Full-automatic production equipment and process for vertical folding mask

A kind of production equipment and fully automatic technology, applied in the direction of sewing tools, clothing, clothing, etc., can solve the problems of large length and size of production equipment, incomplete cutting, and affect the accuracy of trimming, so as to improve production efficiency and product quality , The difficulty of debugging is reduced, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

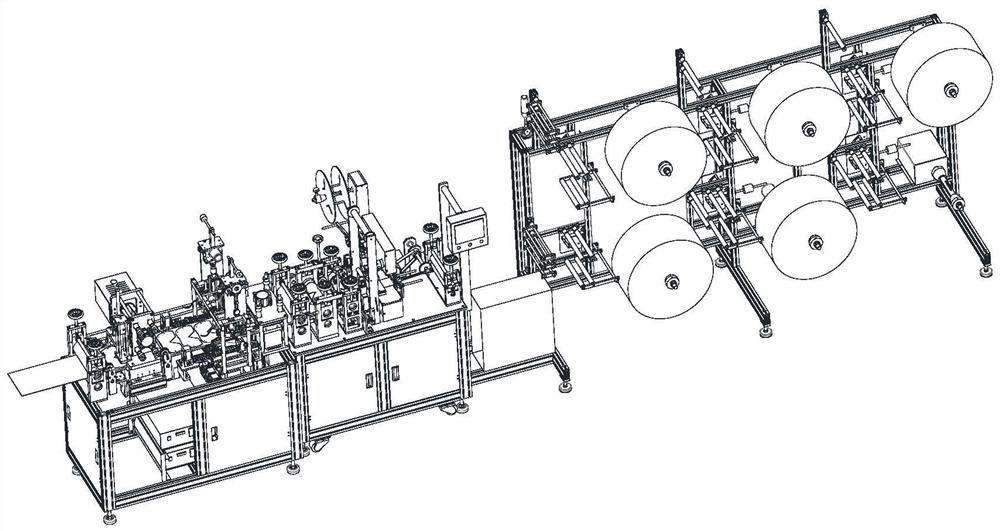

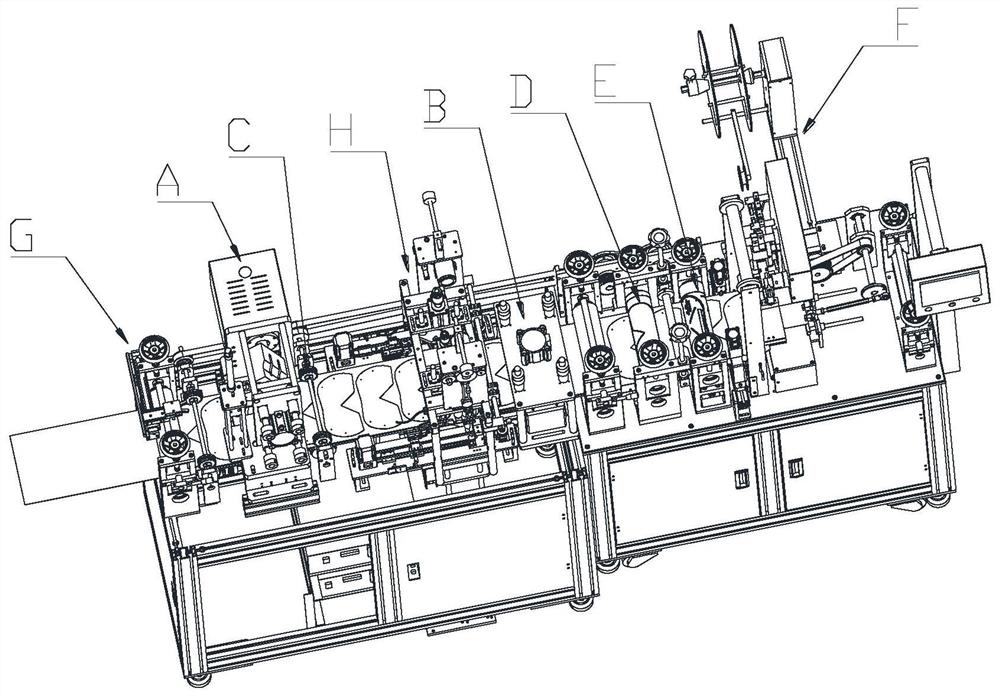

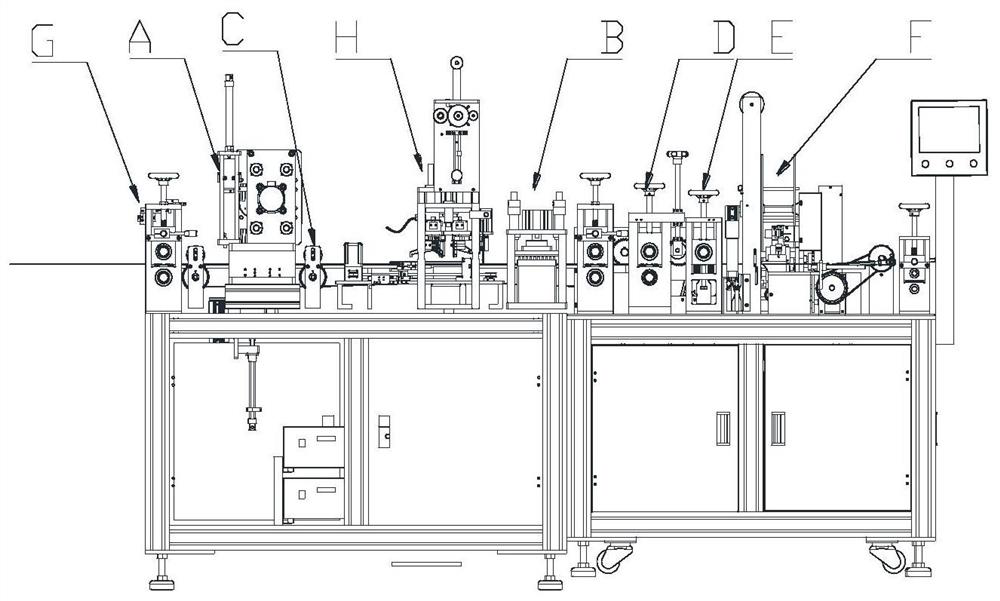

[0048] see Figure 1-Figure 23 , the vertical folding mask full-automatic mask production equipment of the present invention, comprises the feeding module I that arranges successively, bridge of the nose line inserting module F, knurling module E, trimming module D, ear wire welding module F, edge banding module A And waste traction module F, is provided with some cloth traction modules for traction cloth forward conveying between above-mentioned modules; Wherein,

[0049] The feeding module 1 is used to transport the multi-layer cloth to the follow-up station;

[0050] The knurling module E includes a knurling shaft and a knurling drive mechanism that drives the knurling shaft to rotate;

[0051] The trimming module D is adjacent to the downstream station of the knurling module E. The trimming module D includes a trimming shaft and a trimming drive mechanism that drives the rotation of the trimming shaft. After being knurled by the knurling module E, it enters the trimming ...

Embodiment 2

[0094] see Figure 24 , the difference between this embodiment and embodiment 1 is:

[0095] The positioning module C includes a bracket 4c, a first positioning wheel 1c arranged on the bracket 4c, a second positioning wheel 3c, and a positioning drive mechanism for driving the rotation of the first positioning wheel 1c and the second positioning wheel 3c, wherein the Described first positioning wheel 1c is arranged on the top of the conveying plane of mouth mask base body, and described second positioning wheel 4c is arranged on the below of the conveying plane of mouth mask base body, and this second positioning wheel 3c is provided with the positioning on the mouth mask base body. There are a plurality of positioning protrusions 3-1c that are matched with the holes, and the plurality of positioning protrusions 3-1c are positioned on the side of the second positioning wheel 3c along the circumferential direction of the second positioning wheel 3c. Evenly arranged on the out...

Embodiment 3

[0101] The difference between this embodiment and Embodiment 1 is that the punching module B is located between the trimming module D and the knurling module E; position and edge banding station.

[0102] The remaining structures can be implemented with reference to Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com