Cement slurry preparing, stirring and conveying integrated system

An integrated system and cement slurry technology, which is applied in the direction of cement mixing device, clay preparation device, mixing operation control, etc., can solve the problems of pulping quality influence, installation, disassembly and maintenance time-consuming and laborious, low precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

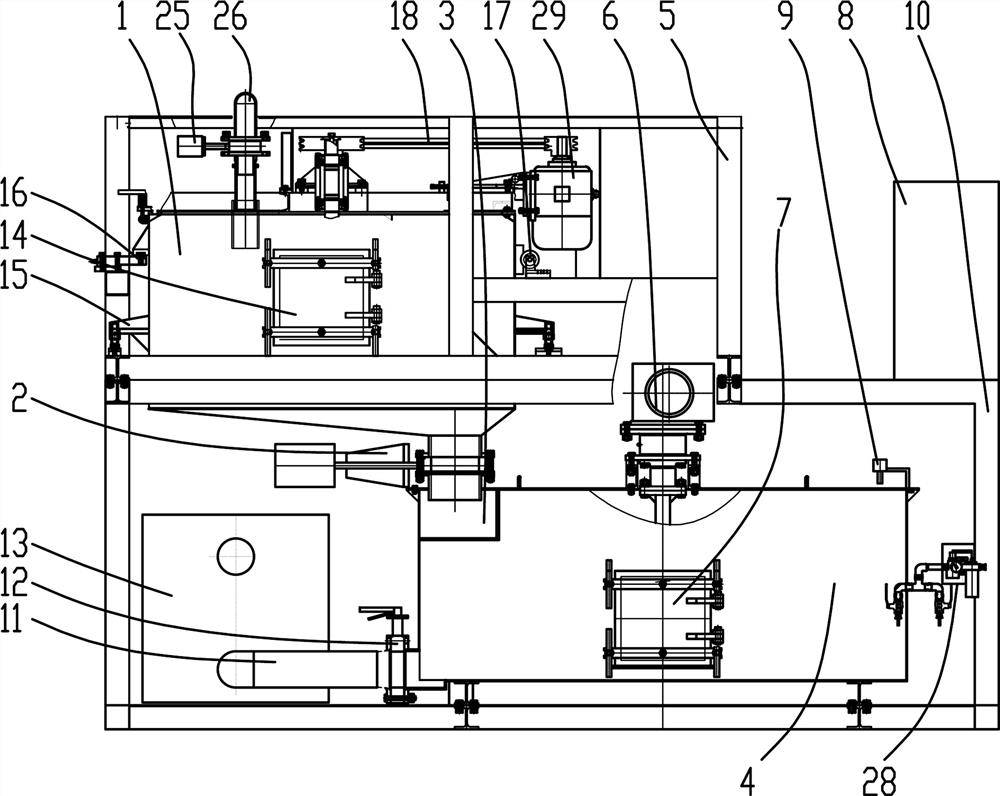

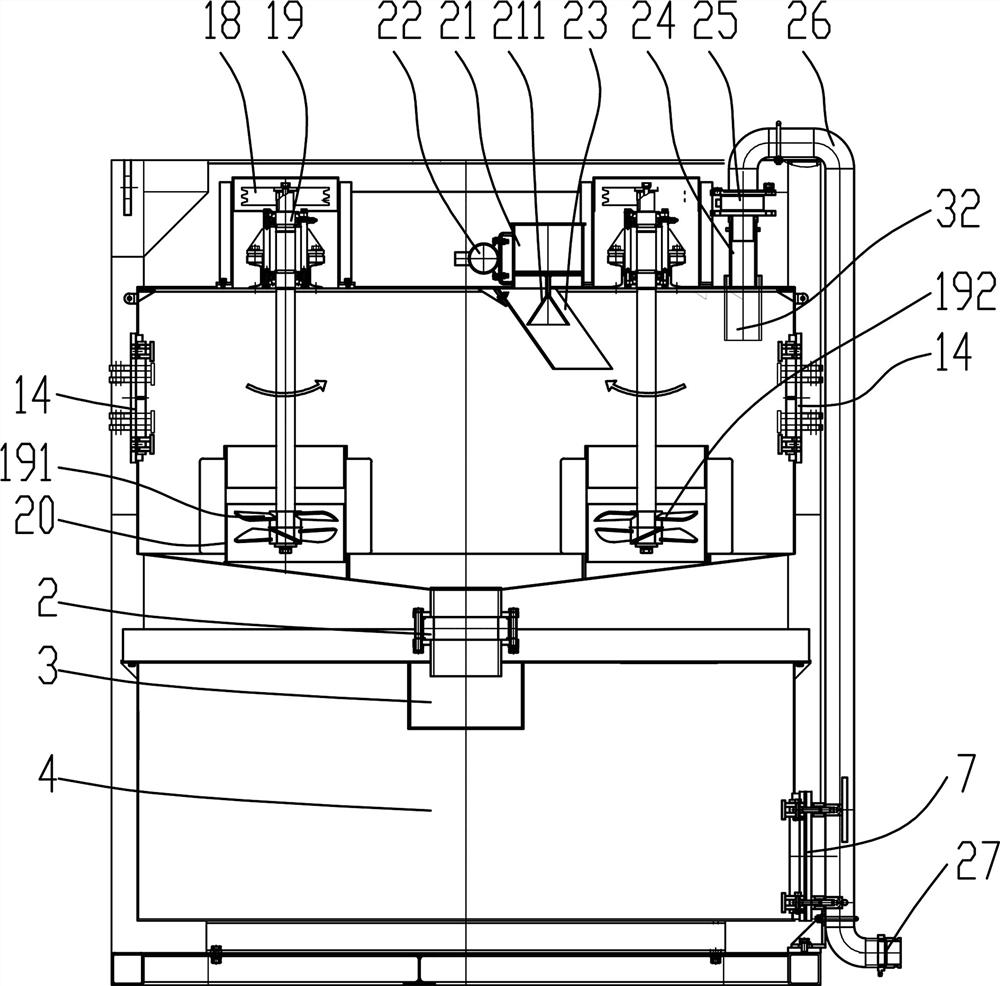

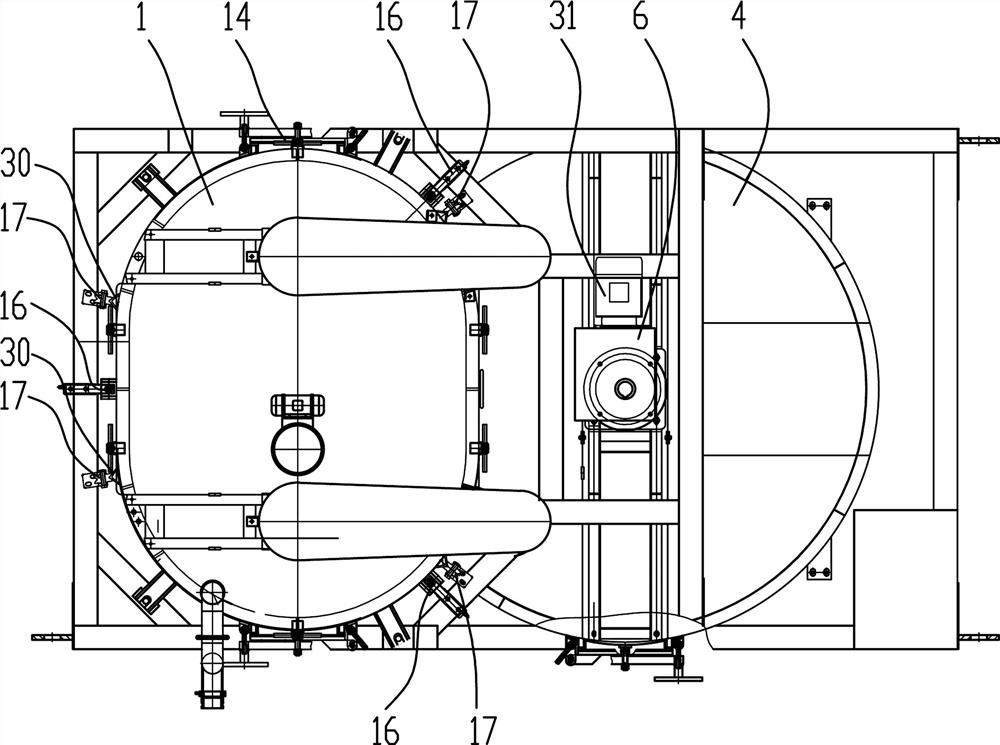

[0029] Such as Figure 1~3 Among them, an integrated system for mixing and transporting cement slurry, including a pulper 1 and a mixer 4, the pulper 1 is located above the mixer 4, and the slurry outlet pipeline 11 of the mixer 4 is connected to the inlet of the delivery pump 13; preferably , A manual valve 12 or an electronically controlled valve is also provided in the slurry outlet pipeline 11.

[0030] The pulping machine 1 is supported on the upper frame 5 by a plurality of load cells 16, and the top of the pulping machine 1 is provided with a water inlet pipeline 26. The water inlet pipeline 26 is provided with an automatic water inlet valve 25, and the water inlet pipeline 26 is connected to the The liquid inlet 32 at the top of the cylinder of the pulping machine 1 is flexibly connected;

[0031] A cement feed port 21 is also provided on the top of the pulp machine 1 . With this structure, the automatic preparation of cement slurry is realized, and the cement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com