Configuration mode for an electrobath overhaul workshop and a furnace dismounting room

A configuration method and electrolytic cell technology, applied in industrial buildings, etc., can solve the problems of workers’ influence and environmental damage, high labor intensity, and low efficiency of manual furnace dismantling, and achieve the goal of improving furnace repair speed, convenient transfer, and improving working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

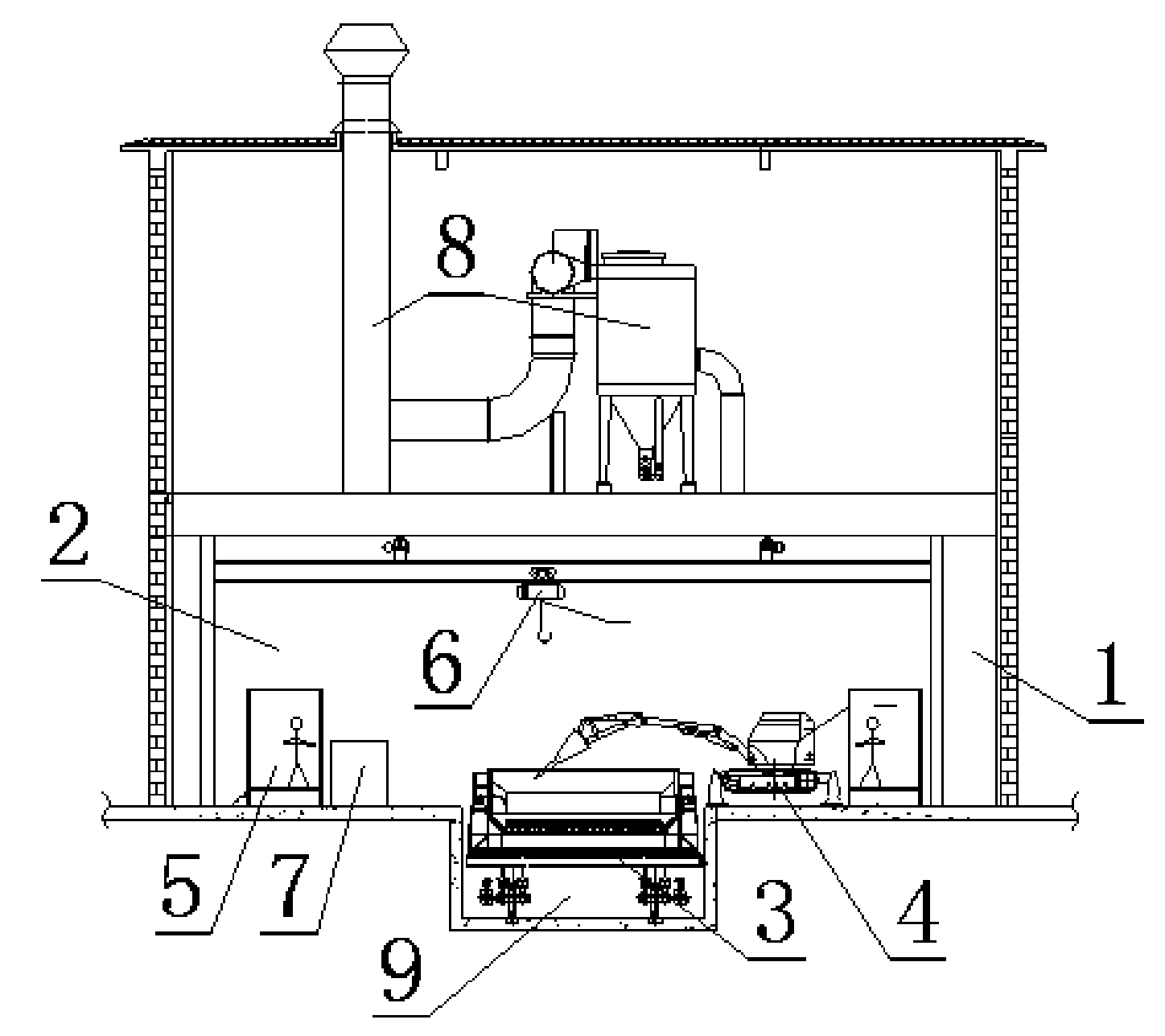

[0012] Embodiments of the present invention: as attached figure 1 As shown, a furnace dismantling room 2 is built with bricks or color steel plates in the tank overhaul workshop 1 or outside, and a pit 9 is set on the gate of the tank overhaul workshop 1 and the passage connecting the furnace dismantling room 2, and in the pit 9 An electric flat car 3 is set, and the place where the pit 9 of the furnace dismantling room 2 is opened is provided with a closed door, and this closed door can be an electric rolling shutter door. In the dismantling room 2, there are one or two multifunctional remote control furnace planers 4 equipped with hydraulic hammers, shovels, grabs and other tools, a sealed operation room 5, a suspension crane 6 and a slag box 7, multifunctional remote control planers The operators of the furnace machine 4 and the suspension crane 6 operate in the sealed operation room 5 .

[0013] When maintaining the aluminum electrolytic cell, the aluminum electrolytic ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com