Unmanned system and operation method of steel ladle casting area

A technology of ladle pouring and operation method, which is applied to the configuration of indicating equipment/measuring equipment, casting molten material containers, manufacturing tools, etc. The operation, the operation is convenient and fast, and the effect of less equipment changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

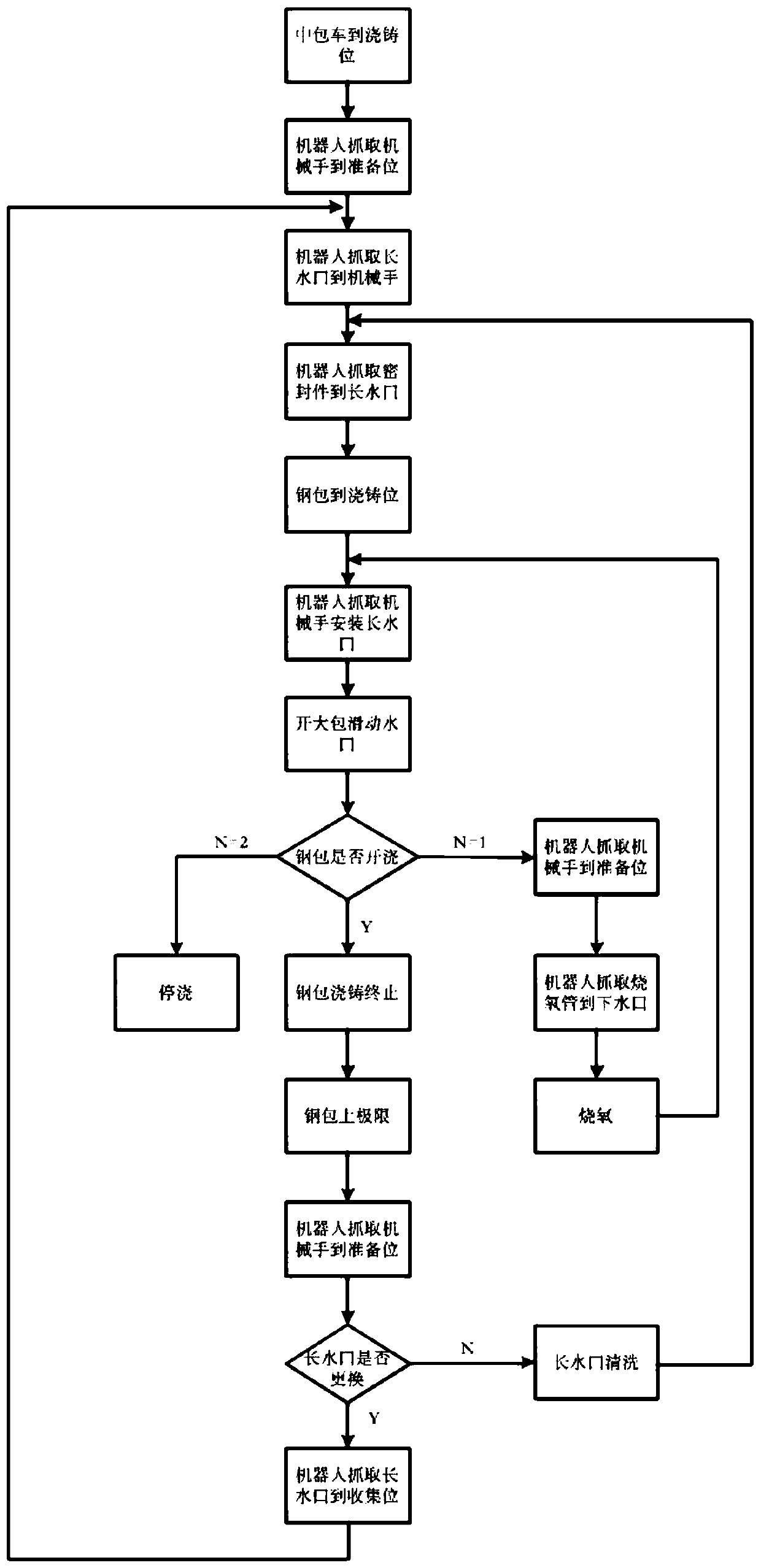

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

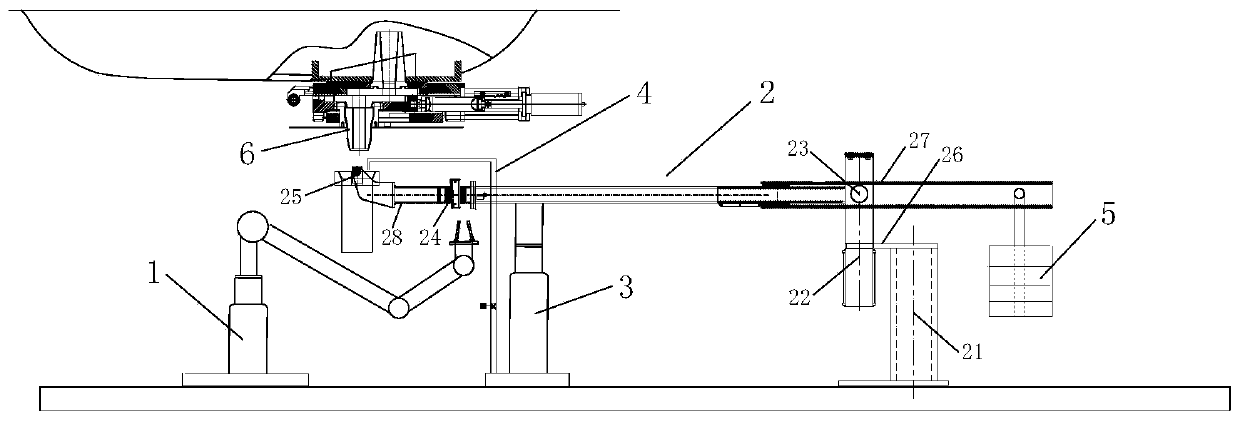

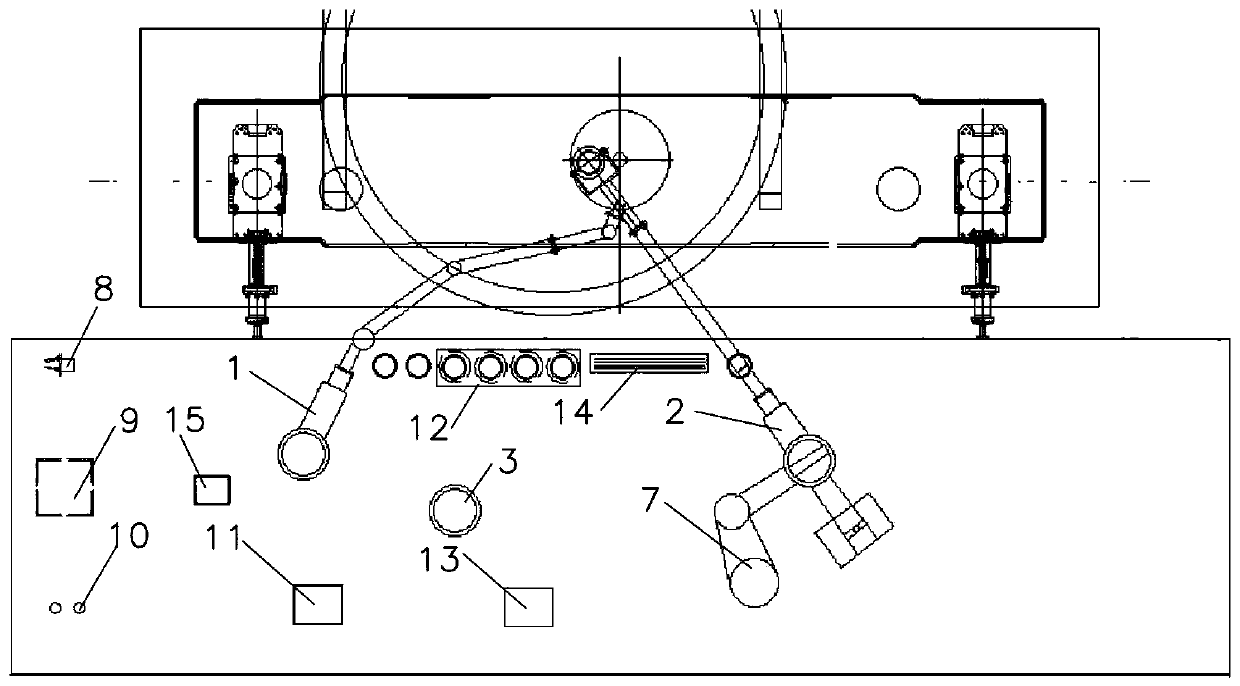

[0044] See figure 1 , figure 2 , an unmanned system for ladle pouring area, comprising:

[0045] Robot 1: Robot 1 is a 6-axis manipulator with a weight of more than 750kg; it is used to complete the replacement of fixtures, replacement of long nozzles, temperature measurement and sampling of molten steel in tundishes, and addition of tundish covering agent; robot 1 can replace manual operations on long nozzles. That is, assembly, disassembly and replacement of the long nozzle, installation of 6 seals at the long nozzle and the lower nozzle; burning oxygen when the ladle pours abnormally; adding covering agent to the tundish; measuring and sampling the temperature of the tundish, etc.

[0046] Manipulator: It is a 5-axis structure, one end is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com