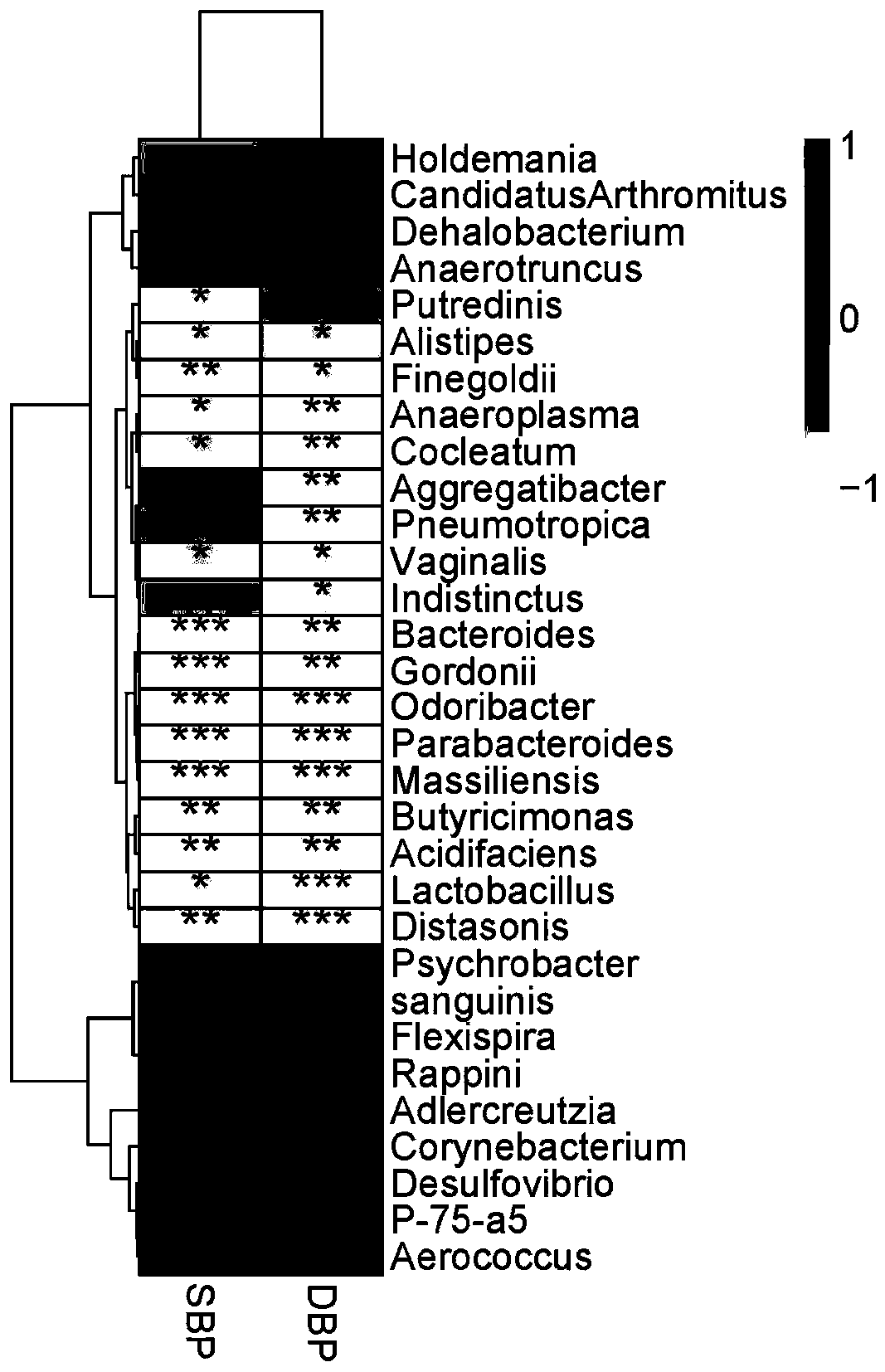

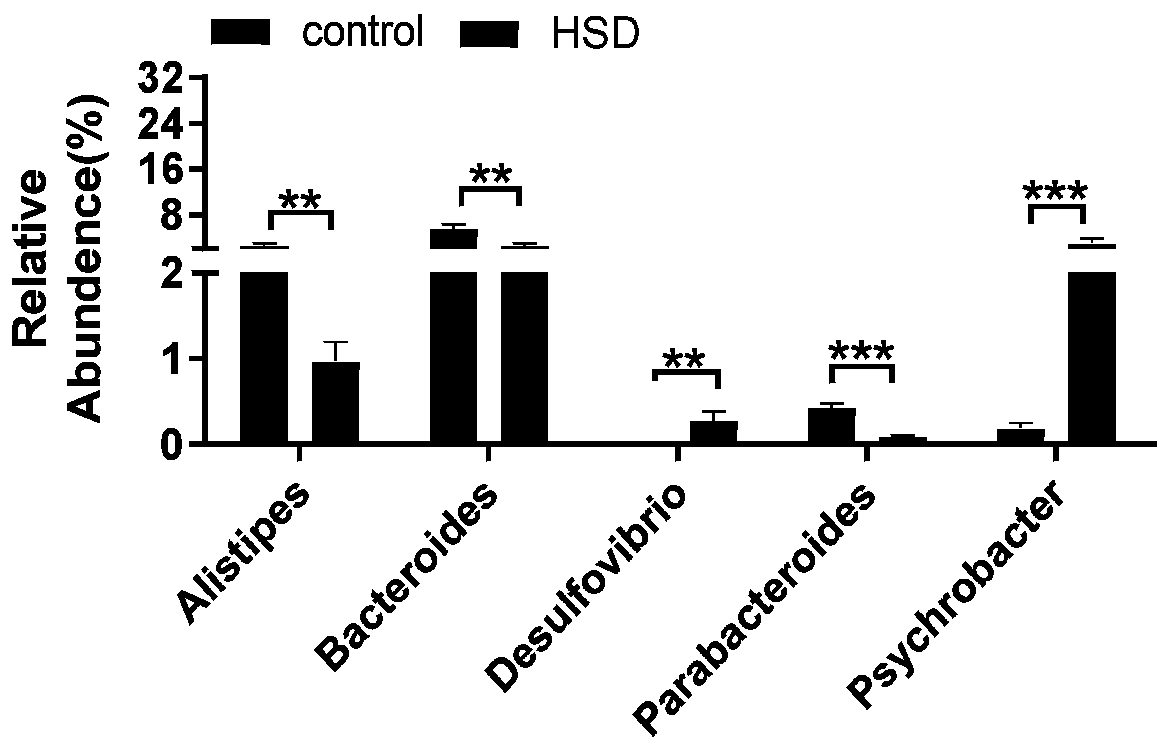

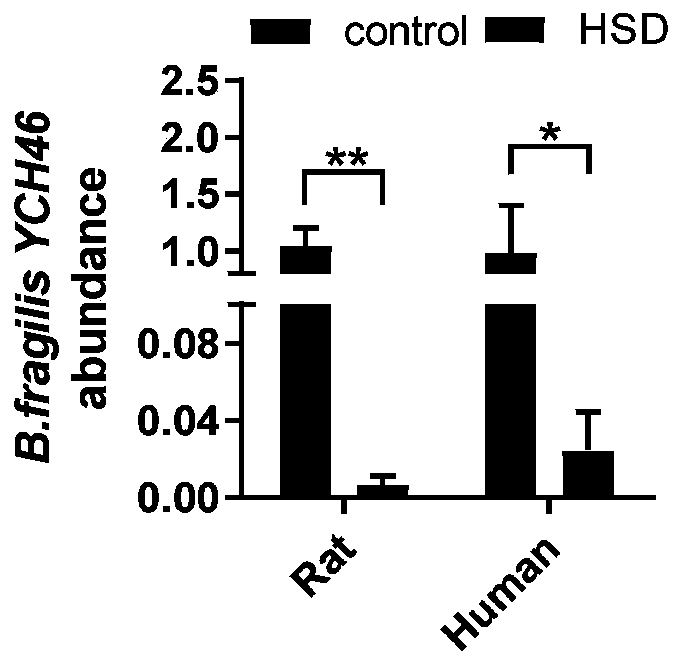

Application of bacteroides fragilis YCH46 in preparation of drugs for treatment or adjuvant treatment of hypertension

PendingCN110420228AReduce activationEasy to acceptBacteria material medical ingredientsCardiovascular disorderFood additiveDisease

The invention relates to application of bacteroides fragilis YCH46 in preparation of drugs for treatment or adjuvant treatment of hypertension. A pivotal role of the bacteroides fragilis YCH46 in a human intestinal tract in a hypertension disease is firstly found, the bacteroides fragilis YCH46 can restrain synthesis of intestinal tract corticosterone, and blood pressure is effectively reduced. Inaddition, because the bacteroides fragilis YCH46 is a microorganism normally existing in the intestinal tract, has no side effect on a body, and has the incomparable advantages than other new drugs.The pivotal role of the bacteroides fragilis YCH46 in the hypertension disease is used, drugs, drug compositions, food, health care products or food additives can be prepared, the bacteroides fragilisYCH46 can be used for treating the hypertension disease comprising primary hypertension and salt-sensitive hypertension, and important application value is achieved.

Owner:SHANDONG UNIV QILU HOSPITAL

Electric pulse control method and device for iron phase in iron-rich aluminum-silicon alloy

InactiveCN103817314BImprove mechanical propertiesHigh tensile strengthSilicon alloyElectrical impulse

The invention discloses an electric pulse control method for iron-rich aluminum-silicon alloy iron phases. The method includes the following steps that step1, iron-rich aluminum-silicon alloy is smelted to obtain iron-rich aluminum-silicon alloy melt, wherein the iron content in the iron-rich aluminum-silicon alloy is 0.5-1.2%, and the silicon content is 9-13%; step2, the iron-rich aluminum-silicon alloy melt is heated to 720 DEG C-760 DEG C, and electric pulse equipment is used for performing electric pulse treatment on the iron-rich aluminum-silicon alloy melt, wherein the electric pulse equipment comprises a pair of pulse electrodes which are inserted into the iron-rich aluminum-silicon alloy melt, in the process of electric pulse treatment, the pulse voltage is 500 V-1200 V, the pulse frequency is 3 Hz-15 Hz, and the continuing time is 10s-60s; step3, the iron-rich aluminum-silicon alloy melt which is subjected to the electric pulse treatment in the step2 is formed in a casting mode. Mechanical properties of the alloy treated through the method are greatly improved, the tensile strength is improved by 8-25%, the ductility is improved by 5-14%, and the invention further provides a device used for implementation of the method.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

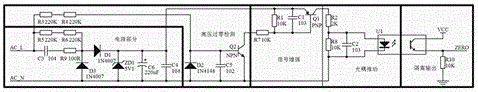

Isolation type precision zero-crossing detection circuit

InactiveCN106501587AHigh precisionWork reliablyCurrent/voltage measurementVoltage/current isolationCapacitanceZener diode

The invention discloses an isolation type precision zero-crossing detection circuit, which comprises a power supply circuit part, a high voltage zero-crossing detection circuit part, a signal enhancing circuit part, an optical coupler drive circuit part and an isolation output circuit part. The power supply circuit part includes a resistor R5, a resistor R6, a resistor R9, a rectifier diode D1, a rectifier diode D3, a Zener diode ZD1, a capacitor C3, a capacitor C4, and a capacitor C6. The high voltage zero crossing detection circuit part includes a resistor R3, a resistor R4, a triode Q2, a capacitor C5, and a rectifier diode D2. The signal enhancing circuit part includes a resistor R1, a resistor R7, a capacitor C1 and a triode Q1. The optical coupler drive circuit part includes a resistor R2, a resistor R8 and a capacitor C2. The isolation output circuit part includes a resistor R10. With a proper design, the precision of zero-crossing detection in a strong and weak power isolation circuit can be increased; the manufacturing cost and development difficulty for products with demanding requirement on power precision control can be reduced; and the development cycle is shortened.

Owner:青岛新芯智能电子科技有限公司

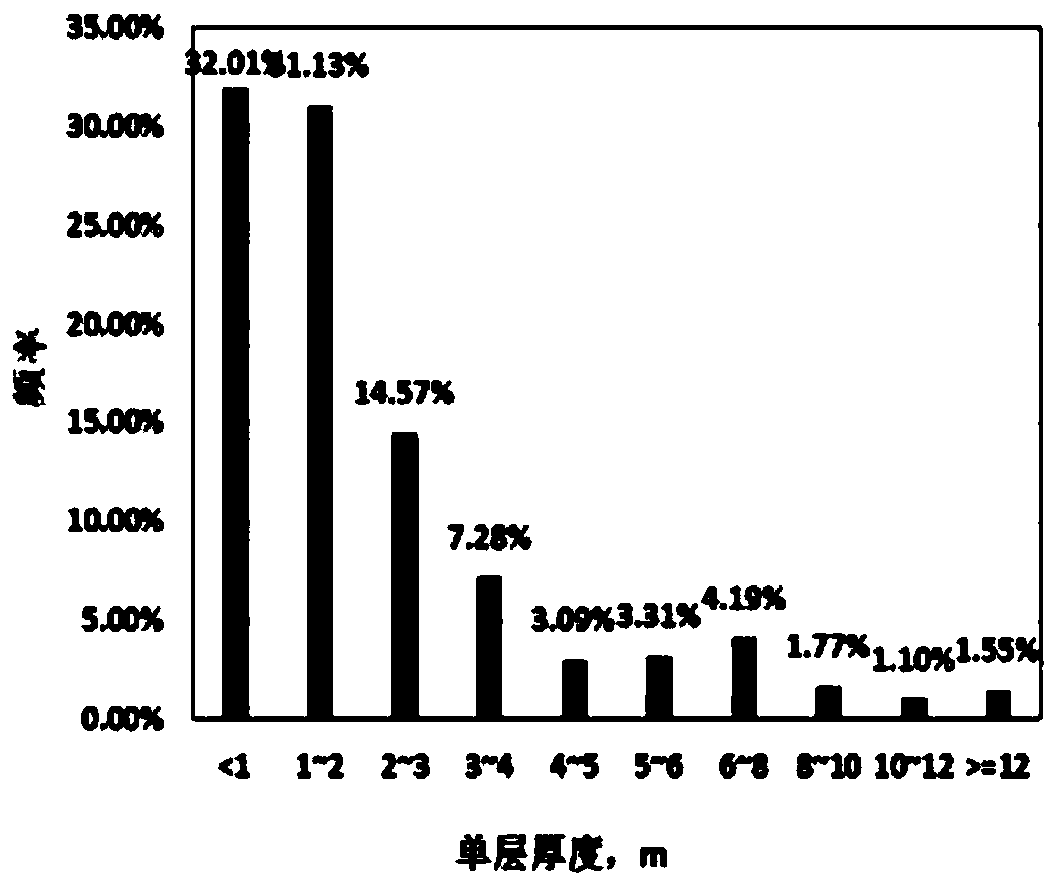

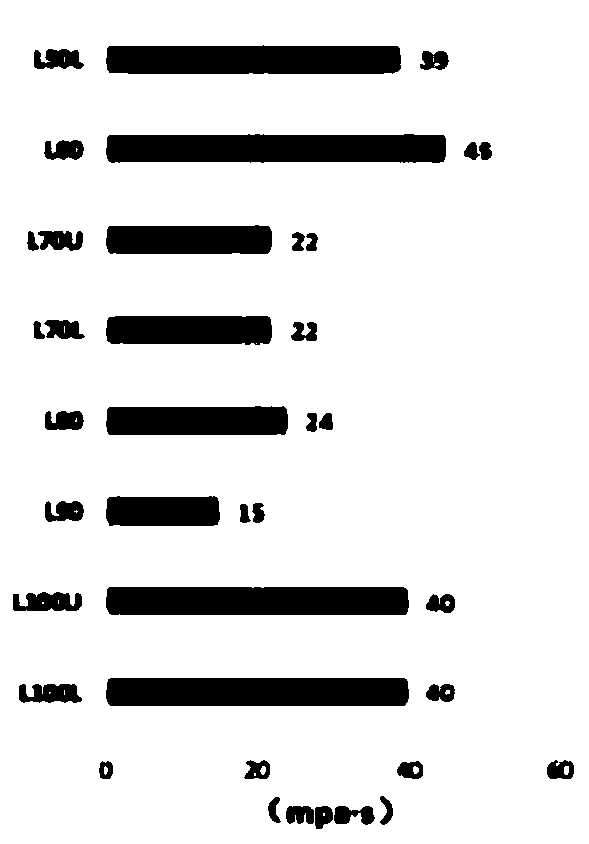

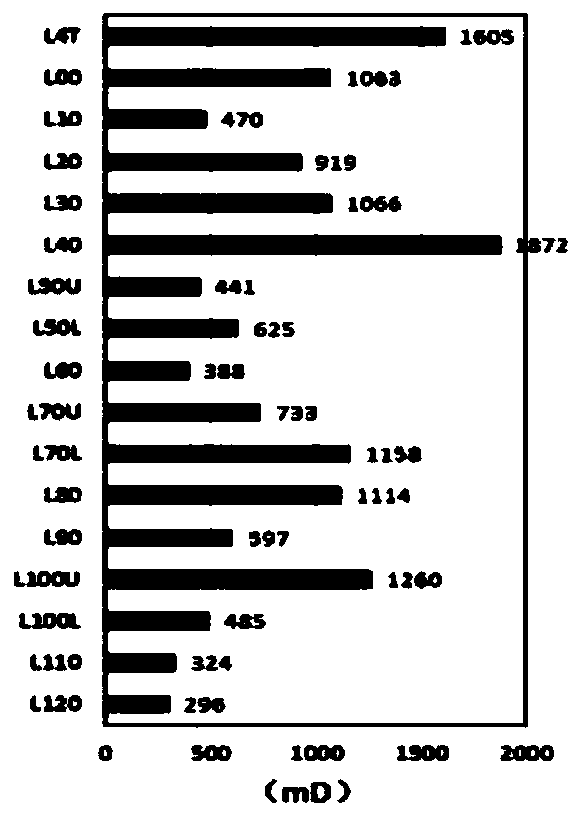

Development experimental design method based on main contradiction breakthrough direction of oil deposit development difficulties

The invention discloses a development experimental design method based on the main contradiction breakthrough direction of oil deposit development difficulties. The development experimental design method based on the main contradiction breakthrough direction of the oil deposit development difficulties comprise the following steps that S1, early experimental data of the oil deposit are analyzed interms of the target oil deposit; S2, the development difficulties of the target oil deposit are found according to early experimental data analysis; S3, according to the development difficulties of the target oil deposit and the oil deposit seepage mode, a core obtained through a cored well is taken as the represent of distribution of the rock quality of the oil deposit, the seepage mode of fluidin the oil deposit is stimulated in the target oil deposit, the main problems in the oil field regulation stage is described, and the oil field development experiment is designed specifically. According to the development experimental design method based on the main contradiction breakthrough direction of the oil deposit development difficulties, development experiment is specifically designed according to characteristics of the target oil deposit, the unnecessary experimental cost is reduced, and meanwhile the time is more saved, through the results of the development experiment, and the corresponding problems of the oil field is instructed to be solved so that the oil field can be put into production faster, and meanwhile the experiment design reference is provided for adjustment schemein the later period of the oil field.

Owner:SOUTHWEST PETROLEUM UNIV

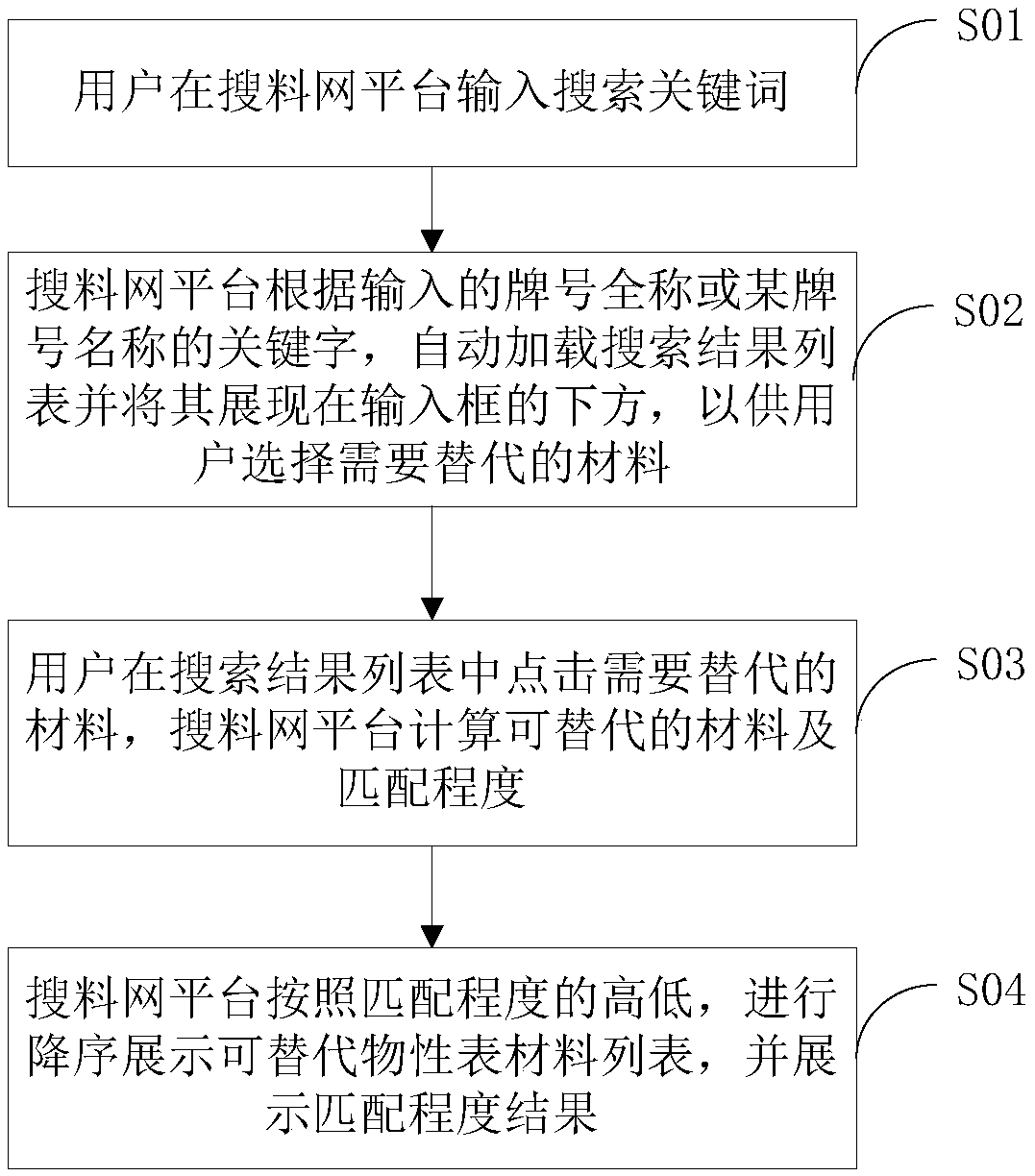

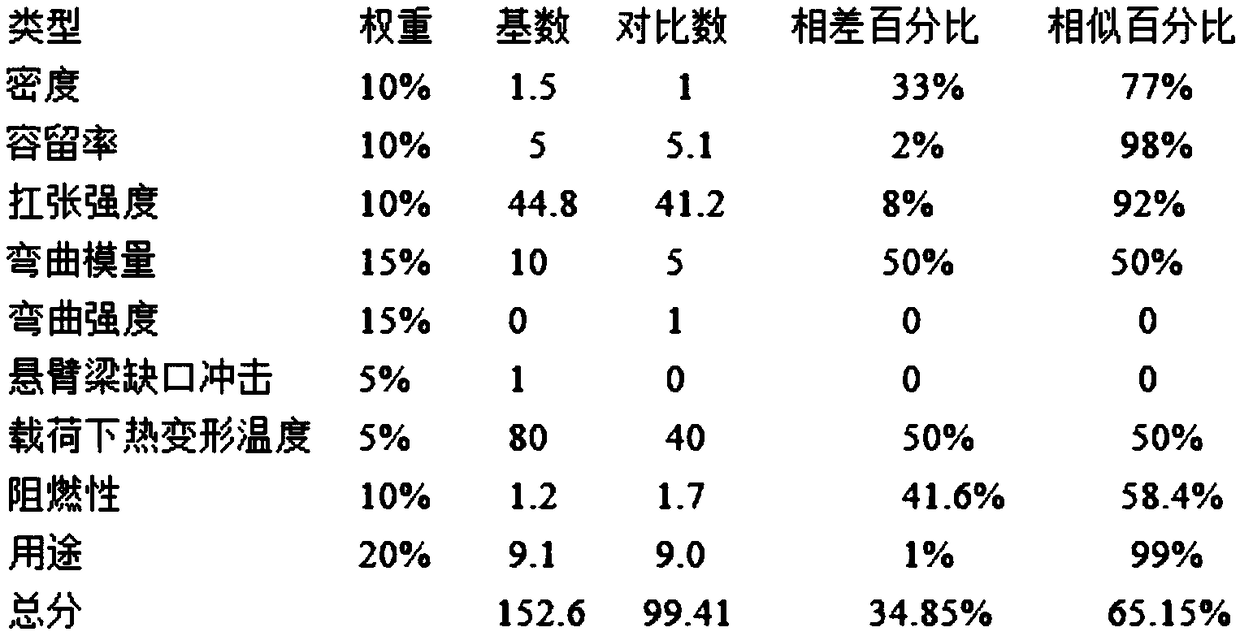

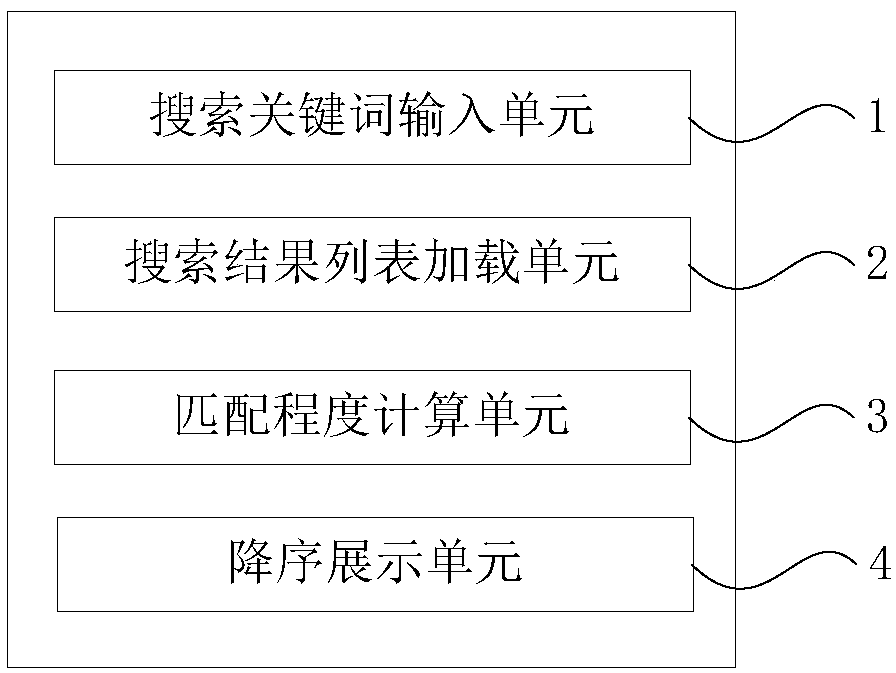

Method for searching for alternative materials based on physical property table of material searching network platform

PendingCN108846078ALow professional knowledge requirementQuickly put into productionData processing applicationsSpecial data processing applicationsQuality levelTrademark

The invention discloses a method for searching for alternative materials based on a physical property table of a material searching network platform, which comprises the following steps: a user inputsa searching keyword on the material searching network platform; according to the input full name of a trademark or the keyword of the name of the trademark, a search result list is automatically loaded and displayed at the bottom of an input box; a user clicks the alternative materials in the search result list, and the material searching network platform calculates the alternative materials andthe matching degrees; the material searching network platform displays an alternative physical property table material list in a descending order according to the matching degrees, and displays the matching degree result. The invention also relates to a device for realizing the method of searching for the alternative materials based on the physical property table of the material searching networkplatform. The invention can reduce the cost, on material selection analysis, of the enterprise, improve the quality level and production efficiency of the manufacturing industry, enable the enterpriseto put into production more quickly, and solve the problem that selection of the alternative raw material of a product is difficult in the manufacturing industry.

Owner:广州搜料信息技术有限公司

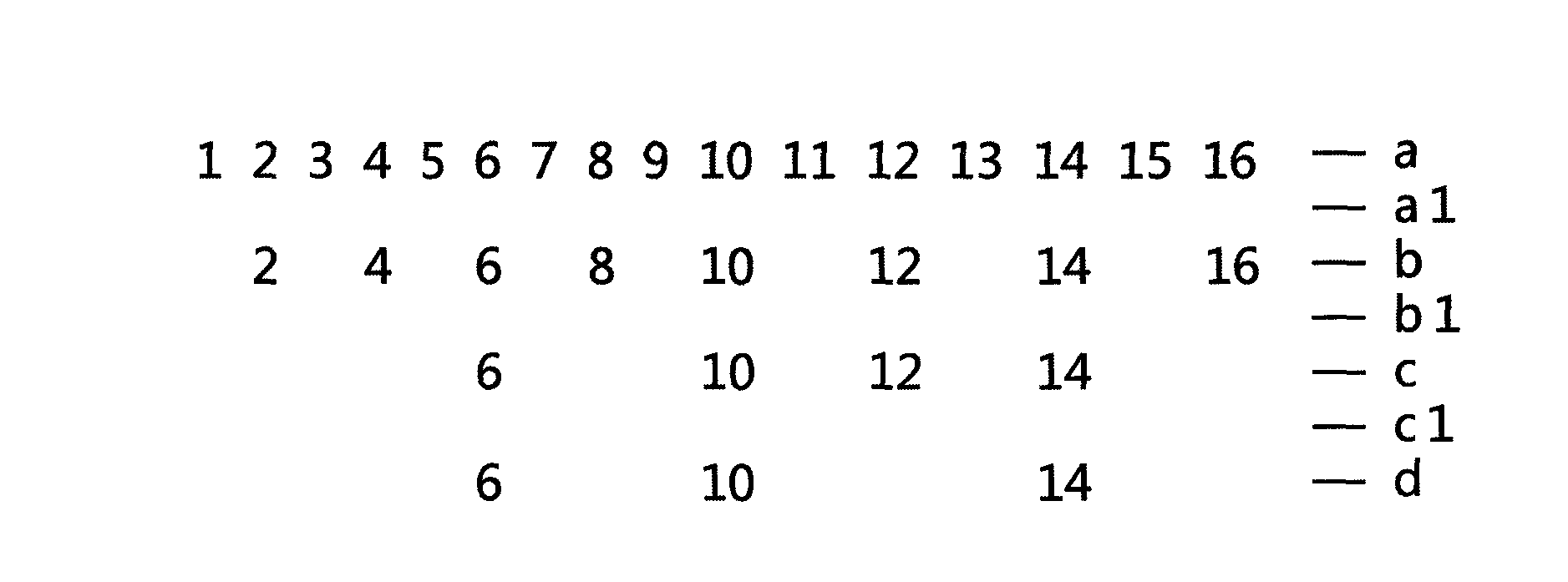

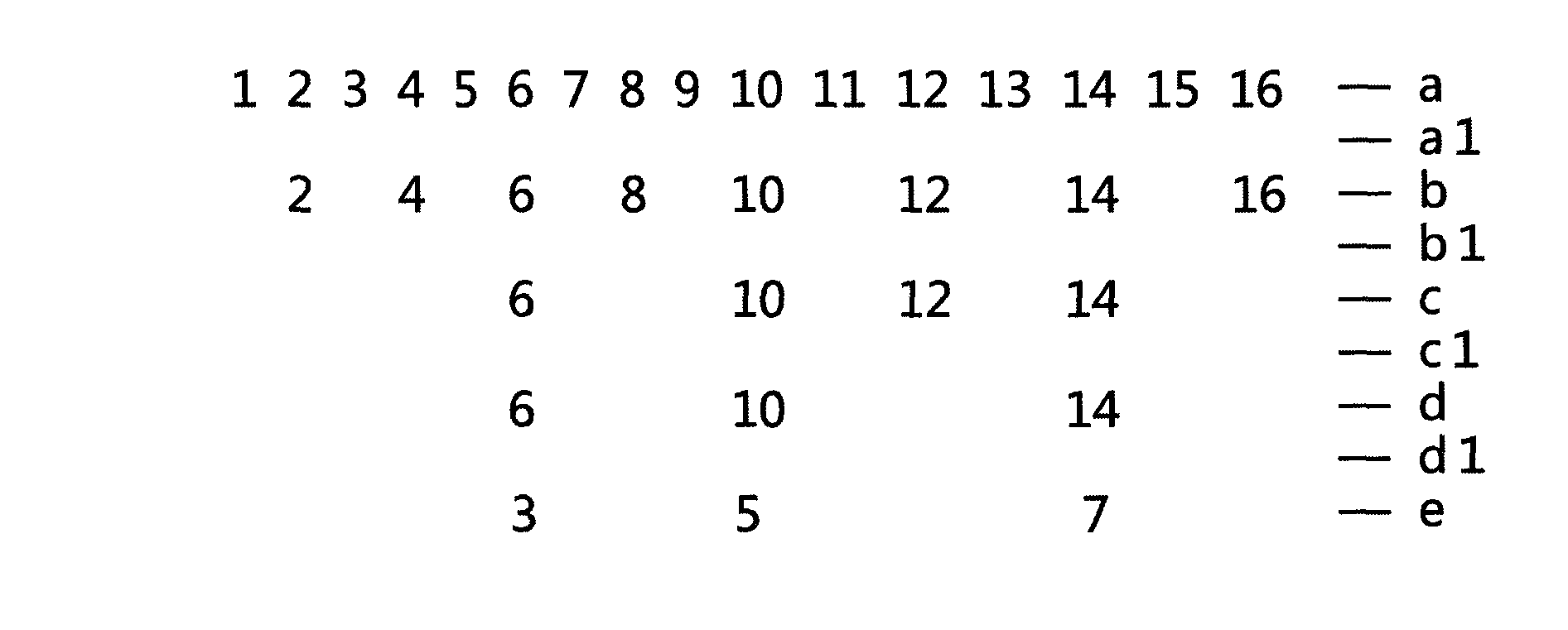

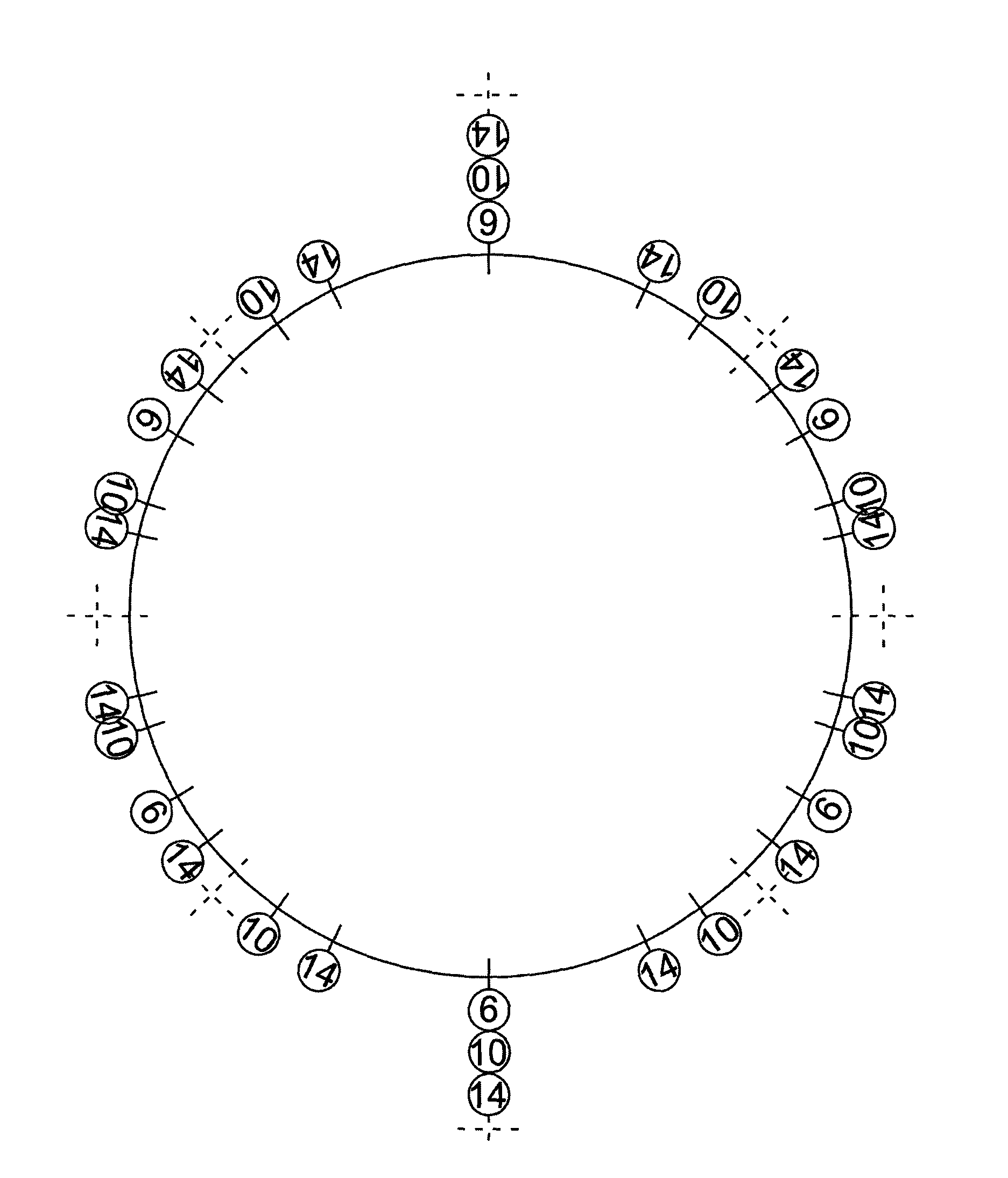

Dividing method meeting demands for different dividing parts of cake and having wide application scope

InactiveCN104094994ANo user limitNo hassle of carryingBaked article cutting/slicingGraphicsComputer science

The invention relates to a dividing method meeting demands for different dividing parts of a cake and having a wide application scope, which belongs to the field of daily consumption. The method mainly overcomes the problem of incapable of rapid dividing of a cake into different parts, especially into parts with a number difficult to obtain, such as 6 parts, 10 parts and 14 parts. The method comprises the following two parts: 1, scale marks for 3 parts, 5 parts and 7 parts or for 6 parts, 10 parts and 14 parts displayed after scientific analysis are presented on related articles like a bottom cake support / bottom cake packing paper in a planar or stereo form; and 2, a drawing corresponding to the dividing method is presented on the bottom support, the bottom packing paper or an external packing box of a cake or on an individual card, etc. Thus, a consumer can easily divide a cake into desired parts according to figure marks and instructions. Usage of the dividing method is not restricted by a place, a usage medium or the dimension of a cake; and the method is convenient, practical, fast and full of fun.

Owner:吴兵兵

Modular assembly type steel body container and assembly method thereof

The invention relates to a modular assembly type steel body container and an assembly method thereof. The modular assembly type steel body container comprises a first module, a third module and a second module which can be detachably assembled in sequence from left to right, the third module comprises 0 or at least one single body, and the single bodies can be detachably assembled. The assembly method of the modular assembly type steel body container comprises the steps that a site is flattened and the first module is fixed, then the single bodies of the third module are assembled in a sealing manner with bolts and a sealing material, and the first module, the third module and the second module are assembled in a sealing manner with bolts and a sealing material. The modular assembly type steel body container is convenient to transport, rapid to assemble and disassemble, good in sealing effect and easy and convenient to maintain, leakage is prevented when the modular assembly type steel body container is used for storing petroleum and chemical waste liquids, and the environment of a construction site can be prevented from being polluted.

Owner:HEBEI KUNRUI ENG TECH

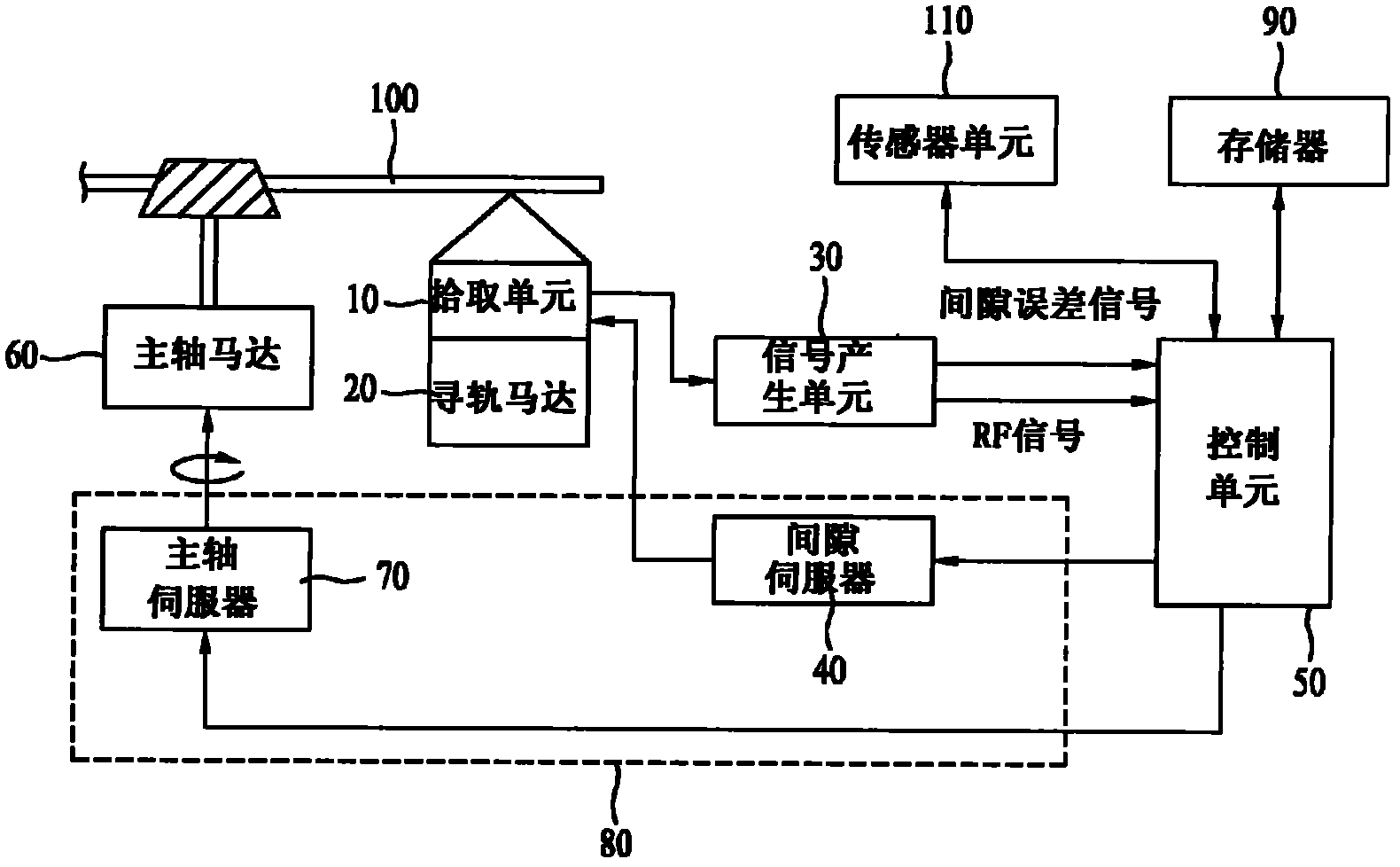

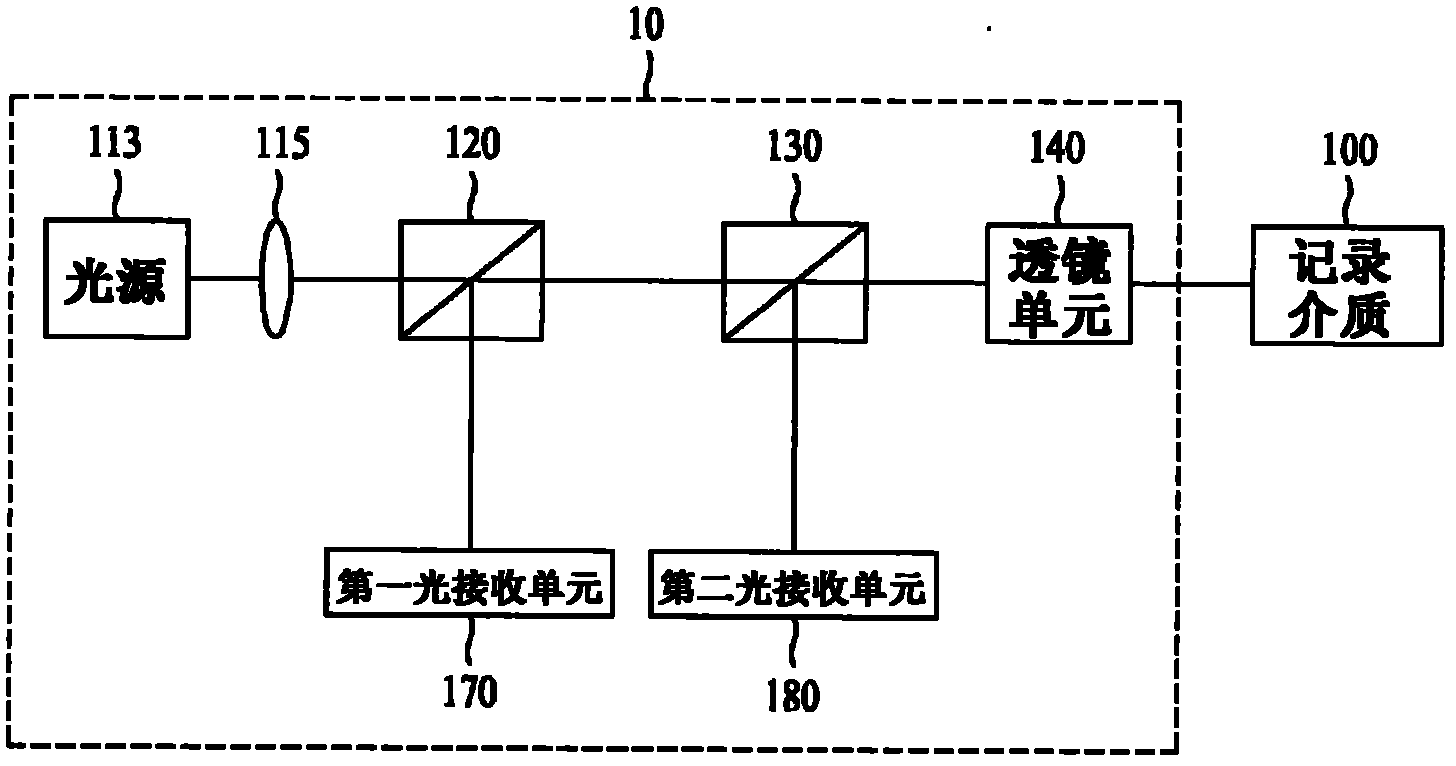

Recording medium, and recording/reproducing method and recording/reproducing apparatus for recording medium

InactiveCN102067223AEnsure safetyQuickly put into productionOptical discsRecord information storageRecording layerData recording

Owner:LG ELECTRONICS INC

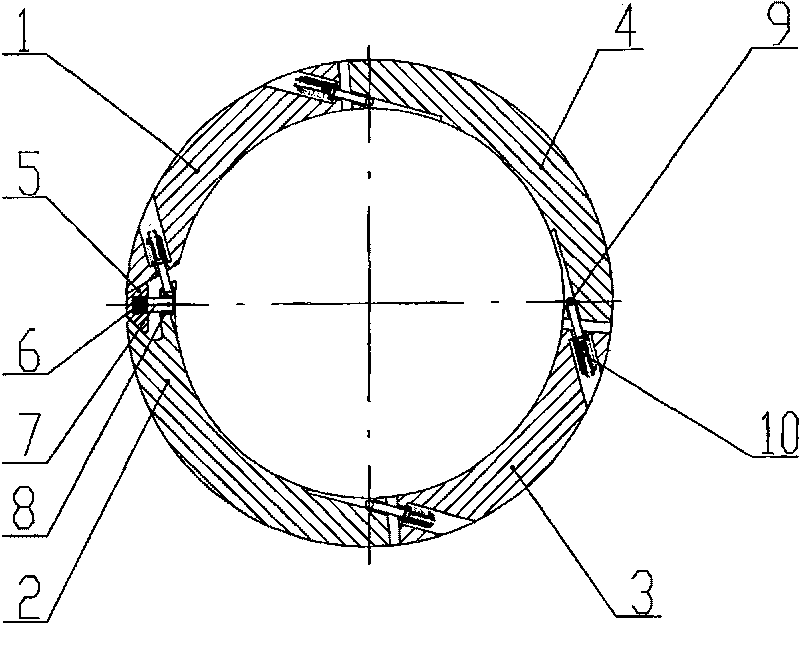

Coiling machine sleeve barrel with wrench jaw

The invention relates to a recoiler sleeve provided with a gate, comprising more than 3 sector-shaped boards. By being connected with bolts, the sector-shaped boards are connected into a whole with disk springs on the joint position. The invention is characterized in that a gate is arranged between two of the sector-shaped boards; the gate position also comprises a gate slide block, a gate slide block jack device and a gate slide block resetting device. The clamp slide block is matched and inosculated with the gate and is pushed out and back to and fro through the gate under the action of thegate slide block jack device and the gate slide block resetting device along with the diameter expanding and shrinking of the recoiler sleeve, thus the tightening and opening of the gate is realized.The invention realizes rolling up belt coils with different internal diameters on one recoiler, which enhances the utilization rate and production efficiency of the equipment and has dramatic economicbenefit.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Adjusting device of rotary stock bin for chain wheel machining

ActiveCN113305628AImprove stabilityEasy to changeCleaningMetal working apparatusGear wheelControl engineering

The invention discloses an adjusting device of a rotary stock bin for chain wheel machining. The adjusting device comprises a conveying platform, a chain I arranged on the conveying platform and driven by two driving gears, a plurality of object carrying platforms fixedly connected with the chain I through fixing plates, and adjusting device bodies arranged in the object carrying platforms, and each object carrying platform is provided with an inner groove. The device has the advantages that the plurality of object carrying platforms can be connected through a chain II, a transmission gear and other structures, when the size of the object carrying platforms needs to be adjusted, all the object carrying platforms can be synchronously adjusted at the same time only by starting a motor, in this way, the efficiency of adjusting the size of the object carrying platforms by workers can be improved, the whole device can be put into production faster, the production yield is increased, due to the fact that the position of a limiting rod is controlled through a lead screw and a screw sleeve, the adjusted position of the limiting rod is not prone to change, the stability of the object carrying platform can be improved, and therefore the chain wheel can be better borne and conveyed.

Owner:江苏思克赛斯机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com