Die-casting magnesium alloy surface modified powder infiltration process

A surface modification and powder technology, applied in the field of die-casting magnesium alloy surface modification powder infiltration process, can solve the problems of poor stability, easy cracking or peeling, difficult process and cost, and achieve good corrosion resistance and Abrasion resistance, resistance to surface cracking or peeling, and the effect of simplifying the surface modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

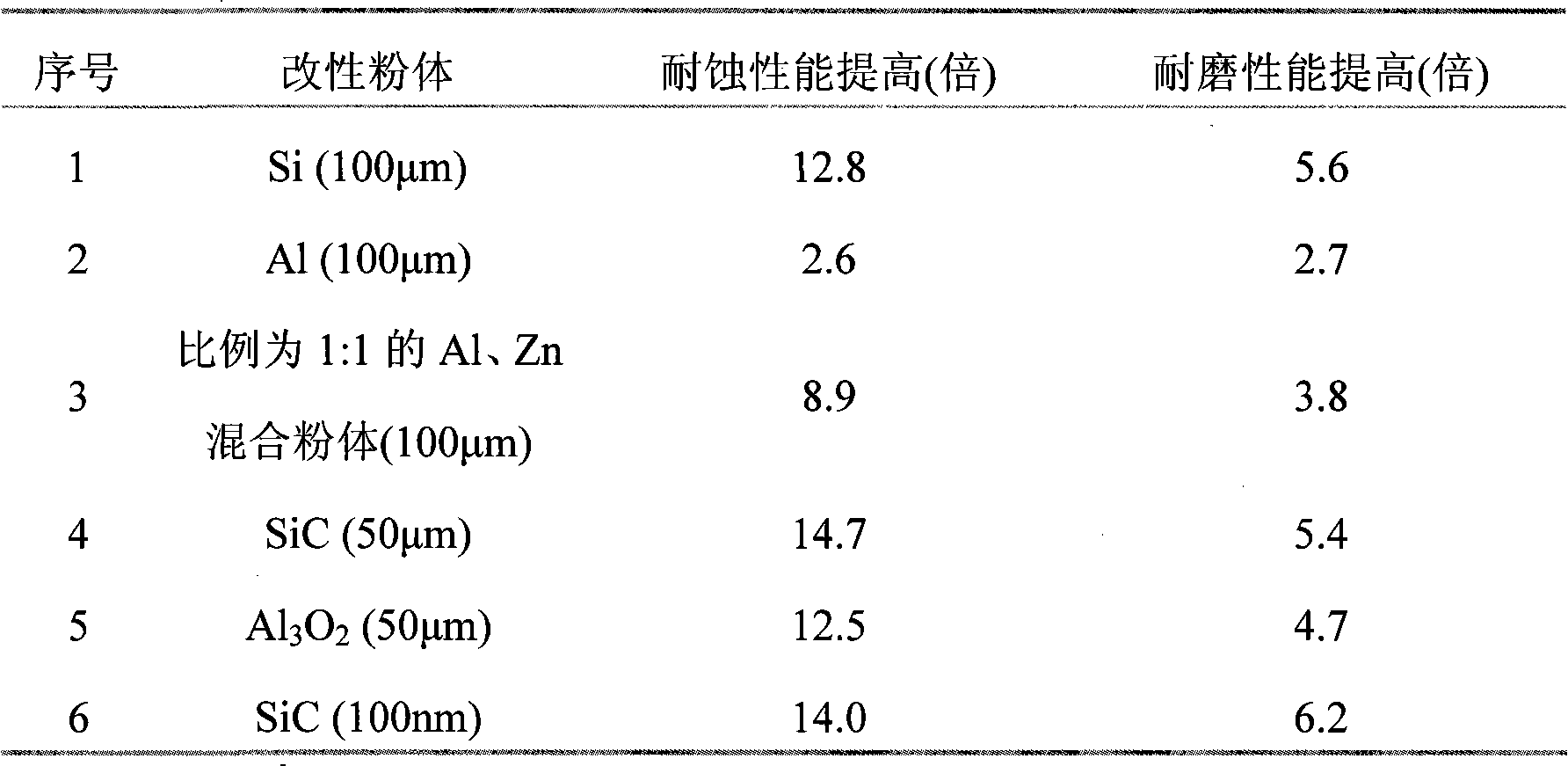

Embodiment 1

[0021] Apply the parting agent evenly on the surface of the die-casting mold, take Si powder with a particle size of 100 μm, and use a wide-mouth dry powder sprayer to evenly spray the powder on the entire surface of the parting agent, with a thickness of about 1.0mm. Under the die-casting condition, that is Pouring temperature: 660-680 degrees; Injection speed: 2-4m / s; Injection specific pressure: 40-60MPa, the liquid magnesium alloy is poured into the metal mold and cooled to form a surface modification layer of 0.4-0.6mm .

Embodiment 2

[0023] Apply the parting agent evenly on the surface of the die-casting mold, take Al powder with a particle size of 100 μm, and use a wide-mouth dry powder sprayer to evenly spray the powder on the entire surface of the parting agent with a thickness of about 1.0 mm. Under the condition, the surface modification layer of 0.4-0.6mm can be formed by pouring the liquid magnesium alloy into the metal mold and die-casting and cooling.

Embodiment 3

[0025] Apply the mold release agent evenly on the surface of the die-casting mold, take Al and Zn mixed powder with a ratio of 1:1, the particle size is about 100 μm, use a wide-mouth dry powder sprayer to evenly spray the powder on the entire surface of the mold release agent, the thickness It is about 1.0mm, and under the above-mentioned die-casting conditions, the liquid magnesium alloy is poured into the metal casting mold and die-casted and cooled to form a surface modification layer of 0.4-0.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com