Coiling machine sleeve barrel with wrench jaw

A technology of jaws and machine sleeves, which is applied in the field of coiler supporting equipment, can solve problems such as increased equipment maintenance and operating costs, reduced product yield, and complex equipment structure, and achieves the goal of improving equipment utilization and improving utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

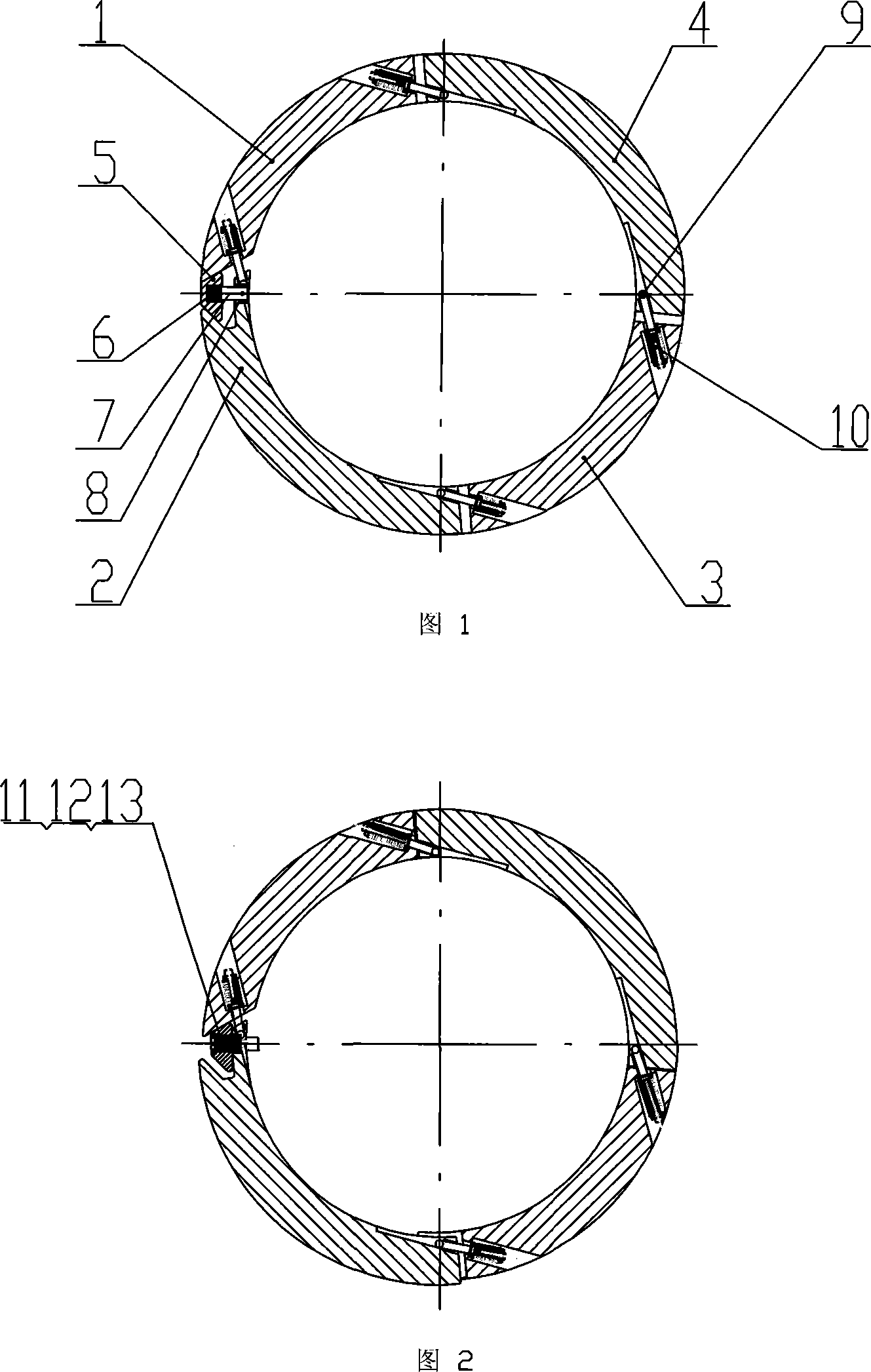

[0019] Now in conjunction with accompanying drawing, structure and working principle of the present invention are further specifically described:

[0020] The coiler sleeve with jaws includes four sector plates, namely sector plate one 1, sector plate two 2, sector plate three 3, sector plate four 4, and the sector plates are connected by connecting bolts 9 and joints Belleville spring 10 is connected as a whole, jaws are set between fan-shaped plate one 1 and fan-shaped plate two 2, and jaw slide block 5 is matched with it at the position of said jaws; Diameter expansion and diameter reduction, the jaw slider is reciprocally ejected and pulled back between the jaws under the action of the jaw slider lifting device and the jaw slider reset device, thereby realizing the clamping and tightening of the jaws. Open; the jaw slider jacking device includes jaw disc springs, jaw guide pins and jaw guide sleeves, and the jaw slider reset device includes compression springs, jaw sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com